Parker Racor Absolute Series Manual

Other Parker Industrial Equipment manuals

Parker

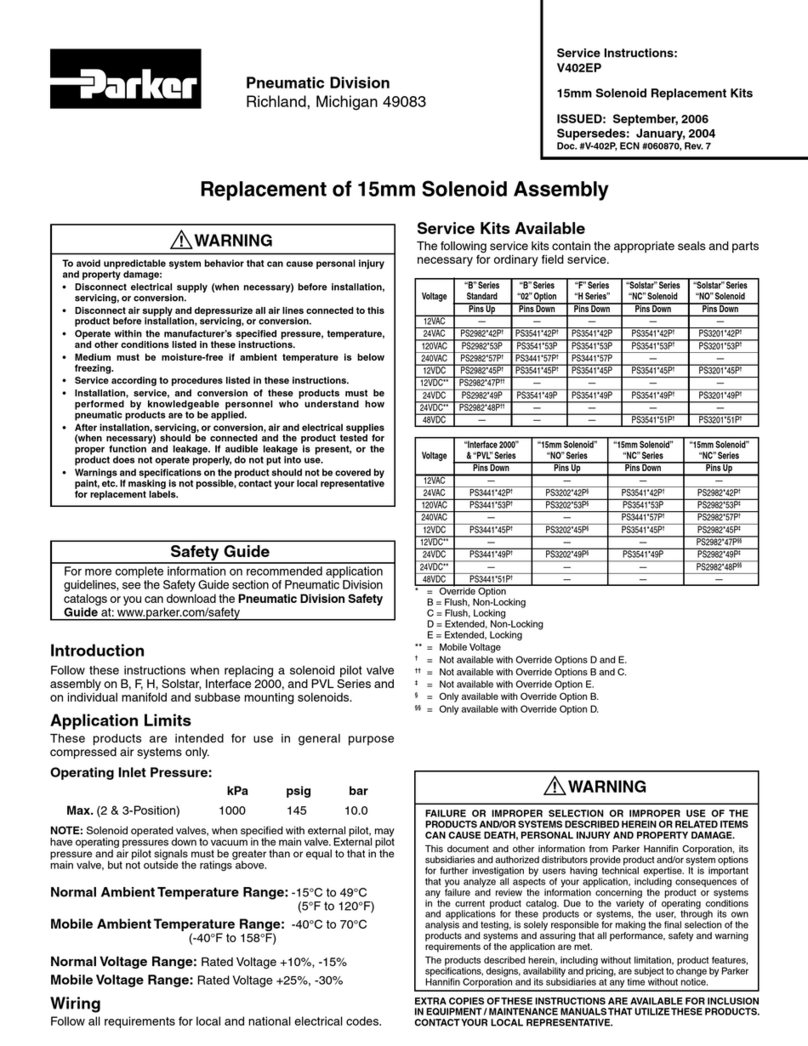

Parker V402EP User manual

Parker

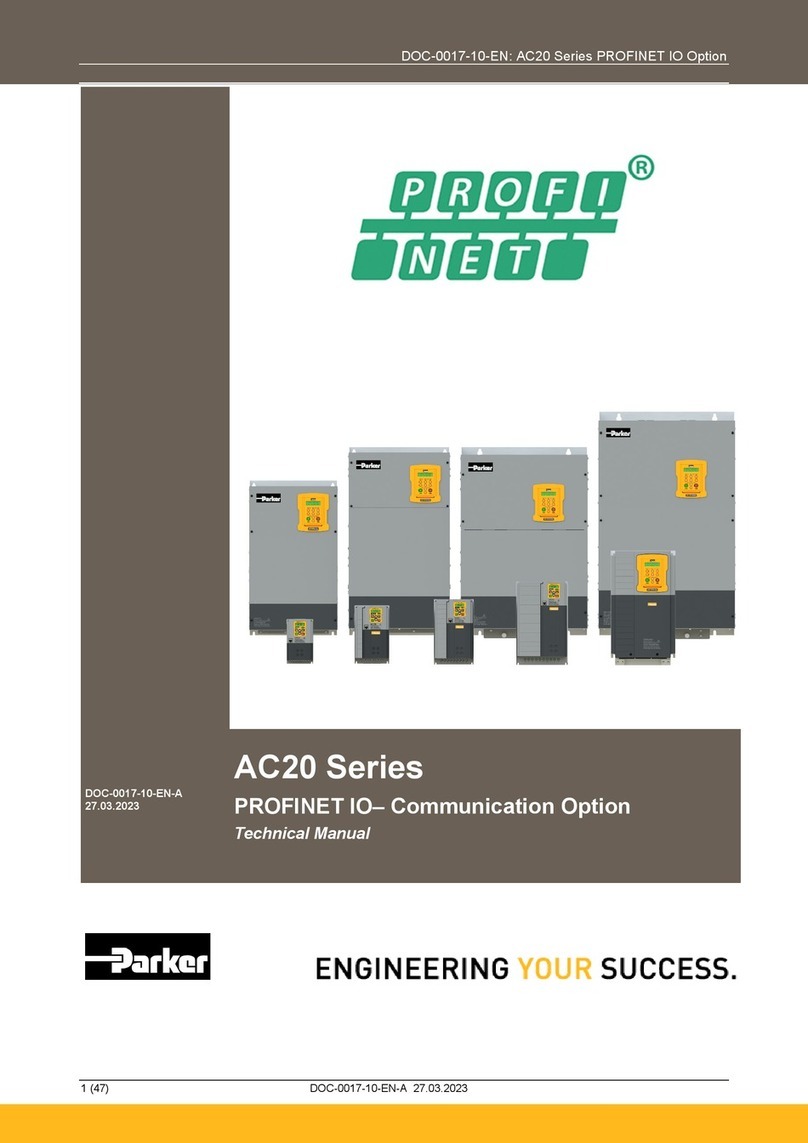

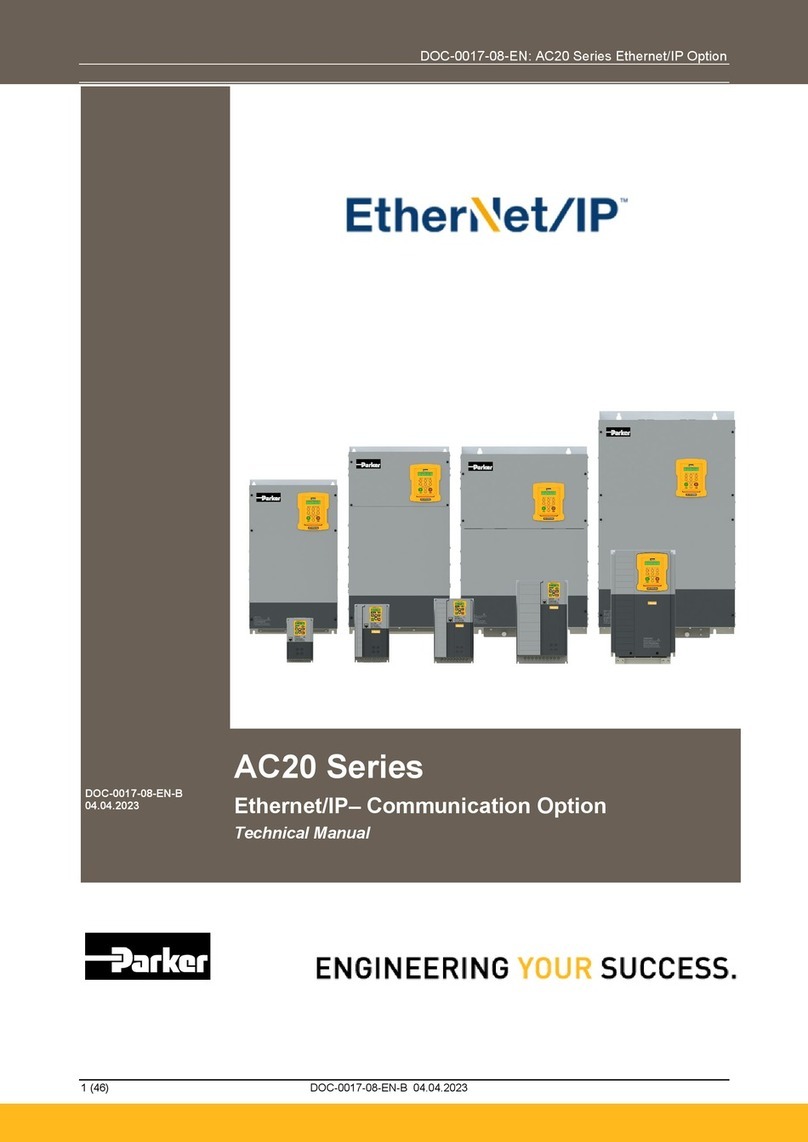

Parker AC20 Series User manual

Parker

Parker Helac PowerTilt Series Installation and operating manual

Parker

Parker SAT Series User manual

Parker

Parker PCO2 User manual

Parker

Parker PCO2 User manual

Parker

Parker LX80L User manual

Parker

Parker ORIGA P120 Series User manual

Parker

Parker 732 Series User manual

Parker

Parker SciLog FilterTec Plus Guide

Parker

Parker HTG Series Manual

Parker

Parker Siemens APOGEE P1 User manual

Parker

Parker PowerStation HPC Series User manual

Parker

Parker MA3 Series Manual

Parker

Parker EOMAT ECO User manual

Parker

Parker ASV2000 Series User manual

Parker

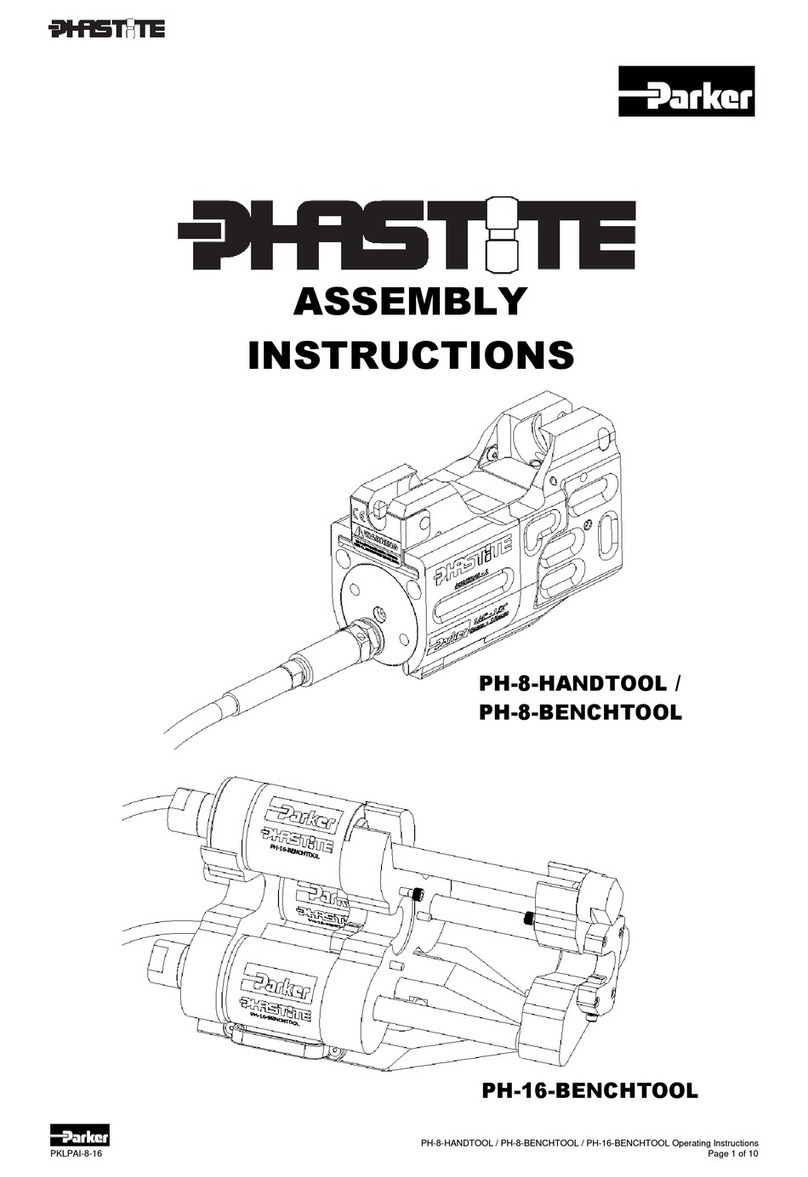

Parker Phastite PH-8-HANDTOOL User manual

Parker

Parker Parflange ECO 25 User manual

Parker

Parker 8903/RS User manual

Parker

Parker 2003-IP-00 User manual