*CET is a trademark of CET Fire Pumps Mfg Ltd.

75 Hector St., P.O. Box 90, Pierreville (Québec) Canada J0G 1J0 Telephone: 1-800-567-2719 Fax: 1-800-434-2613 www.fire-pump.com

ACCEPT ONLY THE BEST

A CENTURY OF ENGINEERING FOR THE BRAVEST

PFP-9hpHND-M INSTRUCTIONS MANUAL

STARTING PROCEDURE

• Place your pump on a hard, stable surface within 15° from horizontal

• Check the oil

• Check the gas tank level

• Connect your suction hose. Make sure that there is a rubber seal on the adapter and screw it tight.

• Close all the drain valves (underneath the body of the discharge valve and below the casing of the pump)

• Start the engine and let it idle

• Open the priming valve between the pump casing and the venturi connected to the exhaust system

• Close the exhaust port

• Speed up the engine with the throttle cable to its maximum speed

• When water comes out of the venturi (it should take approximately 10 to 20 sec. with a 10 ft x 2 1/2¨ suction hose),

close the priming valve

• Open the discharge valve to allow water to run through the pump

• Open the exhaust port

• Adjust the RPM to desired pressure

N.B. 1 The exhaust system is very hot. Do not touch

N.B. 2 When you are done with the pump, always drain the pump casing

IMPORTANT NOTICE - FRESH WATER FLUSH AFTER EVERY USE

After Operating a CET Pump, it is critical to FRESH WATER F USH the pump at the end of use before restoring it as a good damage

control practice.

If the pump has been used to pump seawater, the seawater must be drained from the pump by opening the pump casing drain valve.

The pump must be flushed with fresh water to prevent corrosion and salt crystals from forming on close tolerance pump internals.

After flushing the pump, apply a spray silicone compound to pump internals and replace hose connection caps. Taking care of the

pump will help prevent the pump from seizing up.

TROUBLESHOOTING

Before calling us, try the following if your pump does not operate properly.

If the venturi does not work properly.

• Check the exhaust port, it should be closed tightly without any exhaust gas whistling out between the seal and the pipe.

• Check the casing drain valve, it should be closed.

• Check any air leakage from suction hose.

If the engine seems to speed up and down (lost of suction)

• Make sure the suction hose is straight and does not allow any air pockets to be trapped.

• Check any air leakage in the suction or mechanical seal (between the pump casing and the engine)

Loss of suction head.

• Check the rubber seal in the suction hose

The pump is not pumping as much as it should and the revolutions of the engine are high

• Check for any obstruction in the suction hose (leaves, rocks, etc.)

BREAK-IN PERIOD

Do not use the pump more than 1/2 throttle for the first one and half hour.

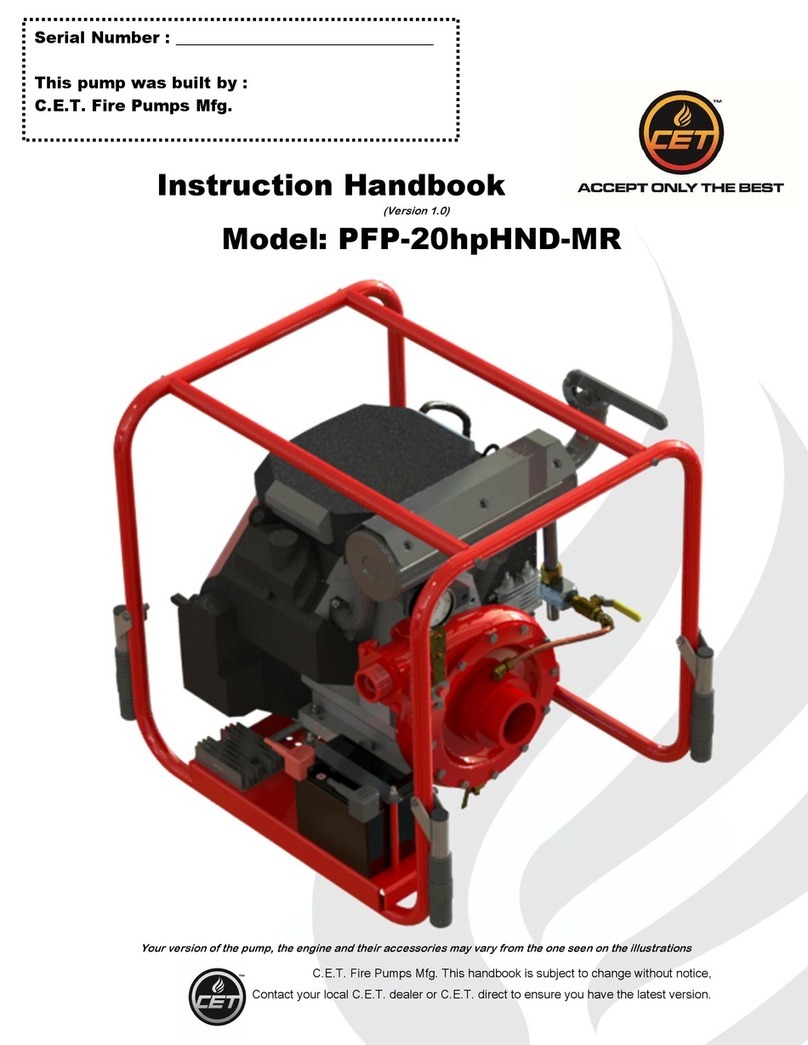

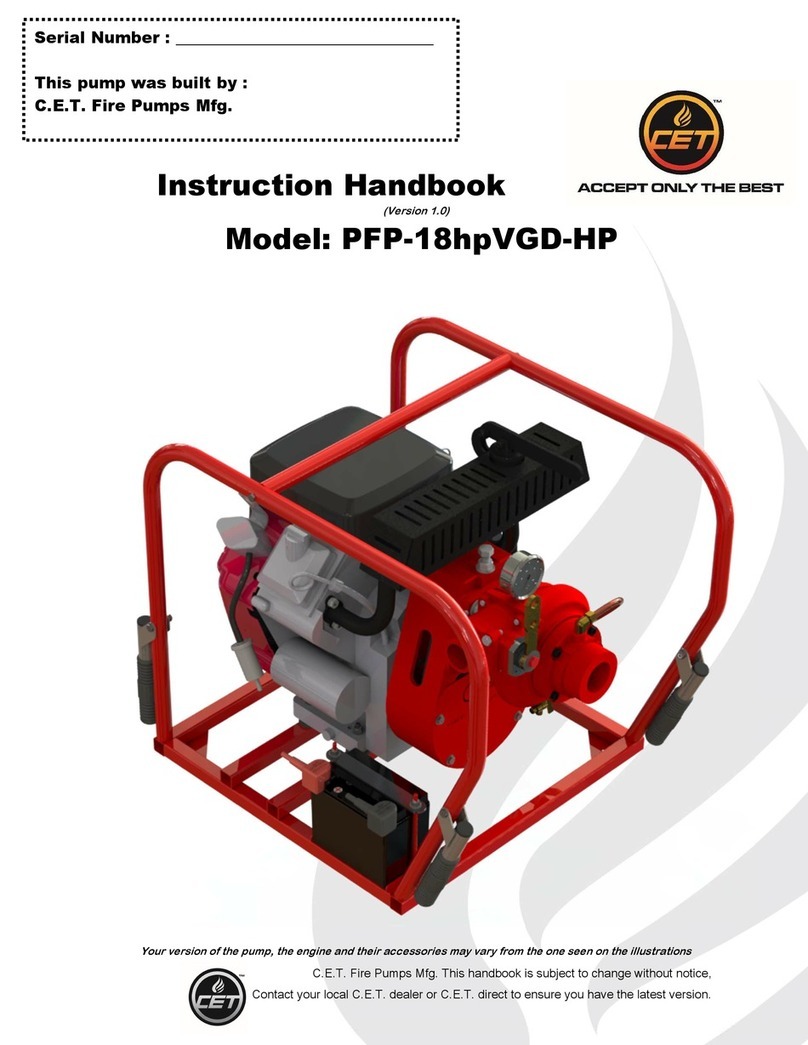

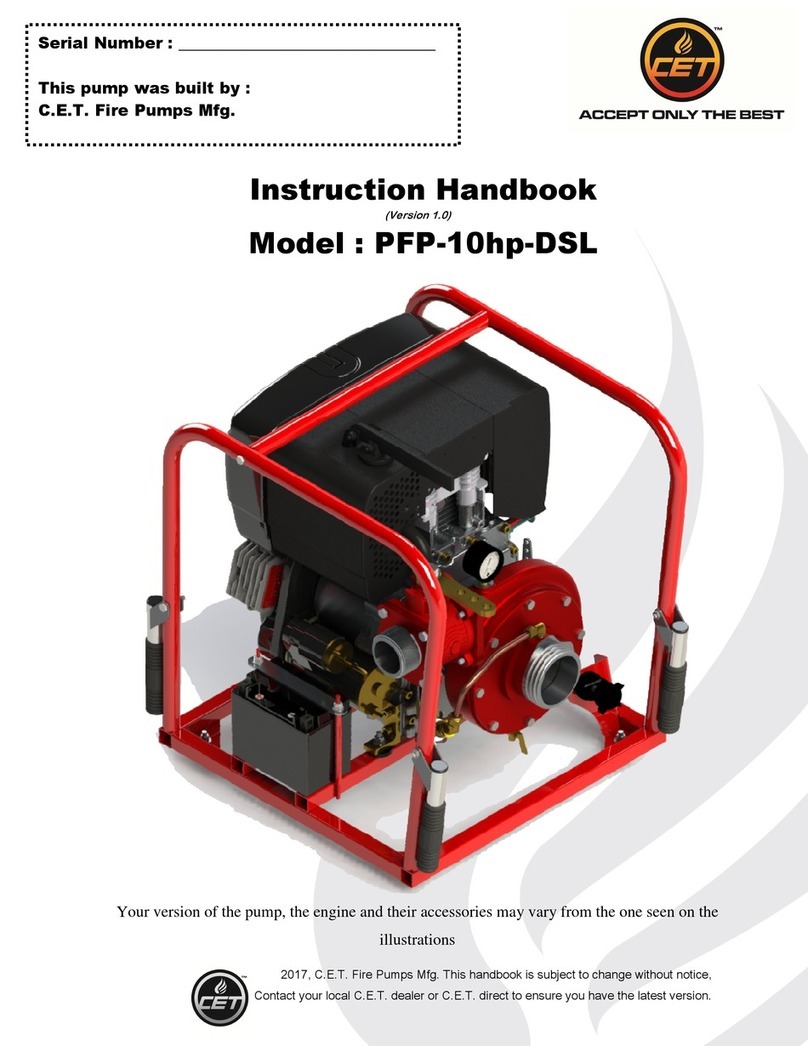

MODELS AVAILABLE

From 2 hp to 60 hp, diesel and gas engines. Skid mounted to floating pump, ask your local dealer for more information or call us.