1

A Honeywell Company

EN1C-0131SZ20 R0305

INTRODUCTION

The burner control box DMG 973 controls and supervises

power burner for gas and dual fuel. The control box is

currently under approval according the relevant European

standards. The use on direct air heaters according DIN 4794

is also possible.

With the facility to connect an air damper unit, a 2 stage

operation with two fuel valves or a modulating operation

with one fuel valve is possible.

The microprocessor- based programming sequence ensu-

res extremely stable timings independent of voltage varia-

tions, ambient temperature and/or switch-on cycles. The

built-in information system not only provides a continuous

monitoring of the actual state of the box (very helpful es-

pecially for monitoring the start-up phase) but also informs

about the cause of a possible lock out. The lock out cause

is stored in such a way that it can be retrieved even after a

power failure.

The control box is designed for maximum safety in case of

fluctuations in the voltage supply. If the mains voltage drops

below the permitted level, operation is interrupted and the

control box automatically prevents the start sequence from

being repeated. In this way, the safety of the system is not

put at risk by a drop in the mains voltage. This low-voltage

protection works not only during start-up but also perma-

nently during operation.

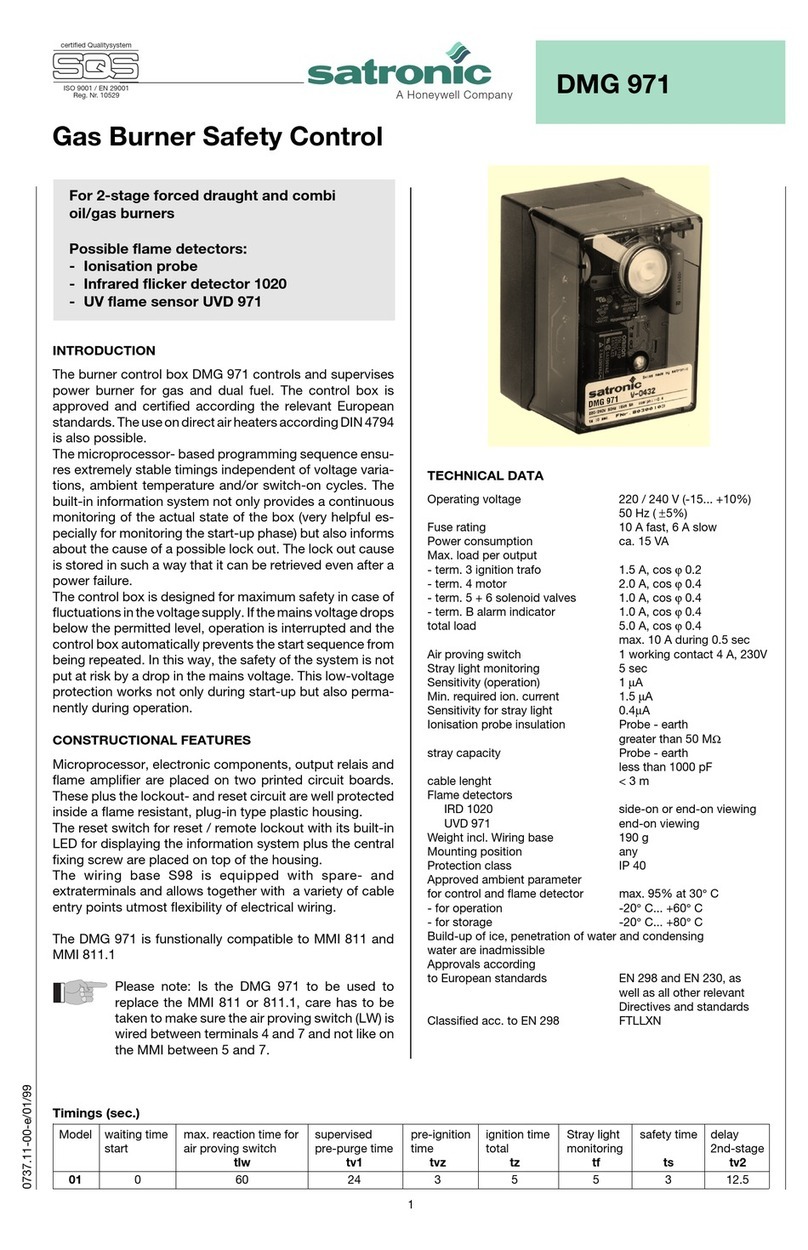

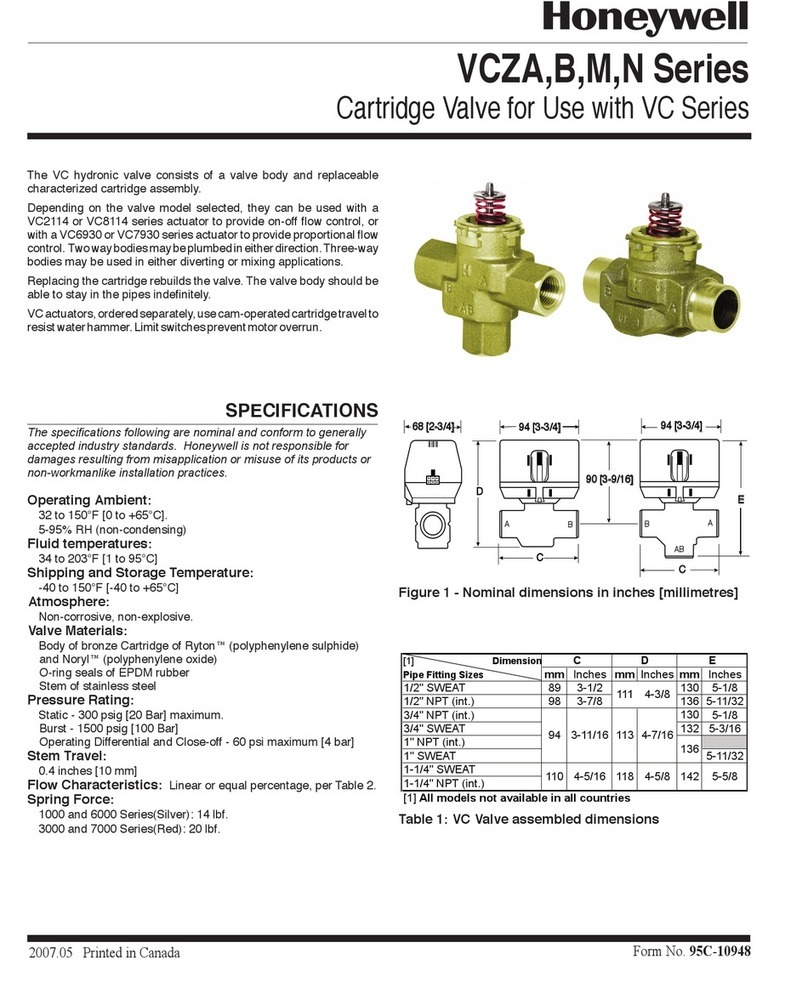

CONSTRUCTIONAL FEATURES

Microprocessor, electronic components, output relais and

flame amplifier are placed on two printed circuit boards.

These plus the lockout- and reset circuit are well protected

inside a flame resistant, plug-in type plastic housing.

The reset switch for reset / remote lockout with its built-in

LED for displaying the information system plus the central

fixing screw are placed on top of the housing.

The wiring base S98 is equipped with spare- and

extraterminals and allows together with a variety of cable

entry points utmost flexibility of electrical wiring.

The DMG 973 is funstionally compatible to MMI 813 and

MMI 813.1

Please note: Is the DMG 973 to be used to

replace the MMI 813 or 813.1, care has to be

taken to make sure the air proving switch (LW) is

wired between terminals 4 and 7 and not like on

the MMI between 5 and 7.

DMG 973

Gas Burner Safety Control

For 2-stage forced draught and combi

oil/gas burners, facility to connect an air

damper unit

Possible flame detectors:

- Ionisation probe

- Infrared flicker detector 1020.1

- UV flame sensor UVD 971

TECHNICAL DATA

Operating voltage 220 / 240 V (-15... +10%)

50 Hz ( ±5%)

or 110 / 120 V (-15... +10%)

60 Hz ( ±5%)

Fuse rating 10 A fast, 6 A slow

Power consumption ca. 12 VA

Max. load per output

- term. 3 ignition trafo 1.5 A, cos ϕ 0.2

- term. 4 motor 2.0 A, cos ϕ0.4

- term. 5 + 6 solenoid valves 1.0 A, cos ϕ 0.4

- term. C air damper 1.0 A, cos ϕ0.4

- term. B alarm indicator 1.0 A, cos ϕ0.4

total load 5.0 A, cos ϕ0.4

max. 20 A during 0.5 sec

Direct lockout after a loss-of-flame during operation

Air proving switch 1 working contact 4 A, 230V

Sensitivity (operation) 1 µA

Min. required ion. current 1.5 µA

Sensitivity for stray light 0.4µA

Ionisation probe insulation Probe - earth

greater than 50 MΩ

stray capacity Probe - earth

less than 1000 pF

cable lenght < 3 m

Flame detectors

IRD 1020.1 side-on or end-on viewing

UVD 971 end-on viewing

Weight incl. Wiring base 190 g

Mounting position any

Protection class IP 40

Approved ambient parameter

for control and flame detector max. 95% at 30°C

- for operation -20°C... +60°C

- for storage -20°C... +80°C

Build-up of ice, penetration of

water and condensing water are inadmissible

Approvals according

to European standards EN 298 and EN 230, as

well as all other relevant

Directives and standards

Classified acc. to EN 298 FTLLXN

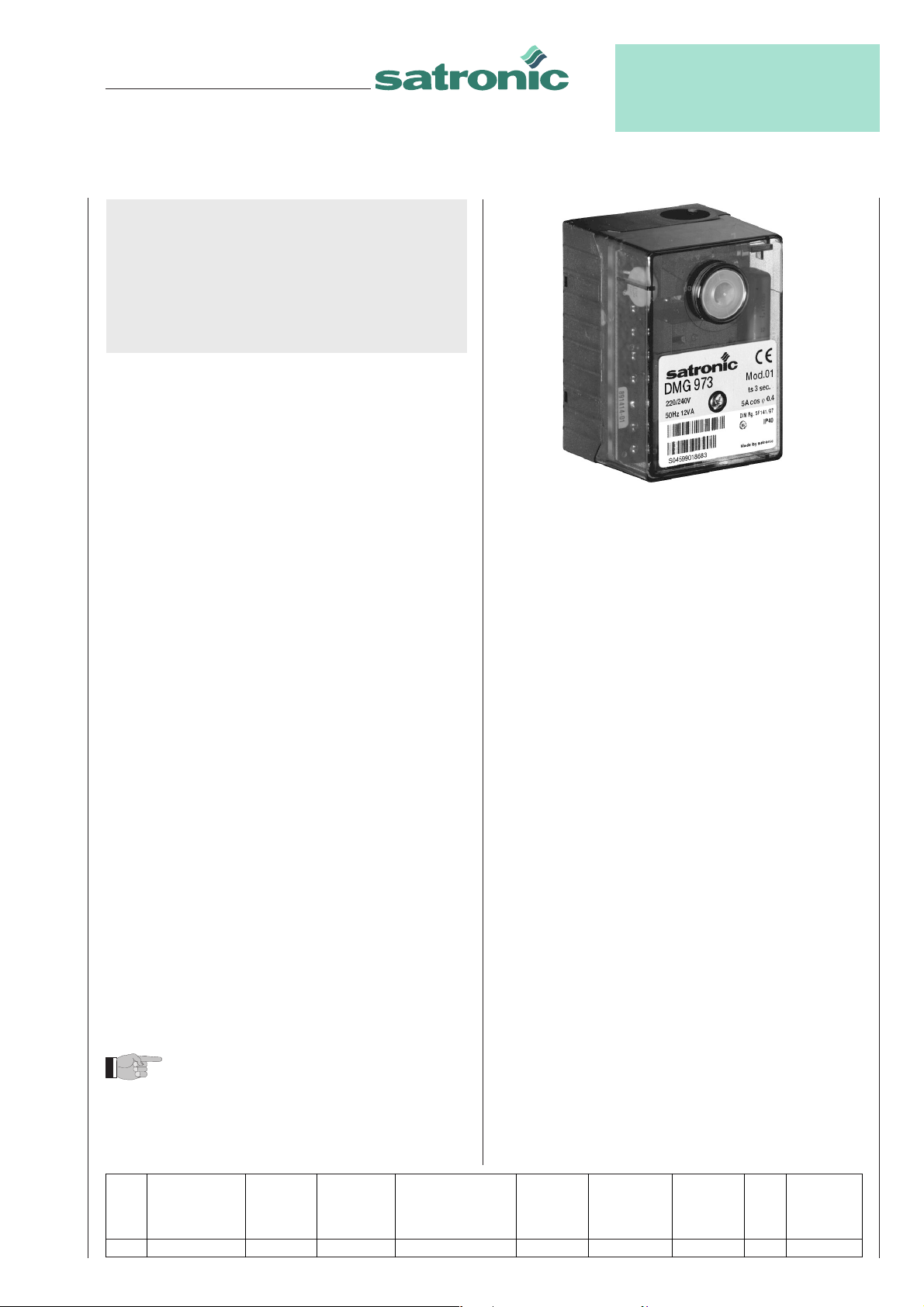

Model max. reaction supervised pre-ignition LK-open command LK-close post-ignition Stray light safety delay

time for air pre-purge time during pre-purge movement time monitoring time terminal 6/C

proving switch time

tlw tv1 tvz tkl tr tn tf ts tv2

01 60 44 3 36 8 2,5 5 3 6

Table of timings (sec.)