Cervelo S5 User manual

S5 DISC MANUAL

1

Introduction..................................... 1

Frame Features................................... 2

Handlebar & Stem Components...................... 3

Handlebar Components - Stack..................... 4

Handlebar Components - Pitch Adjust.............. 5

Fork & Headset Components........................ 6

Small Parts...................................... 7

Frame Preparation................................ 8

S5 Disc Assembly Overview........................ 9

Before You Build................................ 11

Electric Cable Preparation...................... 12

Mechanical Cable Preparation.................... 13

Brake Housing Routing........................... 14

Electric Cable Routing.......................... 16

Mechanical Cable Routing........................ 17

Fork Installation............................... 18

Fork Topper Installation................................19

Stem Installation.......................................20

Stack Adjustment........................................21

Stem Fixing Screw Guide.................................22

Handlebar Installation..................................23

Handlebar & Stem - Electric Cable Routing ............24

Handlebar & Stem - Mechanical Cable Routing.............25

Di2 Battery Installation................................26

Electric Cable Installation.............................27

Mechanical Cable Installation...........................28

Seatpost Assembly.......................................29

Seatpost Cutting Instructions...........................30

Frame Protection Installation...........................31

Tire Clearance..........................................32

Rapid Axle Wheel Installation...........................33

Version 1 - 2018-07-31

TABLE OF CONTENTS

This manual is intended to assist Cervélo retailers in setting up and customizing the

2019 S5 Disc bicycle.This manual is not intended for consumer use, and requires the

use of the specied tools to ensure proper assembly. This manual also references

proprietary parts available only to retailers through direct ordering from Cervélo.

Failure to use the specied parts and to follow the supplied assembly instructions

may result in a loss of control while riding and serious injury.This manual is an

overview of the steps required to assemble this bicycle and to make any desired

modications as set forth in this manual. This manual assumes that the retailer has

the minimum required background and skill level required of all professional bicycle

mechanics. See https://www.probma.org/

IMPORTANT INFORMATION

NOTE: Cervélo strongly recommends that

all assembly and adjustment procedures

be performed by an authorized Cervélo

retailer.If you are a Cervélo S5 Disc

consumer/purchaser reading this manual we

suggest that before attempting to undertake

any of the procedures in this manual

that you consult your authorized Cervélo

retailer, or visit us at

www.cervelo.com/support

2

This manual outlines a number of procedures for

making optional adjustments to the S5 Disc which

dier from the way the bicycle is originally sold

by Cervélo.The following tools and parts listed

are required for these adjustments.These parts

are not available for consumer purchase and are

only available for purchase by Cervélo retailers.

Cervélo strongly recommends that all assembly

and adjustment procedures be performed by an

authorized Cervélo retailer.

All parts available for separate purchase are noted

in this manual with Cervélo part numbers listed in

ALL- CAPS FORMAT, with a full listing provided

on page 3.These parts are available by visiting the

Cervelo Customer Portal https://dealers.cervelo.com

LIST OF TOOLS & SUPPLIES

NOTE: All non-proprietary components

such as those from Shimano or SRAM are

available from your local distributor.

NOTE: This manual was developed to

compliment the Cervelo General User

Manual, and is intended as a supplement

to the assembly and installation

instructions supplied by the component

manufacturers (provided with this

bicycle).

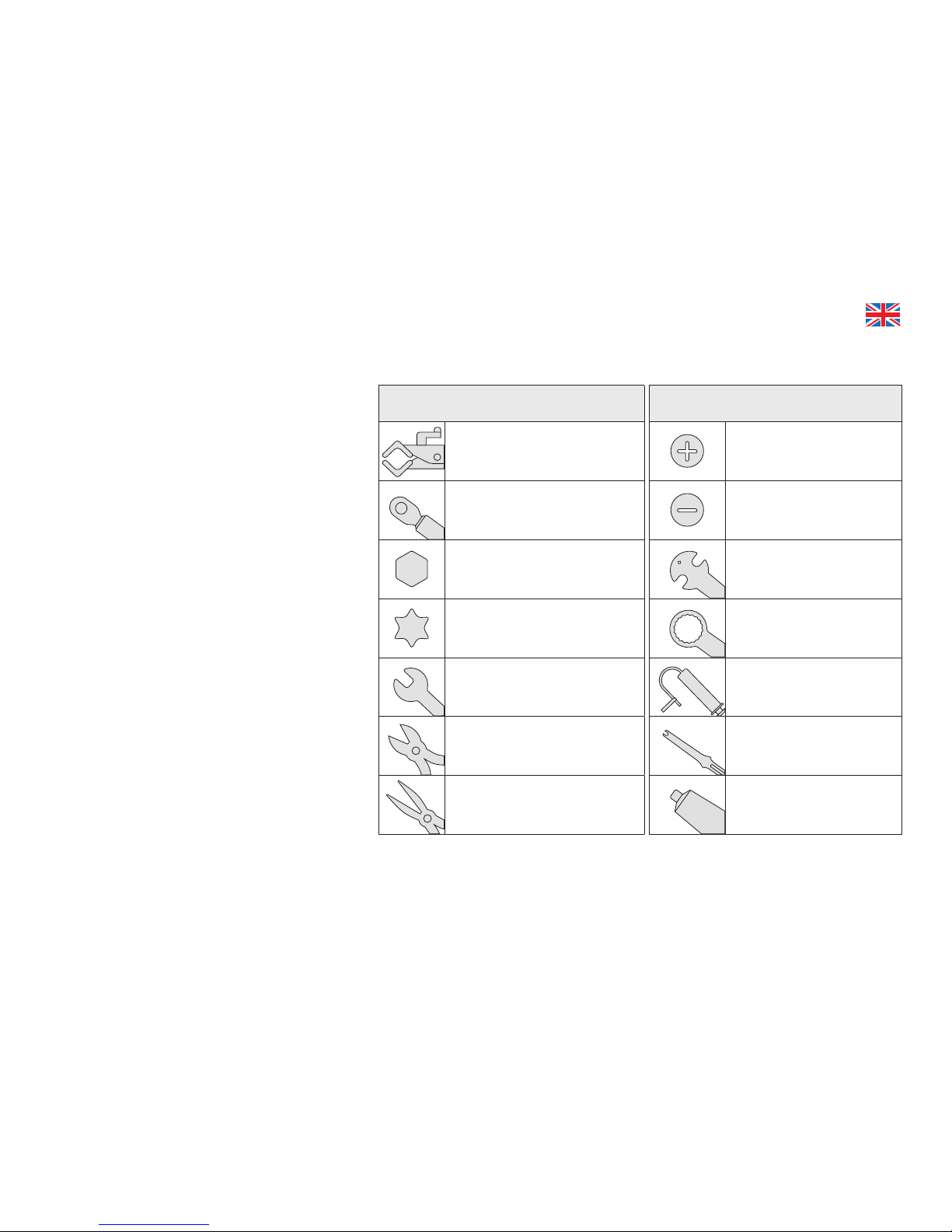

Tools

Bicycle workstand (types which

secure bike by the seatpost, or

pro-type stand with fork mount)

Torque wrench(es) with 2.5Nm

to 15Nm range and adaptors:

Allen (Hex) head inserts:

2mm, 2.5mm, 3mm, 4mm,

5mm, 6mm, 8mm, 10mm

Torx head inserts:T25

Open ended wrenches:

7mm, 8mm, 10mm, 17mm

Cable cutters

Pliers

Tools

Philips-head screwdriver

Slot-head screwdriver

Pedal wrench

Brake rotor lockring tools

Hydraulic bleed kit

Di2 wire tool – Shimano

Good quality bicycle grease

3

2019 S5 DISC PARTS LIST

Item Description Cervélo Part No.

S5 Stack Adjustment

Dealer Kit KP-0E0S5

Conventional 1 1/8"

Stem Adapter FKA-FK60-1125

Computer Mount

Adapter Plate MT-AB08-CAP

M6X1.0X14 CS028

BOLT KIT BT-C028-14

M6X1.0X20 CS028

BOLT KIT BT-C028-20

M6X1.0X25 CS028

BOLT KIT BT-C028-25

M6X1.0X30 CS028

BOLT KIT BT-C028-30

M6X1.0X35 CS028

BOLT KIT BT-C028-35

M6X1.0X40 CS028

BOLT KIT BT-C028-40

M6X1.0X45 CS028

BOLT KIT BT-C028-45

Aftermarket FK60 Fork

Assembly Kit 48 FKA-FK60-SM

Aftermarket FK60 Fork

Assembly Kit 51 FKA-FK60-MD

Item Description Cervélo Part No.

Aftermarket FK60 Fork

Assembly Kit 54-58 FKA-FK60-LG

CS028 Stem 80mm w/

Plugs ST-CS028-80

CS028 Stem 90mm w/

Plugs ST-CS028-90

CS028 Stem 100mm w/

Plugs ST-CS028-100

CS028 Stem 110mm w/

Plugs ST-CS028-110

CS028 Stem 120mm w/

Plugs ST-CS028-120

CS028 Stem 130mm w/

Plugs ST-CS028-130

AB08 Mounting Kit

0mm HBP-AB08-ZERO

AB08 Mounting Kit

2.5mm HBP-AB08-2.5MM

AB08 Mounting Kit 2.5

Degrees HBP-AB08-2.5DEG

AB08 Mounting Kit 5

Degrees HBP-AB08-5DEG

AB08 Carbon

Handlebar 380mm HB-AB08-38

Item Description Cervélo Part No.

AB08 Carbon

Handlebar 400mm HB-AB08-40

AB08 Carbon

Handlebar 420mm HB-AB08-42

AB08 Carbon

Handlebar 440mm HB-AB08-44

SP20 Carbon Post

0mm Oset w/Head SP-SP20-ZERO

SP20 Carbon Post

25mm Oset w/Head SP-SP20-25MM

Seat Post Clamp

Assembly 0E0 S5 SPC-0E0S5

Internal Battery

Mount Assembly 0E0 MT-BINT

BB Cable Guide/Cover

0E0 BBG-0E0

Chainstay Protector

0E0 S Series PRO-CS-S

Disc Brake Hose

Guide CBG-DBH

ST28 Spacer Kit

30mm SS-C028-KIT

Front Der Mount for

0E0 S5 w/Rivets FDM-0E0S5

4

A guide to your Cervélo S5 Disc frame.

Rear Dropout Cable Exit

Front Derailleur Wire

Exit Hole, electric

and mechanical

Bottom Bracket Cable Port

Internal Di2 Battery

Mount Holes

FRAME FEATURES

5

HANDLEBAR & STEM COMPONENTS

Cervélo AB08

Handlebar

Cervélo CS28 Stem

38cm HB-AB08-38

40cm HB-AB08-40

42cm HB-AB08-42

44cm HB-AB08-44

5mm Stem Spacers x6

SS-C028-KIT

M6 Stem Fixing Screws

(Sets of 3)

0mm Stack BT-C028-14

5mm Stack BT-C028-20

10mm Stack BT-C028-25

15mm Stack BT-C028-30

20mm Stack BT-C028-35

25mm Stack BT-C028-40

30mm Stack BT-C028-45

Stem Cap* (Rear)

Stem Cap* (Front)

80mm ST-CS28-80

90mm ST-CS28-90

100mm ST-CS28-100

110mm ST-CS28-110

120mm ST-CS28-120

130mm ST-CS28-130

*Stem Caps are

included with stem

WARNING

Only use the components

speci ed in this manual for

handlebar and stem assembly.

Failure to use the speci ed

parts and to follow the supplied

assembly instructions may result

in a loss of control while riding

and serious injury.

0˚

0˚

+2.5mm

6

HANDLEBAR COMPONENTS – STACK

- Handlebar Fixing

Nuts (L + R) for

0mm stack

- M5 x 14mm Bolts (x4)

- Handlebar Fixing Nuts (L + R)

for 2.5mm stack

- 2.5mm Bar Spacers (L + R)

- M5 x 16mm Bolts (x4)

0mm Stack Kit

2.5mm Stack Kit

Bar Fixing Screw

M5 x 14mm

Actual Size

Bar Fixing Screw

M5 x 16mm

Actual Size

14mm

16mm

The AB08 handlebar stack can be increased by 2.5mm or

rotated in increments of 2.5˚ or 5˚ by the use of specic

Stack or Pitch Adjust Wedge kits.

WARNING

All handlebar mounting parts are

clearly labeled for proper installation.

Mixing parts will void warranty and

may result in injury.

HBP-AB08-2.5MM

HBP-AB08-ZERO

2.5˚

5˚

7

HANDLEBAR COMPONENTS – PITCH ADJUST

- Handlebar Fixing Nut

(L + R) for 2.5˚ rotation

- 2.5˚ Pitch Adjust Wedge (L + R)

- M5 x 16mm Bolts (x4)

- Handlebar Fixing Nuts (L + R)

for 5˚ rotation

- 5˚ Pitch Adjust Wedge (L + R)

- M5 x 16mm Bolts (x4)

2.5˚ Pitch Adjust Kit

5˚ Pitch Adjust Kit

WARNING

Handlebar Pitch Adjust Wedges

are not designed to be used in

conjunction with Handlebar Stack

spacers.

Bar Fixing Screw

M5 x 16mm

Actual Size

16mm

HBP-AB08-2.5DEG

HBP-AB08-5DEG

8

FORK & HEADSET COMPONENTS

WARNING

Your Cervélo frame & fork have

been designed to work together.

Do not attempt to install an

alternative fork.

Preload Cone

Fork Topper

Top Bearing

Dust Seal

Fork Topper

Fixing Screws x4

M5 x 16

Top Bearing

1", 36° x 45°

Bottom Bearing

1-3/8", 36° x 45°

Preload Cone

Fixing Screw

M6 x 18mm

NOTE: The S5 Disc headset

assembly does not require

a compression ring.

Fit Top Bearing Dust

Seal to Fork Topper

before installation.

FK60 Fork

Assembly Kit

FKA-FK60-SM

FKA-FK60-MD

FKA-FK60-LG

9

Front Fork Axle Insert

QRI-RAT

Internal Battery Mount Kit

MT-BINT

BB Cable

Guide/Cover

BBG-0E0

Front Derailleur

Wire Hole Blanking

Plug

GR-ST-CLOSED

Disc Hose Bushing x2

CBG-DBH

Seatpost Clamp

SPC-0E0S5

Computer Mount

Adaptor Plate

MT-AB08-CAP

Rear Derailleur

Hanger Assembly

DRH-RAT

Rear Derailleur

Press-In Cable

Stop (Mechanical)

CBS-DRPOUT

Rear Derailleur

Wire Guide

(Electric)

GR-DRPOUT-GUIDE

Rear Derailleur

Blanking Plug

(Wireless)

GR-DRPOUT-CLOSED

Designed to accommodate electronic, mechanical and hydraulic controls, the S5 Disc frame

is engineered to provide seamless integration of all shifting systems, regardless of method or

brand. In order to do so, you will require the parts shown below:

SMALL PARTS

10

FRAME PREPARATION

1. Apply carbon paste to both frame and seatpost.

2. Insert Seatpost Clamp (SPC-0E0S5).

3. Adjust height and torque to 8Nm maximum.

Clamping the top tube can

damage the frame and void

your warranty.

Hold the frame using a

secured seatpost only.

Lightly grease Rear Derailleur Hanger Fixing

Nut and install Rear Derailleur Hanger

(DRH-RAT for Cervélo Rapid Axle) nger

tight. Final tightening will be done after rear

wheel installation.

Do not nal tighten rear derailleur hanger

assembly without rear wheel installed.

Doing so will result in a misaligned

derailleur and poor shifting.

Lightly grease supplied M4 xing screw,

and install the Front Fork Axle Insert (QRI-

RAT for Cervélo Rapid Axle) to the fork.

Tighten to 3Nm.

11

S5 DISC ASSEMBLY OVERVIEW

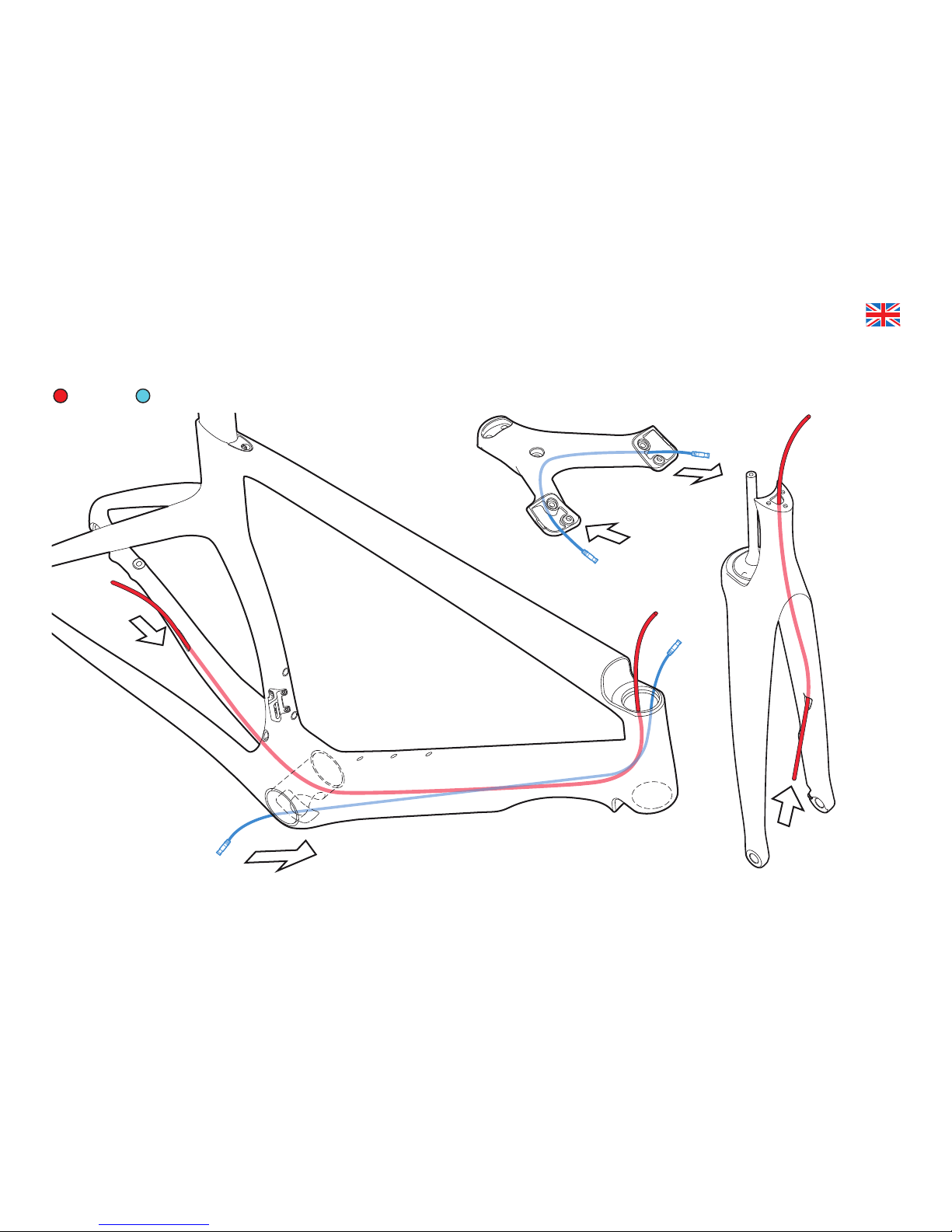

Prepare the frame by installing the rear brake

hose and derailleur controls, exiting the frame

through the upper surface of the headtube. Do

not trim.

Attach the rear brake caliper. Derailleur control

wires can either be attached at this point, or

remain exposed through the Bottom Bracket

Cable Port.

Prepare the fork by installing the brake hose

from the lower leg hose passage, exiting

through the top of the leading edge of the fork.

Attach the front brake caliper.

Prepare the handlebar by installing the shift/

brake levers.

For Di2 builds, prepare the stem, by routing

the 750mm length E-Wire so it passes

through both blades, with the connector

ends exposed at the handlebar end of each

port.

01

NOTE: See the following pages for more detailed assembly instructions.

02

03

04

05

06

12

Grease the bearing cups in the frame, then

install bearings. Feed brake hose and

derailleur controls through Preload Cone.

Install fork and tighten Preload Cone until fork

has no play but still rotates smoothly. Refer to

page 20.

Feed hoses and derailleur controls through Fork

Topper. Use the supplied M5 x 16mm screws to

secure fork. Refer to page 21.

Feed cables and hoses through desired

amount of 5mm Stem Spacers.

Install the stem so that the brake hoses

pass through the appropriate blades. E-Wire

travels up through the right hand blade. With

mechanical controls the rear housing is on the

right and the front on the left.

Ensure you have the correct length bolts,

apply Loctite 242 and secure the stem and

stem spacers to the ForkTopper. Refer to

pages 22-24.

Install handlebar and connect the controls.

Refer to page 25

07

08

09

10

11

12

13

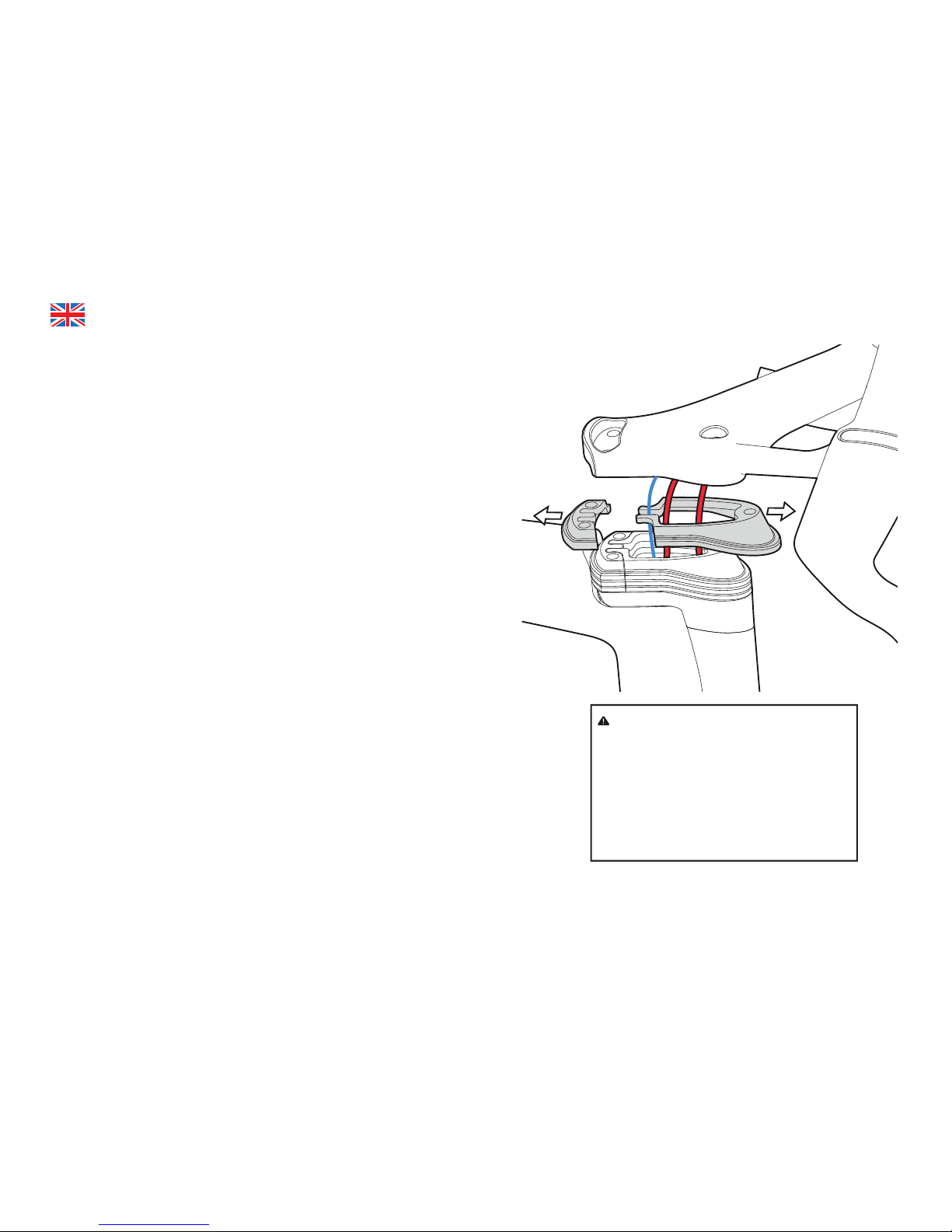

• While the two-piece 5mm Stem Spacers allow for addition/removal without

re-cabling the bike, the length of the cables used during rst assembly will

dictate how much adjustment is possible later on.

• After rst assembly it is simpler to remove Stem Spacers (go lower) and

trim the hydraulic brake hose at the brake lever as required.

• Adding spacers after rst assembly (go higher) may require replacement of

the cables to get the required length.

• Whenever possible, it is best to establish the correct t before performing

nal cabling of the S5.

Here are a few tricks that we have learned along the way that may help with

reinstallation:

Before reinstalling the stem with no spacers:

• Loosen the handlebar xing screws a few turns.

• In order to avoid pinching the rear brake hose during reinstallation of the

stem, simply remove the rear brake caliper from the frame and draw the

extra hose length out, by gently pulling the caliper toward the rear of the

bike.

• Taking care not to kink the derailleur housing (if using mechanical), carefully

reinstall the stem by feeding the extra hoses into the frame, and tighten the

stem xing bolts to 7Nm.

• Reinstall the rear brake caliper by pushing the extra housing into the frame.

• Ensure the hoses and housings are located in the appropriate slot in the

bar, and tighten the handlebar xing bolts to 5Nm.

BEFORE YOU BUILD

WARNING

Do not attempt to force hydraulic brake

hose that will not slide smoothly into

the frame through the fork topper/

head tube. This may result in the

cables becoming kinked or cracked,

and cause a uid leak which can result

in a loss of brake function and a risk of

serious injury.

14

ELECTRIC CABLE PREPARATION

Run 750mm Di2

E-Wire cable

through stem

blades.

Run brake

hose from

bottom of

fork up

through top.

Route 1400mm Di2

E-Wire cable from

bottom bracket

through headtube.

Route

brake hose

from chainstay

through head tube.

Brake E-Wire

15

MECHANICAL CABLE PREPARATION

Run brake hose

from bottom of

fork up through

top.

Route shifter

housing from

bottom bracket

through headtube.

Route

brake hose

from chainstay

through head tube.

Brake E-Wire Front Shifter

16

Electric: Route rear brake

hose through the right

Preload Cone pass-through.

Mechanical: Route rear brake

hose through the front Preload

Cone pass-through.

It is recommended that the hydraulic brake hoses or brake cable housing is installed rst. These

routing illustrations are intended as a supplement to the manufacturer’s installation instructions only.

For both hydraulic and mechanical disc brakes, please refer to the component manufacturer’s service

center or website for further information.

BRAKE HOUSING ROUTING

17

Route hydraulic brake hose or mechanical brake housing through the frame and fork with the Disc

Hose Bushings (CBG-DBH). Install and adjust calipers as per manufacturer’s instructions.

BRAKE HOUSING ROUTING

18

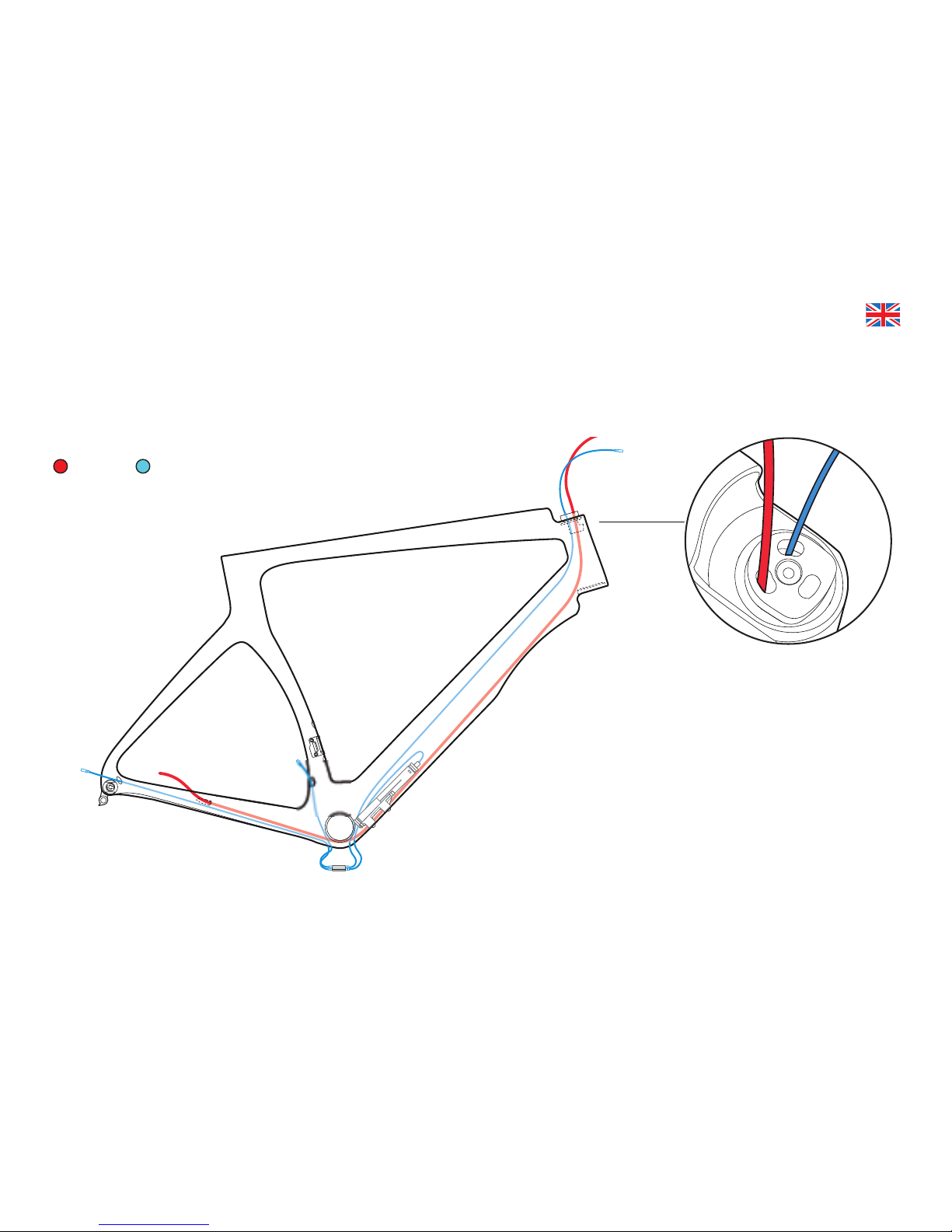

It is recommended that electric cabling and junction points be installed after

the brake hose has been installed.These routing illustrations are intended as a

supplement to the manufacturer’s installation instructions only. Please refer to the

component manufacturer’s service center or website for further information.

ELECTRIC CABLE ROUTING

Route rear brake hose

through the right Preload

Cone pass-through and Di2

E-Wire through the left.

Brake E-Wire

19

It is recommended that front and rear derailleur cables be installed after

the brake hose has been installed.These routing illustrations are intended

as a supplement to the manufacturer’s installation instructions only. Please

refer to the component manufacturer’s service center or website for further

information.

MECHANICAL CABLE ROUTING

Route gear cable housing

out of the Bottom

Bracket Cable Port.

Ensure that the housing

is not twisted together.

Add ferrules to the

bottom bracket end of

the housing.

Route rear brake hose through the

front Preload Cone pass-through.

Route the rear shifter cable

through the right and the front

shifter cable through the left.

Brake E-Wire Front Shifter

Other manuals for S5

4

Table of contents

Other Cervelo Bicycle manuals