CONTENTS

06/2021 5 NP-DK50-Nx2VTM-AD-EN-3_06-2021

CONTENTS

IMPORTANT INFORMATION........................................................................................................6

1. CONFORMITY WITH THE REQUIREMENTS OF THE EUROPEAN UNION...................6

2. INTENDED USE ..............................................................................................................6

3. CONTRAINDICATIONS AND SIDE-EFFECTS................................................................6

4. SYMBOLS........................................................................................................................6

5. WARNINGS.....................................................................................................................7

6. STORAGE AND TRANSPORT CONDITIONS.................................................................9

PRODUCT DESCRIPTION ..........................................................................................................10

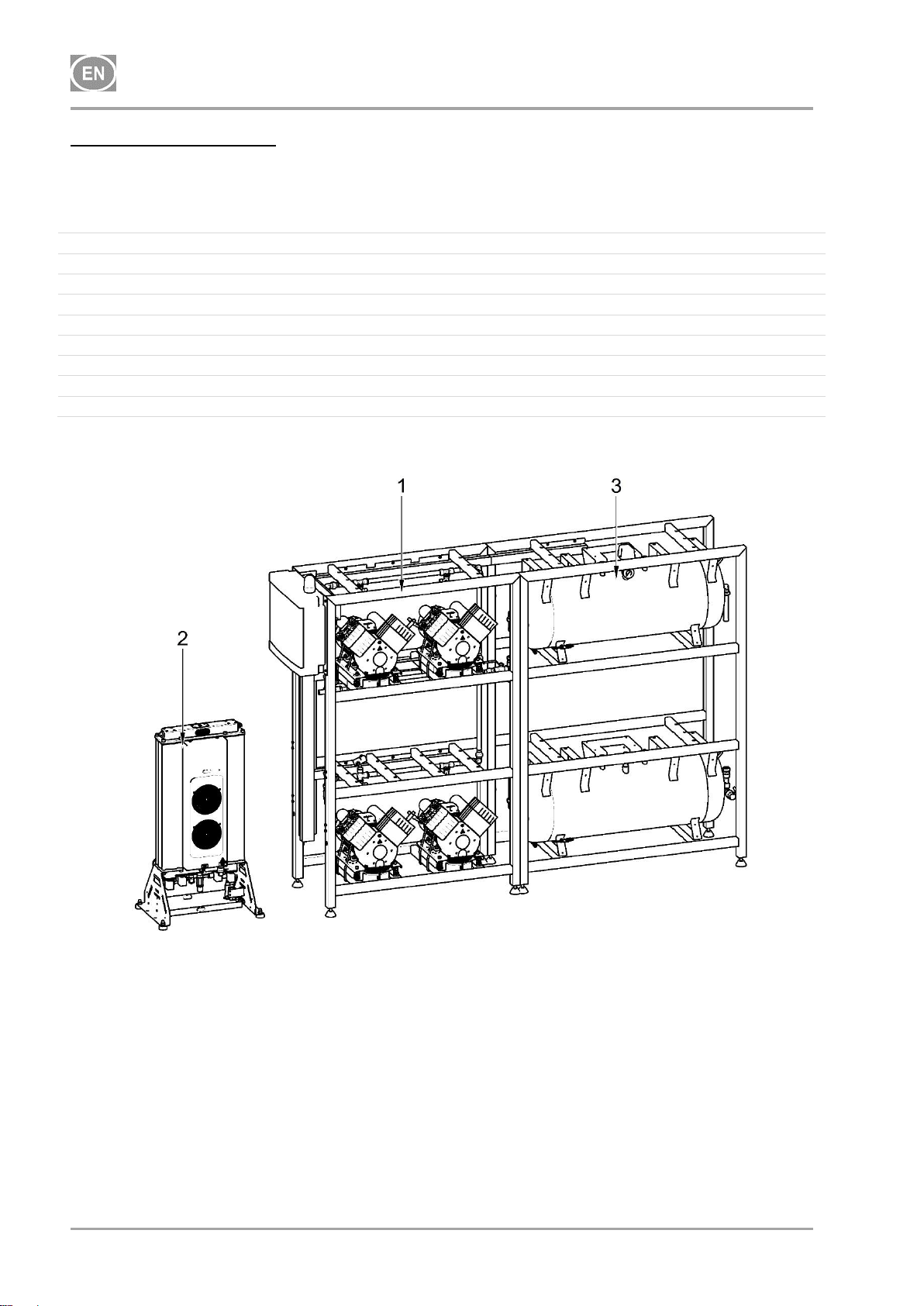

7. VARIANTS.....................................................................................................................10

8. ACCESSORIES.............................................................................................................12

9. PRODUCT FUNCTION..................................................................................................13

TECHNICAL DATA......................................................................................................................17

INSTALLATION...........................................................................................................................23

10. INSTALLATION CONDITIONS ......................................................................................23

11. COMPRESSOR ASSEMBLY.........................................................................................24

12. PNEUMATIC CONNECTION.........................................................................................27

13. ELECTRICAL CONNECTION........................................................................................30

14. COMMISSIONING .........................................................................................................32

15. PNEUMATC DIAGRAMS...............................................................................................33

OPERATION................................................................................................................................36

16. SWITCHING THE COMPRESSOR................................................................................37

17. SWITCHING OFF THE COMPRESSOR........................................................................40

PRODUCT MAINTENANCE ........................................................................................................41

18. PRODUCT MAINTENANCE...........................................................................................41

TROUBLESHOOTING.................................................................................................................53

19. REPAIR SERVICE.........................................................................................................55

20. LONG-TERM SHUTDOWN............................................................................................56

21. DISPOSAL OF DEVICE.................................................................................................56

ANNEX ........................................................................................................................................57

22. INSTALLATION RECORD .............................................................................................57