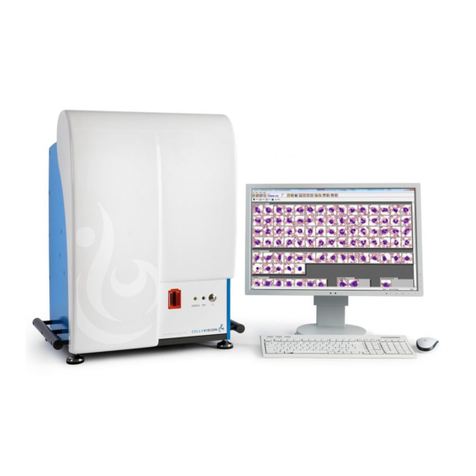

Quick Guide — CellaVision

®

DM96

Copyright © 2005-2009 CellaVision AB PM-10113 2009-08-12

Maintenance Procedure

Notes for all Maintenance

-Refer to CellaVision DM96 User’s Manual

(Maintenance) for details and images.

-Refer to CellaVision DM96 User’s Manual for

cautionary notes.

Daily Maintenance

1Make sure there are no magazines in the system.

2Shut down the system according to the instructions in

this manual.

3Open the main hatch.

4Clean the XY stage from immersion oil with a lint-

free soft cloth.

5Close the main hatch.

Weekly Maintenance

1. Cleaning of Objectives

1Make sure there are no magazines in the system.

2Shut down the system according to the instructions in

this manual.

3Open the main hatch.

4Clean the lens on all objectives by wiping them

gently with lens paper. Always use a fresh lens paper

to avoid oil contamination. To reach all lenses,

carefully turn the objective turret.

5Apply step 5-11 only on the high power wet

objectives. Put a drop of isopropyl alcohol on a piece

of crumbled lens paper. Do not use an excessive

amount of solvent.

6Wipe the objective once to remove most of the oil.

Do not use a circular motion to clean lenses as this

increases the risk of scratching the surface.

7Take a new piece of lens paper and put a drop of lens

cleaner in the middle.

8Place the lens paper over the objective.

9Use a cotton swab to gently hold the paper against

the objective while you drag the lens paper away

from the objective.

10 The cotton swab should remain over the center of the

objective and the lens paper under it should be wet. If

the lens paper dries out then repeat starting on a wet

(but non-oily) spot on the lens.

11 Repeat once from step 5.

2. Database Performance

-To maintain a high database performance, it is very

important to control the size of the database.

-It is also recommended to restart the system

computer at least once a week.

As Needed Maintenance

1. Immersion Oil Refill

1Open the main hatch.

2Remove the screw cap from the oil canister.

3Fill up with specified oil, using a clean funnel, to the

black line of the glass tube of the funnel. We

recommend not filling up more oil than will be used

in 6 months. A full oil canister of 500 ml corresponds

to about 10 000 slides. Do not fill up above the black

line.

4Clean the system from immersion oil spillage with a

lint-free soft cloth.

5Refit the screw cork.

6Close the main hatch.

2. Bulb Exchange

-----Warning -------------------------------------------

Switch off the SSU and wait for the lamp housing

and lamp bulb to cool before touching.

-----Caution --------------------------------------------

Do not touch the new bulb with bare hands.

1Loosen the 2 non-detachable screws, which hold the

lamp hatch, about half a turn counter clockwise,

using a 3 mm Allen key.

2Remove the hatch by pulling it outwards and then

upwards.

3Loosen the non-detachable screw of the lamp house

cover using a 3 mm Allen key.

4Lift and remove the cover of the lamp house.

5Press the bulb clamping levers and gently withdraw

the old bulb from the lamp housing.

6Press the bulb clamping levers and fully insert the

bulb pins into the pin holes.

7Gently release the bulb clamping levers to their

original position to secure the bulb.

8Refit the lamp house cover.

9Tighten the screw of the lamp house cover.

10 Refit the lamp hatch.

11 Tighten the screws of the lamp hatch.

Preventive Maintenance

-No preventive maintenance by the user is necessary.

Preventive maintenance is to be performed by

CellaVision authorized personnel.