Century UK MAX-THRUST RUCKUS User guide

Copyright Century UK Limited 2018 www.centuryuk.com

R/C Aerobatic Sports Aircraft

Assembly And Instruction Manual

Copyright Century UK Limited 2018 www.centuryuk.com

Revision V1.0

Warning:

This radio controlled model is not a toy. It requires skill to y and is not

recommended for use by beginners without assistance from an experienced

model pilot. It should not be operated by children without the supervision of a

suitably experienced adult.

Max-Thrust reserves the right to modify the specication of this model at any time.

Safety Precautions

1. Do not attempt to repair or modify this aircraft with non-factory parts.

2. Never y this model over roads, railway lines, near to power lines, airports, do

not y this model in excessively strong winds, in the rain, or thunderstorms.

3. Do not y or launch the model towards people.

4. Keep hands and face away from rotating propeller at all times.

5. We strongly recommend that all xings and fasteners used in the construction

of this model are checked regularly for integrity. Failure to do so could cause a

crash, injury to yourself or others around you.

6. We only recommend the use of 2.4GHz radio equipment with this model.

Disclaimer

1. This radio controlled model is not a toy. Used incorrectly it is capable of inicting

serious injury to persons or damage to property. The owner/pilot assumes all

responsibility for any damage to persons or property resulting from the use of this

product.

2. The manufacturer and distributor decline all responsibility for any liability arising

from use of this product.

3. It is very important that you follow all instructions for assembling and setting up

of this model. Failure to do so could result in a loss of control and possibly a crash.

EPOFLEXY

“EPOFLEXY” is a very tough and durable material perfect for the manufacture of

model aircraft. When using screwed xings with “EPOFLEXY” components it is

important to tighten the screws sufciently to provide a rm xing.

Excess tightening could result in the foam material becoming compressed,

possibly damaging or distorting the part. We recommend that all xings are

checked regularly for security and safety purposes.

Copyright Century UK Limited 2018 www.centuryuk.com

Revision V1.0

Overview

Thank you for purchasing this MAX-THRUST Ruckus radio controlled model aircraft.

The Ruckus offers a stunning combination of terric looks and sensational ight

performance. Manufactured from “EPOFLEXY” it is extremely robust, however, in

the event of a “less than perfect” arrival, we supply a range of spares to get you

ying again in the shortest time. It is capable of a wide range of amazing aerobatic

manoeuvres to thrill the experienced pilot, but with reduced control throws it

provides a solid and predictable ight performance, perfect for the sports yer.

We are certain you will enjoy your new model. Please take the time to read this

manual thoroughly and understand its contents completely prior to commencing

assembly.

Key Features

Powerful Brushless Motor

40A Brushless Electronic Speed Controller

Efcient 2 Blade Propeller

Pre-Installed servos

“Live” Control Surface Hinges

Durable “EPOFLEXY” Construction

Steerable Tail Wheel

Superb Flight Performance

High Brightness LED Lighting System

Specication

Wingspan: 1380mm

Length: 1130mm

Weight: 1480g

Motor: KV-850 Out-Runner Brushless

ESC: 40A Brushless

Servos: 2 x 17g 2 x 9g

Battery Required: 2200 - 2600mAh 11.1v Li-Po (Not Included)

2200 - 2600mAh 14.4v Li-Po (Not Included)

This manual has been produced by Century UK’s graphic department. Whilst every

effort has been made to reproduce accurate information, we reserve the right to

change the specications, equipment, colour etc without prior notice. The

information in this manual cannot be recorded as infallible, and as such if you are

unsure of anything please check with your local model shop or ourselves before

proceeding further.

Copyright Century UK Limited 2018 www.centuryuk.com

Revision V1.0

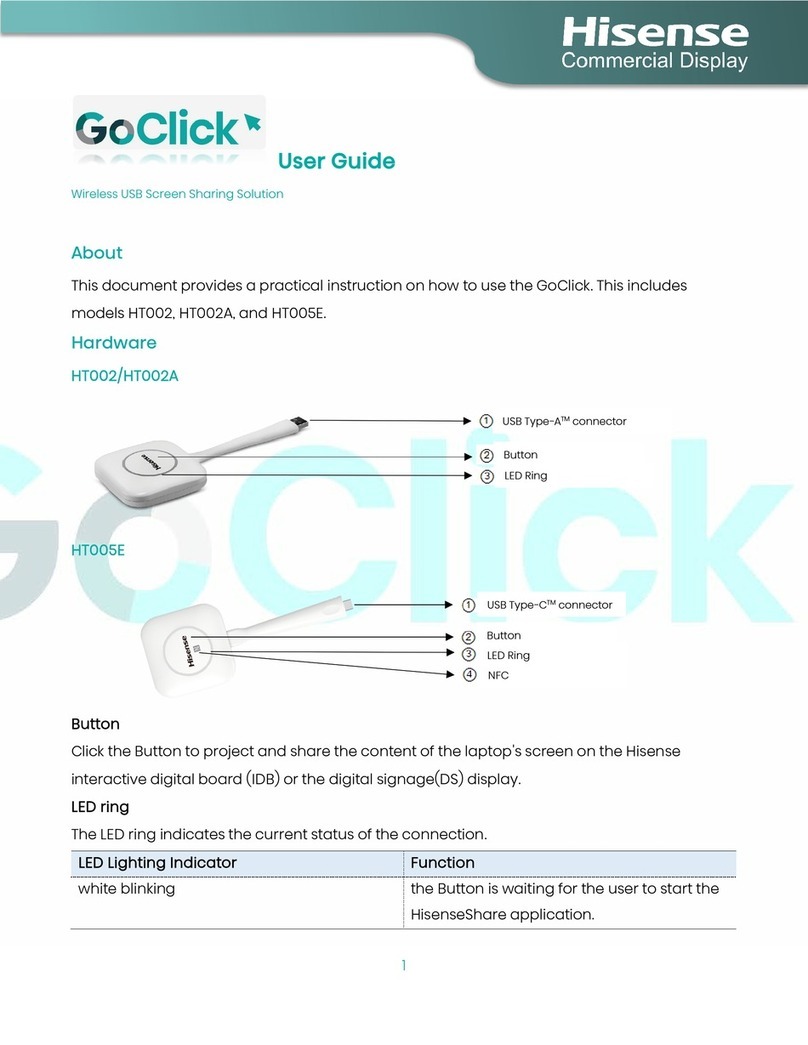

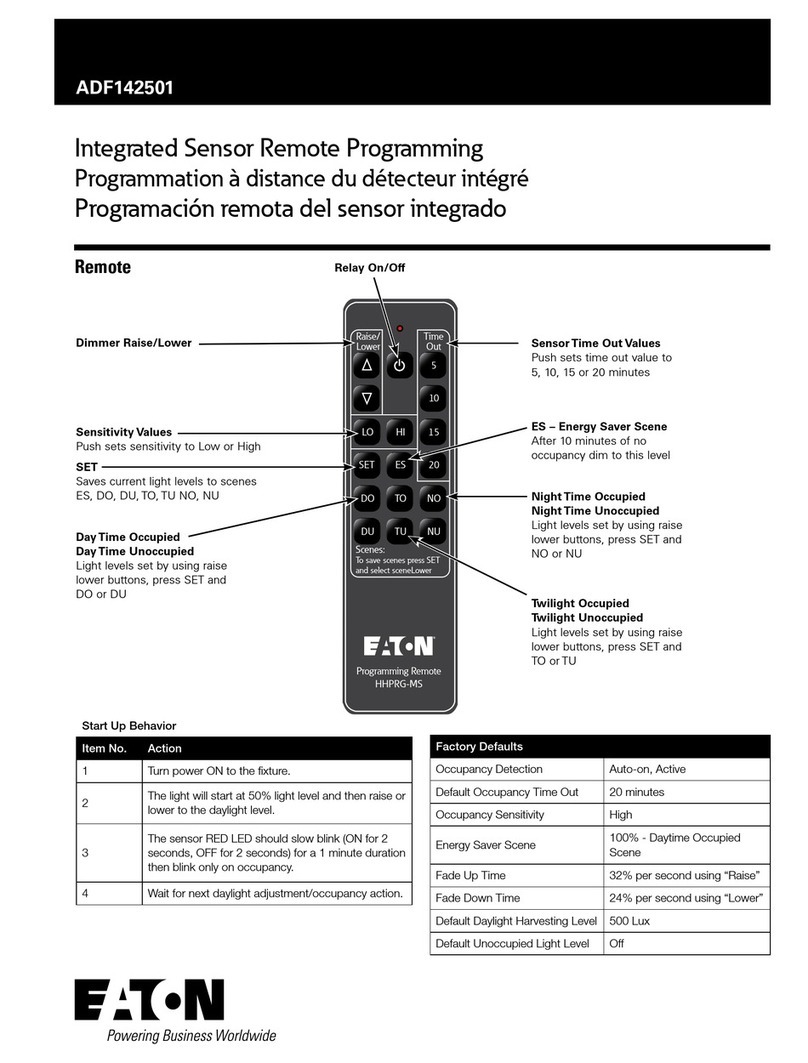

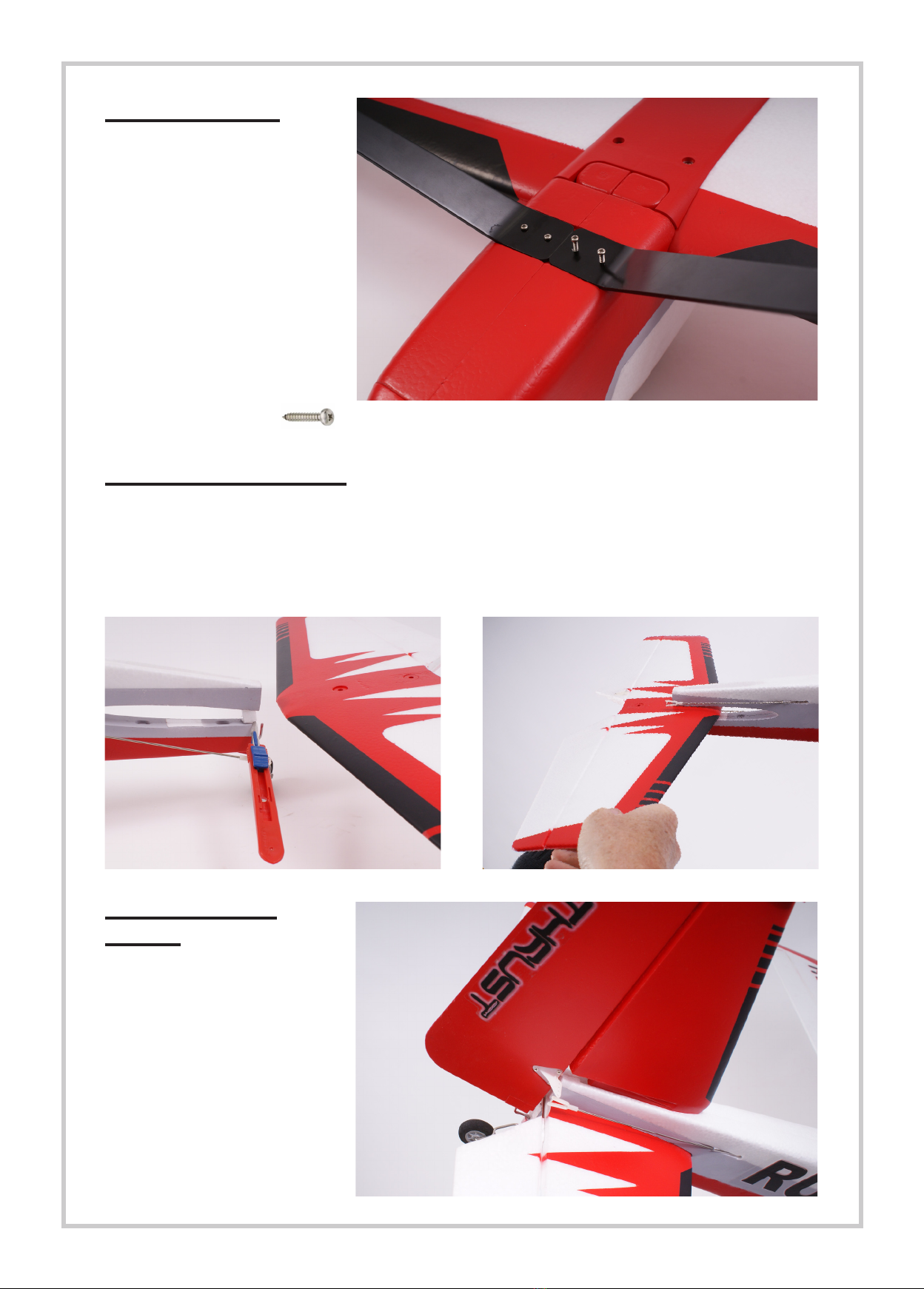

3. Vertical Fin &

Rudder

Install the vertical n and

rudder assembly into the

slot in the fuselage. Please

make certain that the tail-

wheel control wire is located

correctly in the rudder slot as

shown.

If desired, a small amount of

foam glue can be used for

maximum security

1. Undercarriage

Fix the undercarriage in

position with the four 2.6 x

12mm self-tapping screws as

shown. If the screws become

excessively tight whilst xing,

simply back them off a turn or

two, and then continue. Note:

The undercarriage legs are

angled towards the front of

the fuselage.

2. Horizontal Tail-Plane

Remove the moulded tab at the end of the fuselage with a sharp knife. Slide the horizontal

tail-plane into the fuselage slot as shown. Make certain that the holes in the tail-plane line-up

with the corresponding fuselage holes. If desired, a small amount of foam glue can be used for

maximum security.

4 x 2.6 x 12mm Screw

Copyright Century UK Limited 2018 www.centuryuk.com

Revision V1.0

5. Tail Control Horns

Connect the rudder and

elevator snap-links to their

respective control horns as

shown in images to the right.

Minor adjustment to obtain

perfect neutral positions

of the control surfaces can

be achieved by rotating the

plastic link on the threaded

portion of the control push-

rod.

Make certain the plastic link

is securely “snapped” closed

when connected to the control

horn.

4. Tail-Plane Fixing

Fix the horizontal tail-plane

and vertical n in position

with the two 2.6 x 35mm

screws provided. The screws

must be tightened sufciently

to securely x the parts in

position, however be careful

not to over-tighten the screws.

2 x 2.6 x 35mm Screw

Copyright Century UK Limited 2018 www.centuryuk.com

Revision V1.0

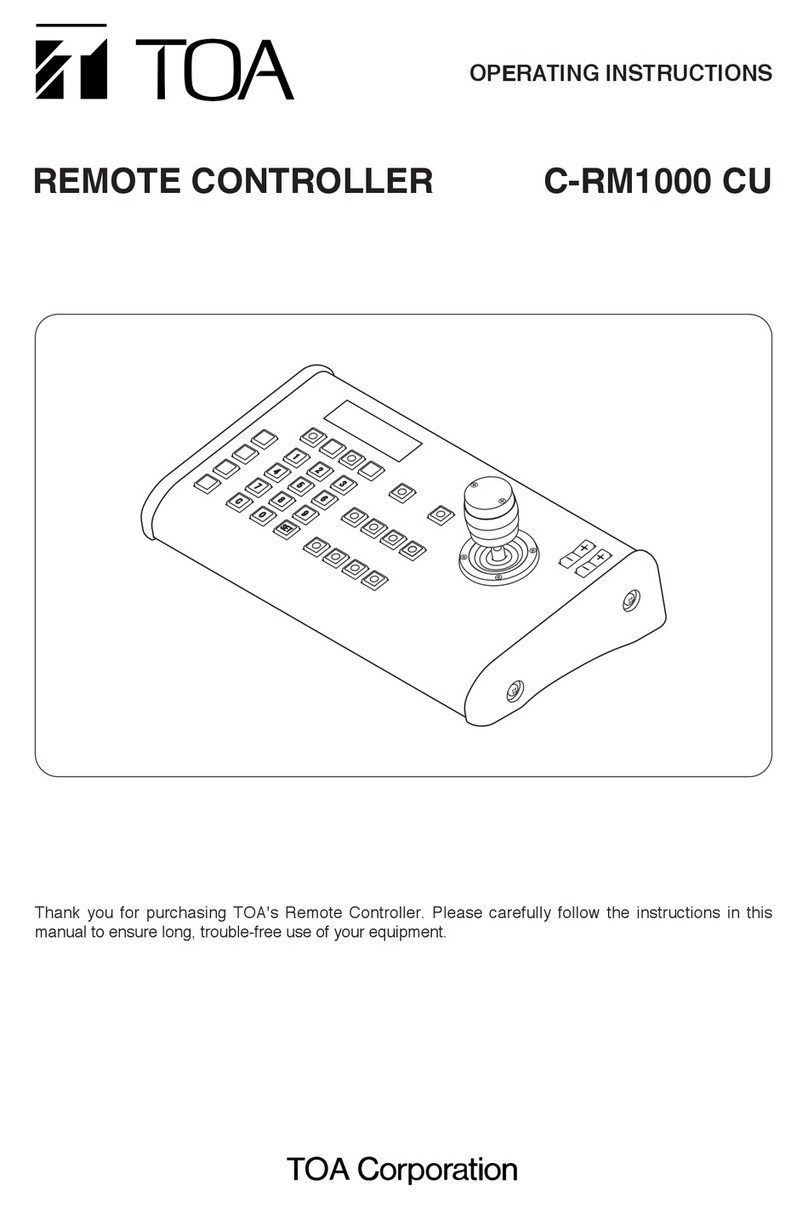

Connect the two black aileron

servo plugs from the wing

to the Y- lead as shown. The

plugs can only be inserted

easily one way round. Make

sure the signal wires match

up (signal is either white or

orange)

The remaining red and black

wires (2 core) from the wing

are for the model’s built-

in LED lighting system and

should be connected to the

Y-lead with the black and red

leads.

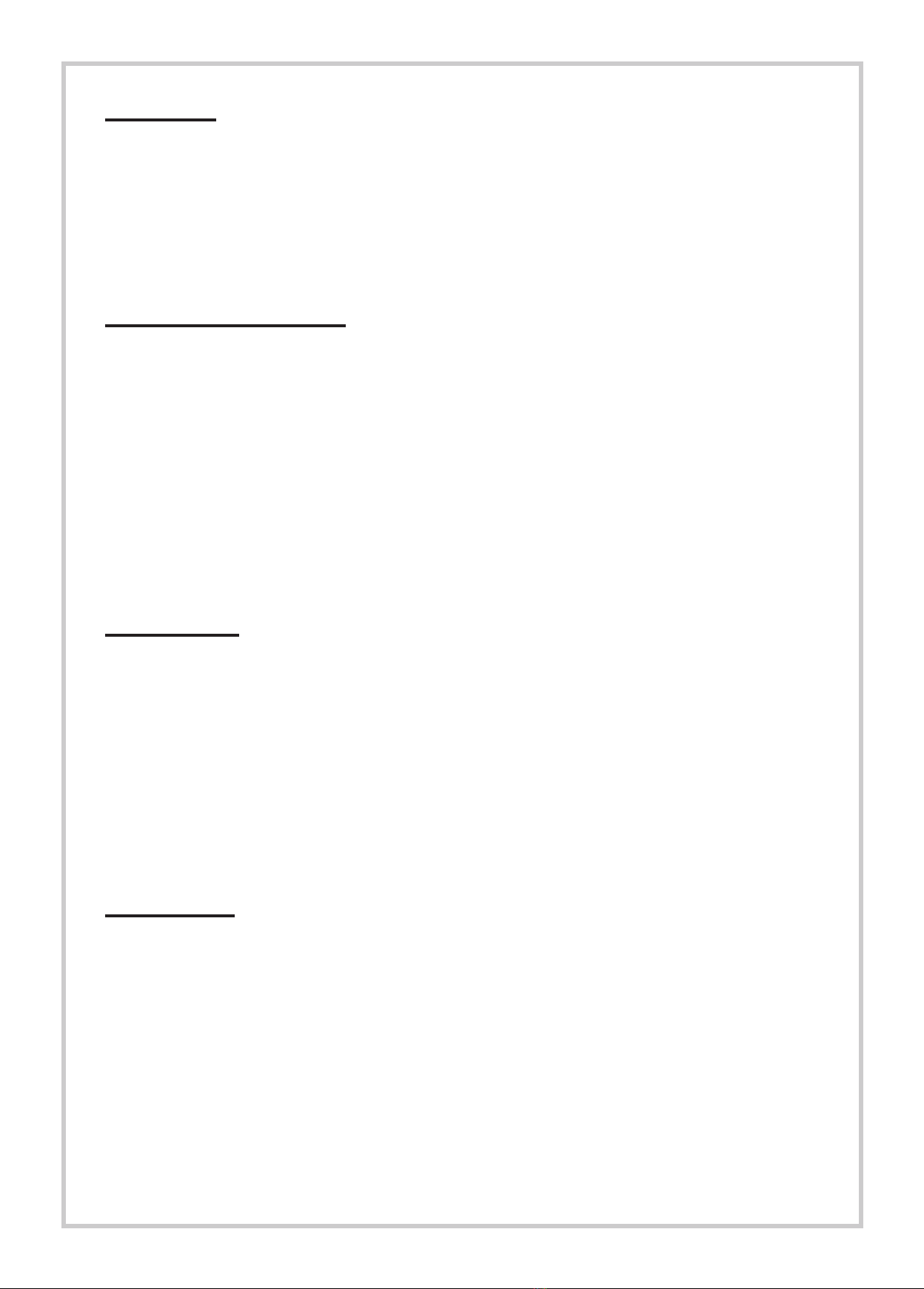

6. Wing Assembly

Locate the 500mm aluminium

wing joining spar and slide

into the round aperture of one

wing panel up to the centre

locating collar. Locate the

small plywood wing locking

plate and insert into the

rectangular aperture behind

the main wing spar, (image G).

Slide the remaining wing panel

onto the exposed portion

of the aluminium spar. The

plywood locking plate will ensure perfect alignment of the two wing halves. Be certain that all

wires are routed correctly via the moulded slots and do not foul the joint between the wing roots.

If desired, a small amount of foam glue can be used for maximum security.

The 2 Y-leads can then be

threaded through the hole in

the fuselage and plugged in

to the corresponding channels

on your reciever.

Copyright Century UK Limited 2018 www.centuryuk.com

Revision V1.0

The moulded wing cowling

should be installed once the

wing is in place and the cables

are threaded though to the

cockpit area. The wing and

cowling can now be secured

to the fuselage using the 3

M4 screws.

7. Wing Fixing

The moulded wing cowling

is used to secure the wing

to the fuselage and can only

be tted one way round. The

cutout is towards the front on

the aircraft.

The longer screws are used at

the front.

2 x M4 x 55mm Screw 1 x M4 x 38mm Screw

8. Receiver Installation

Connect the speed controller to the throttle channel of your receiver (receiver not included in

PNP versions). This wire is easily identied, it is the only one that is routed from the front of the

model.

Connect the rudder and elevator servos to the corresponding channel outputs of the receiver

and then connect the Y-lead from the ailerons to the aileron channel output and the lights to any

spare receiver channel. There is a moulded recess in this compartment which is sufcient to

accommodate most popular 2.4GHz receivers; however there is ample room elsewhere to locate

yours if it does not.

We recommend that it should be securely positioned with self-adhesive “Velcro”.

You must adhere to the receiver manufacturer recommendations regarding positioning and

aerial routing.

Copyright Century UK Limited 2018 www.centuryuk.com

Revision V1.0

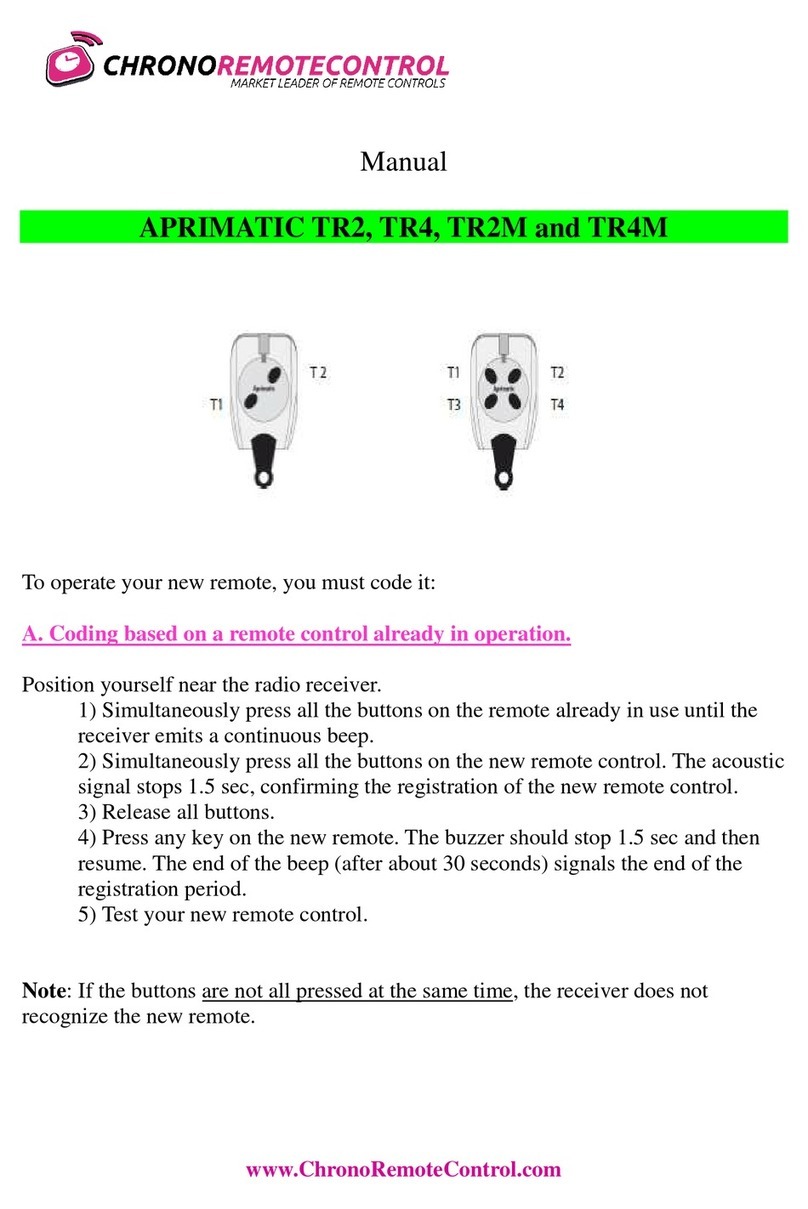

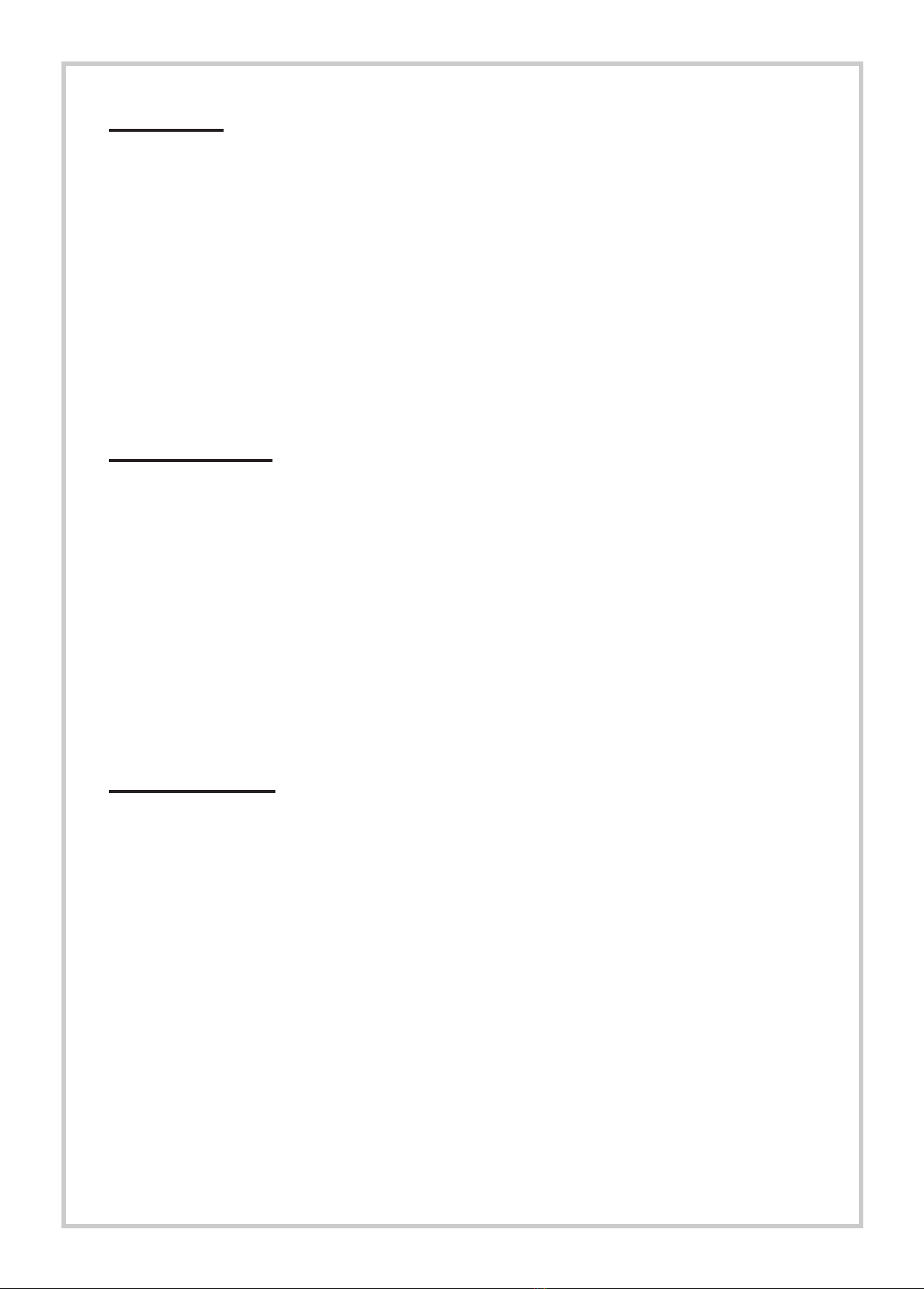

9. Propeller &

Spinner

Following steps “1” to “9”,

slide the aluminium propeller

adaptor onto the motor shaft,

followed by the tapered

aluminium driver. Slide the

plastic spinner back plate

onto the adaptor shaft.

Fit the propeller using the

washer and securing nut.

Securely tightening the nut

will clamp the adaptor to

the motor shaft and x the

propeller in position. Note:

Use of excessive force

will cause damage to the

aluminium adaptor.

Attach the front section of the

plastic spinner and secure

with the two screws provided.

Note: It is essential that the propeller is securely xed. Failure to

do so could result in serious injury

10. Propeller Rotation

Double-check that the

propeller is securely xed and

it is rotating in the correct

direction. When standing

behind the plane the propeller

should be rotating in a

clockwise direction.

1 2 3

4 5 6

7 8 9

Copyright Century UK Limited 2018 www.centuryuk.com

Revision V1.0

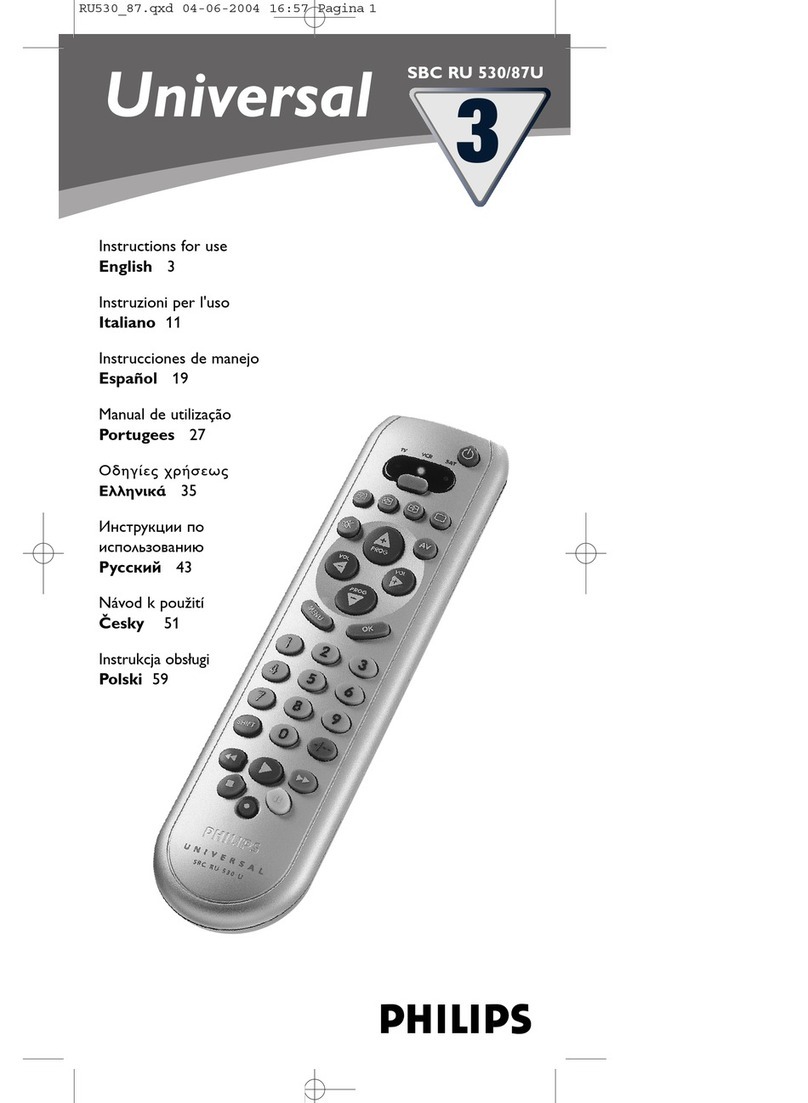

13. Centre Of Gravity

It is vital that you check that

the centre of gravity is correct.

Failure to do so could result in

a complete loss of control. We

recommend the balance point

of the model, complete with

battery, should be 80 -100mm

back from the leading edge of

the wing for initial ights. Very

experienced pilots may wish

to move the balance point

further back after initial ight

testing.

80 ~ 100 mm

12. Control Surface

Check that all control surfaces are centred and responding correctly to transmitter inputs.

Adjustments can be made to control surface centres by carefully rotating the plastic control

horns on the threaded portion of the metal control rods. Use the servo reversing function on

your transmitter for any control that is not responding in the correct sense to control inputs.

Make certain that all plastic links are securely “snapped” closed and that all control surface

hinges are secure. Use a small amount of foam glue if any hinges are not rmly attached.

We make the following recommendations for control surface deections. Experienced pilots may

wish to increase these movements after initial ight testing.

Ailerons: 15mm each way

Elevator: 20mm each way

Rudder: 28mm each way

11. Battery

Installation

The battery is mounted in to

the model by removing the

upper canopy that is held in

place by magnets.

Your ight battery, (not

included in the PNP Version)

can easily be installed and

connected to the factory

tted “T” style connector.

Make certain the battery

is secured using the velcro

straps and that the canopy is

secure before ight.

For added security of the battery pack we recommend using

some self adhesive velcro applied to the battery and battery

tray.

Copyright Century UK Limited 2018 www.centuryuk.com

Revision V1.0

MAX-T-RUCKUS-1 MAX-T-RUCKUS-2 MAX-T-RUCKUS-3

MAX-T-RIOT-4 MAX-T-RUCKUS-5 MAX-T-RUCKUS-6

MAX-T-RUCKUS-4 MAX-T-RIOT-10 MAX-T-RIOT-11

MAX-T-RIOT-12 MAX-T-RIOT-6-R MAX-T-RIOT-5

MAX-T-RIOT-7 MAX-T-RIOT-16 MAX-T-RIOT-8

MAX-T-RIOT-15 MAX-T-RIOT-14

Table of contents