Central Pneumatic 38898 User manual

Popular Compressor manuals by other brands

Prebena

Prebena PKT-fillmaster 350 Operating and maintenance instructions

Conrad

Conrad CE-70 operating instructions

Schulz

Schulz MSI 5,2 ML quick start guide

Luna

Luna ACD1.5-24OL manual

Scheppach

Scheppach HC 53dc Operating and safety instructions

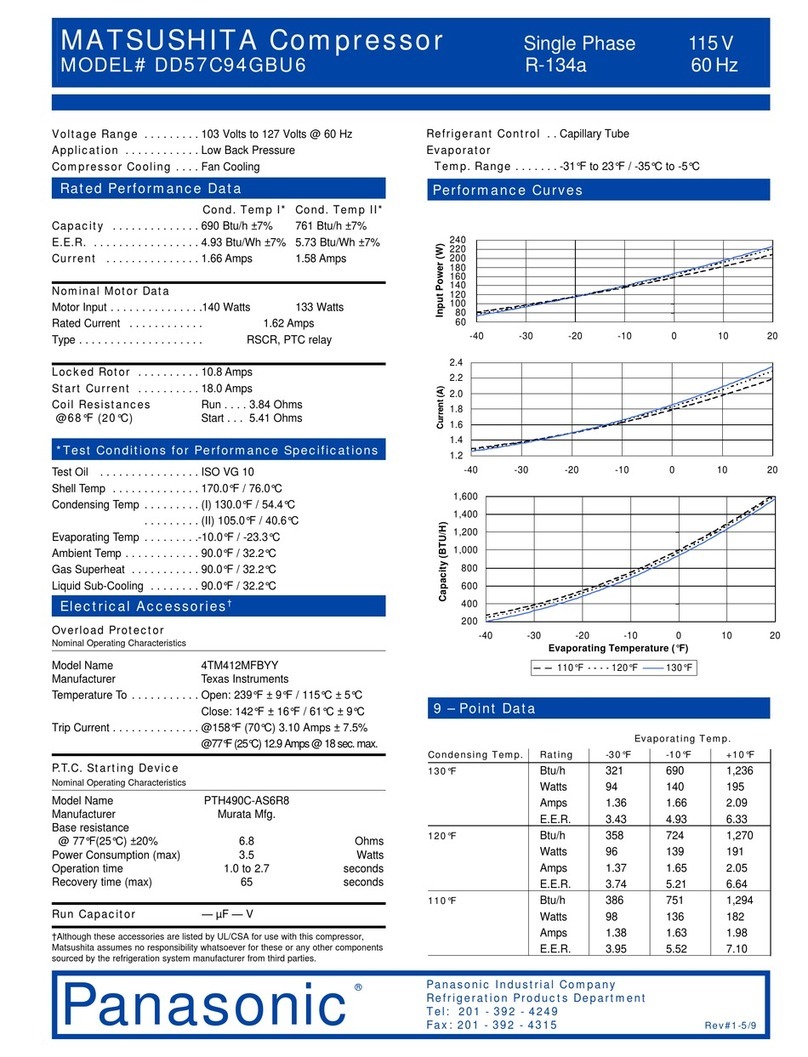

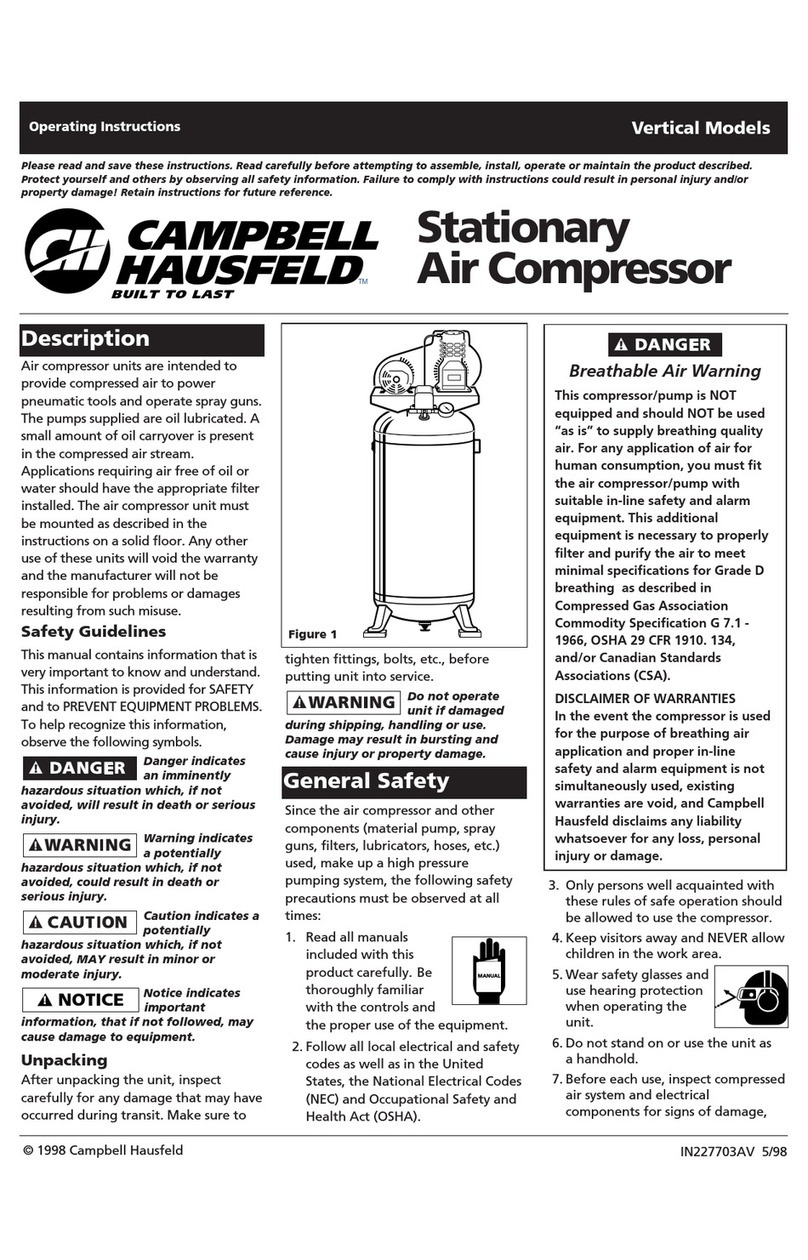

Campbell Hausfeld

Campbell Hausfeld VS260000KB operating instructions

Ingersoll-Rand

Ingersoll-Rand centac C950 Planning and installation manual

PRESONUS

PRESONUS Smart Compressor user manual

EKOM

EKOM DK50 4x2VT/M user manual

Invacare

Invacare Envoy Jr. IRC1001 owner's manual

Demeter Amplification

Demeter Amplification VTCL-2 user guide

Hitachi

Hitachi NEXT Series Service manual