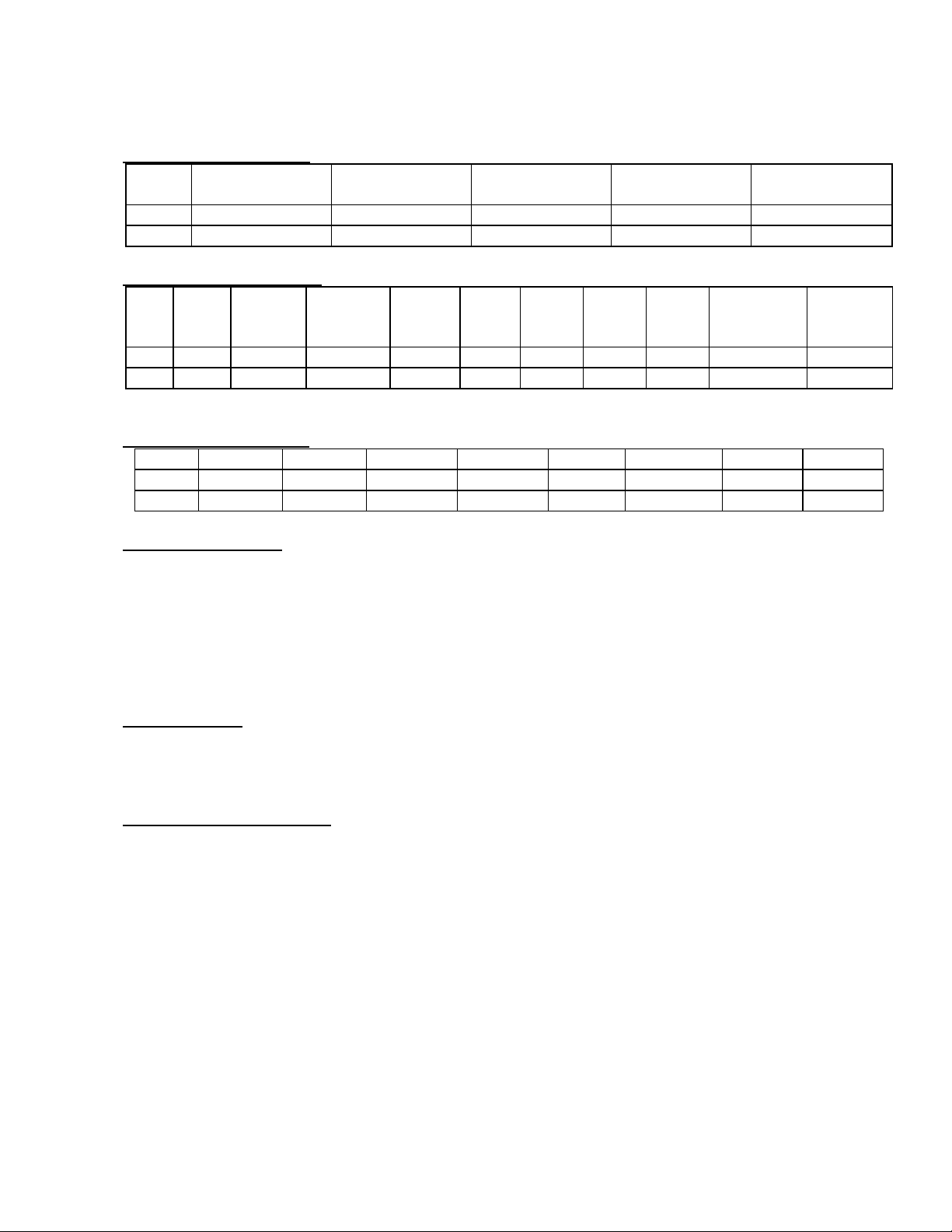

Table of Contents

CHAPTER 1 - Introduction

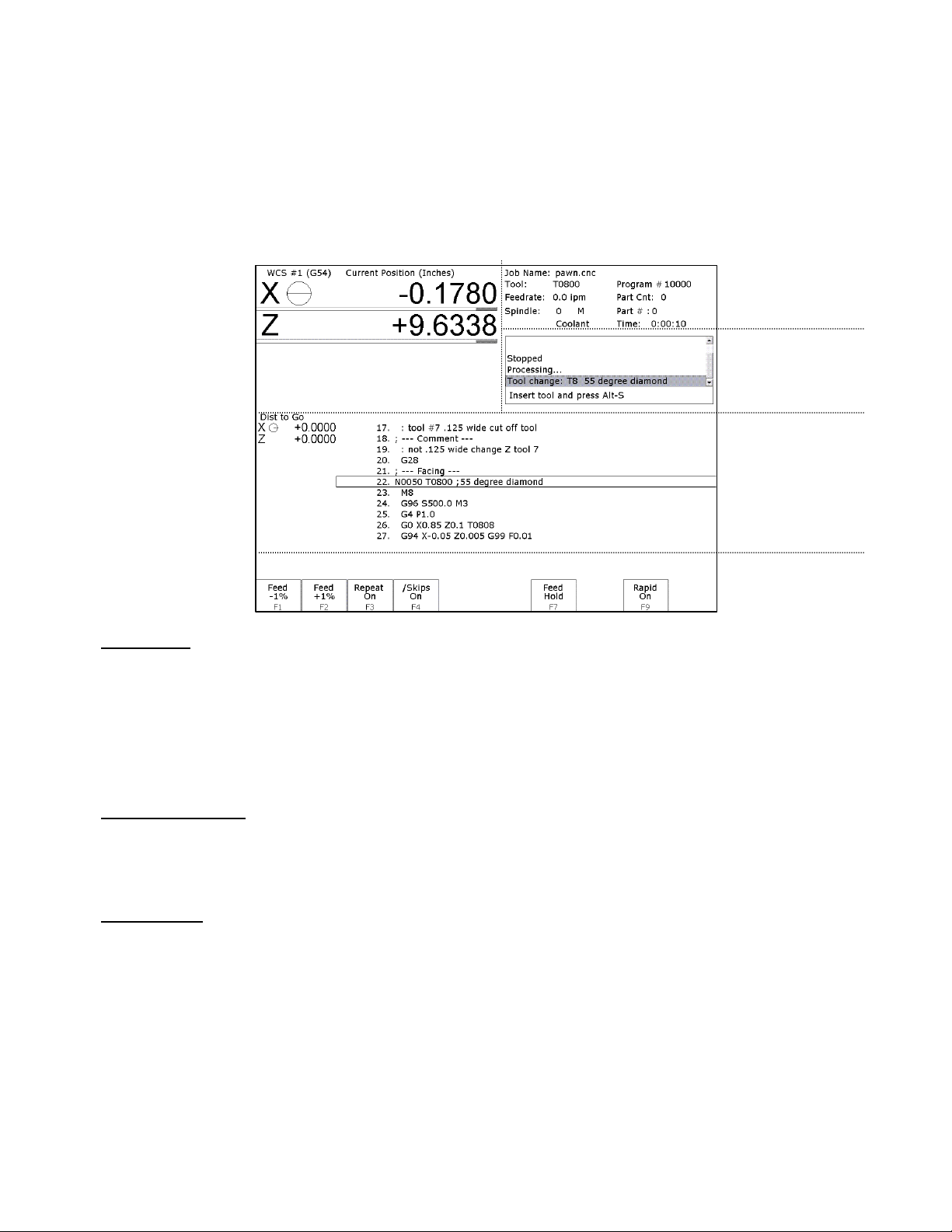

Window Description 1-1

Conventions 1-3

Machine Home 1-4

Lathe M and G Codes 1-5

CHAPTER 2 - Operator Panels

T-Series Jog Panel 2-1

Keyboard Jog Panel 2-5

Keyboard Shortcut Keys 2-8

CHAPTER 3 - Main Screen

Option Descriptions 3-1

CHAPTER 4 - Tool Setup

Offset Library 4-1

Tool Wear Offset Adjustment Screen 4-1

Tool Geometry Offset Adjustment Screen 4-2

Tool Orient 4-4

Procedures for Setting Tool Offsets 4-6

Setting the Nose Radius 4-15

Setting the Nose Vector 4-15

CHAPTER 5 - Part Zero and WCS

Part Zero Menu 5-1

Setting Part Zeros 5-3

WCS Configuration Menu 5-6

Using Work Coordinate Systems 5-7

CHAPTER 6 – Running a Job

Job Running Menu 6-1

Canceling a Job in Progress 6-2

Resuming a Canceled Job 6-2

Run Menu 6-3

Power Feed 6-5

CHAPTER 7 - The Utility Menu

F1 Format 7-1

CHAPTER 8 - Lathe Intercon Manual

Lathe Intercon Main Menu 8-1

Lathe Intercon File Menu 8-5

Insert Operation 8-8

Graphics 8-33

Math Help 8-34

Intercon Lathe Tool Library 8-40

CHAPTER 9 - Lathe Intercon Tutorials

Lathe Intercon Tutorial #1 9-1

Lathe Intercon Tutorial #2 9-9

CHAPTER 10 - CNC Program Codes

Miscellaneous Program Symbols 10-1

User and System Variables 10-4

Advanced Macro Statements (Optional) 10-8

CHAPTER 11 - G Codes

G-Code Quick Reference 11-1

G-Code Descriptions 11-2

CHAPTER 12 - M-functions

Macro M-functions 12-1

CHAPTER 13 - CNC Program Example

CHAPTER 14 - Configuration

Password 14-1

Control Configuration 14-2

User-Specified Paths 14-4

Machine Configuration 14-4

Machine Parameters 14-7

PID Configuration 14-25

Handwheel Configuration 14-27

CHAPTER 15 – CNC10 messages

CNC10 Message Descriptions 15-1

F2 Update 7-1

F5 File Ops 7-2

F6 User Maint., F7 Report, F8 Options, F9 Log 7-3

Using the Location Chooser 7-3