Page 3For technical questions, please call 1-800-444-3353.SKU 46149

they can become caught in moving

parts. Wear a protective hair covering

to prevent long hair from becoming

caught in moving parts.

INDUSTRIAL APPLICATIONS MUST7. FOLLOW OSHA REQUIREMENTS.

DO NOT OVERREACH.8. Keep

proper footing and balance at all

times to prevent tripping, falling, and

back injury, etc.

REPLACEMENT PARTS AND9. ACCESSORIES. When servicing,

use only identical replacement parts.

Only use accessories intended for

use with this product. Approved

accessories are available from

Harbor Freight Tools.

STAY ALERT.10. Watch what you are

doing at all times. Use common

sense. Do not use this equipment

when you are tired or distracted from

the job at hand.

CHECK FOR DAMAGED PARTS.11.

Before using this product, carefully

check that it will operate properly

and perform its intended function.

Check for damaged parts and any

other conditions that may affect the

operation of this product. Replace

or repair damaged or worn parts

immediately.

MAINTAIN THIS PRODUCT WITH12. CARE. Keep this product clean and

dry for better and safer performance.

MAINTENANCE:13. For your safety,

service and maintenance should be

performed regularly by a qualied

technician.

USE THE RIGHT PRODUCT FOR14. THE RIGHT JOB. There are certain

applications for which this product

was designed. Do not use small

equipment to do the work of larger

industrial equipment. Do not use this

product for a purpose for which it was

not intended.

SPECIFIC PRODUCT WARNINGS

AND PRECAUTIONS

MAINTAIN A SAFE WORK1. ENVIRONMENT. Do not use this

product in or near damp or wet

areas. Keep work area oor free of

oil, grease, and other liquids. Do not

expose this product to rain. Keep

work area well lit. Make sure there

is adequate surrounding work space.

Remove all ammable liquids and

objects from the work area. Do not

operate this product in the presence

of ammable liquids, gases, or dust.

DISCONNECT EQUIPMENT FROM2. ITS AIR SUPPLY SOURCE AND

RELEASE ALL COMPRESSED

AIR FROM THE SYSTEM BEFORE

PERFORMING ANY SERVICES OR

MAINTENANCE.

NEVER LEAVE THIS PRODUCT3. UNATTENDED WHILE

EVACUATING OIL.

NEVER USE THIS EQUIPMENT4. NEAR OPEN FLAMES, HEAT OR

IGNITION SOURCES. ALLOW OIL

TO BE EXTRACTED TO COOL

DOWN TO BETWEEN 70-80° F

BEFORE EXTRACTING OIL.

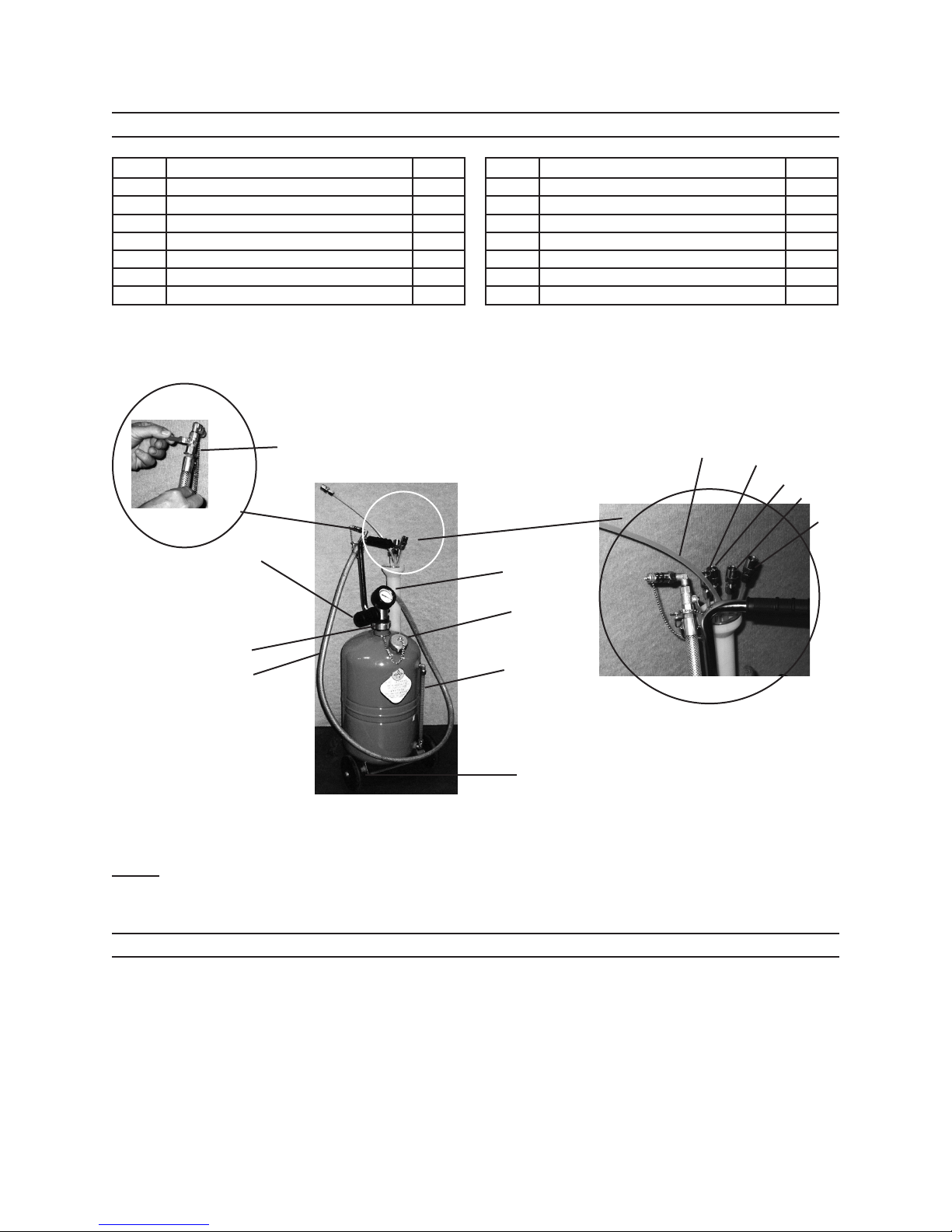

CLOSE BALL VALVE (4) BEFORE5. PRESSURIZATION. Do not attempt

to pressurize Tank (1) with Ball Valve

open.

IF USED OIL DOES NOT6. EVACUATE TANK (1) UPON