Waters 2690 User manual

Waters 2690

Separations Module

Quick Start Guide

34 Maple Street

Milford, MA 01757

WAT553-03TP, Revision 3

NOTICE

The information in this document is subject to change without notice and should not be

construed as a commitment by Waters Corporation. Waters Corporation assumes no

responsibility for any errors that may appear in this document. This manual is believed to

be complete and accurate at the time of publication. In no event shall Waters Corporation

be liable for incidental or consequential damages in connection with, or arising from, the

use of this manual.

© 1996, 1998, 2000 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA. ALL RIGHTS RESERVED. THIS BOOK OR PARTS THEREOF MAY NOT BE

REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF THE

PUBLISHER.

Alliance, Millennium, and Waters are trademarks of Waters Corporation.

All other trademarks are the sole property of their respective owners.

Quick Summary

The figure below summarizes the information contained in this Quick Start Guide. Use it

as a reference after you have read the entire document.

Start

Power on the

Separations

Module

PrimetheSolvent

Management

System

Prime the Plunger

Seal Wash Pump

(If Installed)

The Function

Begins to Run

Configure the

Separations

Module

Degas or

Sparge Eluents

Purge the Sample

Management

System

Adjust the

Seal Pack

Prime the Needle

Wash Pump

Load the

Carousels

Yes

No

Perform

an Automatic

Run?

Set Control

Switches

Set Flow Rate and

Composition

Set Sparge Rate

(if Applicable)

Press Direct

Function

Screen Key

Select Direct

Function to Perform

Enter Function

Parameters

Press the Run

SamplesScreenKey

on the Main Screen

Enter Data Required by

the Separation Method,

Sample Set, or

Sample Template

The Run Ends as

Programmed

Select the Separation

Method, Sample Set, or

Template to Run, then

Press Run Screen Key

Press the Routine

Screen Key to Start

the Run

Conventions Used in This Guide

This Quick Start Guide uses the following conventions:

• Bold text indicates user input or action. For example, press Enter.

• When you are instructed to “press the Xkey”, press the indicated keypad key.

• When you are instructed to “press the Xscreen key,” press the keypad key directly

below the key name displayed on the screen.

Notes and Warnings

This guide uses the following note and warning conventions:

• Notes call out information that is important to the operator. For example:

Note: Record your result before you proceed to the next step.

• Attentions provide information about preventing possible damage to the system or

equipment. For example:

• Cautions provide information essential to the safety of the operator. For example:

STOP

Attention: To avoid damaging the detector flow cell, do not touch the flow

cell window.

Caution: To avoid chemical or electrical hazards, always observe safe

laboratory practices when you operate your system.

Caution: To avoid electrical shock and possible injury, remove the power

cord from the rear panel of the instrument before you perform the

procedures in this section.

Introduction 5

1

Introduction

The

Waters 2690 Separations Module Quick Start Guide

introduces you to the basic

features of the Waters 2690 Separations Module and describes how to make a run.

Who Should Use This Guide?

This guide is intended for both novice and experienced chromatographers who need to

operate the Waters 2690 Separations Module.

What Is In This Guide?

The

Waters 2690 Separations Module Quick Start Guide

contains basic procedural

information to help you set up the Waters 2690 Separations Module and make a run. In

addition, this guide contains detailed flow charts that provide Waters-recommended steps

to prime, equilibrate, and purge both degasser and sparge-based 2690 Separations

Modules. Refer to Chapter 6, Recommended Preparation Procedures.

Note: This guide is not designed to teach you chemistry and does not contain background

or reference information.

For additional information, or if you want to learn how to modify any of the procedures in

this guide, refer to the

Waters 2690 Separations Module Operator’s Guide

.

Note: With the purchase of the 2690 Separations Module, Waters supplies both this guide

and the Waters 2690 Separations Module Operator’s Guide in electronic format on a

CD-ROM. To install and view these guides on your computer, refer to the Readme file on

the CD-ROM. To purchase a printed version of the Operator’s Guide, contact Waters Sales

Support at 800-252-4752, extension 8101.

Before You Begin

This guide assumes that:

• Your system is properly installed (refer to the

Waters 2690 Separations Module

Operator’s Guide

, Chapter 2, Installing the Separations Module).

• Your separation methods, sample sets, and/or sample templates are already

created and stored (refer to the

Waters 2690 Separations Module Operator’s Guide

,

Chapter 6,

Creating Methods, Sample Sets, and Sample Templates).

6 Introduction

System Description

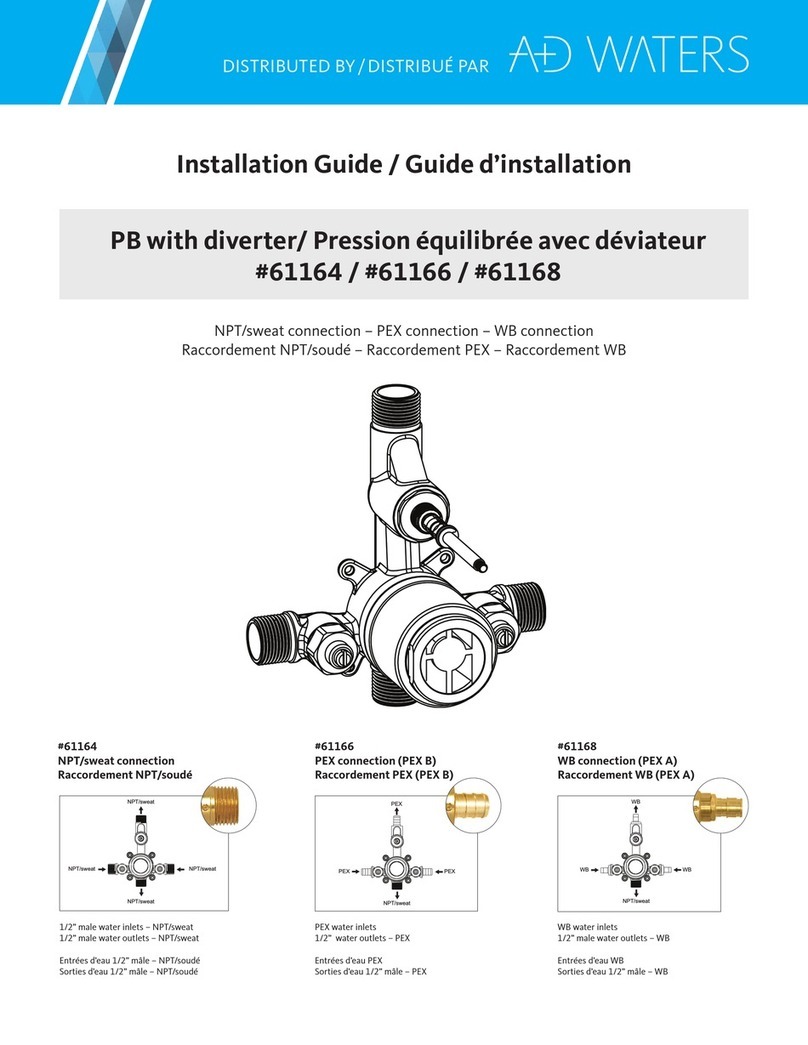

The Waters™2690 Separations Module (Figure 1-1) is an integrated solvent and sample

management platform. This integration of two traditional high performance liquid

chromatography (HPLC) components streamlines all critical separation functions.

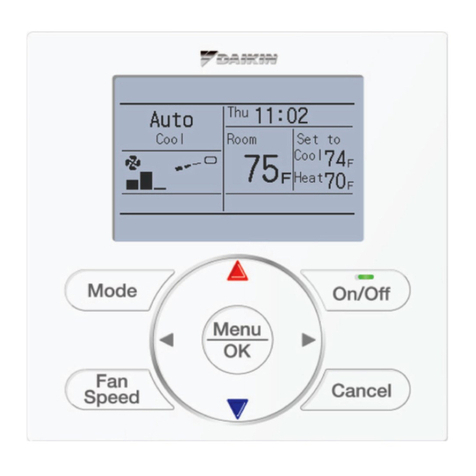

Figure 1-1 Waters 2690 XE Separations Module (Front View)

The sample management system in the Waters 2690 Separations Module uses five

carousels with a total capacity of 120 vials. A carrier rotates the carousels to the injection

station in the sample compartment.

The Waters 2690 Separations Module is available from Waters in a number of

configurations, differing from each other by the options that are included.

The two primary configurations are designated:

•2690 – Provides quaternary solvent, high-performance solvent delivery, integral

helium sparge for solvent conditioning, integral plunger seal-wash system, 120-vial

capacity sample management system, liquid-crystal display and keyboard user

interface, and floppy disk drive.

•2690 XE – Provides the capabilities of the 2690 base product, replaces the helium

sparge system with a four-channel in-line vacuum degasser, and adds a column

heater and a sample heater/cooler.

TP01354

Column Heater Module

Syringe Access Door

FrontPanel Display

and Keyboard

Floppy Disk Drive

Solvent Delivery

Tray Access Door Solvent Conditioning

Tray Access Door

Sample

Compartment

Access Door

Solvent Bottle Tray

Detector Drip Tray

Preparing the Separations Module for Operation 7

2

Preparing the Separations

Module for Operation

Before you can prepare the Separations Module for operation, you need to power on the

2690 Separations Module by moving the power switch (located at the top of the left side

panel) to the I(On) position. The startup diagnostics routine begins.

2.1 Powering On

Startup Diagnostics

The startup diagnostics routine performs the following functions and tests:

• CPU board

• Memory (RAM and ROM)

• Keypad

•Display

• External communication

• Digital signal processor (DSP)

• Floppy disk drive

Once the electronic part of the diagnostics test is complete, the front-panel screen

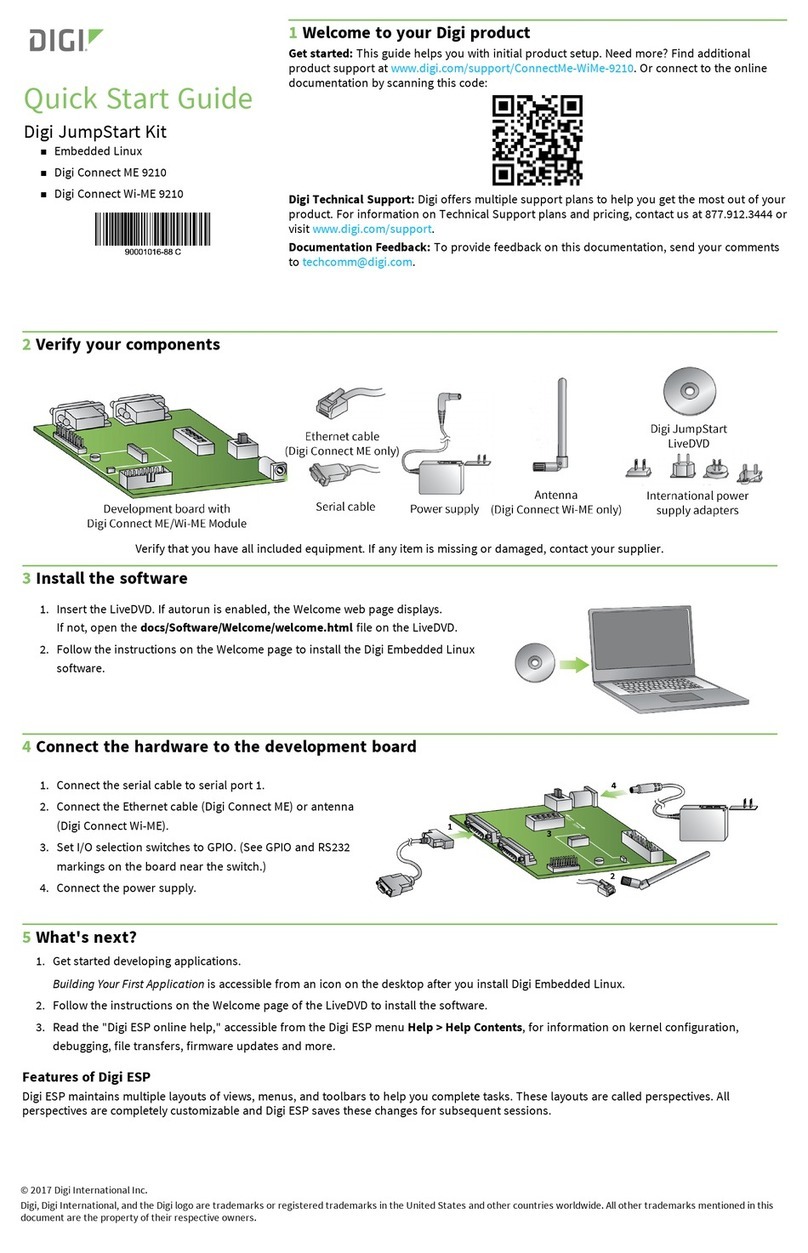

displays the results of the tests, as shown in Figure 2-1.

Figure 2-1 Diagnostic Test Results Screen

CPU

ROM

RAM

KEYPAD

DISPLAY

DMA

GPIB

FLASH

DSP

FLOPPY

CLOCK OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

STARTUP DIAGNOSTICS

8 Preparing the Separations Module for Operation

The Main Screen

When the initial part of the startup diagnostics routine is successful, the Main screen

appears in the front panel display (Figure 2-2). The startup diagnostics routine continues

by initializing the:

• Needle, syringe, and valves

• Carousel carrier

• Solvent management system

The statuses of these mechanical diagnostics tests appear in the banner area of the Main

screen (Figure 2-2) while the diagnostics are running. If the startup diagnostics routine is

not successful, refer to the

Waters 2690 Separations Module Operator’s Guide

, Section

8.5, Troubleshooting. When the startup diagnostics routine is complete, the Separations

Module enters the Idle mode.

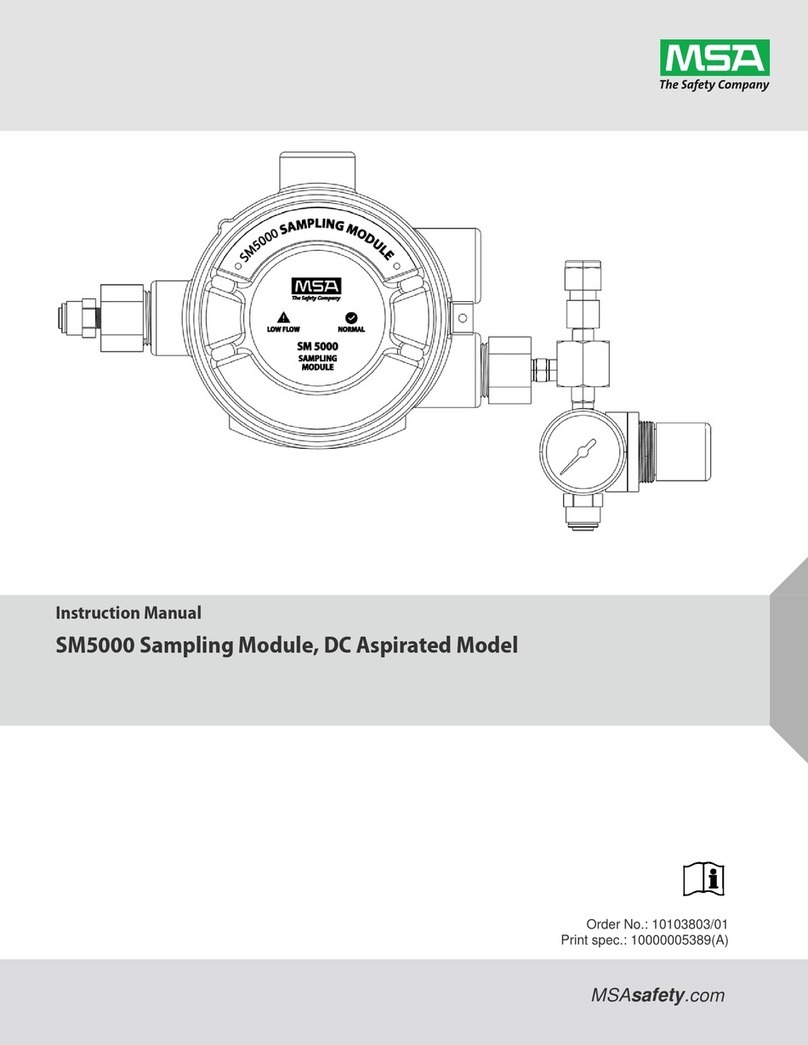

Figure 2-2 Main Screen

Banner Area

Data Area

Screen Keys

Preparing the Separations Module for Operation 9

2.2 Configuring the Separations Module

Before you can operate the Separations Module, you need to configure the Separations

Module for stand-alone or remote control and for a variety of other operating parameters.

No Interaction Mode

In this standalone mode, the Separations Module is not connected to the IEEE-488

interface bus. The Separations Module controls other non-IEEE devices in the HPLC

system using the I/O connections on the rear panel. Refer to the

Waters 2690 Separations

Module Operator’s Guide

, Section 2.7.1, I/O Signal Connections, for the procedure to

make I/O connections. Use this mode if you want to suspend communication with a

connected Millennium ChromatographyManager workstation and operate the Separations

Module and the other HPLC system components from their front panels.

To set the Separations Module to the No Interaction mode:

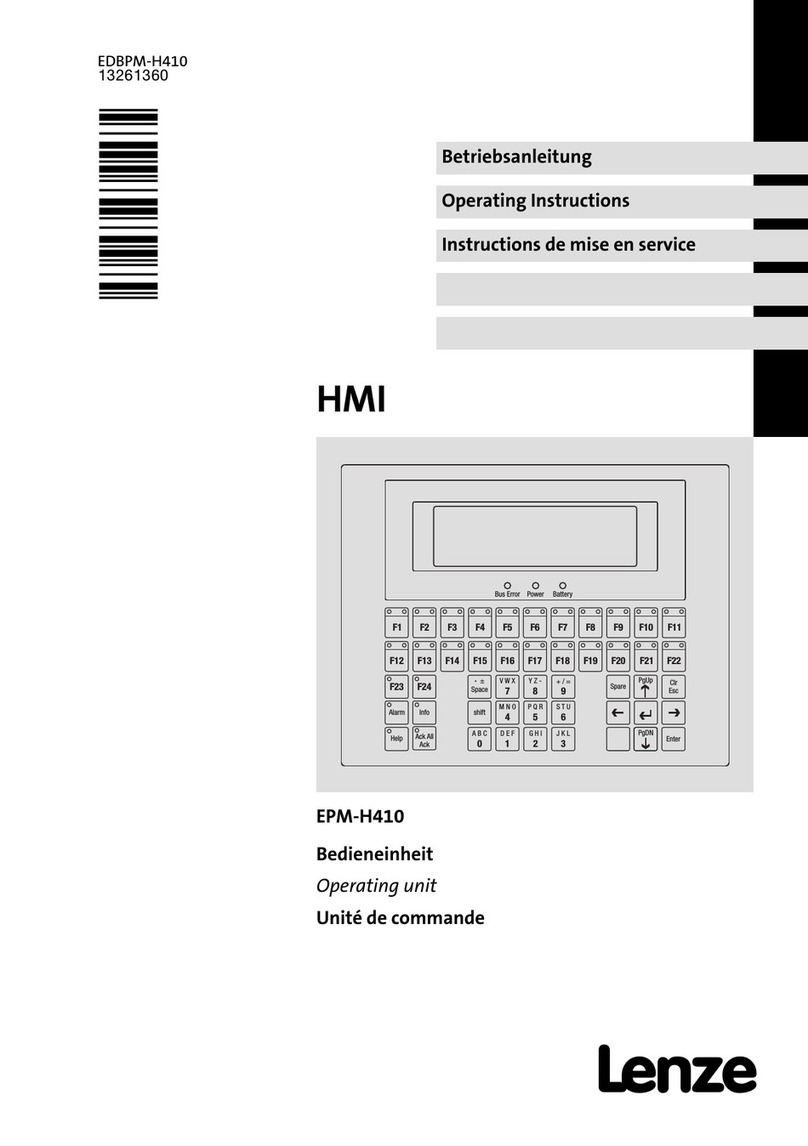

1. Press the Config screen key in the Main screen. The Configuration screen appears

(Figure 2-3).

2. Select the System field, then press Enter to display a list of choices.

3. Select No interaction, then press Enter.

4. Press Exit.

System Controller Mode

In this standalone mode, the Separations Module controls up to three detector channels

on the IEEE-488 bus. This can include two UV detector channels (Waters 2487 and/or 486

Tunable Absorbance Detectors) and one RI detector channel (Waters 2410 or 410

Differential Refractometer). You can also control other HPLC modules using the I/O

connections.

To set the Separations Module to the System Controller mode:

1. Press the Config screen key in the Main screen. The Configuration screen appears

(Figure 2-3).

10 Preparing the Separations Module for Operation

Figure 2-3 Configuration Screen

2. Select the System field, then press Enter to display a list of choices.

3. Select System Controller, then press Enter.

4. Press the Detectors screen key. A list of active devices (with their IEEE-488

interface bus addresses) appears.

a. Press the Scan screen key to update the list.

b. Press the OK screen key to return to the Configuration screen.

5. Press Exit. The Separations Module is ready to control Waters detectors using

separation methods, sample sets, or sample templates.

Controlled by Millennium32 Mode

In this remote-control mode, a Millennium Chromatography Manager workstation running

Millennium32 software (Windows 95, 98, or NT) controls the operation of your HPLC

system using the IEEE-488 interface bus.

To set the Separations Module to the Controlled by Millennium32 mode:

1. Select the System field in the Configuration screen, then press Enter to display a

list of choices.

2. Select Controlled by Millennium32, then press Enter. The IEEE 488 Address

field is highlighted.

3. Press Enter to display a list of addresses.

4. Select an address that is unused by other chromatographic components connected

to the Millennium Chromatography Manager workstation, then press Enter.

5. Press Exit. The Separations Module is ready to be controlled from the

Millennium Chromatography Manager workstation.

Preparing the Separations Module for Operation 11

Controlled by MassLynx Mode

In this remote-control mode, Micromass MassLynx NT software (Version 3.1 Build 004 or

higher) controls the 2690 Separations Module. MassLynx software is used with Micromass

mass spectrometry (MS) detectors, using the IEEE-488 interface between the Micromass

computer and the 2690 Separations Module.

To set the Separations Module to the Controlled by MassLynx mode:

1. Select the System field in the Configuration screen, then press Enter to display a

list of choices.

2. Select Controlled by MassLynx, then press Enter. The IEEE 488 Address field

is highlighted.

3. Press Enter to display a list of addresses.

4. Select an address that is unused by other chromatographic components connected

to the Micromass computer, then press Enter.

5. Press Exit. The Separations Module is ready to be controlled from the MassLynx

computer.

Controlled by Millennium 2.xx Mode

In this remote-control mode, a Millennium Chromatography Manager workstation running

Millennium 2.xx software (Windows 3.1) controls the operation of your HPLC system using

the IEEE-488 interface bus.

To set the Separations Module to the Controlled by Millennium 2.xx mode:

1. Select the System field in the Configuration screen, then press Enter to display a

list of choices.

2. Select Controlled by Millennium 2.xx, then press Enter. The IEEE 488 Address

field is highlighted.

3. Press Enter to display a list of address pairs.

4. Select an address pair that is unused by other chromatographic components

connected to the Millennium Chromatography Manager, then press Enter.

5. Press Exit. The Separations Module is ready to be controlled from the

Millennium Chromatography Manager workstation.

The Separations Module appears as two devices in the Millennium System view:

•The solvent and sample management systems – With an even address.

•The optional sample heater/cooler – With an odd address.

12 Preparing the Separations Module for Operation

Refer to the

Waters 2690 Separations Module Operator’s Guide

, Section 5.2, Making

Automatic Runs Under Millennium Control, for details on making runs under Millennium

control.

Controlled by Operate Gradient by Event In

In the Operate Gradient by Event In mode, an external autosampler (a Waters 2700

Sample Manager, for example) signals the Solvent Management System of the

Separations Module to begin a gradient. In this mode, the Separations Module has no

control of IEEE-488 devices, however, the Separations Module

can

control non-IEEE

devices using the I/O connections on the rear panel.

To set the Separations Module to the Operate Gradient by Event In mode:

1. Select the System field in the Configuration screen, then press Enter to display a

list of choices.

2. Select Operate Gradient by Event In, then press Enter.

3. Press the Events In screen key to display the Events In dialog box. If you need

more detailed steps on defining Events In conditions, refer to the

Waters 2690

Separations Module Operator’s Guide

, Events In discussion, Section 3.2.1,

Setting Configuration Parameters.

4. Set the Stop Flow field to the appropriate condition (Ignore,High, or Low), then

press Enter.

• Choose Ignore if the Stop Flow I/O terminals of the Separations Module are

not used.

• Choose High if the output connection from the external autosampler to the

Stop Flow I/O terminals of the Separations Module changes to a high (more

positive) TTL-level.

• Choose Low if the output connection from the external autosampler to the Stop

Flow I/O terminals of the Separations Module changes to a low (more negative)

TTL-level.

5. Set the Hold 1 field to the appropriate condition (High or Low), then press Enter.

• Choose High if the output connection from the external autosampler to the

Hold 1 Inject terminals of the Separations Module changes to a high (more

positive) TTL-level to initiate a chromatographic run (and prevent an injection by

the Separations Module).

• Choose Low if the output connection from the external autosampler to the Hold

1 Inject terminals of the Separations Module changes to a low (more negative)

TTL-level to initiate a chromatographic run (and prevent an injection by the

Separations Module).

Note: If you are configuring the Separations Module with a Waters 2700 Sample

Manager, choose Low.

Preparing the Separations Module for Operation 13

6. Set the Logic field to Or, then press Enter.

7. Set the Hold 2 field to Ignore, then press Enter.

8. Press the OK screen key to save your selections and exit from the Events In

dialog box.

Controlled via RS-232 (ASCII) or (Binary) Modes

In these remote-control modes, a non-Waters data system (a mass spectrometry system,

for example) controls the Separations Module using RS-232 ASCII or binary

communications. The Separations Module disconnects from the IEEE-488 interface bus

when either of these modes is selected. The Separations Module can control other

non-IEEE devices in the HPLC system using the I/O connections on the rear panel.

To set the Separations Module to the Controlled via RS-232 (ASCII) or (Binary) mode:

1. Select the System field in the Configuration screen, then press Enter to display a

list of choices.

2. Select Controlled via RS232 (ASCII) or Controlled via RS232 (Binary),then

press Enter.

3. Press Exit. The Separations Module is ready to be controlled by a remote data

system using RS-232 communications.

Setting Report Options

Use the Report Options dialog box to define the information that is sent to the printer,

integrator, and/or floppy disk. (Before you print a report, select the printer in the Printer

section of the Configuration screen. You select the destination of the report in the print

dialog box that appears when you press the Print screen key.)

To define the information sent to a printer, integrator, and/or floppy disk:

1. Press the Reports screen key on the Configuration screen to display the Report

Options dialog box (Figure 2-4).

14 Preparing the Separations Module for Operation

Figure 2-4 Report Options Dialog Box

2. Select the destination for the report in the drop-down list.

3. Select any option and press any numeric key to enable or disable the option,

then press Enter. An “X” in the box means the option is enabled. The options

include:

•Gradient table – Generates the gradient table

•I/O event table – Generates the I/O events table

•Detector table – Generates the detector table

•Event overview – Generates an overview of all merged tables

•Misc. parameters – Generates a list of all parameters not included in tables

•System config – Generates a list of the instrument configuration parameters

•Per-inject data – Generates a list of the minimum, maximum, and average

values for temperature, pressure, the time and date of each injection, and so

on.

•Alarms – Generates a list of the error conditions that occurred during the run

4. Press the OK screen key to exit from the Report Options dialog box.

5. Press Exit to return to the Main screen

Programming for Auto Shutdown

You can set up the Separations Module to shut down automatically after a specified period

of inactivity. Inactivity is defined as:

• No keyboard use

• No injections performed

Preparing the Separations Module for Operation 15

• No changes sent to the Separations Module from a remotely connected Millennium

Chromatography Manager workstation, MassLynx computer, or external

autosampler

• An error condition that suspends the operation of the Separations Module

You can leave the Separations Module in the shutdown state indefinitely. The separation

method you specify in the Auto Shutdown dialog box defines the initial conditions that are

applied after the specified period of inactivity. Use the auto shutdown function:

• When there is a long delay between injections

• To minimize solvent flow after an unattended or long run

• To minimize sparge gas consumption

• To disable the vacuum degasser

• To disable temperature controls

• To turn off detector lamps

To enable the auto shutdown function:

1. Press the Config screen key in the Main screen, then press the More screen key

once.

2. Press the Auto Shutdown screen key. The Auto-Shutdown dialog box appears

(Figure 2-5).

Figure 2-5 Auto-Shutdown Dialog Box

3. Select the separation method to be used while the Separations Module is shut

down. Only the

initial

conditions in the method you select are used.

16 Preparing the Separations Module for Operation

4. Enter a time period (in minutes) after which you want the Separations Module to

shut down (or press Clear to disable the Auto Shutdown function).

5. Press OK. The Separations Module shuts down when there has been no activity

for the specified period.

6. Press Exit to return to the Main screen.

Note: If you want to use Auto Shutdown to turn off the lamp of a 2487 or 486 detector,

program a Lamp Off event and specify a time of INIT in the I/O Events Timed Table screen

(see Section 6.2.5, Setting I/O Parameter Values in the Waters 2690 Separations Module

Operator’s Guide).

Preparing the Separations Module for Operation 17

2.3 Preparing the Solvent Management System

For optimal performance of your Separations Module, perform the steps identified in

Figure 2-6.

Note: For details on how to prepare both degasser and sparge-based 2690 Separations

Modules for operation, refer to

Chapter 6, Recommended Preparation Procedures

.

Figure 2-6 Preparing the Solvent Management System for Operation

2.3.1 Degassing Solvents

In-Line Vacuum Degassing

In-line vacuum degassing reduces the total dissolved gas in the mobile phase. For more

information on vacuum degassing, refer to Section 1.5, the “Degasser Considerations”

discussion in the

Waters 2690 Separations Module Operator’s Guide

.

Caution: Observe safe laboratory practices when you handle solvents. Refer to the

Material Safety Data Sheet for each solvent you use.

Start

Degas or Sparge

Solvents

Prime the Plunger

Seal Wash Pump

Solvent

Management

System is Ready to

Operate

Prepare Solvent

Reservoirs

Prime the Solvent

Management

System

18 Preparing the Separations Module for Operation

Note: Do not run the degasser for extended periods of time without analytical solvent flow.

Doing so causes solvent vaporization that results in recondensation (once dissolved

gasses have been removed), possibly leading to a misdiagnosis of a vacuum chamber

leak.

Note: For proper operation of the in-line vacuum degasser, you must fill each vacuum

chamber with solvent. Use the dry prime direct function to prime all solvent lines. See

Section 2.3.2, Priming the Solvent Management System

, for the procedure to dry prime

the solvent lines.

To control the operation of the in-line vacuum degasser from the Status screen:

1. Press the Menu/Status key. The Status screen appears, as shown in Figure 2-7.

The content and layout of the Status screen varies with the options installed in the

Separations Module and with the mode of operation.

Figure 2-7 Status Screen

2. Press the Next Page screen key (if necessary) to display the Degasser fields.

3. Select the Degasser mode field, then press Enter to display a list of degasser

modes. The modes are:

•Normal – The degasser cycles on and off on a pressure-regulated cycle

•Continuous – The degasser is always on

•Disable – The degasser is always off

4. Select the desired operating mode, then press Enter.

The Vac pump field displays the current status of the vacuum degasser pump.

The Pressure field displays the current vacuum level in psig, bar, or kPa.

Preparing the Separations Module for Operation 19

Sparging

You set the initial and maintenance sparge cycles from the Sparge screen. You can set

different sparge cycles for each of the four solvent reservoirs.

To program the sparge cycles from the Direct Function menu:

1. Press the Direct Function screen key in the Status screen. The Direct Functions

menu appears (Figure 3-4).

2. Select the Program Sparge option, then press Enter. The Programmed Sparge

dialog box appears (Figure 2-8).

Figure 2-8 Programmed Sparge Dialog Box

3. In the Time field, enter the time to run the initial sparge cycle, then enter values

for each solvent reservoir for the following parameters:

• Initial sparge cycle rates

• Idle sparge cycle rates

At a sparge cycle rate of 100%, the sparge valve is on at all times; at a sparge

cycle rate of less than 100%, the sparge valve turns on and off periodically.

Press the Disable Sparge screen key if you do not want to sparge the

reservoirs.

Press the OK screen key. The timer starts counting down, and the sparge gas

flows at the initial sparge cycle rates. The idle sparge cycle rate begins when the

timer expires.

20 Preparing the Separations Module for Operation

2.3.2 Priming the Solvent Management System

Dry Prime

Use the dry prime option to prime the system when the fluidic path in the solvent

management system is dry.

To perform a dry prime:

1. Set up the reservoirs as described in the

Waters 2690 Separations Module

Operator’s Guide

. Section 2.6, Making Fluidic Connections.

2. Insert the solvent tubing into the appropriate reservoir(s). Be sure the detector

waste line and the sample loop waste line drain into an appropriate container.

3. Gently shake the filters in the reservoirs to remove any bubbles that may be

trapped.

4. Attach an empty syringe to the prime/vent valve, as shown in Figure 2-9, then

open the valve by turning it counterclockwise 1/2-turn.

Note: The syringe does not lock onto the prime/vent valve; hold it in place while you

pull on the plunger.

Figure 2-9 Prime/Vent Valve with Syringe

5. Press the Direct Function screen key in the Status screen. The Direct Functions

menu appears (Figure 3-4).

TP01359A

Table of contents

Other Waters Control Unit manuals