6MB Pool & spa heater

3. Make visual check of the burner and pilot

flame. Flame pattern on the main burner and

pilot is indicated in the previous illustration. Yellow

flame means restriction of the air openings. Lifting

or blowing flame indicates high gas pressure. Low

flame means low gas pressure. Should this occur,

shut the heater off and contact your gas supplier

or qualified service agency.

4. On indoor heaters, clean room intake open-

ings to assure adequate flow of combustion and

ventilation air.

CAUTION: Combustion air must not be contami-

nated by corrosive chemical fumes which can

damage the heater and void the warranty.

5. Keep area around heater clear and free from

combustible materials, gasoline and other flam-

mable and corrosive vapours and liquids.

POOL & SPA WATER CHEMISTRY

IMPORTANT! These Heaters are not suitable for

use on Salt Chlorinated pools. If this is intended

please contact the Manufacturer.

Chemical imbalance can cause severe damage to

your heater and associated equipment. Maintain

your water pH between 7.4 and 7.8 and total alka-

linity between 100 and 150 p.p.m. If the mineral

content and dissolved solids in the water become

too high, scale forms inside the heat exchanger

tubes, reducing heater efficiency and also dam-

aging the heater. If the pH drops below 7.2, the

heater will be severely damaged. This will result in

corrosion of the heat exchanger. Heat exchanger

damage resulting from chemical imbalance is

not covered by the warranty.

AUTOMATIC CHLORINATORS AND CHEMICAL

FEEDERS

All chemicals must be introduced and completely

diluted into the pool or spa water before being cir-

culated through the heater. Do not place chlorine

tablets or bromine sticks in the skimmer. High

chemical concentrations will result when the pump

is not running (i.e. overnight).

Chlorinators must feed downstream of the heater

and have an anti-siphoning device to prevent

chemical back-up into the heater when the pump is

shut off.

NOTE: High chemical concentrates from feeders

and chlorinators that are out of adjustment will

cause very rapid corrosion to the heat exchanger in

the heaters. Such damage is not covered under the

warranty.

COLD WEATHER OPERATION

MODERATE CLIMATE: Heater operation can

continue during short term cold spells. When tem-

peraturesarebelowfreezing,flow(continuouspump

operation) must be maintained.

CAUTION: Do not use the heater to maintain wa-

ter temperatures just above freezing or for freeze

protection. When heater is used during freezing

weather, care must be taken to avoid freeze ups.

Continuous pump operation is a must. Additional

protection may be required. The heater is not war-

ranted against freeze ups.

COLD CLIMATE: Prolonged operation with water

temperatures below 10°C (50°F) is not recommend-

ed. Whenstartingtheheaterwithpooltemperatures

below 10°C (50°F) operate the heater continuously

until higher temperatures are reached. Operating

the heater for prolonged periods with pool water

below10°C(50°F)canseriouslydamagetheheater,

and is not covered by the warranty.

For cold climate areas, please follow the winterizing

procedures listed.

WINTERIZING THE POOL & SPA HEATER

When heaters installed outdoors in freezing climate

areasaretobeshutdownforthewinter, observethe

following step-by-step procedure:

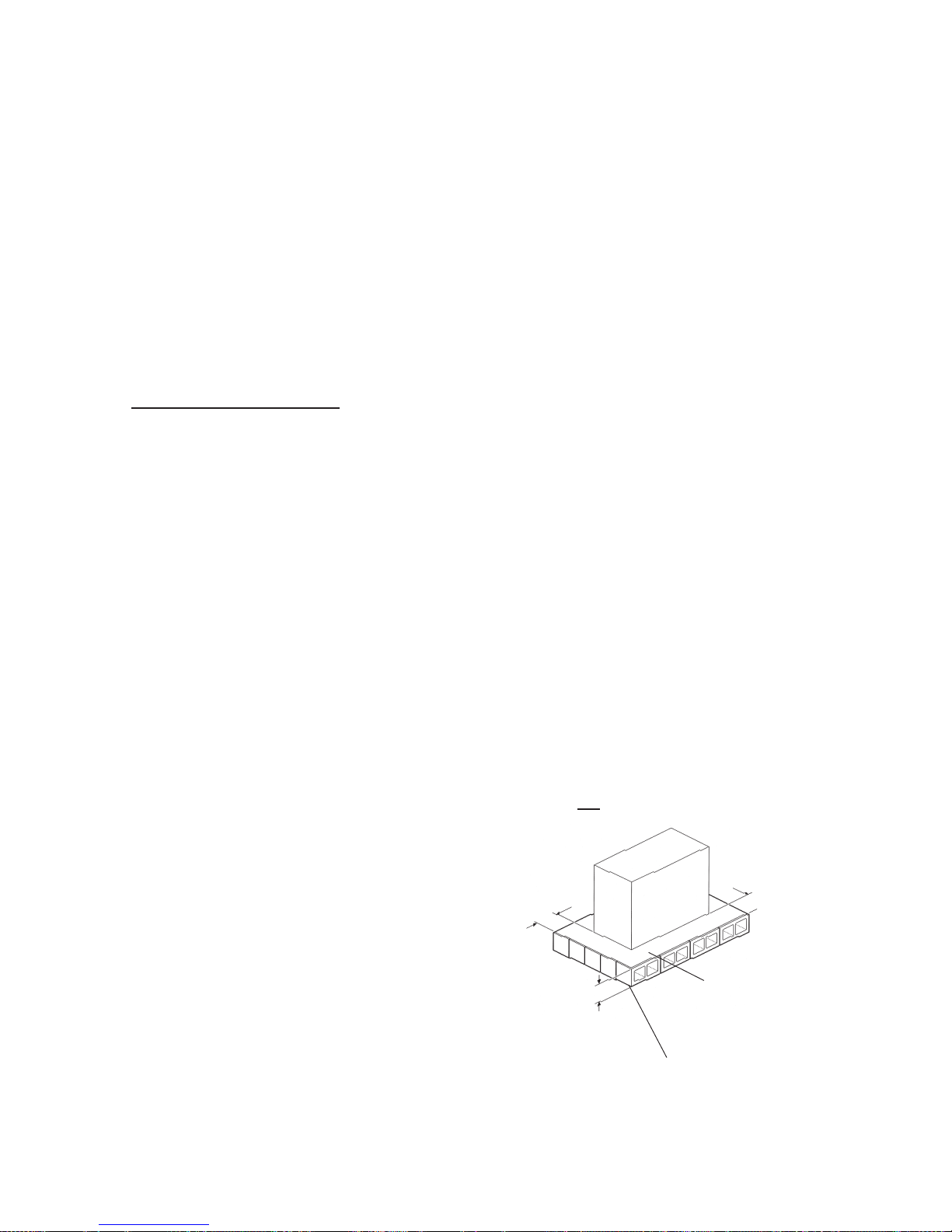

1. Shutoffthegassupplytotheheater,and turnoff

the electrical supply at the fused spur.

2. With the pool pipe work system drained as

necessary, drain the return header by either re-

movingthedrain plug oropeningthe drain valve

(refertoreplacementpartssectionofyourheater

model for details on the drain point location).

3. After winter; to put back into use close the drain

point and purge the header and pipework from

all trapped air, before operating the heater