CenterLine 200 Series User manual

MANUAL AND AUTOMATED

RESILIENT SEAT BUTTERFLY VALVES

INSTALLATION

and

MAINTENANCE

INSTRUCTIONS

CENTER

LINE

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

CONTENTS

Introduction

Valve Description................................................................................................................................... 3

Valve Design Features .......................................................................................................................... 3

Flange and Pipe Schedule Compatibility............................................................................................... 3

Gasket Compatibility.............................................................................................................................. 3

Operating Pressures.............................................................................................................................. 3

Product Identification ............................................................................................................................. 3

Installation Recommendations

Valve Ratings ........................................................................................................................................ 4

Valve Seat Position ............................................................................................................................... 4

Disc Clearances .................................................................................................................................... 4

Opening Rotation................................................................................................................................... 4

Installation Position................................................................................................................................ 4

Valve and Flange Preparation ............................................................................................................... 4

Installation Tools.................................................................................................................................... 4

Required Bolting .................................................................................................................................... 4

Unpacking and Storage Instructions...................................................................................................... 4

Pre-Installation Procedure ..................................................................................................................... 5

Valve Installation Procedure............................................................................................................ 5 & 6

Flange Bolting Recommendations......................................................................................................... 7

Maintenance Instructions

Safety Precautions ................................................................................................................................ 8

General Maintenance ............................................................................................................................ 8

Butterfly Valve Disassembly .................................................................................................................. 8

Butterfly Valve Assembly................................................................................................................. 8 & 9

Check Valve Disassembly ..................................................................................................................... 9

Check Valve Assembly........................................................................................................................ 10

Ratchet Handle Mounting Procedure .................................................................................................. 10

Manual Gear Mounting Procedure ...................................................................................................... 10

Remote Actuator (Male Drive) Mounting Procedure............................................................................ 10

Remote Actuator (Female Drive) Mounting Procedure ....................................................................... 10

Parts List.............................................................................................................................................. 11

Centerline Figure Number System ........................................................................................Back Cover

2

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

SERIES

BODY

DISC

SEAT

RATING PSI

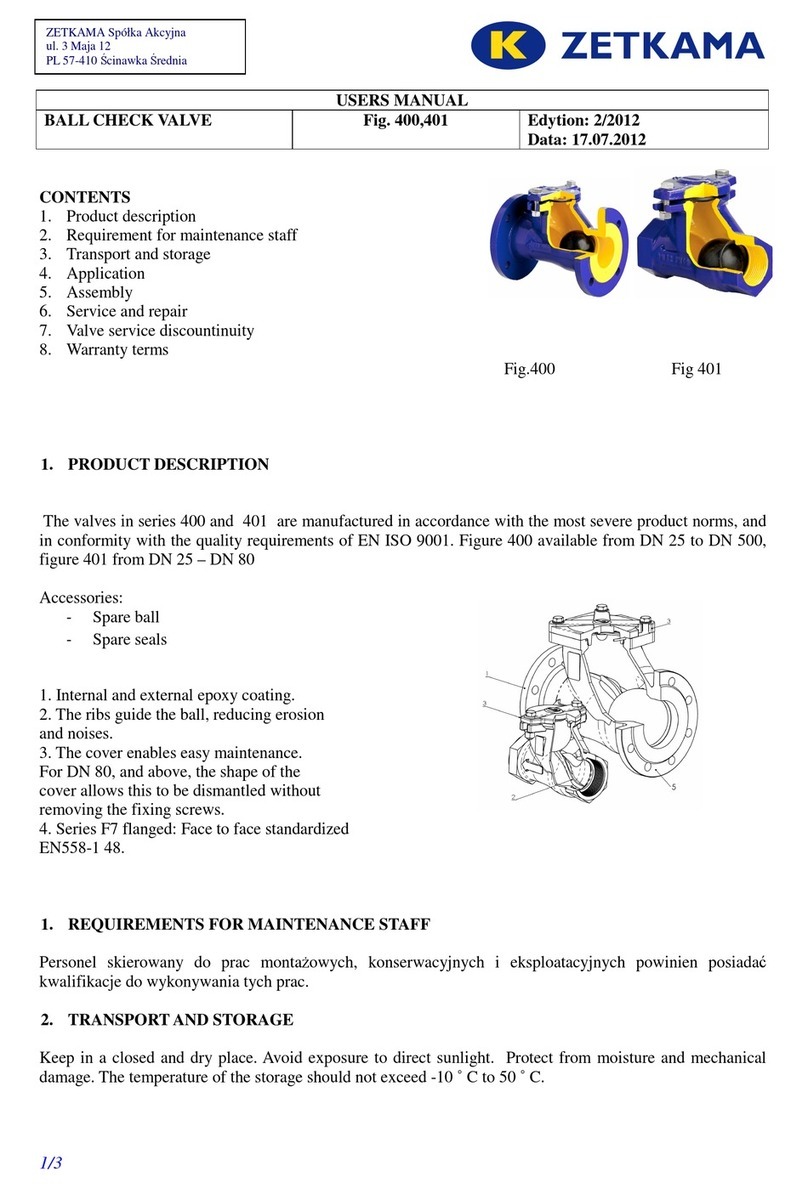

Valve Description

The Center Line Resilient Seat Butterfly Valve (RSBFV) is

designed for use in ANSI Class 150 piping systems and is

available in both Wafer and Lug style body designs. The

standard valve size range available is as follows:

• Series 200 200 psi Standard BFV 2" to 12"

150 psi Standard BFV 14" to 36"

• Series 205 200 psi Short Neck BFV 2" to 12"

• Series 225 285 psi BFV 2" to 24"

• Series 400 Damper Style BFV 2" to 12"

• Series 800 Check Valve 2" to 24"

Center Line Series 225 Butterfly Valve are also available

with an ANSI Class 300 bolt pattern for Lug bodies of sizes

2" through 12".

Valve Design Features

• The unique Center Line seat and disc design insures

positivevalvesealingwhilemaintaininglowseatingtorque.

• All Center Line Butterfly Valve discs are precision ma-

chinedtoahalfballprofile,providingaprecisedisctoseat

relationship.

• Center Line's cartridge style seat incorporates an elas-

tomer bonded to a phenolic stabilizing ring, eliminating

elastomermovementandreducingseattearingorfatigu-

ing due to bunching.

• Center Line's basic three bushing design completely

isolates the valve shaft from the body, resulting in in-

creased control of the valve disc, lower valve seating

torque, and longer valve life.

• TheCenter Line cartridge seat has a much smallermass

of elastomer than traditional boot seat designs, limiting

seat swell and the accompaning variations in seating

torque.

Flange and Pipe Schedule Compatibility

TheCenterLineRSBFVisdesignedtofitbetweenstandard

piping flanges as follows:

• ANSI 125 Cast Iron Flanges (All Sizes)

• ANSI 150 Steel Flanges, Schedule 40 (All Sizes)

• ANSI 150 Steel Flanges, Schedule 80 (2" to 10")

• ANSI 300SteelFlanges,Schedule40(Series225Lug,

2" to 12" only).

WhenusingSchedule80piping,specialcaremustbetaken

to make sure the valve is centered between the flanges to

prevent damage to the disc edge when opening or closing.

3

INTRODUCTION

SECTION 1

CENTER LINE

Long Beach, CA

Gasket Compatibility

IntheCenterLinebutterflyvalveandcheckvalvedesign,the

elastomerseatextendsbeyond thevalvefaceandprovides

a leakproof seal between the valve and the mating pipe

flange faces. Gaskets are not needed and should not be

used when the valve is installed between standard weld

neck or slip-on type flanges.

Operating Pressures

AllCenterLineSeries200and205ButterflyValvesarerated

at200psibubbletightshut-offforsizes2"to12"and150psi

bubble tight shut-off for sizes 14" and larger. Center Line

Series 225 Butterfly Valves are rated for bubble tight shut-

offat285psi,whileSeries400DamperValveswhicharenot

designed for bubble tight shut-off have a body working

pressure of 200 psi. Center Line Series 800 Check Valves

are rated at a minimum pressure differential of 25 psi and a

maximum pressure differential of 150 psi for bubble tight

shut-off.

Product Identification

EachCenter Line valve has an identification tag attached to

the valve body. Information on this tag includes the valve

SeriesNumber,materialsofconstructionfortheBody,Disc,

and Seat, and the valve Pressure Rating.

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

1.

2.

3.

4.

5.

6.

7.

8.

Check the packing list against the valve received to

verify that the size, material, and trim are correct.

Checktomakesurethatthevalveandoperatorwerenot

damaged during shipment.

When lifting the valve, take care to avoid damage to the

flange faces, disc sealing edge, or operator.

Ifthevalveistobestoredbeforebeinginstalled,itshould

be protected from harsh environmental conditions.

Store the valve with the disc in the “almost closed”

position to protect the sealing edge and the seat.

Keepthevalveinacleanlocation,awayfromdirt,debris

and corrosive materials.

Keep the valve in a dry area with the flanges protected

and on a suitable skid or pallet.

Keepthe valve in a cool location if possible, out of direct

sunlight.

Opening Rotation

The Center Line valve disc can rotate 360°without damag-

ing the valve or elastomer seat. The valve is designed to

open with either clockwise or counterclockwise rotation of

the shaft.

Valve Ratings

Center Line valves are intended for use at the pressure

indicated on the nameplate attached to each individual

valve.Check thevalveoperating temperature andpressure

rating before proceeding with installation.

4

INSTALLATION RECOMMENDATIONS

SECTION 2

Valve and Flange Preparation

If the valve and mating pipe are properly prepared for

installation, future problems can be avoided. All valve seat

and pipe flange faces should be free of dirt, grit, dents, or

surface irregularities which may disrupt flange sealing and

cause external leakage. The valve disc sealing surface

should also be inspected to eliminate any dirt or foreign

material that will adversely affect the operation of the valve.

Installation Position

To prevent damage to the disc and seat during installation,

the valve disc should be slightly open but not extending

beyond the valve liner face. Positioning the disc in this

“almost closed” position will reduce seat interference and

initial torque build-up during valve installation.

Ingeneral,itispreferabletoinstallRSBFV'swiththe shaft

in a horizontal orientation. In this position, shaft and disc

weights are evenly distributed, minimizing seat wear.

Additionally, any foreign matter which may accumulate at

the bottom of the disc and shaft is effectively removed

each time the valve is opened.

Center Line butterfly valves are designed to operate be-

tweentwoflanges.If the valve installation calls for theuse

of one pipe flange only, a Lug style valve with Dead End

Service feature must be used.

Disc Clearances

Prior to installing the valve, it is important to make sure the

IDofthepipeandthepipeflangesare largeenoughtoallow

thediscedgetoswingintotheopeningwithoutinterference.

Damagetothediscedgecanseverlyaffecttheperformance

of the valve. Flange and pipe schedule compatibility for

Center Line valves is shown in Section 1 of this manual.

Valve Seat Position

All Center Line butterfly valves are completely bi-directional,

soinstallationisnotdependentonseatorientation. ForCenter

LineSeries800CheckValves,everyeffortshouldbemadefor

installationwithbackflowprotection(noflow)intotheseatside

of the valve. Bubble-tight shutoff will be achieved in this

orientation with 25 to 150 psi ∆P across the valve.

Unpacking and Storage Instructions

Installation Tools

The only tool required in the installation of a Center Line

RSBFV is a wrench suitable for tightening the flange bolts

and/ornutsrequiredtosecurethevalvein-line.A hoistmay

berequiredtohelpmanipulatevalves10"andlarger.Smaller

sized valves can usually be installed by hand. Temporary

pipe supports may be used to keep mating flange faces

parallel in order to aid in valve installation.

Required Bolting

ThetableoutlinedonPage7isfurnishedtoprovideinforma-

tion regarding the size, type, and quantity of bolting recom-

mended for the installation of Center Line RSBFV's. This

table is intended for use as a planning and procurement

guide. All recommendations are based on pipe flanges in

accordance with ANSI 125/150 specifications. Flange bolt-

ing is not included with the valve shipment.

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

Remove any protective flange covers from the valve.

Inspect the valve to be certain the waterway is free from

dirtandforeignmatter.Becertaintheadjoiningpipelineis

freefromanyforeign materialsuchas rustandpipe scale

or welding slag that could damage the seat and disc

sealing surfaces.

Any actuator should be mounted on the valve prior to

installation to facilitate proper alignment of the disc in the

valve seat.

Checkthe valve identification tag for materials, and oper-

ating pressure to be sure they are correct for the applica-

tion.

Checktheflangeboltsorstudsforpropersize,threading,

and length.

INSTALLATION RECOMMENDATIONS

5

Pre-Installation Procedure

1.

2.

3.

4.

5.

Personal injury or property damage

may result if the valve is installed

where service conditions could ex-

ceed the valve ratings.

WARNING!

Position the connecting pipe flanges in the line to insure

proper alignment prior to valve installation. Spread the pipe

flanges apart enough to allow the valve body to be located

between the flanges without actually contacting the flange

surfaces(SeeFigure1.)Exerciseparticularcareinhandling

thevalvesoastopreventpossibledamagetothediscorseat

faces.

Valve Installation Procedure

For Lug style valves:

a. Place the valve between the flanges.

b. Install all bolts between the valve and the mating

flanges. Hand tighten bolts as necessary.

For Check Valves:

a. Note the opening direction of the disc for proper

valve orientation.

b. Place the valve between the flanges using the four

(4) alignment holes provided.

c. Install the remaining flange bolts, shifting the valve

asnecessarytopermittheboltstopassbythevalve

body. Hand tighten bolts as necessary.

2.

3.

4.

5.

6.

Beforecompletingthe tighteningofanybolts,thevalve

should be centered between the flanges and then

carefully opened and closed to insure free, unob-

structed disc movement (See Figure 2.)

Using the sequence shown in Figure 3, tighten the

flange bolts evenly to assure uniform compression.

If an actuator is to be used, air hoses or electricity

should be connected to the unit as specified by the

actuator manufacturer.

Cycle the valve to the fully open position, then back to

the fully closed position, checking the actuator travel

stop settings for proper disc alignment. The valve

should be operated to assure that no binding is taking

place.

The valve is now ready for operation.

Remember: Install the valve with the disc in

the “ALMOST CLOSED” position.

Do not use any flange gaskets.

Correct

Disc positioned in the

almost closed position.

Pipe flange spread allows

sufficient room for valve.

Incorrect

Disc opened beyond valve

body face. Pipe flanges not

spread sufficiently.

Figure 1-Initial Installation ofValve

1. For Wafer style valves:

a. Place the valve between the flanges.

b. Loosely install the two upper and lower flange bolts

that pass through the body alignment holes.

c. Installthe remaining flange bolts,shiftingthe valve as

necessary to permit the bolts to pass by the valve

body. Hand tighten all bolts as necessary.

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

Gasket

INSTALLATION RECOMMENDATIONS

6

Incorrect

Pipe Flanges mis-aligned.

Uneven torque applied to

bolting.

Correct

Piping aligned.

Thread engagement even

on both sides of valve.

Incorrect

Disc in closed position.

Gaskets installed between

valve and mating flanges.

Correct

No flange gaskets used.

Disc in the “almost closed”

position.

Figure 2-Centering and Flanging of Valve

Figure 3-Flange BoltTightening Sequence

Figure 4-FinalValve Alignment andTightening of Flange Bolts

1

15

8

12

4

10 614 2 16 7

11

3

9

5

13

1

8

4

62

7

3

51

8

4

6211

7

3

9

5

10

12

1

2

3

4

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

7

Flange Bolting Recommendations

INSTALLATION RECOMMENDATIONS

2" 5/8-11 4 4.750 5.125 1.250 15-60

2 1/2" 5/8-11 4 5.250 5.375 1.500 15-60

3" 5/8-11 4 5.250 5.375 1.500 15-60

4" 5/8-11 8 5.750 6.000 1.750 15-60

5" 3/4-10 8 6.000 6.375 1.750 25-100

6" 3/4-10 8 6.250 7.000 2.000 25-100

8" 3/4-10 8 6.750 8.000 2.250 25-100

10" 7/8-9 12 7.250 8.500 2.250 50-200

12" 7/8-9 12 7.750 9.750 2.500 50-200

14" 1-8 12 8.250 12.250 2.750 70-300

16" 1-8 16 8.750 11.750 2.750 70-300

18" 1 1/8-7 16 10.000 13.000 3.500 100-400

20" Series 200 1 1/8-7 20 11.250 14.500 4.250 100-400

20" Series 225 1 1/8-7 16 11.250 4.250 100-400

+ 4 ea. 5.000 3.250 100-400

24" Series 200 1 1/4-7 20 12.750 15.125 4.750 150-500

24" Series 225 1 1/4-7 16 12.750 4.750 150-500

+4 ea. 5.250 3.750 150-500

30" Series 200 1 1/4-7 24 13.750 4.500 150-500

+4 ea. 5.750 4.250 150-500

Center Line Wafer And Lug Valves, 2"-30", ANSI 125/150 Bolt Pattern

Valve Thread Number Stud Length Stud Length Bolt Length Req. Torque

Size Size Required Wafer B'fly (in.) Check Valve (in.) Lug B'fly (in.) (Ft-lbs)

Bolting and torque recommendations are made without a warranty, and apply only to steel weld-neck or slip-on flanges.

The use of lock washers and/or lubrication with the bolting will affect stated torque values.

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

MAINTENANCE INSTRUCTIONS

SECTION 3

Be sure the line is depressurized and drained.

Be sure of the pipeline media. Proper care should be

taken for protection against toxic and/or flammable

fluids.

NeverremovethevalvewithoutanOperator(Manualor

Automatic) already attached to the valve shaft.

Never remove the Operator from the valve while the

valve is in the pipeline under pressure.

Always be sure that the disc is in the closed position

before removing the valve.

1.

2.

3.

4.

5.

Thoroughly clean all parts. Inspect components for any

defects.

Apply a small amount of silicone grease to the inside

surfaces of the body, including the upper and lower shaft

holes.

Inserttheshaftbushingsintothebodybeingcarefulnotto

allow intrusion into the body seat bore.

Installtheseatintothecenterofthebody,makingsurethe

shaft holes in the seat line up with the holes in the body.

1.

2.

3.

4.

8

Resilient Seat

Bushings

Completely coat the inside surfaces of the seat with

siliconegrease.Carefullypushthediscintotheseatinthe

open position (90 degrees to the body.) Line up the shaft

holes of the disc as close as possible with the shaft holes

in the seat body.

5.

Disc

1.

2.

3.

4.

5.

6.

Position valve flat with the disc in the closed position.

Loosen the taper pin(s) from the valve disc using a

hammer and punch.

Note: Punch should be of same size or larger

diameter as small end of taper pin to avoid mush-

rooming of taper pin.

Remove taper pin(s) from disc. Extract the valve shaft

from the body using a twisting motion.

Remove the valve disc from body making sure not to

damage the seat or disc sealing edge.

Cartridge seat removal can be accomplished from ei-

ther direction by applying pressure evenly on one face

topushtheseatthroughthe body.Ifthevalveisofdead

end service design, remove set screws around periph-

ery of body extending into seat prior to seat removal.

Remove shaft bushings from body as required.

General Maintenance

The following periodic preventative maintenance practices

are recommended for all Center Line Butterfly Valves.

1.

2.

3.

4.

Operate the valve from full open to full closed to assure

operability.

Check flange bolting for evidence of loosening and

correct as needed.

Inspect the valve and surrounding area for previous or

existing leakage at flange faces or shaft connections.

Check piping and/or wiring to actuators and related

equipment for looseness and correct as needed.

Before removing the valve from the line or loosening any

bolts, it is important to verify the following conditions:

Butterfly Valve Assembly

Safety Precautions

Butterfly Valve Disassembly

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

3

4

6

6

2

1

2

5

7

5

8

8

1

MAINTENANCE INSTRUCTIONS

1.

2.

3.

4.

5.

Check Valve Disassembly

Remove set screw (7) from the alignment body (1).

Remove the valve insert (4) from the alignment body (1).

Removeshaftplugs(8)fromtheinsertwithascrewdriver.

Note: Plugs are sometimes difficult to loosen. When this

happens,applyheatwithsmalltorchdirectlytotheplugfor

30seconds.Donotallowtheflametotouchtheelastomer

face on either side of the inset.

Remove the shaft (3) from the valve insert.

Note: When the stem is removed, the springs (5) behind

the check plates (2) will be released. On sizes 8" to 20",

thesespringsmust besecurelyheldtopreventrecoil upon

loss of tension.

Remove the check valve plates (2) from the valve insert.

Notethelocationofthethrustwashers(6).Thesemustbe

replaced in the same location upon reassembly.

Butterfly Valve Assembly

(continued from page 8)

6.

7.

8.

9

Insert the shaft through the body and disc, use a twisting

motion to align the keyway parallel with the disc.

Shaft

Insert taper pin(s) into the disc and set with two or three

sharp blows. Wipe dust shield o-ring with silicone grease

and place over the shaft into the top of the body.

Ifthevalveisofdeadendservicedesign,insertsetscrews

through the body into the seat.

Key

Taper Pins

O-Ring

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

Position the disc in the closed position.

Install the actuator mounting bracket on the valve body

with the actuator mounting holes facing up-ward. Fasten

the bracket securely in place with the appropriate ma-

chine bolts, nuts, and lock washers.

Installthedrivekeyinthekeywayoftheshaft.Tapthekey

in place to insure it is fully seated.

Install the drive coupling on the shaft by lining up the

proper keyway in the coupling with the key in the shaft.

Rotate the actuator shaft to the full clockwise position.

Align the drive coupling with the actuator shaft and install

the actuator on the mounting bracket.

Fasten the actuator to the mounting bracket with the

appropriate machine bolts and lock washers. It may be

necessary to slightly rotate the actuator shaft to align the

mountingholesintheactuatorwiththemountingbracket.

Adjust the stops in the actuator to position the face of the

disc parallel with the face of the valve body in the closed

positionandperpendiculartothefaceofthevalvebodyin

the open position.

Position the disc in the closed position.

Installtheratchetplateusingmachinebolts,nutsandlock

washers, but do not tighten the fasteners.

Install the drive key in the shaft. Tap the key into place to

ensure it is fully seated in the keyway .

Install the handle so that it is parallel with the disc face.

Thelockinglevermustbefullyretractedbeforeitwillpass

through the ratchet plate. Tighten the set screw in the

handle against the key.

With the handle installed flush with the ratchet plate,

engage the locking lever with the ratchet plate. Using the

handle,adjustthepositionoftheratchetplateuntilthedisc

face is parallel with the valve face, then tighten the

fasteners securely.

Position the disc in the closed position.

Install the drive key in the shaft. Tap the key into place to

ensure it is fully seated.

Rotate the gear shaft to the full clockwise position. Align

the keyway in the gearbox bore with the key in the shaft

and slide the gearbox onto the shaft.

Fasten the gearbox to the mounting bracket with the

appropriate machine bolts and lock washers. It may be

necessary to rotate the gear shaft slightly to align the

mounting holes in the gear with the plate.

Adjust the stops in the gearbox to position the face of the

discparallelwiththefaceofthevalveintheclosedposition

and perpendicular to the face of the valve in the open

position.

Check Valve Assembly

MAINTENANCE INSTRUCTIONS

Place valve plates (2) into the insert (4).

Replace thrust washers (6) in original location.

Install shaft (3) half way into the insert.

Pre-load first spring (5) with 1/2 turn windup. Do not

unwind spring. Legs of spring should be horizontal, 180°

apart.

Place spring (5) on shaft (3) and release.

Install shaft (3) just far enough to allow installation of

second spring (5).

Push shaft (3) completely into insert (4).

Replace shaft plugs (8) in insert (4) with pipe thread

sealant and tighten firmly.

Placeinsert(4)inbody(1)withtappedholeinbodyaligned

with drill point in insert.

Replace set screw (7) and tighten.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Remote Actuator (Male Drive)

Mounting Procedure

1.

2.

3.

4.

5.

6.

7.

10

Ratchet Handle Mounting Procedure

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

Manual Gear Mounting Procedure

Remote Actuator (Female Drive)

Mounting Procedure

1.

2.

3.

4.

5.

6.

7.

8.

Position the disc in the closed position.

Installtheactuatormountingbracketonthevalvebody

withtheactuatormountingholesfacingup.Fastenthe

bracketsecurelyinplacewiththeappropriatemachine

bolts, nuts, and lock washers.

Installthe drive key in the shaft. Tap thekeyinplaceto

insure it is fully seated.

Install the drive coupling on the shaft by lining up the

proper coupling keyway with the key in the shaft.

Install the drive key in the drive coupling. Tap the key

in place to insure it is properly seated.

Rotate the actuator to the full clockwise position. Align

thekeywayintheactuatorborewiththekeyinthedrive

coupling and slide the actuator on the drive coupling.

Fasten the actuator to the mounting bracket with the

appropriatemachineboltsandlockwashers.Itmaybe

necessary to rotate the actuator slightly to align the

actuator with the mounting bracket.

Adjust the stops in the actuator to position the face of

!he disc parallel with the face of the valve body in the

closed position and perpendicular to the face of the

valve body in the open position.

CENTER

LINE

3201 Walnut Avenue, Long Beach, CA 90807

562/426-2531

FAX 562/490-9546

6

4

7

8

9

3

5

2

10

1

3

10

2

4

9

1

7

5

See Detail

A

1

4

4

6

5

6

9

8

10

7

7

3

2

1 * Valve Body

2 * Liner (Molded to Item 1)

3 Shaft

4 Shaft Plug (Qty. 2)

5 Plate (Qty. 2)

6 Thrust Washer (Qty. 4)

7 Spring (Qty. 2)

8 Alignment Body

9 Set Screw

10 Plate Travel Stop (14" &

larger only)

1 Body

2 Disc

3* Seat

4 Shaft

5* Taper Pin

6 Key

7* O-Ring

8 Bushing

9 Bushing

10 Bushing

1 Body

2 Disc

3 Shaft

4 * Taper Pin

5 Key

6 * Packing (V-Ring)

7 Packing Retainer

8 Washer (Qty. 2)

9 Bushing

10 Bushing

11 Snap Ring

Parts List

MAINTENANCE INSTRUCTIONS

Item Description

*Recommended Spare Parts

Item Description

*Recommended Spare Parts

Series 200, 205, 225

Butterfly Valve

Series 400

Damper Valve

Series 800

Check Valve

Item Description

11

* Items 1 and 2 Must Be

Ordered Together.

,

,

,

,

6

11

8

Detail

A

Bronze 0

PTFE 3

Springs (CLC):

316 SS D

Nitronic 50 F

Cast Iron 1

* Ductile Iron 2

Carbon Steel 3

316 SS 4

Ductile Iron-(A395) G

A395 Epoxy H

A395-HI Epoxy J

Cast Iron-Epoxy S

* Ductile Iron-Epoxy V

Cast Iron-HI Epoxy D

* Ductile Iron-HI Epoxy P

No Body X

2" 02

21/2" 25

3" 03

To

36" 36

456789213

ORDERING INFORMATION

3201 Walnut Avenue Long Beach, California 90807

310/430-1094 • FAX: 310/490-9546

CENTER

LINE

CENTER LINE

FIGURE NUMBER SYSTEM

1. Size Code 7. Bushing Code

3. Body Code

416 SS 1

316 SS 4

Monel K500 5

Monel 400 7

17-4 PH 9

Ductile Iron-ENP 2

316 SS 4

Ductile Iron-Zinc Paint 5

Aluminum Bronze 6

Monel 7

Ductile Iron-Abrasion Resistant E

Ductile Iron-HI Epoxy T

6. Shaft Code

200 PSI 0

232 PSI (16 Bar) 1

75 PSI 3

285 PSI 5

150 PSI 6

125 PSI (For PTFE Seats) 8

For ATC:

200 PSI Shut-off A

75 PSI Shut-off B

285 PSI Shut-off C

For Damper:

250 DEG F P

500 DEG F T

4. Pressure Code

5. Disc Code

Buna 1

Abrasion Resistant Buna 2

Black Neoprene 3

EPDM 5

Low Temp Viton 6

Hypalon 7

PTFE/Buna L

High Temp Viton P

EPDM Food Grade V

No Seat X

Viton O

White Buna-Food Grade W

Peroxide Cured Buna 8

Potable Water EPDM D

White Buna B

Handle (DIT) 2

Handle/Infinite Adjustment/ 3

Lockable (DIT/IOL)

Handle/Infinite Adjustment 4

(DIT/IO)

Gear/Handwheel 5

Gear/Chainwheel U

Gear W/Balance Stop/Handwheel G

Buried Service Gear 2" Sq. Nut C

Direct Nut Operator D

No Operator X

9. Actuator Code

8. Seat/Liner Code

2. Series/Style Code

200-Wafer A

200-Lug B

200-Lug/Dead End C

36"-Series 200 Flanged D

205-Wafer F

205-Lug G

205-Lug/Dead End H

225-Wafer J

225-Lug K

225-Lug/Dead End L

225-Lug /ANSI 300 Bolt Pattern M

255-Lug/Dead End /ANSI 300 N

400 P

800 R

200-Wafer, Euro T

• 2"-12", Universal

• 14"-30", PN16

• 36"-Flanged, PN16

200-Lug, Euro U

• 2"-30", PN16

200-Lug/Dead End, Euro V

• 2"-30, PN16

800-Euro W

• 2"-10", Universal

• 12"-16", PN10

200-Wafer, Euro 7

• 14"-30", PN10

• 36"-Flanged, PN10

200-Lug, Euro 8

• 2"-30", PN10

200-Lug/Dead End, Euro 9

• 2"-30", PN10

200-Wafer S

• Silicone Free

200-Lug E

• Silicone Free

200-Lug/Dead End Q

• Silicone Free

800-Silicone Free Y

* A536

This manual suits for next models

4

Table of contents

Popular Control Unit manuals by other brands

SMC Networks

SMC Networks 4501 Series manual

Tektronix

Tektronix DAS MTIF instructions

Ponar

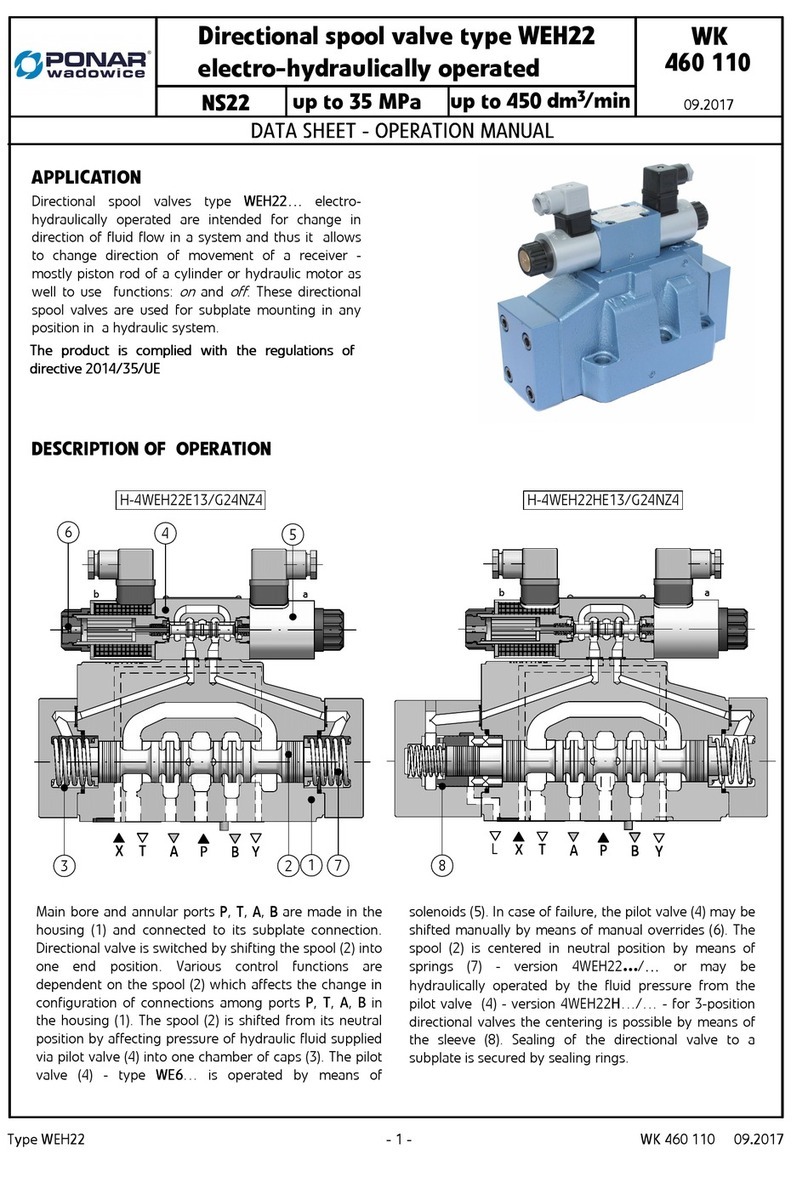

Ponar WEH22 Series Operation manual

Allen-Bradley

Allen-Bradley ControlLogix 1756-ENET/B user manual

Lutron Electronics

Lutron Electronics GRAFIK Eye QS Quick installation and operation guide

Siemens

Siemens XC1003-A Operation