IO extension module user quick

reference manual

Thank you for using MC5000 series PLC of Megmeet. Before using the

PLC product, please carefully read this booklet so as to better

understand it, fully use it, and ensure safety.This user manual is to offer

you a quick guide to the design, installation, connection and

maintenance of MC5000 series IO extension module.This quick

reference manual is used for the design, installation, connection and

maintenance of the MC5000 series IO extension module. It is

convenient for users to consult the required information on the spot, as

well as the introduction of the relevant optional accessories, FAQ, etc.,

for easy reference.

This manual for the following members:

MC5000-0016ERN-T

Version 1.0

Revision date Dec 02, 2018

BOM

If you need more detailed product information, please refer to MC5000

series PLC user manual ,MStart programming software user manual

and MC5000 series PLC programming reference manual issued by our

company. Consult the supplier if necessary.

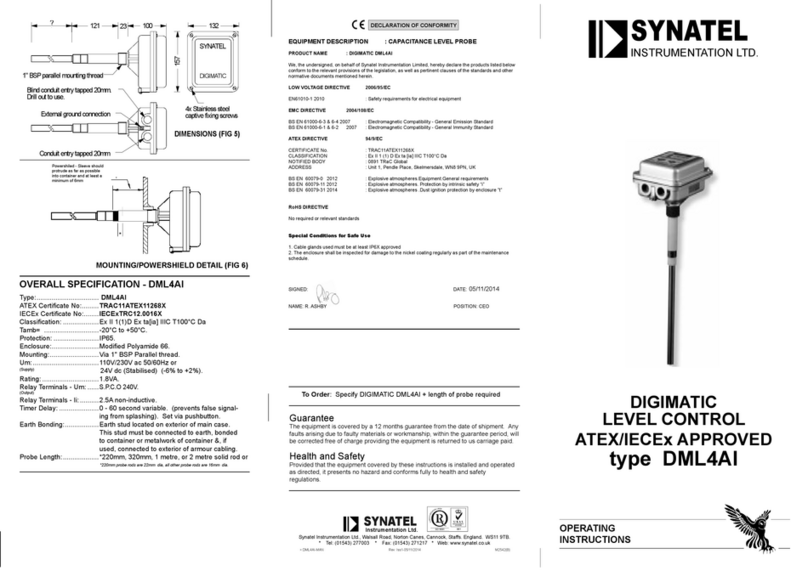

1. Appearance and parts name

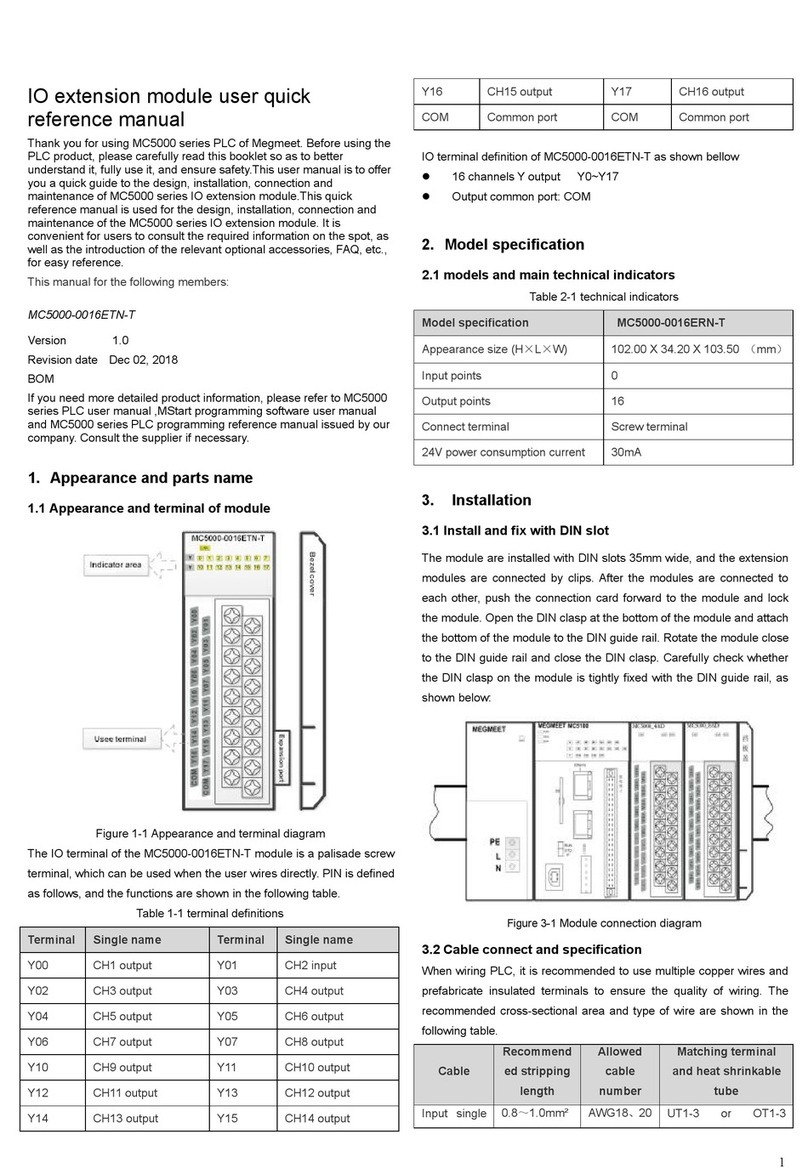

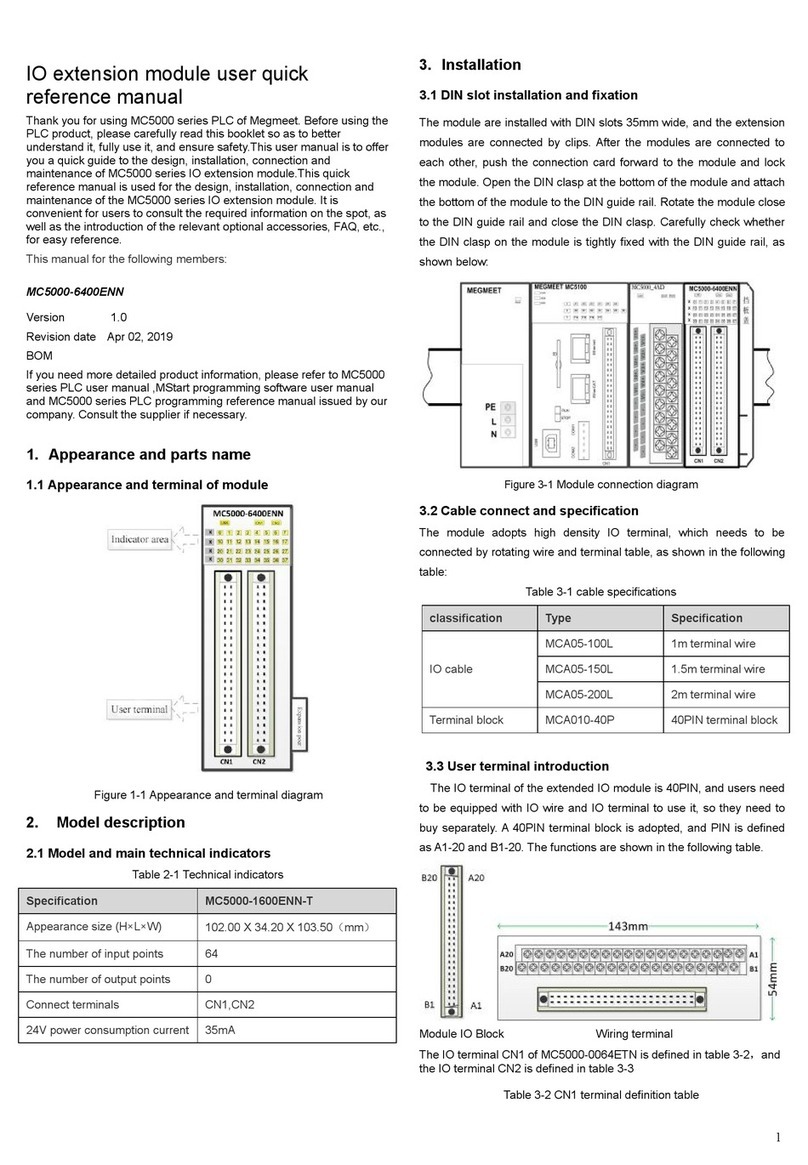

1.1 Appearance and terminal of module

Figure 1-1 Appearance and terminal diagram

The IO terminal of the MC5000-0016ERN-T module is a palisade screw

terminal, which can be used when the user wires directly. PIN is defined

as follows, and the functions are shown in the following table.

Table 1-1 terminal definitions

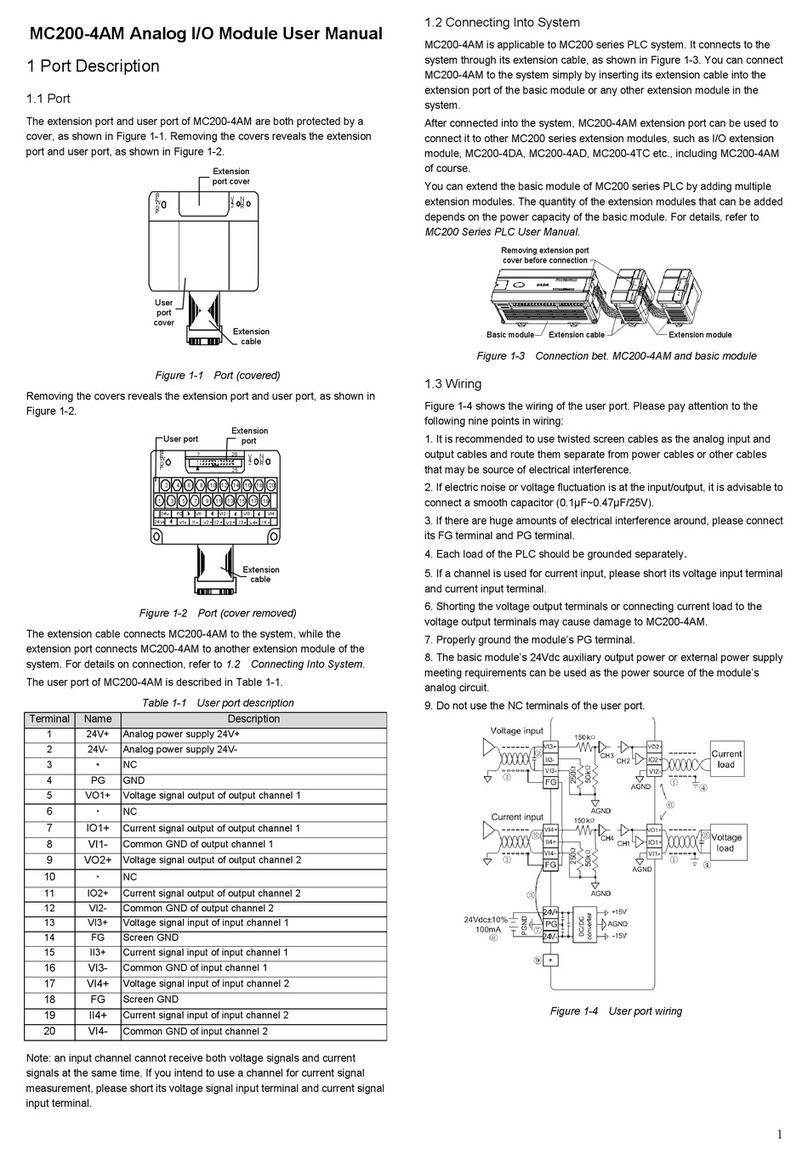

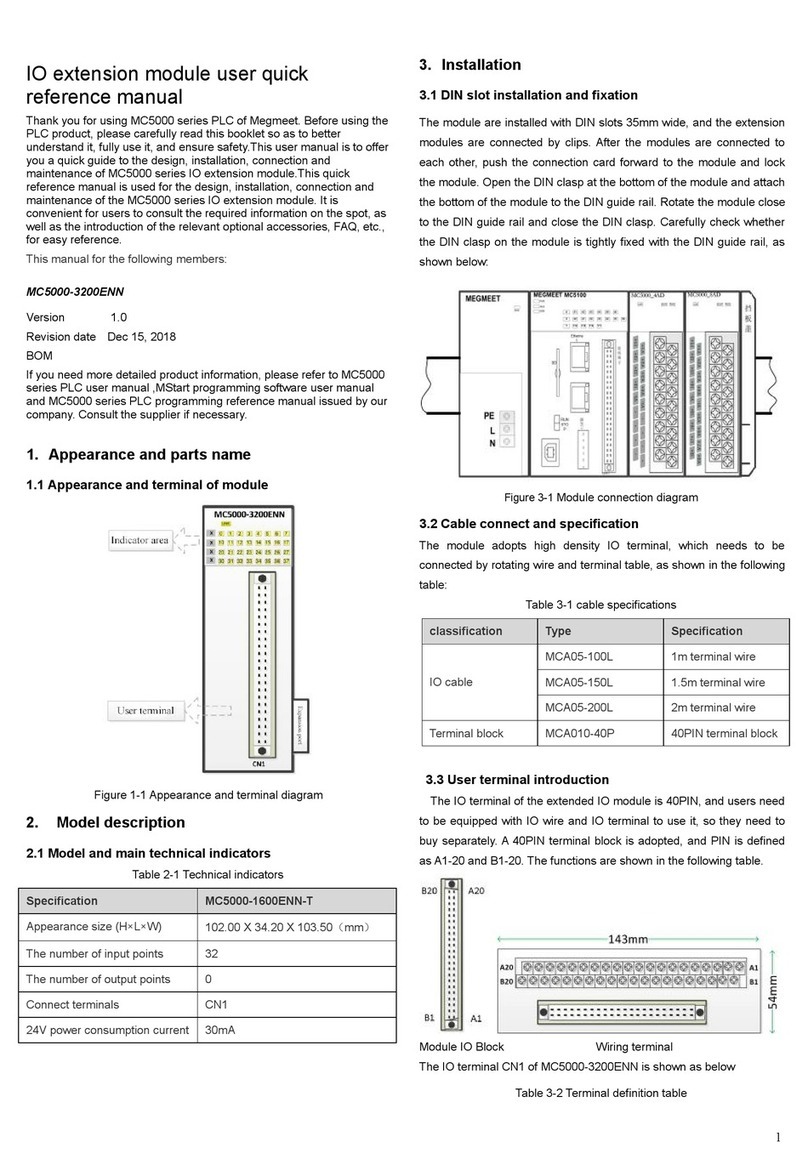

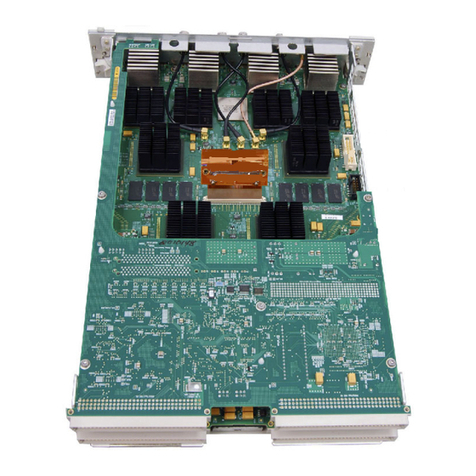

3. Installation

3.1 Install and fix with DIN slot

The module are installed with DIN slots 35mm wide, and the extension

modules are connected by clips. After the modules are connected to

each other, push the connection card forward to the module and lock

the module. Open the DIN clasp at the bottom of the module and attach

the bottom of the module to the DIN guide rail. Rotate the module close

to the DIN guide rail and close the DIN clasp. Carefully check whether

the DIN clasp on the module is tightly fixed with the DIN guide rail, as

shown below:

Figure 3-1 Module connection diagram

3.2 Cable connect and specification

When wiring PLC, it is recommended to use multiple copper wires and

prefabricate insulated terminals to ensure the quality of wiring. The

recommended cross-sectional area and type of wire are shown in the

following table.