MechanoCulture TM User Manual

Table of Contents

1. General Information................................................................................................................. 1

Environmental and Electrical Specifications................................................................................ 1

System Assembly......................................................................................................................... 1

Connections to Supply................................................................................................................. 1

Safety Warnings........................................................................................................................... 1

Manual Operating Controls.......................................................................................................... 1

General Maintenance................................................................................................................... 1

Approvals and Certification.......................................................................................................... 1

2. Components Overview............................................................................................................. 2

3. Testing Terminology ................................................................................................................ 3

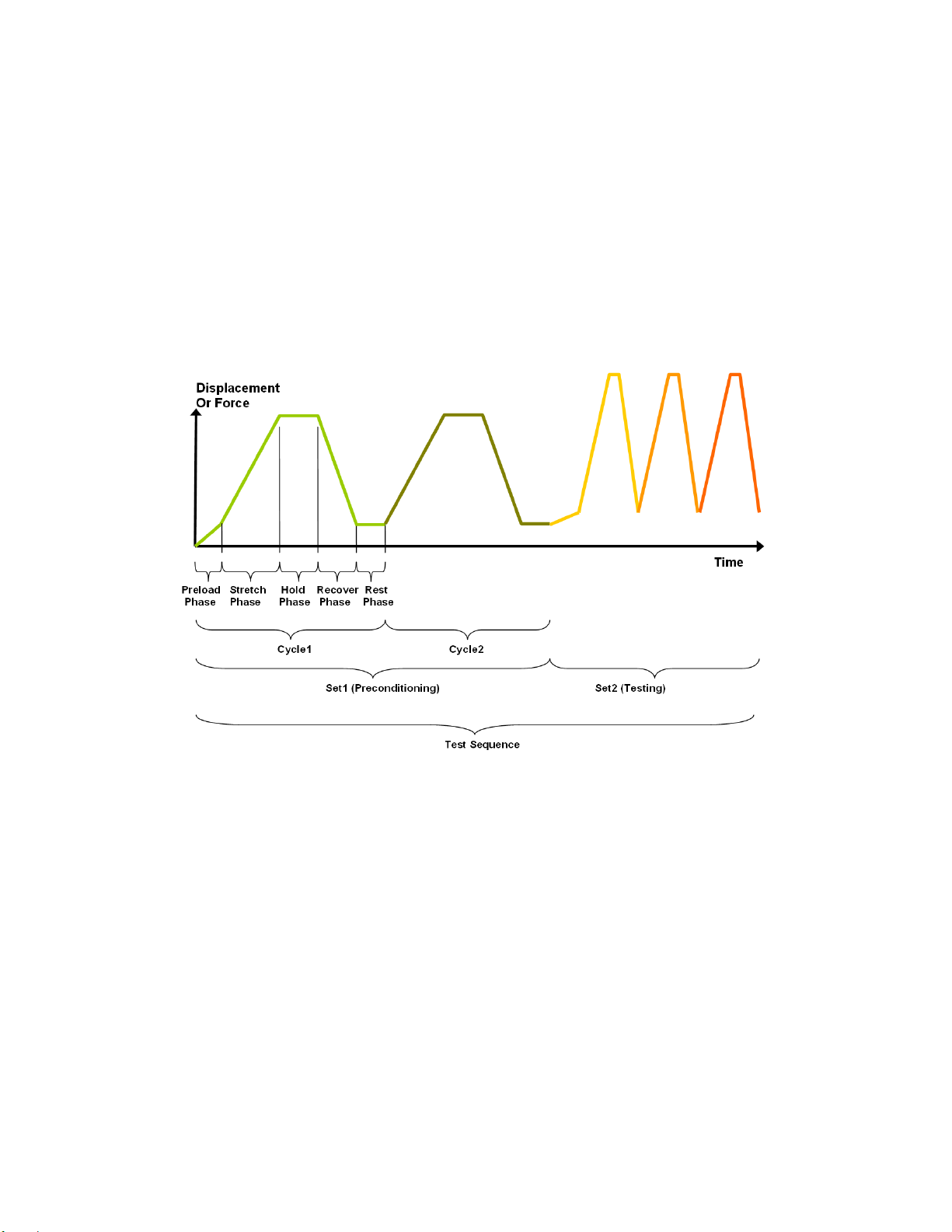

Multiphase Test Cycles................................................................................................................ 3

Phases, Cycles, and Test Sequences......................................................................................... 3

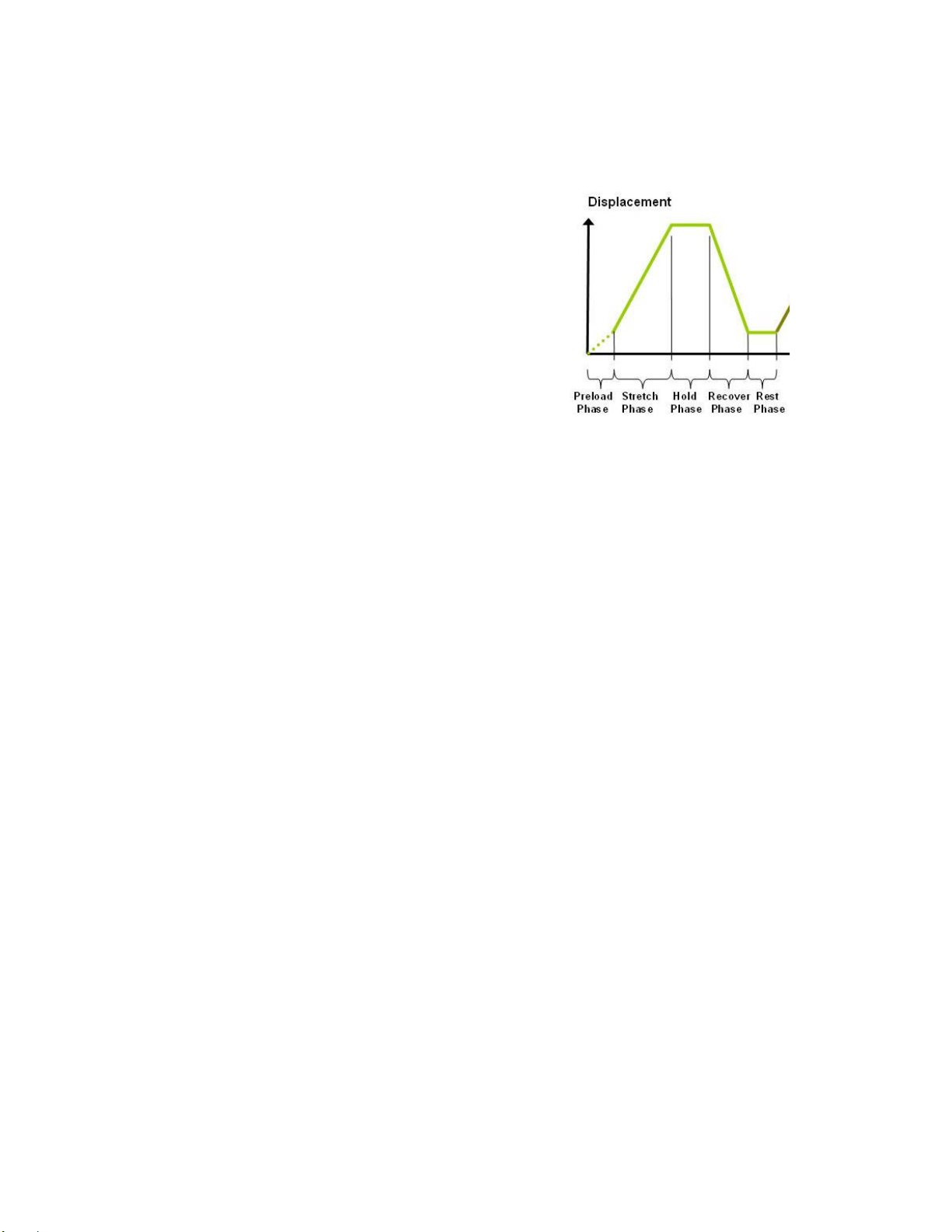

Test Phases: The Smallest Unit of Testing.................................................................................. 4

Control Functions......................................................................................................................... 4

4. Software Overview................................................................................................................... 5

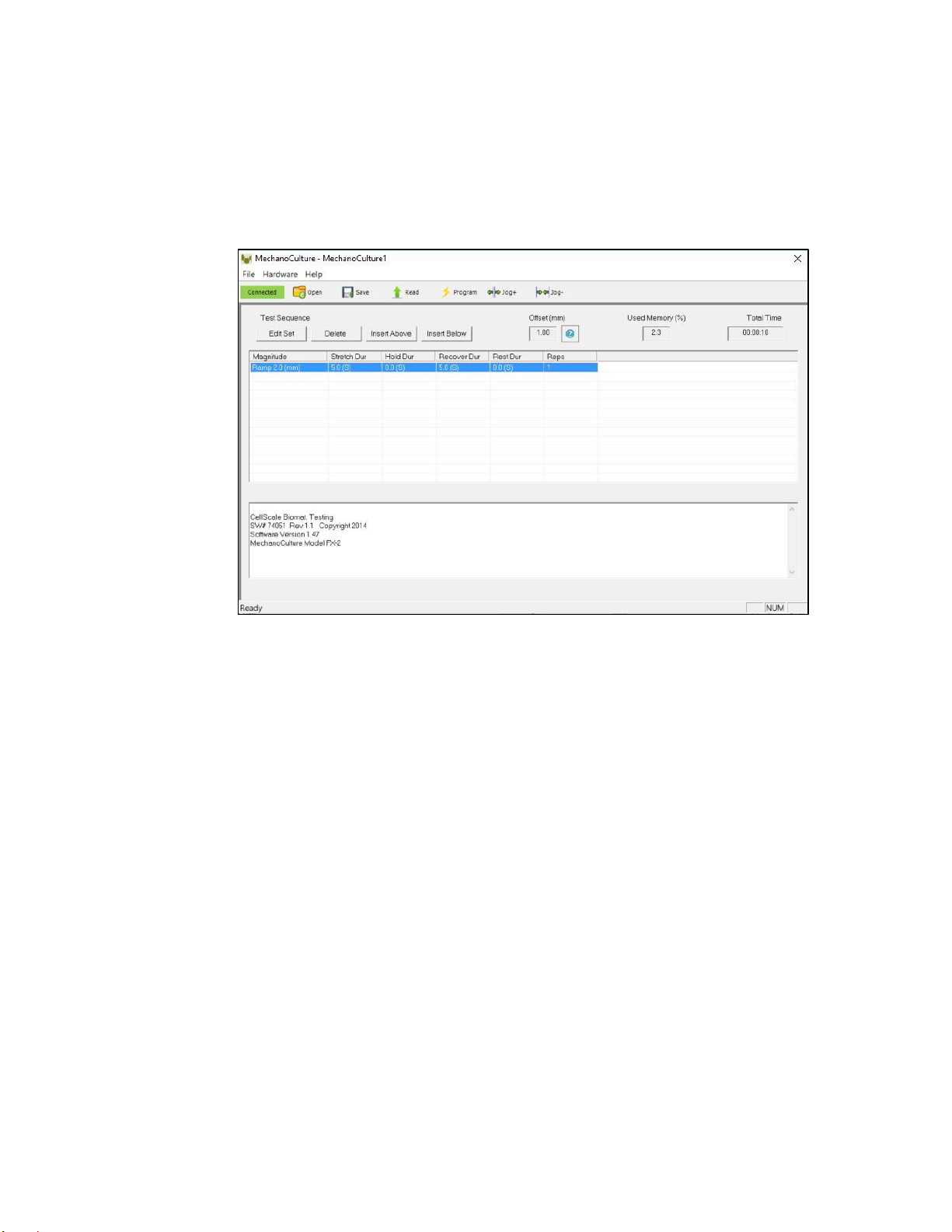

Step 1: Initiate a Test Sequence.................................................................................................. 5

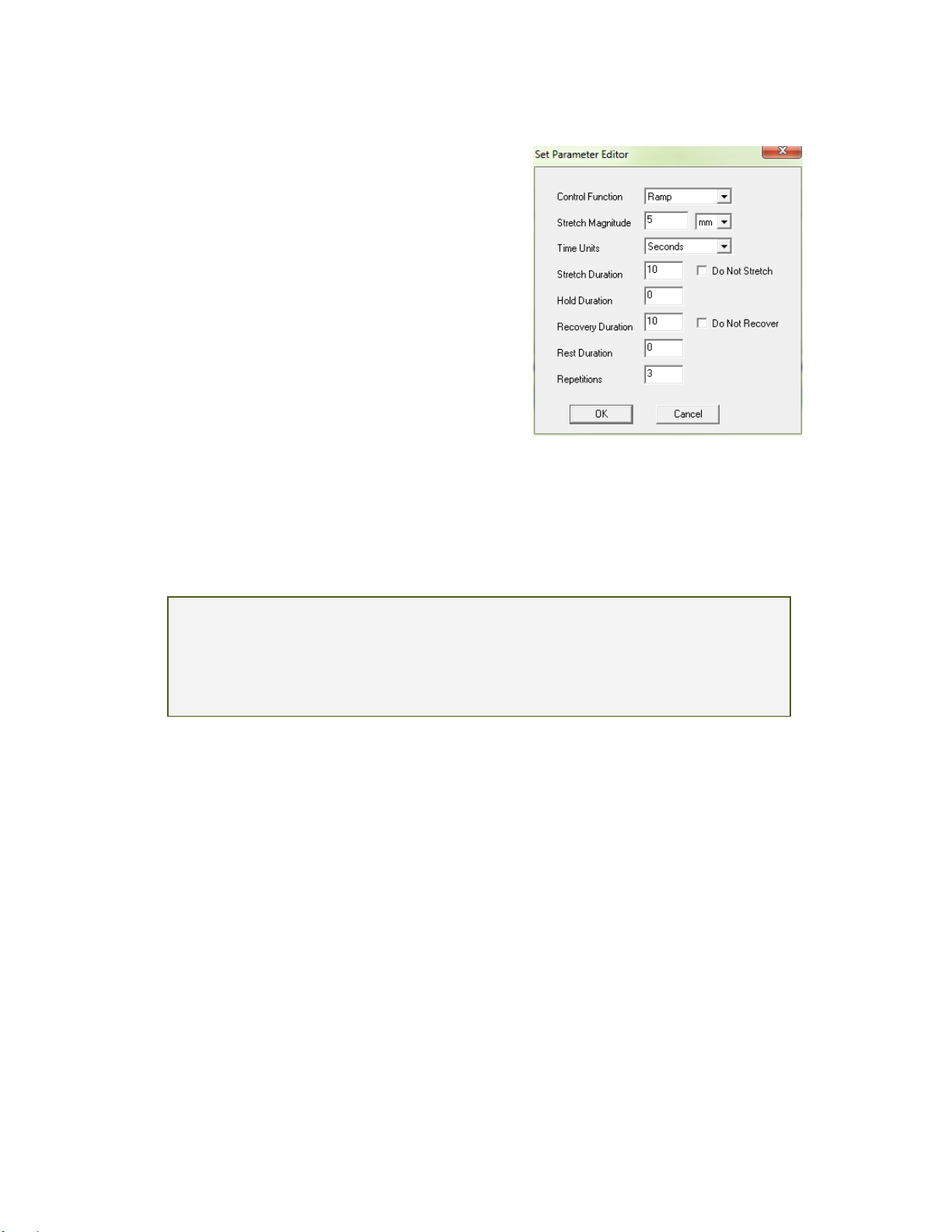

Step 2: Modify Testing Parameters (optional) ............................................................................. 6

Step 3: Program a Device with the Specified Test Sequence..................................................... 6

Well Plate Pre-Stretch, Device Reset Movement, and Offset Distance ...................................... 7

Offset and Jog Functions............................................................................................................. 8

5. Designing Test Sequences...................................................................................................... 9

Example 1: Continuous Cycling for Fixed Duration and then Stop.............................................. 9

Example 2: Pre-stretch a Single Time, Then Cycle for a Fixed Duration, and Then Stop ........ 11

Example 3: Intermittent Stretching............................................................................................. 13

6. Setting Up & Running a Test ................................................................................................. 14

Overview.................................................................................................................................... 14

Attach the Sterilized Membrane to the Test Device................................................................... 14

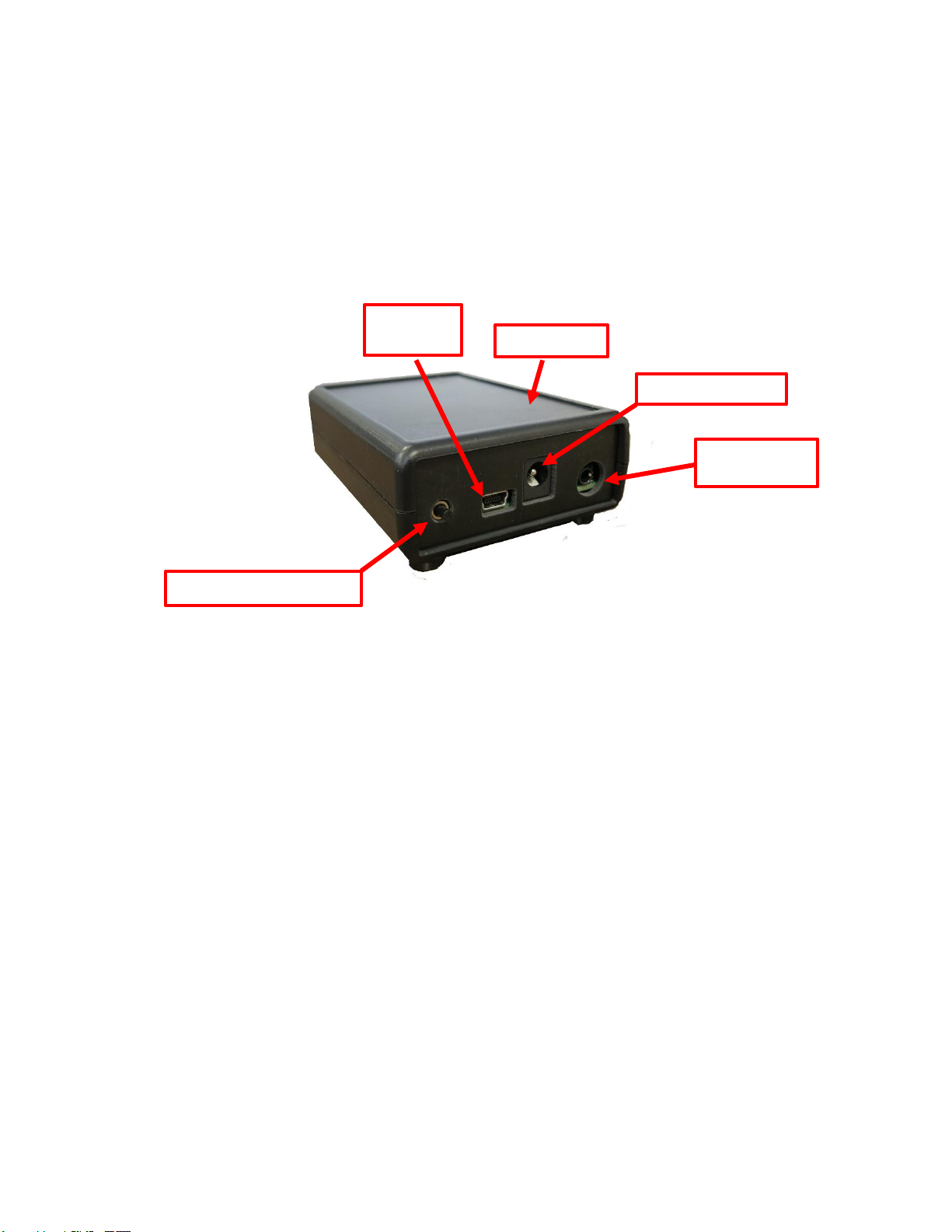

Plug in Control Box Power. Connect Control Box and Test System ........................................ 14

Program the Device (if needed)................................................................................................. 14

Reset the system (hold down the button for 5 seconds)............................................................ 14

Add Cell Media and Cells. Culture to Develop Adhesion ......................................................... 14

Execute Test.............................................................................................................................. 14

7. Advanced Parameters ........................................................................................................... 15

8. Appendix A: Updating the Firmware...................................................................................... 16

9. Appendix B: Software Installation.......................................................................................... 17