1

Hydro-Quip 8000 Series Solid-State Systems were designed for indoor or outdoor installations.

This equipment may be used for in-ground as well as aboveground spas.

INSTALLATION CONSIDERATIONS

lThe Equipment System must be installed on a firm, level surface

(ie: concrete pad)

lThe area where the system is installed must have adequate

drainage to prevent flooding of the equipment under all

circumstances.

lFor performance reasons locate the system as close to the spa as

practical. (Consult local codes for minimum distance between

equipment and spa)

lProvide adequate access around and above the System for service

and maintenance. Three (3’) of clearance around the equipment is

recommended.

lThe pump(s) provided with the system may or may not be self-

priming. Pumps that are NOT self priming must be installed

BELOW water level or they will not prime.

lAll components such as pump, blower, etc are powered from a

multi-position terminal strip inside the upper control box.

Level Surface

Water Level

INSTALLATION INSTRUCTIONS

To assure adequate performance, the spa plumbing must be 1 1/2” minimum. The use of 2” is recommended.

There may be three separate plumbing systems in the spa. Verify the function of each pipe.

1) Suction Side Plumbing - this plumbing will connect to the spa’s skimmer, main drain and suction fittings.

This plumbing connects to the open end of the pump on your Equipment System.

2) Discharge Side Plumbing - this plumbing will go to the spa’s hydrotherapy jet and message fittings. This

plumbing connects to the open end of the heater on your Equipment System.

3) Air Blower Plumbing - this plumbing will go to an air channel under the floor or to an air distribution

manifold of the spa. This plumbing connects only to an air blower.

To allow for safe operation of the spa, the suction fittings connected to the suction opening of the Equipment

System should be listed or approved for the purpose.

ŸEach pump must be provided with two suction fittings. Pump 1 is generally attached to a suction fitting and

a skimmer, while Pump 2 is generally attached to two suction fittings.

After plumbing is complete, secure the Hydro-Quip Equipment System with the appropriate hardware.

Suction Discharge

Page 5 55065-04_97_A

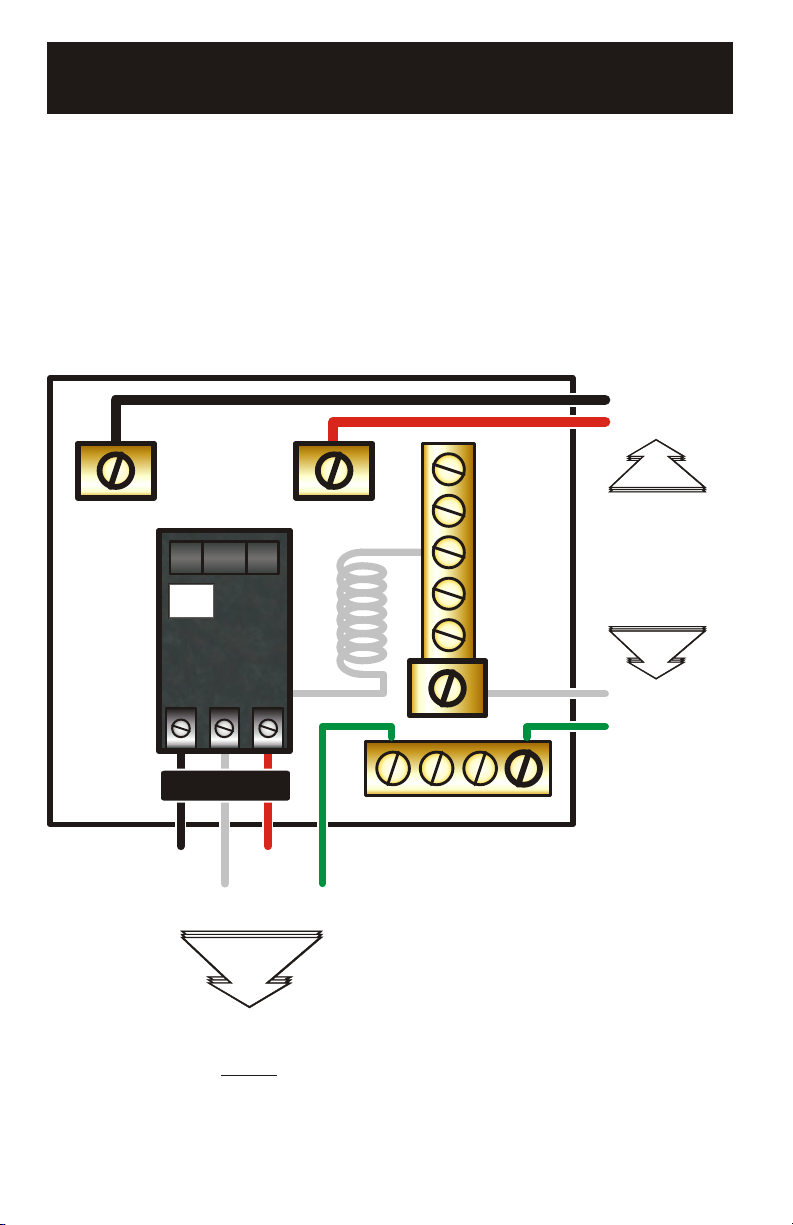

RED AC

WHT AC

J53

J23 J19 J43 J48

K12

U4

J50J52

BLK AC

J66 J65 J63

J64 J42

J54 J56J55

J25J57 J26

TB1

CLASS G

FUSE 30A

CLASS G

FUSE 30A

F6

F7

F4

K4

W1

F2

K7

T1

HTR2 HTR1

FUSE

0.3A 250V

K6

K8

GR

B

W

J79J

J46

J45

J81

12VAC

ADCM

J37J37

J4

J7J7

J74

W8

1

2

3FUSE

3A 250V

TORQUE

RANGE

FOR TB1:

27-30 IN. LBS.

HOT

BLACK

NEUTRAL

WHITE

HOT

RED

Balboa

J11J11 J8J8

BARCODE

GR

B

W

W W J12

J14

W13

W12

K13

W20

W15

BALBOA INSTRUMENTS, INC. MADE IN U.S.A.

EL2000 TC MACH III COPYRIGHT 2005

P/N 22896 REV B

K10

J2

MAIN

PANEL

MAIN

PANEL

MAIN

PANEL

AUX

PANEL

AUX

PANEL

J9

J5

J6

K3

J3

K2

W2

F5

W9 W7

REMOTE

K11

K9

J1

K1

GR

B

W

GR

B

W

GR

B

W

J86

J80

J60J60

J69

J20J1

0

FUSE 10A 250V

J39

J71 J70

J98J98

J89

J91

J17

J15 J13

J83

J22 J24

J82

J36

TST

SENS. A VAC EXT. 2SP PUMP 3 EXT. RLY

AUX. F

J72

CFG

SWITCHBANK A SWITCHBANK B

J90

J977

GR

B

W

J85J85J85

RTC Enabled

5.5 kW

A.V.

Blower

1-Spd P2

Ozone

Circ.Pump

12V Light

Spa

Light

2-Spd P1

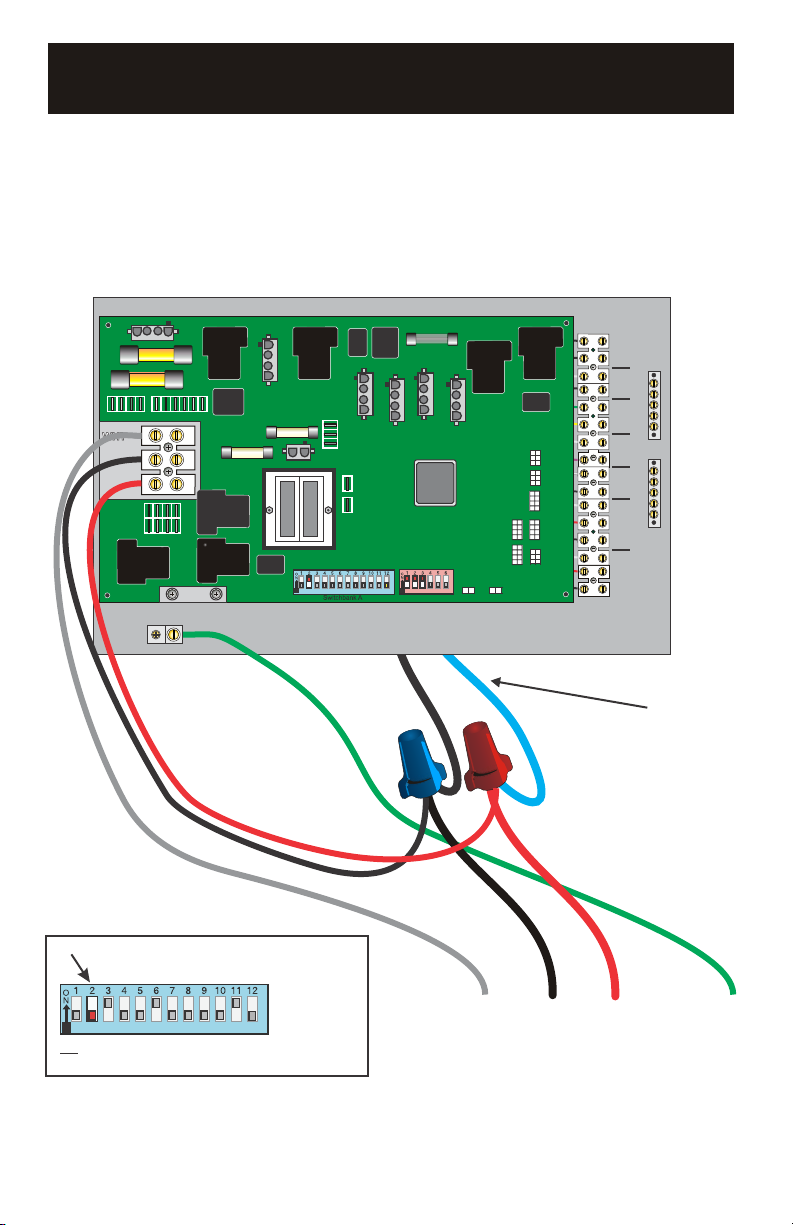

Wiring Configuration and DIP Settings

Setup 1 (As Manufactured)

Switchbank A Switchbank B

A2, Low Amp

A5, Degrees F

A6, Short Timeouts

A9/A10,

No Circ Pump

A1, Test Mode OFF

A3, Filter by Time

A4, 12 Hr Time

A7, Cleanup Cycle OFF

A8, 1Hr O3 Supress OFF

A12, Memory Retained

B1, Pump 2 2-Speed

B2, Pump 2 Disabled

B3, Blower Disabled

B4, No Fiber/Wheel

B5, Pump 3 Disabled

B6, Panel Scrunching OFF

100

114

32

SSID #

J37

3

2

1

12 V

Light

J91

RTC

Enabled

(Not Jumpered)

B3, Blower Enabled

B2, Pump 2 Enabled

B1, Pump 2 1-Speed

A11, O3 w/ P1 Low

and P1 is 2-Spd

A2, High Amp

J17

J15

J83

J22

AUX.F

SENS. A

TST

CFG

When the Logic Jumper is not installed on J83 (CFG),

DIP Switch Settings are enabled.

DIP Switches will then operate as shown below.

120 Volt Connections

240 Volt Connections

Black AC Jumpers

12 Volt Connections

Relay Control Wires

Wiring Color Key

Typically Line voltage

Typically Line voltage for 2-speed pumps

Neutral (Common)

Ground

Note flat sides in connector

1

2

3

4

Board Connector Key

WARNING: Main Power to system should be turned OFF BEFORE adjusting DIP switches.

WARNING: Persistent Memory (A12) must be RESET to allow new DIP switch settings to take effect. (See Persistent Memory page)

SENS. B

GAS HEATER CONNECTION