CGM GUA Series User manual

www.ggm.co.kr

OPERATION MANUAL

GUA SERIES

SPEED CONTROL UNIT

■Headquarters / 1st Factory : 22, Gyeongin-ro 3beon-gil, Bucheon-si, Gyeonggi-do, Republic of Korea

Tel:+82-32-664-7790 Fax:+82-32-611-7791

■Attached research institute / No. 2 factory : 180, Oksan-ro, Bucheon-si, Gyeonggi-do, Republic of Korea

Tel:+82-32-684-7791 Fax:+82-32-683-5059

GLOBAL GEARED MOTOR

2

Thank you for purchasing the GGM product.

Before use this product, read well manual certainly and understand all about knowledge,

safety information and cautions of product, and use right way. After read, please be sure

to keep fixed place to refer anytime.

1. Confirmation at product arrival

- Confirm whether product is same with your order.

- If another product is installed, there is danger of injury or fire hazard.

- If, in case is damaged or insufficient, please contact your nearest dealer.

1) CONTROLLER

2) Extension line (8PIN)

3) Manual (this booklet)

------------------- 1unit

------------------- 1unit

------------------- 1copy

In case of CONTROLLER and MOTOR are

far away, refer to OPTION specification of

above table. It can be extended up to 2m

by single extension Line, and there is

worries of motor characteristics decline

when extend more than 2.5m that do not

use in this case.

KE-05

KE-10

KE-15

KE-20

0.5m

1m

1.5m

2m

Name of Product Length of Extension Line

2. Specifications

Option ( Extension Cable )

Characteristics

Model

Rated voltage and

Power Frequency

Single Phase AC110V 60Hz

Single Phase AC115V 60Hz

Single Phase AC220V 50/60Hz

Single Phase AC230V 50/60Hz

Single Phase AC240V 50Hz

Operating Voltage Range

Application Motor output

Speed control Range

Speed regulation

Speed setting

Ambient temperature Range

Storage temperature Range

Operating humidity Range

±10%(Contrast over rated voltage)

INDUCTION : 6 ~ 180W

REVERSIBLE : 6 ~ 90W

60Hz : 90~1700rpm

50Hz : 90~1400rpm

5%(Normal value)

Set by VOLUME

-10 ~ 40℃

-20 ~ 60℃

Below 85% (where is no condensation)

GUA-U GUA-C

2

3

3. CONTROLLER CODING SYSTEM

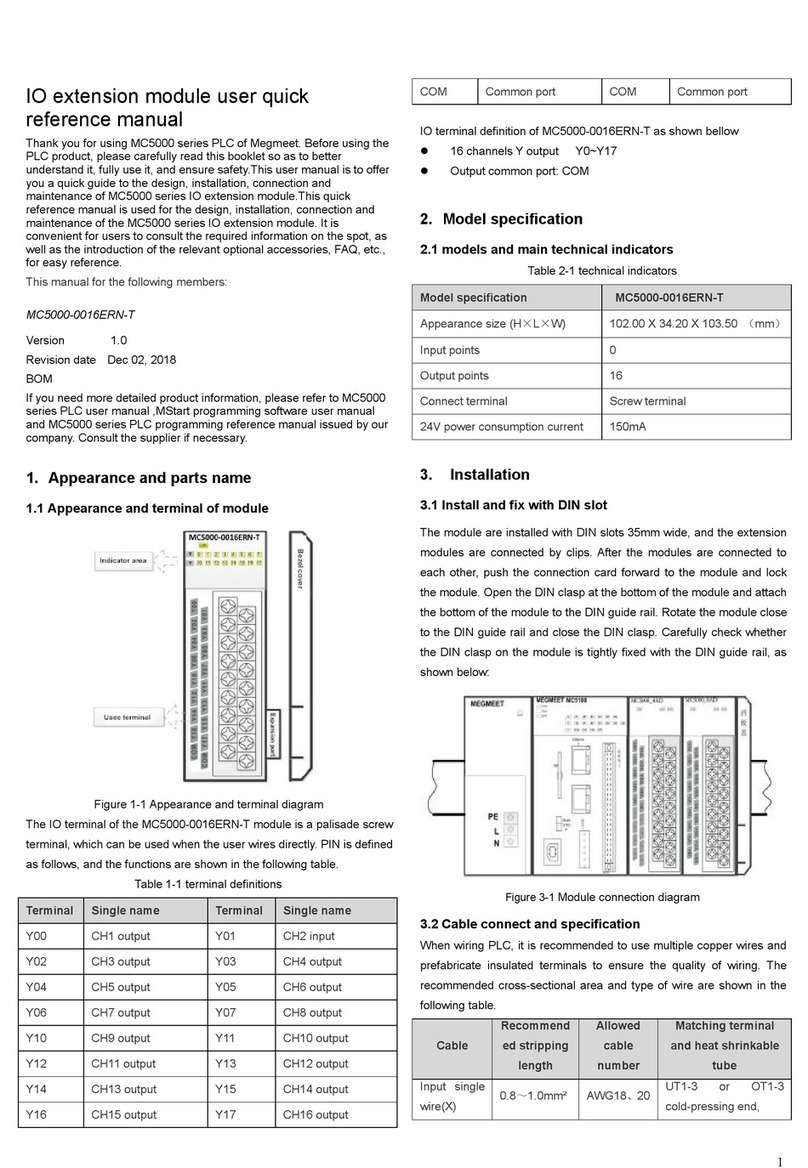

4. Outside View of Product

Front and side of main body

G U A C 60

06 : 6W

15 : 15W

25 : 25W

40 : 40W

60 : 60W

90 : 90W

120 : 120W

180 : 180W

C: Single Phase

AC220V 50/60Hz

AC230V 50/60Hz

AC240V 50Hz

U: Single Phase

AC110V 60Hz

AC115V 60Hz

Analogue

Type

Unit

Type

GGM

Co.,LTD.

3

4

Use and operate device according to the following precautions. If do not follow the

precautions, there may be electric shock, injury, worries of fire. Please keep certainly

because it is important contents.

1. Please check whether actual products is same with order sheet.

2. Use at place where ambient temperature range is -10~40 ℃ and humidity is 85%

or less. Avoid such places of direct sunlight, moisture and fat and should be installed

COVER when use in such places.

3. Should be avoided such places where is shock, serious impact, a lot of dusts,

flammability GAS, generating corrosive GAS.

4. Body COVER, KNOB etc. are resin products so that do not in the environments where

is methanol, benzene, organic solvents such as thinner, ammonia, caustic soda, strong

alkali.

5. There is ventil part on back side of CONTROLLER. It should be installed in a box not

to be contacted easily by outsiders.

6. Do not put combustibles absolutely on surroundings of MOTOR and CONTROLLER.

7. Do not use in place generated much static electricity.

8. There is no protective device in CONTROLLER. Should be installed overcurrent

protective device, earth leakage breaker, temperature thermal protector for safety.

Rear side of main body

5. Precaution

Installation Precautions

4

5

5

1. If do parallel operation with controlled devices in electric furnace of high capacity,

THYRISTOR for welding machine, there may be occasion of malfunction.

Separate and wire by separate power circuit.

2. When do wiring CW-COM, CCW-COM for switching the direction at wiring for

external remote control, please be careful not to be connected CW-COM,

CCW-COM terminals at the same time.

( when operate in state of connected CW-COM, CCW-COM both terminals,

there may be malfunction and can go hard on the motor. )

Wiring Precautions

1. Do not carry catching LEAD WIRE part of MOTOR. There is risk of disconnection.

2. Protect MOTOR SHAFT to protect against damage.

3. Do not hang down or get on MOTOR absolutely.

4. Take care water not to be bound in place with danger of water contact.

5.Do not operate with wet hands.

6. Turn off power certainly when do installing, moving, wiring and checking.

7. Do not touch absolutely on rotating part of MOTOR.

8. Do not use damaged MOTOR..

9. In case of discard this product, process as industrial waste.

10. If you need repairs, please contact us or purchased shop.

11. Do not remodel by the customer, because it is beyond the scope of the warranty

of our company.

Handling Precautions

1. Use surface temperature of MOTOR at below 90℃.

2. If do not use long period, please turn OFF power.

3. Set switch to 'STOP' position certainly before connect power.

4. Do not touch the hands or body while operating or just after stop.

There are worries of burn ecause MOTOR surface is high temperature.

5. If malfunction occurs, turn off the power immediately and stop.

6. When was power failure or THERMAL PROTECTOR was working, turn off power.

Due to an unexpected restart may cause injury.

Operating Precautions

6

6. Product Features

1. It is an UNIT product of detachable CONTROL MOTOR and CONTROL MOTOR.

CONNECTOR is connected with the ONE TOUCH. It is most suitable in usage that

remote control need.(There is not Moment stop function.)

2. There are assembled all needed devices of Speed control circuit, MOTOR CONDENSER,

speed setter etc.

in CONTROL UNIT. (There is also an external mounting type CONDENSER.)

Connect together MOTOR and CONTROL UNIT by exclusive use CONNECTOR and can

control the speed of MOTOR simply by connection AC terminals to POWER SOURCE.

3. If use an extension cord for the CONNECTOR OPTION, can be controlled speed by

apart MOTOR and MOTOR CONTROL UNIT part maximum up to 2.0m.

4. Variable speed range is widely available by 50Hz: 90~1400rpm, 60Hz: 90~1700rpm

speed widely available.

- MOTOR and SPEED CONTROLLER are packaged in a separate that please check

whether is available to use on the application MOTOR.

7. Application motor

K9 I G 40 N C SU

GGM

Co.,

LTD.

6:□60

7:□70

8:□80

9:□90

I:Induction

R:Reversible

S:Straight

G:Pinion

General

P:Pinion

Powerful

H:High

Strength

K:Key Type

6: 6W

15 : 15W

25 : 25W

40 : 40W

60 : 60W

90 : 90W

120 : 120W

180 : 180W

F:Cooling Fan

N:Non Fan

J:1Ø100V

50/60Hz

U:1Ø110V

60Hz

L:1Ø200V

50/60Hz

C:1Ø220V

50/60Hz

1Ø230V

50/60Hz

D:1Ø240V

50Hz

SU :

SPEED

CONTROL

UNIT TYPE

SP :

SPEED

CONTROL

PLUG IN

TYPE

6

7

8. How to use

When operating CW Direction

7

Setting for

acceleration / deceleration

time

CCW

COM

CW

SPEED OUT

SPEED OUT

AC

AC

Frame Ground

8

8

When operating CCW Direction

When operating both CW and CCW Direction

CCW

COM

CW

SPEED OUT

SPEED OUT

AC

AC

Frame Ground

CCW

COM

CW

SPEED OUT

SPEED OUT

AC

AC

Frame Ground

9

Connects LEAD line CONNECTOR of CONTROLLER UNIT and MOTOR, and connect AC

terminal to AC power.

If set RUN/STOP SWITCH of CONTROL UNIT by RUN side, MOTOR rotates clockwise

direction when view at output side. (It is SET to rotate clockwise when shipping.)

If turn knob of SPEED VOLUME of CONTROLLER UNIT to clockwise, MOTOR's rotation

is faster, if turn in contrary, the speed is delayed. MOTOR's SPEED is possible to control

and set in the range of 50Hz : 90~1400rpm, 60Hz : 90~1700rpm.

8-1 Operation

8-2 Change of speed

If set RUN/STOP SWITCH of CONTROL UNIT, MOTOR will stop.

This SWITCH is not ON/OFFof power that equip separate power switch in case of stop

MOTOR long hours.

④, ⑤ are terminals which use connecting revolution-indicator by SPEED OUT.

* Can see number of rotation connecting DIGITAL indication type revolution-indicator.

8-3 Stop

9

SWITCH Specification

1. Case of continuous operation

SWITCH Number

SW1

SW2

SWITCH Contact Capacity

AC125V or AC250V over 5A

AC125V or AC250V over 5A

When inverse MOTOR's direction of rotation in transfer mechanism such as GEAR HEAD,

please replace the terminal location to be positioned the position of terminals of ② COM

and ③ CW that are attached to CONTROL UNIT backside connected to ② COM and

① CCW position.

Connect Power CORD terminal always to ⑥ AC, ⑦ AC.

This time, please exchange power by OFF certainly and then connect.

2. When control CW/CCW rotation

As like the left [Figure 3], please replace the direction of rotation by installing Power

SWITCH (SW1) for power and exchange SWITCH (SW 2) for CW/CCW rotation.

Instantaneous CW/CCW rotation is impossible. For the moment, and replace

SWITCH(SW2) after turn off power SWITCH(SW1) and MOTOR stops perfectly.

8-4 Switching the direction of rotation

8-5 SPEED OUT

10

9. Mounting method

10

Processing of panels

1. Drill holes on mounting PANEL as shown figure below. Assemble CONTROLLER main

body and front COVER and fix using M4 screws and nuts.

2. Use mounting PANEL with thickness of less than 2mm.

TAP &

PANEL

Screw

11

Anomalies Check parts

Wiring

Terminal No.

①, ⑦

Check change

of speed

setting voltage

Lighten the

load.

3) CONDENSER is bad

Is it wrong wiring?

If the voltage does not

change, SPEED

CONTROLLER is bad.

If Power supply voltage is

changing 0V ~ up to

supply voltage

Is raised voltage

about AC20V at

approximately

1700rpm, about

AC18V at about

1400rpm ?

Supply power

voltage

correctly or set

unit model

properly.

Wiring Check wiring

In case does not happen,

speed generator is bad.

In case happen, SPEED

CONTROLLER is bad.

Wiring

correction

Speed

generator

terminal

④, ⑤

Is the power

voltage is correct?

Checklist

whether the

wrong wiring

Determination of

Breakdown Part

Check wiring

Measures for

Wiring

correction

Occasion

of MOTOR

does

not rotate

MOTOR

rotates but

speed is not

changed

MOTOR is

rotating but

heating

state is not

normal.

10. Failure Causes and Countermeasures

11

2) Overload

1) MOTOR is bad

※ Contact your vendor or our second factory if you haveany questions about

product or requirepost-sales service.

Leader of geared motor GGM CO.,LTD. http://www.ggm.co.kr

Headquarters / 1st Factory

22, Gyeongin-ro 3beon-gil, Bucheon-si,

Gyeonggi-do, Republic of Korea

TEL : 032-664-7790 FAX : 032-611-7791

Attached research institute / No. 2 factory

180, Oksan-ro, Bucheon-si, Gyeonggi-do,

Republic of Korea

TEL : 032-684-7791 FAX : 032-683-5059

12

This manual suits for next models

2

Table of contents

Popular Control Unit manuals by other brands

Burkert

Burkert 6027 operating instructions

Jinmuyu Electronics

Jinmuyu Electronics JMY601H user manual

Kaval

Kaval LINKnet OFR400 Series user manual

Nice

Nice OTA 30 Installation instructions manual

VLT

VLT 670 Series Installation, operating, & maintenance instructions

Wieland

Wieland gesis FLEX-8/0 (12) installation instructions