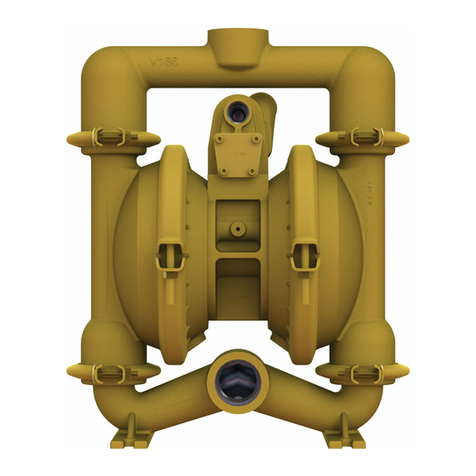

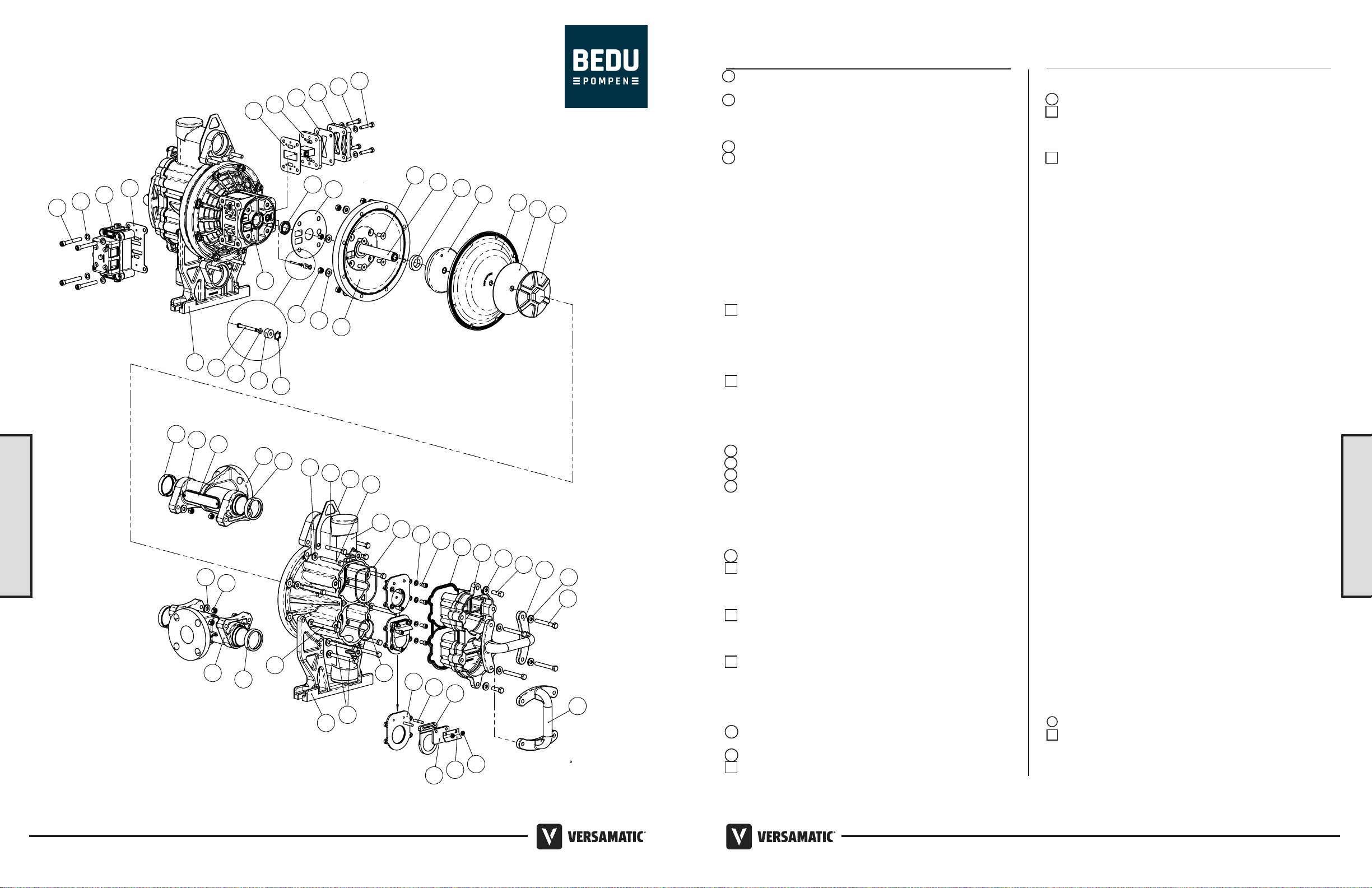

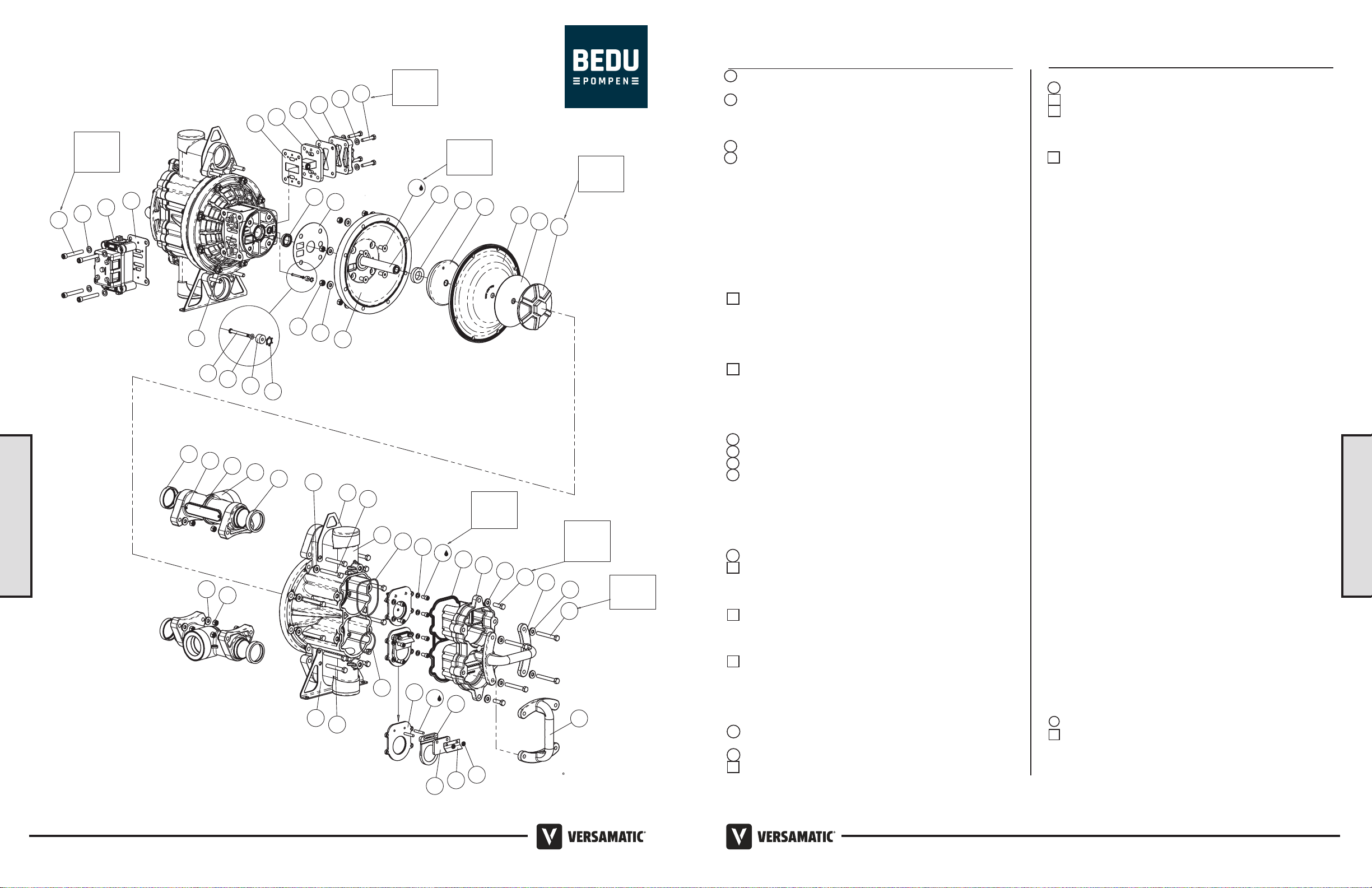

Composite Repair Parts Drawing

19

35

5

18

25 50

13

50 10

43

16

47

44

31

34

6

26 39

11

48

23

2

12

4

13

50

21

1

49

15

24

42

9

40

14

50 28

50

28

17

39 41 27

8

22

OPTIONAL 90

ROTATION

25

33

36

3

30 738

45 46 20

32 37 29

Torque:

120 in-lbs.

(13 N-m)

Torque:

120 in-lbs.

(13 N-m)

Torque:

150 in-lbs.

(16.9 N-m) Torque:

480 in-lbs.

(54 N-m)

Torque:

150 in-lbs.

(16.9 N-m)

Torque:

220 in-lbs.

(24 N-m)

Torque:

220 in-lbs.

(24 N-m)

Item #14: use 242 Loctite or equivalent anaerobic adhesive during installation

Item #16: use 242 Loctite or equivalent anaerobic adhesive during installation

Item #46: if studs are replaced use 277 Loctite or equivalent anaerobic adhesive during installation

Item Part Number Description Qty

1 ** 031.140.000 Air Valve Assembly (Integral Muer) 1

031.141.000 Air Valve Assembly (No Muer) 1

2 095.110.558 Pilot Valve Assembly 1

3 114.024.551 Intermediate Assembly 1

4 115.174.115 Bracket, Foot 2

5 115.177.115 Bracket, Hanging 2

6 132.035.357 Bumper 2

7 135.034.506 Bushing, Plunger 2

8 165.118.551 Cap, Air Inlet 1

9 165.148.551 Cap, Clean Out 2

10 170.018.115 Capscrew, Hex-Hd, 3/8-16 x 1 1/4 4

11 170.069.115 Capscrew, Hex-Hd, 5/16-18 x 1 3/4 4

12 170.129.115 Capscew, Hex-Hd, 3/8-16 x 2 3/4 8

13 170.130.115 Capscrew, Hex-Hd, 3/8-16 x 3 24

14 171.015.115 Capscrew, Flat-Hd, 3/8-16 x 7/8 8

15 171.053.115 Capscrew, Socket-Hd, 3/8-16 x 2 1/2 4

16 171.102.110 CAPSCREW, Socket Hd, 5/16 -18 x .63 16

17 196.217.551 Chamber, Inner 2

18 196.218.552 Chamber, Outer 2

19 286.007.360 Diaphragm, Buna-N 2

286.007.363 Diaphragm, Fluorocarbon FKM 2

286.007.364 Diaphragm, EPDM 2

286.007.365 Diaphragm, Neoprene 2

286.007.354 Diaphragm, Santoprene 2

286.007.356 Diaphragm, Hytrel 2

20 338.005.360 Flap Valve, Buna-N 4

338.005.363 Flap Valve, Fluorocarbon FKM 4

338.005.364 Flap Valve, EPDM 4

338.005.365 Flap Valve, Neoprene 4

338.010.356 Flap Valve, Hytrel 4

338.010.357 Flap Valve, Urethane 4

21 360.093.360 Gasket, Main Air Valve 1

22 360.103.360 Gasket, Pilot Valve 1

23 360.104.360 Gasket, Air Inlet Cap 1

24 360.105.360 Gasket, Inner Chamber 2

25 405.013.551 Handle 2

26 518.222.552 Manifold 2

518.222.552 E Manifold 2

27 535.099.000 Plate, Name 2

28 545.005.115 Nut, Hex 24

29 547.002.110 Nut, Stop 8

30 560.001.360 O-ring 2

31 560.213.360 O-ring, Buna-N 2

560.213.363 O-ring, Fluorocarbon FKM 2

560.213.364 O-ring, EPDM 2

560.213.365 O-ring, Neoprene 2

32 570.001.360 Hinge Pad, Buna-N 4

570.001.363 Hinge Pad, Fluorocarbon FKM 4

570.001.364 Hinge Pad, EPDM 4

570.001.365 Hinge Pad, Neoprene 4

33 570.009.360 Pad, Wear, Buna-N 2

570.009.363 Pad, Wear, Fluorocarbon FKM 2

570.009.364 Pad, Wear, EPDM 2

570.009.365 Pad, Wear, Neoprene 2

34 612.195.157 Plate, Inner Diaphragm 2

35 612.225.552 Plate, Outer Diaphragm (with stud) 2

36 620.007.114 Pin, Plunger 2

37 670.005.110 Retainer, Flap Valve 4

38 675.042.115 Ring, Retaining 2

39 675.073.360 Ring Sealing, Buna-N 4

675.073.363 Ring Sealing, Fluorocarbon FKM 4

675.073.364 Ring Sealing, EPDM 4

675.073.365 Ring Sealing, Neoprene 4

Composite Repair Parts List

LEGEND:

= Items contained within Air End Kits

= Items contianed within Wet End Kits

Note: Kits contain components specic to the material codes.

**Air End Kit does not include entire air valves assembly. It includes

replacement sleeve and spool set, plus o-rings.

Item Part Number Description Qty

40 685.059.120 Rod, Diaphragm 1

41 710.021.115 Screw, Pan Head 4

42 720.004.360 Seal, U-cup 2

43 720.076.360 Seal, Clean Out Cap, Buna-N 2

720.076.363

Seal, Clean Out Cap, Fluorocarbon FKM

2

720.076.364 Seal, Clean Out Cap, EPDM 2

720.076.365 Seal, Clean Out Cap, Neoprene 2

44 720.077.360 Seal, Seat, Buna-N 2

720.077.363 Seal, Seat, Fluorocarbon FKM 2

720.077.364 Seal, Seat, EPDM 2

720.077.365 Seal, Seat, Neoprene 2

45 722.129.110 Seat, Check Valve (includes studs) 4

46 807.018.110 Stud 8

47 900.004.110 Washer, Lock 5/16 16

48 901.038.115 Washer, Flat 5/16 4

49 901.048.115 Washer, Flat 3/8 4

50 901.052.115 Washer, Flat 3/8 48

Model E2 Bolted Plastic Flap • 1312 • Model E2 Bolted Plastic Flap