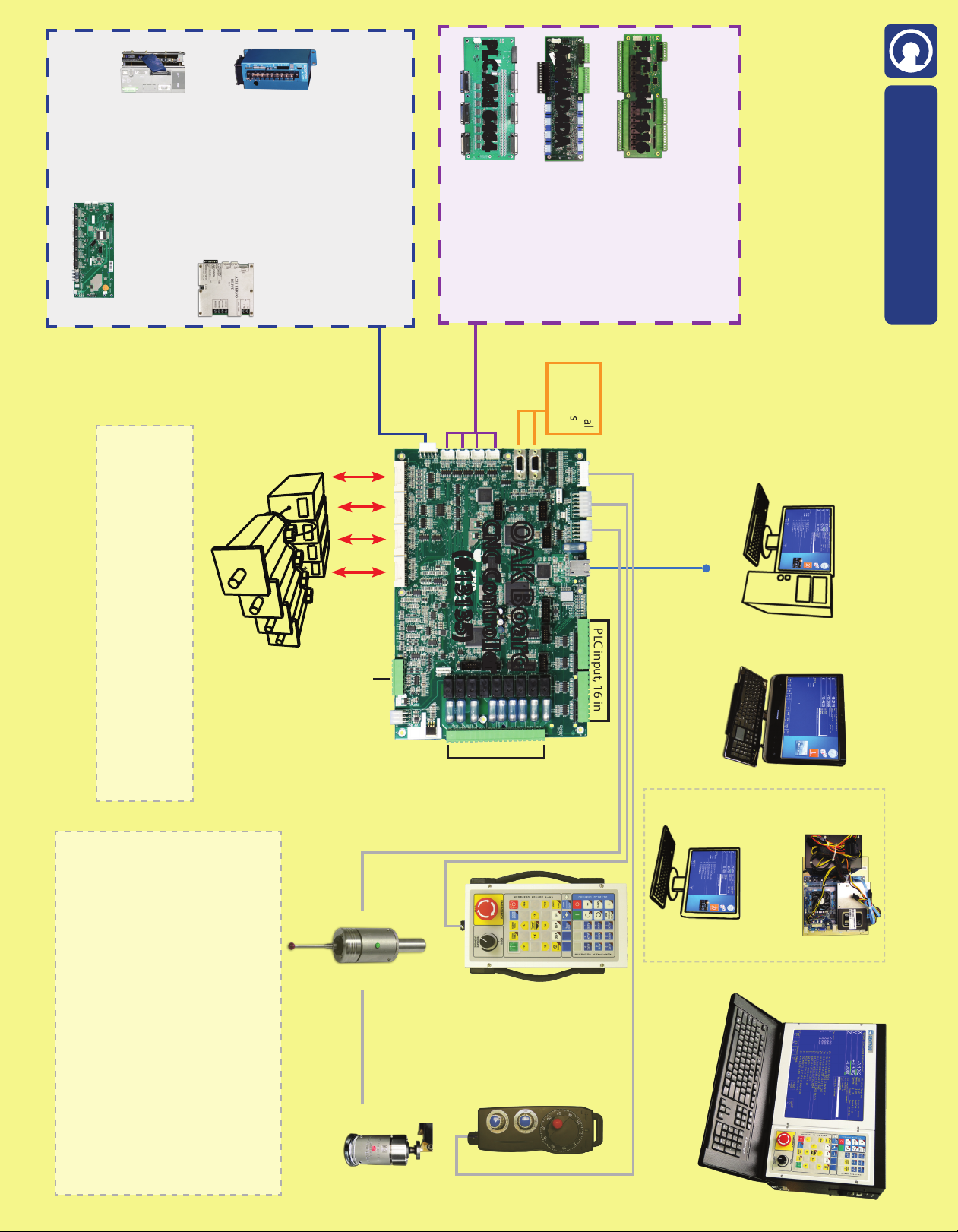

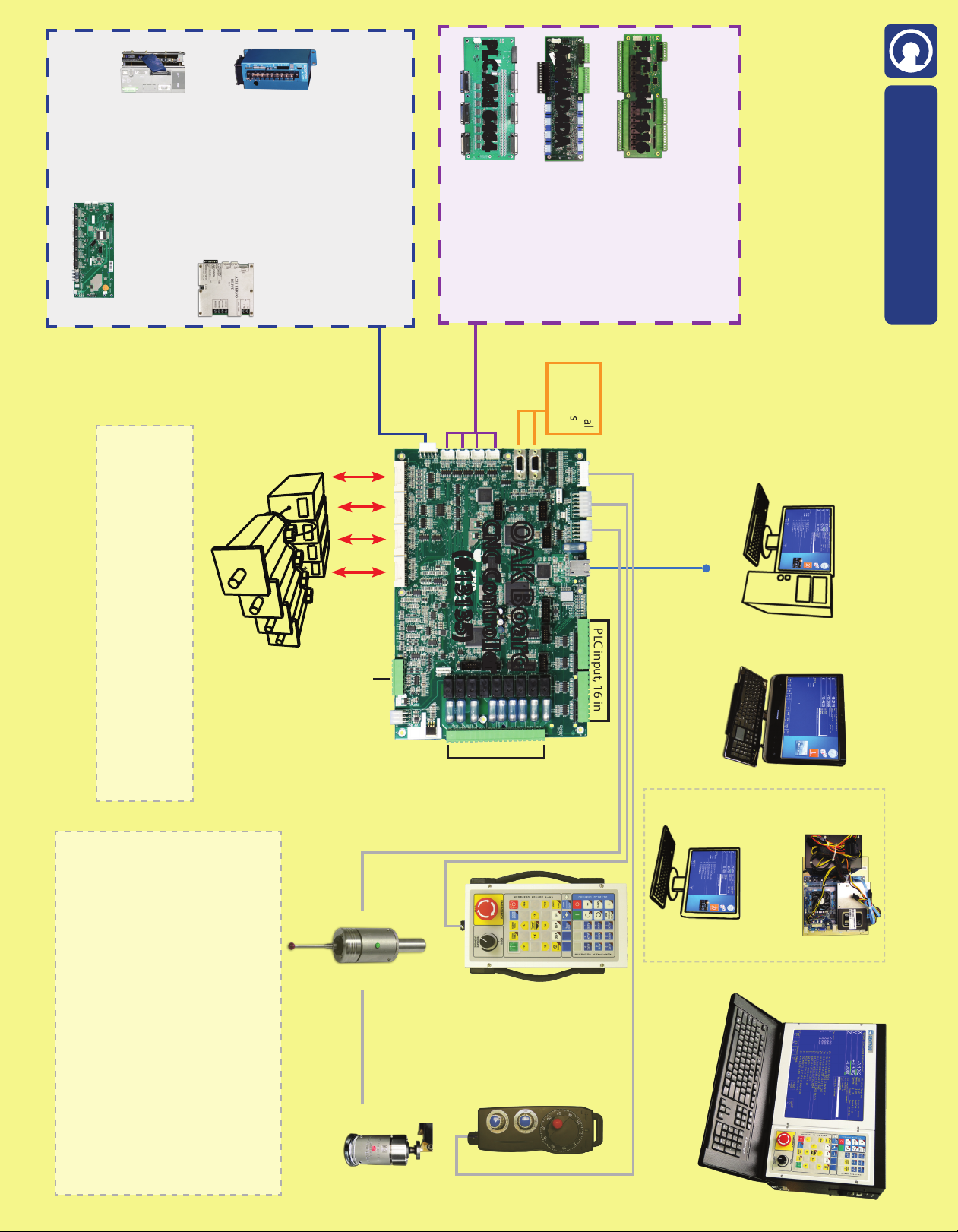

Built-in: 4-Axis 3rd Party Digital Servo Drive Interface, Spindle Control and CNC PLC (16 in/9 relay out)

with CENTROID Mill or Lathe software.

Additional

Encoders

or Scales

159 Gates Road, Howard, PA 16841 USA

(814) 353-9290

www.centroidcnc.com

PLC input, 16 in

TM OAK Board: Single board CNC Controller

16 Inputs (5, 12, 24 VDC)

16 Relay Outputs

(#11025)

4 Digital to Analog Outputs

4 Analog to Digital Inputs

(#11141)

PLC Add 1616

Add4AD4DA

Optional PLC I/O Expansion Boards

Add more I/O, up to 4 in any combination

for up to 272 In / 272Out

64 Inputs 5V non isolated

64 Outputs Open Collector

(#11212)

PLC Add 6464

Your Windows 7/8 PC

Ethernet

Cable to PC

CNC PC choices:

OR:

Our All-in-One PC

(11084tb)

Our CNC PC

cabinet mount (#11084)

& your display

OR:

OR:

Our CNC console

(#11082)

Copyright © 2012-15 CENTROID. rev7 2-10-15

All prices and specications subject to change without notice.

* at time of purchase. This price sheet supersedes all previous pricing.

Optional

Manual Pulse

Generator (MPG)

(#11069)

Optional Touch Probe&Software

DP-4 (#10405)

DP-7 (#12431)

Console, Display, & Cabinet opt. mounting hardware

- Console ext. cable in conduit (6 ft) (#11028)

- Console cable in conduit (over 6ft) (#11028)

- Console mounting arm (#10636)

- Console swivel mount (use w/ your arm) (#10834)

- Rolling cabinet stand and display tray (#10512)

- Rolling console stand (#10695)

- Display/keyboard tray with arm (#10240)

- Operators Pendant mounting hardware (#10491)

- MPG internal cable 20’ w/bulkhead con. (#11086)

- Probe internal cable 6’ w/bulkhead con. (#11085)

- Operators control panel internal cable 20’ (#11029)

- OEM/DIY console cable connector set (#13138)

Optional

Operator’s

Control Panel

(#11077)

Optional Auto Tool Set

- TT-2 (#12486)

- TT-1 (#10220)

Panel Mount console (#11170)

OAK Board

CNC Controller

(#13135)

*must meet minimum performance

requirements, you install software.

Two way digital servo

drive communication

1 2 3 4

CENTROID Servo Drive Interface

Optional: Servo drives, Optical drive interface

and Encoder expansion board.

Connect up to 4 via daisy chain

CENTROID DC1 servo drive

(#11112)

CENTROID OpticDirect drive interface

(#12554)

CENTROID Encoder

Expansion Board

(#13085)

Add up to 4 additional axes, up to 8 axes total

Yaskawa, Delta, Estun,

and many other motor-

drive packages

CENTROID AC/DC servo drive

30 amp AC/DC-30 (#12854)

60 amp AC/DC-60 (#12855)

PLC relay

output,

9 out

Analog Spindle

Control

Oak Plug and Play Drive Interface cables

Delta Interface Cable (#13131)

Estun Interface Cable (#13132)

Yaskawa Interface Cable (#13134)

“Flying lead”cable for connection to other drives (#13133)

CENTROID

(factory installed software)

(factory installed software)