2.0 Requirements 7 Genie S

2.4 WATER TEMPERATURE SETTINGS

The heater is designed to provide maximum heat output

up to 1OC below set point. Output is gradually reduced

over the last 1OC. If the pool is used before the tem-

perature reaches set point, the water entering the pool

from the heater may be noticeably warmer than the

pool water. This is not a fault but part of the design. It

will reduce for the fi nal 1OC up to set point.

Operation without pool water circulation

will cause long term and severe damage to

the heater.

2.5 WINTERISATION

Anti-freeze Inhibitor

As supplied this heater includes a dose of Sentinel

X500 anti-freeze/inhibitor. Subject to not being removed

or diluted, the appliance is protected to -10oC. If the pri-

mary circuit of the appliance is drained for any reason,

the correct quantity of new anti-freeze/inhibitor must be

added to give the level of protection required.

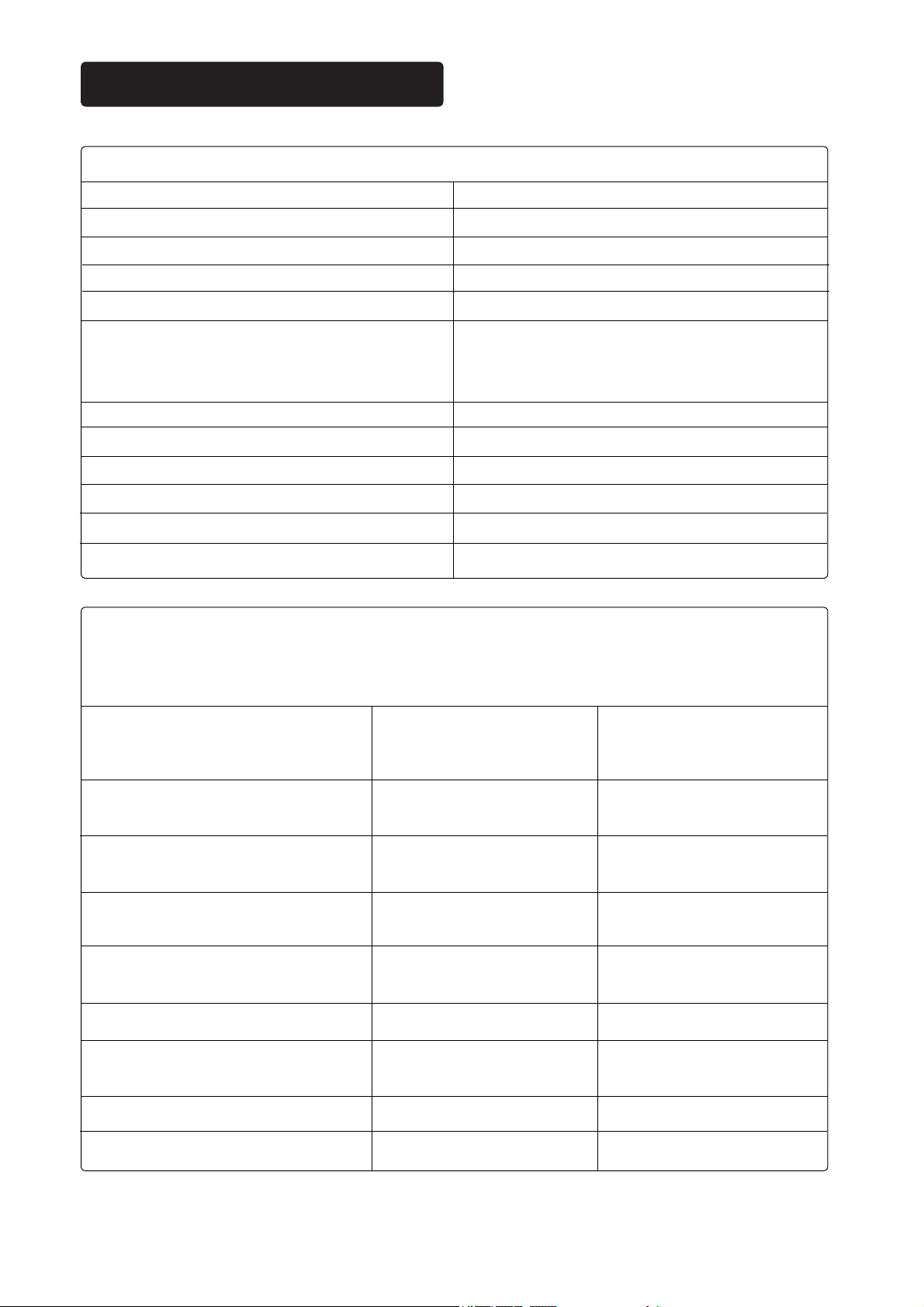

To add anti-freeze/inhibitor to the heater, it is recom-

mended that it is introduced into the side vent after the

primary system has been de-pressurised.

As antifreeze/inhibitor is introduced via the side vent

the top vent can be opened to minimise air venting (see

4.1 for details on venting).

Swimming pool water

With the exception of heating the water and/or keeping

the pool pump operating 24 hours per day, pool water

can not be protected against freezing.

If the above methods are not adopted in the winter

months, it is recommended that the pool water is com-

pletely drained from all pipe work and the secondary

heat exchanger.

To completely remove pool water from inside the sec-

ondary heat exchanger it may be necessary to undo the

6 bolts from one end of the heat exchanger to allow the

water inside to run out.

Failure to follow these guidelines could

cause damage to the heater which will not

be covered by warranty.

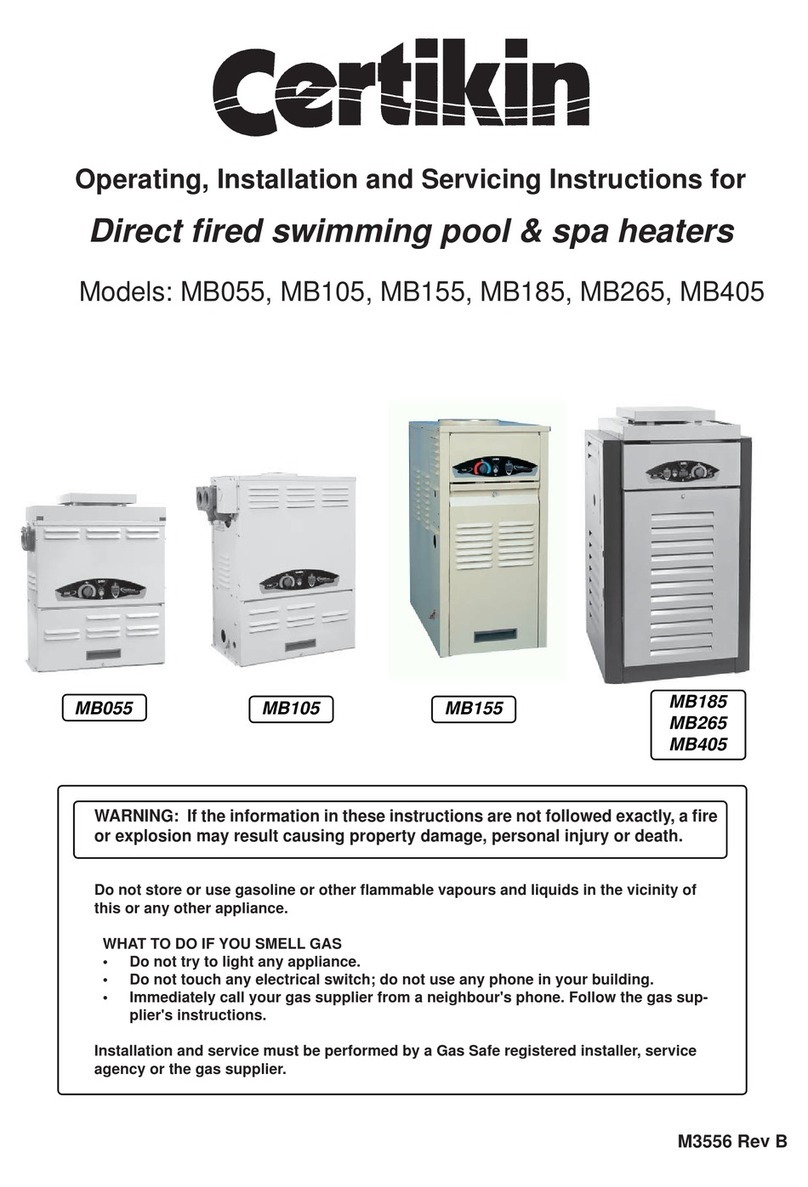

These instructions cover a range of indirect, fl oor

mounted, gas fi red, condensing pool heaters which

are room sealed and fan assisted. The fl ue system

available is concentric, left, right, rear, and vertical,

all up to 20 metres ‘FEL’. There is also an outdoor

top terminal for use where the heater is installed out

of doors. The ignition system is fully automatic.

There are three models with diff erent outputs (see

1.0 for details). These models can be installed in

multiples to obtain a larger, combined output.

2.1 POOL CHEMISTRY

This heater uses a high performance cupro nickel

heat exchanger and are suitable for connection to

pools using chlorinated and salt chlorinated wa-

ter provided the following levels of chemicals are

maintained:-

pH 7.2 to 7.8

Alkalinity 100 to 150 ppm

Calcium Hardness 200 to 400 ppm

Salt concentration < 30,000ppm

Free Chlorines 1 to 4 ppm

Bromine 2 to 4 ppm

Chlorine < 150 ppm

All chemicals must be introduced and completely

diluted into the pool water before being circulated

through an operating heater. Do not place chlorine

tablets or bromine sticks in the skimmer, high chem-

ical concentrations will result when the pump is not

operating. Turn the heater off when shock dosing

Chlorinators must feed downstream of the heater &

have an anti-siphoning device to prevent chemical

back-up into the heater when the pump is shut off .

High chemical concentrates from feed-

ers and chlorinators that are out of

adjustment will cause corrosion to the

heat exchanger inside the heater. Such

damage is not covered under the war-

ranty.

2.2 CLEANING

It is recommended that periodically the casing is

cleaned and sprayed with WD40 or similar liquid,

and any exposed threads are lightly coated in

grease.

2.3 SERVICE & MAINTENANCE

It is recommended that the Heater is serviced

every 2000 hours of operation, or at least every

12 months. The display will alert when you when it

reaches this period by its display, ‘SEr’ alternating

with the temperature.

2.0 REQUIREMENTS

Side

vent

v

Top

vent

End bolts