Table of Contents

IM-1004 | REV181127 Page i ©2018 Celera Motion

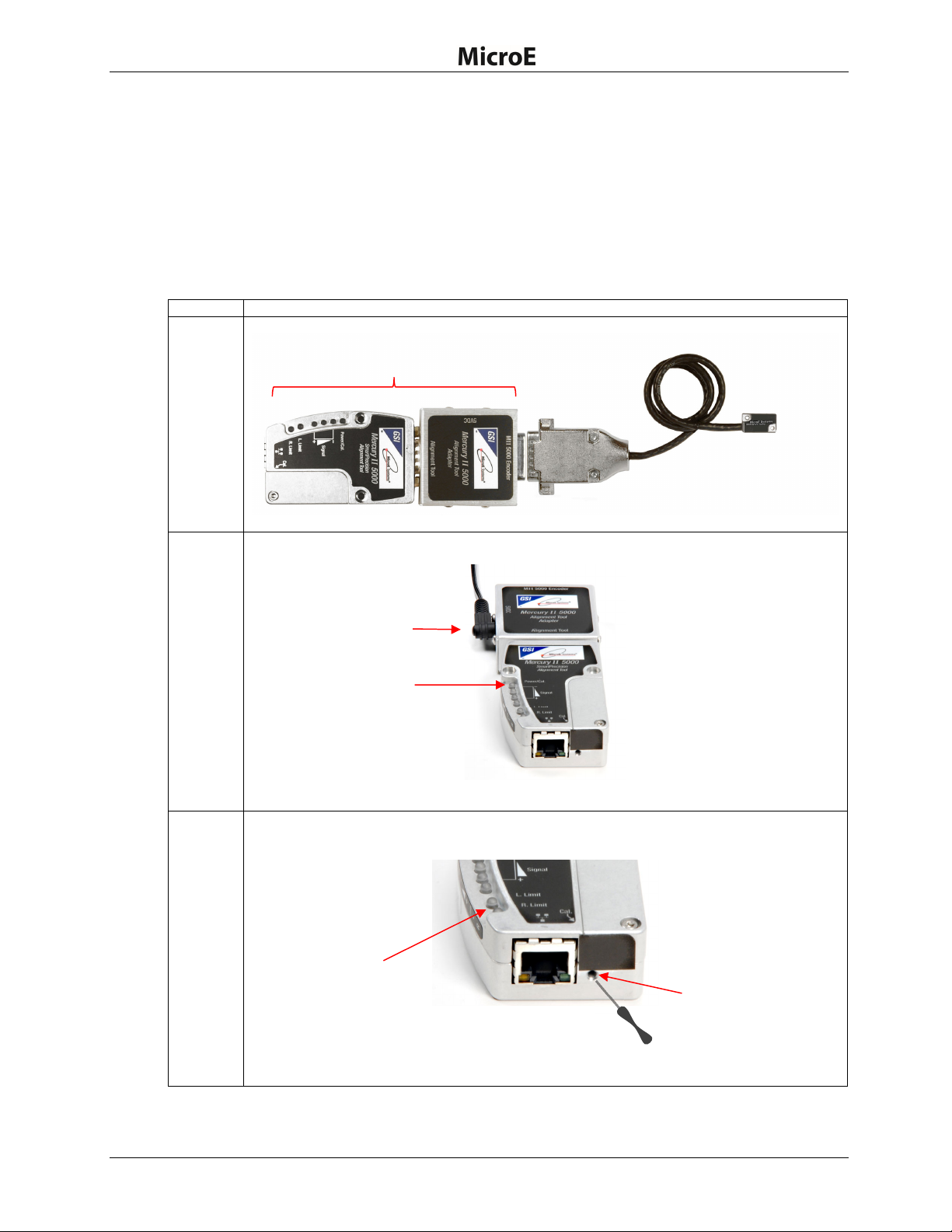

Mercury II 6000 Series Encoders

Sensor Installation Manual and Reference Guide

Table of Contents

1.0Introduction ...................................................................................................................................... 1

1.1Overview ............................................................................................................................. 1

1.2Precautions ......................................................................................................................... 1

1.3Laser Safety Information.....................................................................................................1

1.4Standards Compliance........................................................................................................ 2

1.5Related Documentation ...................................................................................................... 2

1.6Manual Revisions................................................................................................................ 2

1.7Trademarks ......................................................................................................................... 2

2.0Before Installation ............................................................................................................................ 3

2.1Power Recommendations................................................................................................... 3

2.2Installation Considerations..................................................................................................3

2.3Items Required for Installation ............................................................................................ 3

3.0System Overview ............................................................................................................................. 4

3.1System View ....................................................................................................................... 4

3.2Expanded View ................................................................................................................... 4

3.3SmartPrecision Alignment Tool........................................................................................... 5

4.0Sensor Installation............................................................................................................................ 6

4.1Sensor Mounting Orientation and Tolerances .................................................................... 6

4.2Verify Sensor Mounting Surface Height.............................................................................. 6

4.3Install Sensor ...................................................................................................................... 6

5.0Sensor Alignment and Calibration ................................................................................................... 7

5.1Using the Cal. Pushbutton .................................................................................................. 8

5.1.1Sensor Alignment................................................................................................... 8

5.1.2Sensor Calibration ............................................................................................... 10

5.2Using the Software............................................................................................................ 13

5.2.1Connect the Alignment Tool and Encoder ........................................................... 13

5.2.2Use the FindMII Program to Locate the Encoder ................................................ 14

5.2.3Sensor Alignment and Calibration ....................................................................... 15

6.0Alignment Verification with Connector LEDs ................................................................................. 18

7.0Appendix ........................................................................................................................................ 19

7.1Specifications .................................................................................................................... 19

7.2Resolution and Maximum Speed Tables .......................................................................... 21

7.3Wiring Diagrams................................................................................................................ 24

7.4Customer Interface............................................................................................................ 26

7.5Serial Interface Specifications........................................................................................... 29

7.6Index Speed Considerations............................................................................................. 35

7.7RS-422 Compliance .......................................................................................................... 36

7.8Troubleshooting ................................................................................................................ 37

8.0Order Guide ................................................................................................................................... 38

9.0Contacting Celera Motion............................................................................................................... 42