Model No. Recommended

shaft dia. (mm)

Recommended

housing bore dia.

(mm)

BB15/BB15-2GD

15

+0.023

+0.012

35

-0.012

-0.028

BB17/BB17-2GD

17

+0.023

+0.012 40

-0.012

-0.028

BB20/BB20-2GD

20

+0.028

+0.015 47

-0.012

-0.028

BB25/BB25-2GD

25

+0.028

+0.015 52

-0.014

-0.033

BB30/BB30-2GD

30

+0.028

+0.015 62

-0.014

-0.033

BB35/BB35-2GD

35

+0.033

+0.017

72

-0.014

-0.033

BB40/BB40-2GD

40

+0.033

+0.017 80

-0.014

-0.033

Model No. Recommended shaft

dia. (mm)

Recommended housing bore dia. (mm)

BB15-1K-K

BB15-2GD1K-K BB15-2K-K

BB15-1K-K/BB15-2K-K

/BB15-2GD1K-K 15 -0.008

-0.028 35 -0.012

-0.028 35 -0.002

-0.018

BB17-1K-K/BB17-2K-K

/BB17-2GD1K-K

17 -0.008

-0.028 40 -0.012

-0.028 40 -0.002

-0.018

BB20-1K-K/BB20-2K-K

/BB20-2GD1K-K 20 -0.010

-0.031 47 -0.012

-0.028 47 -0.003

-0.022

BB25-1K-K/BB25-2K-K

/BB25-2GD1K-K 25 -0.010

-0.031 52 -0.014

-0.033 52 -0.003

-0.022

BB30-1K-K/BB30-2K-K

/BB30-2GD1K-K 30 -0.010

-0.031 62 -0.014

-0.033 62 -0.003

-0.022

BB35-1K-K/BB35-2K-K

/BB35-2GD1K-K 35 -0.012

-0.037 72 -0.014

-0.033 72 -0.006

-0.025

BB40-1K-K/BB40-2K-K

/BB40-2GD1K-K 40 -0.012

-0.037 80 -0.014

-0.033 80 -0.006

-0.025

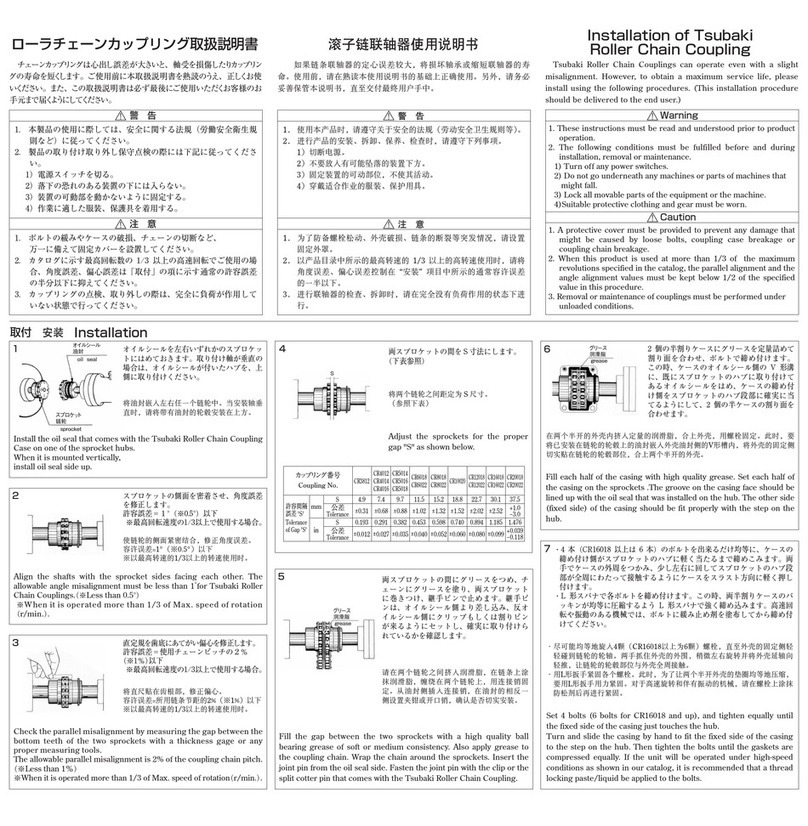

Fig. 1. Installation to housing bore Fig. 2. Installation to shaft

Tsubakimoto Chain Co.: hereinafter referred to as

Seller

Customer: hereinafter referred to as “Buyer”

Goods sold or supplied by Seller to Buyer: hereinafter referred to as “Goods”

1. Warranty period without charge

18 months effective the date of shipment or 12 months effective the first use of Goods, including

installation of Goods to Buyer’s equipment or machines - whichever comes first.

2. Warranty coverage

Should any damage or problem with the Goods arise within the warranty period, given that the Goods

were operated and maintained under instructions provided in the manual, Seller would repair and replace

at no charge once the Goods are returned to Seller. The following are excluded from the warranty.

1) Any costs related to removing Goods from the Buyer’s equipment or machines to repair or replace

parts.

2) Costs to transport Buyer’s equipment or machines to the Buyer’s repair shop.

3) Costs to reimburse any profit loss due to any repair or damage and consequential losses caused by

the Buyer.

3. Warranty with charge

Seller will charge any investigation and repair of Goods caused by:

1) Improper installation by failing to follow the instruction manual.

2 )Insufficient maintenance or improper operation by the Buyer.

3) Incorrect installation of Goods to other equipment or machines.

4) Any modifications or alterations of Goods by the Buyer.

5) Any repair by engineers other than the Seller or those designated by the Seller.

6) Operation in an inappropriate environment not specified in the manual.

7) Force Majeure or forces beyond the Seller’s control such as natural disasters and injustice done

by a third party.

8) Secondary damage or problem incurred by the Buyer’s equipment or machines.

9) Defected parts supplied, or specified by the Buyer.

10) Incorrect wiring or parameter setting by the Buyer.

11) The end of life cycle of the Goods under normal usage.

12) Loss or damage not liable to the Seller.

4. Dispatch Service

Service to dispatch a Seller’s engineer to investigate, adjust or trial test Seller’s Goods is at the Buyer’s

expense.

5. Disclaimer

1) In our constant efforts to improve, Tsubakimoto Chain Co. may change the contents of this

document

without notice.

2) Considerable effort has been made to ensure that the contents of this document are free from

errors. However, Tsubakimoto Chain Co. makes no warranties with respect to the accuracy of

information described herein. In the mean time, we would appreciate comments or reports on any

inaccuracies or omissions found in this document to help us make timely amendments as necessary.

Your cooperation is greatly appreciated.

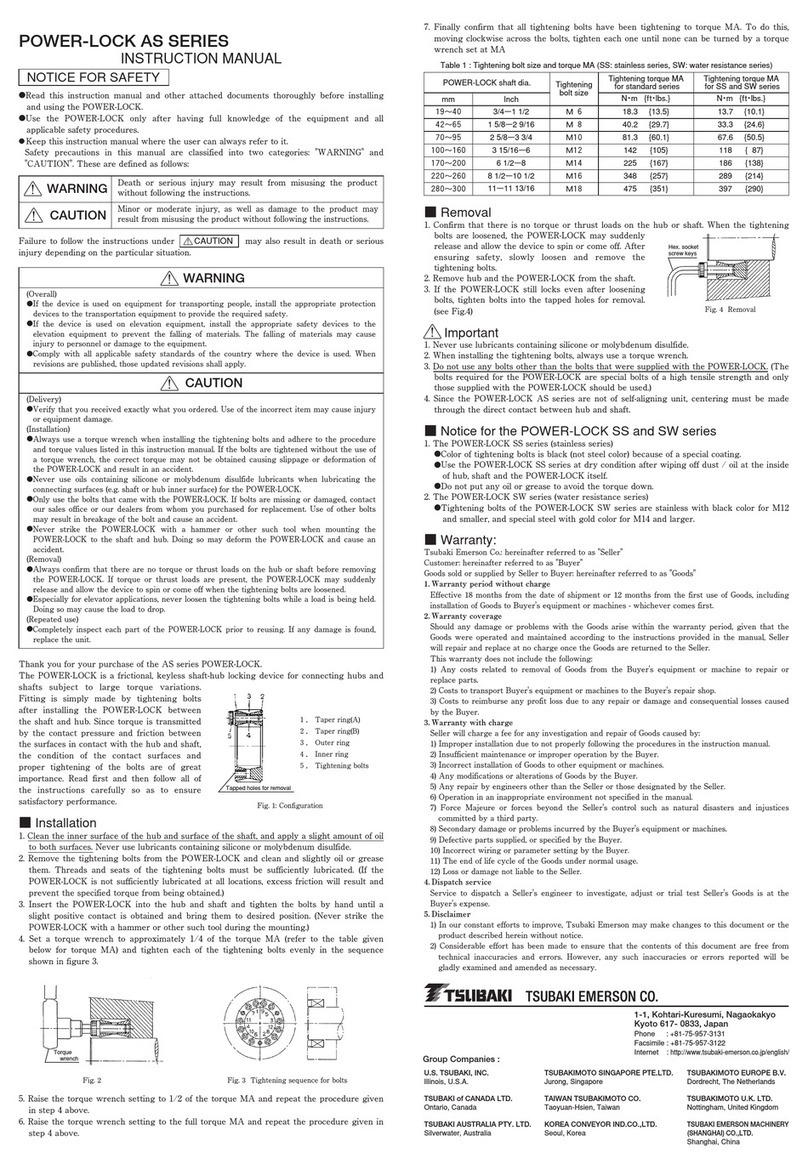

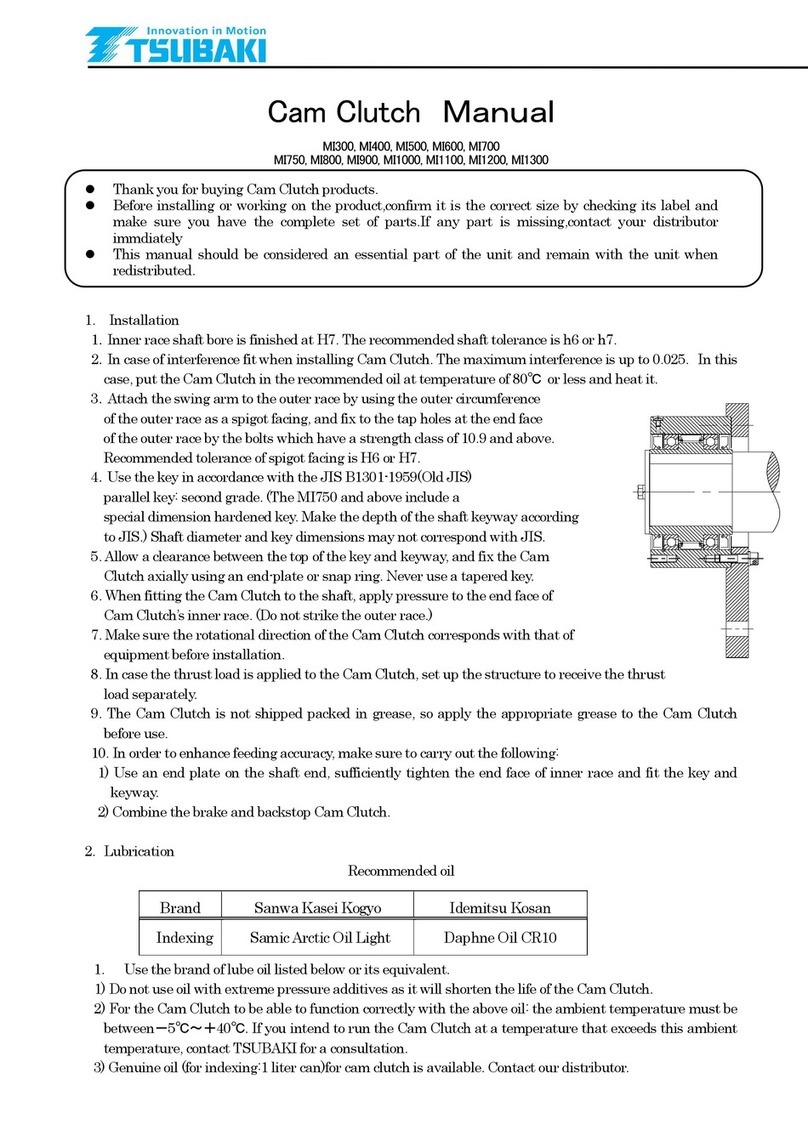

■ Recommended shaft diameter and housing bore diameter.

Machine the shaft and housing to the measurements and tolerances given in the table below.

Torque is transmitted by press fit, for models without keyways. Clutch may slip if the shaft and housing are not machined to the recommended dimensions.

■ Cautions for installation

1.The arrow on the inner race indicates the direction of inner race

engagement.

2.Install to the housing of sprocket, gear, etc.

Press fit types (BB, BB-1K-K, BB-2GD, BB-2GD1K-K)

Press outer race (Refer to Fig. 1)

Keyed outer race type (BB-2K-K)

Use the key provided to secure the housing and Cam Clutch, because

the fit is neither press nor loose. Then, install ball bearing. Never use

set bolt on the outer race to fix the key, because it may deform the

outer race.

3.Installation to shaft

Press fit types (BB, BB-2GD) Press housing (Cam Clutch is already

installed) to the shaft by applying force to the inner race of Cam Clutch. (Refer to Fig. 2)

Keyed inner race types (BB-1K-K, BB-2K-K, BB-2GD1K-K) Use the key provided to install to the shaft.

4.Key and keyway

Standard key and keyway are DIN6885.3.

However, the depth of inner keyways for BB25-1K-K, BB25-2K-K and BB25-2GD1K-K are 0.5mm shallower than standard. So, the depth of outer race should be

0.5mm deeper. Standard inner race key and keyway for BB40-1K-K, BB40-2K-K and BB40-2GD1K-k are DIN6885.1.

5.When pressing Cam Clutch to the shaft and housing, do not press inner race or outer race separately but press them simultaneously. Do not hit Cam Clutch with

a hammer.

6.Refer to the catalog for key dimensions.

■ Lubrication

1.Cam Clutches are factory greased with Esso Beacon 325. Allowable ambient temperature range is – 30℃ to 80℃.

2.Wash out the grease when using BB, BB-1K-K, BB-2K-K types for oil baths. Refer to Cam Clutch or general catalog for recommended oil. Oil level should be the

shaft center or higher.

3.Never use lubricants with extreme-pressure additives to avoid slippage.

■ Warranty