Page 16 SP Manual

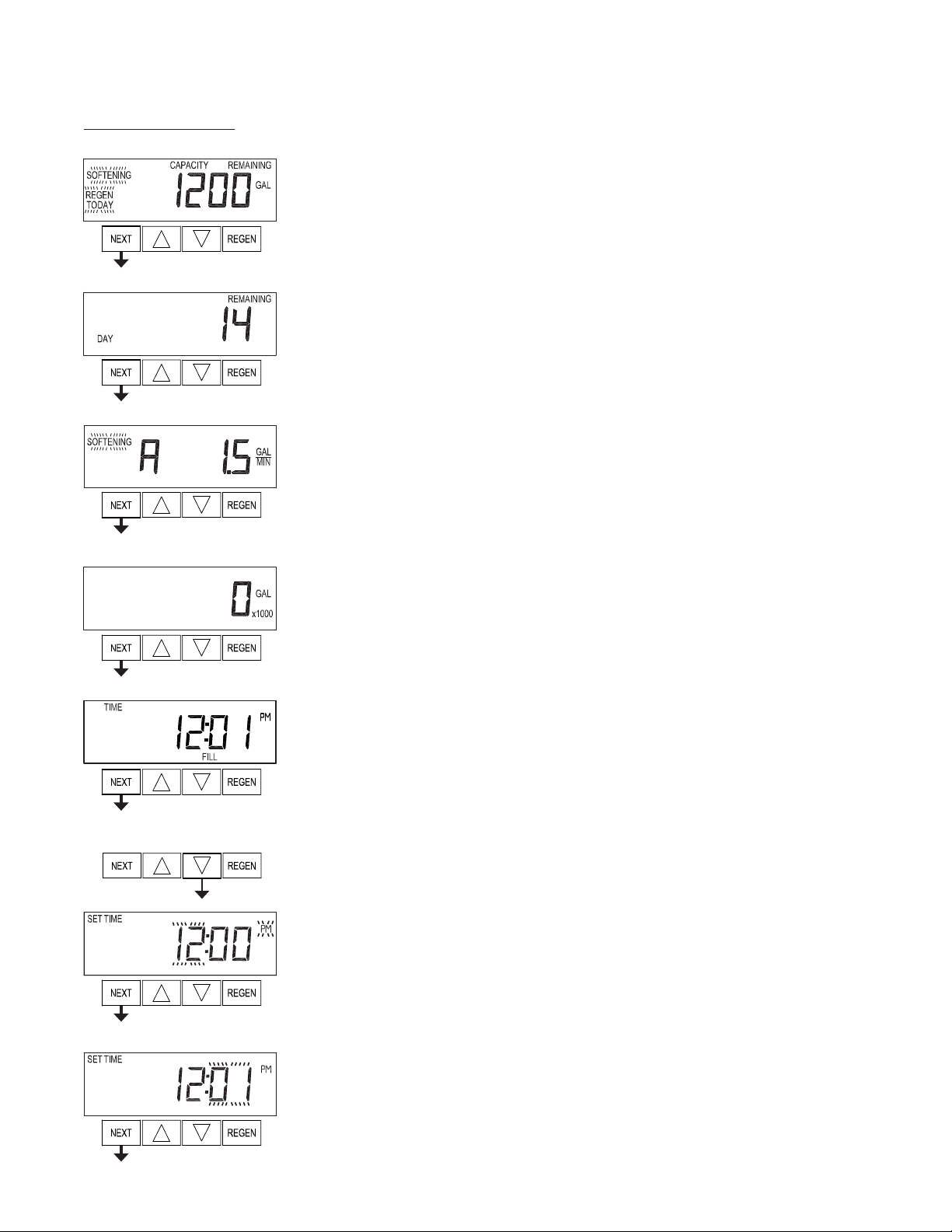

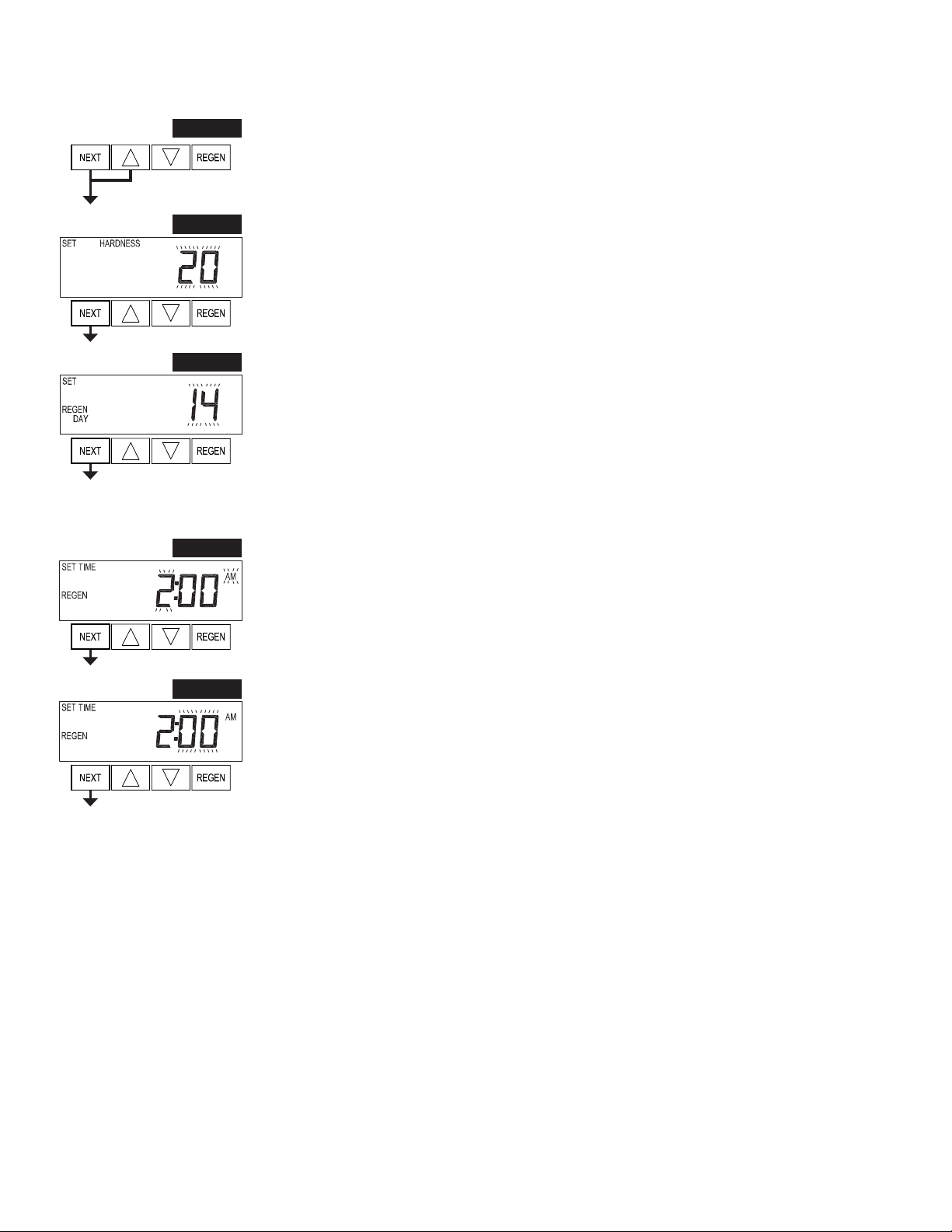

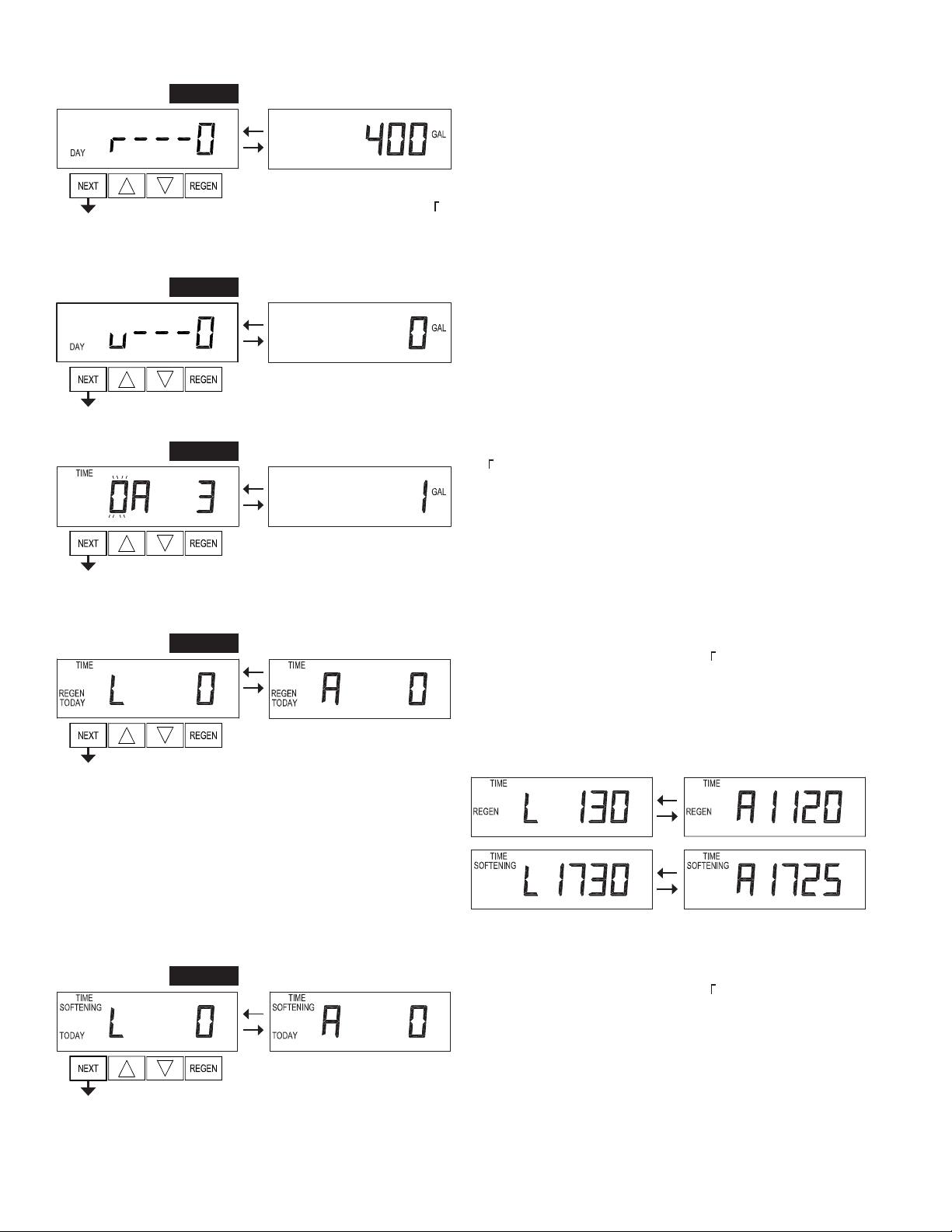

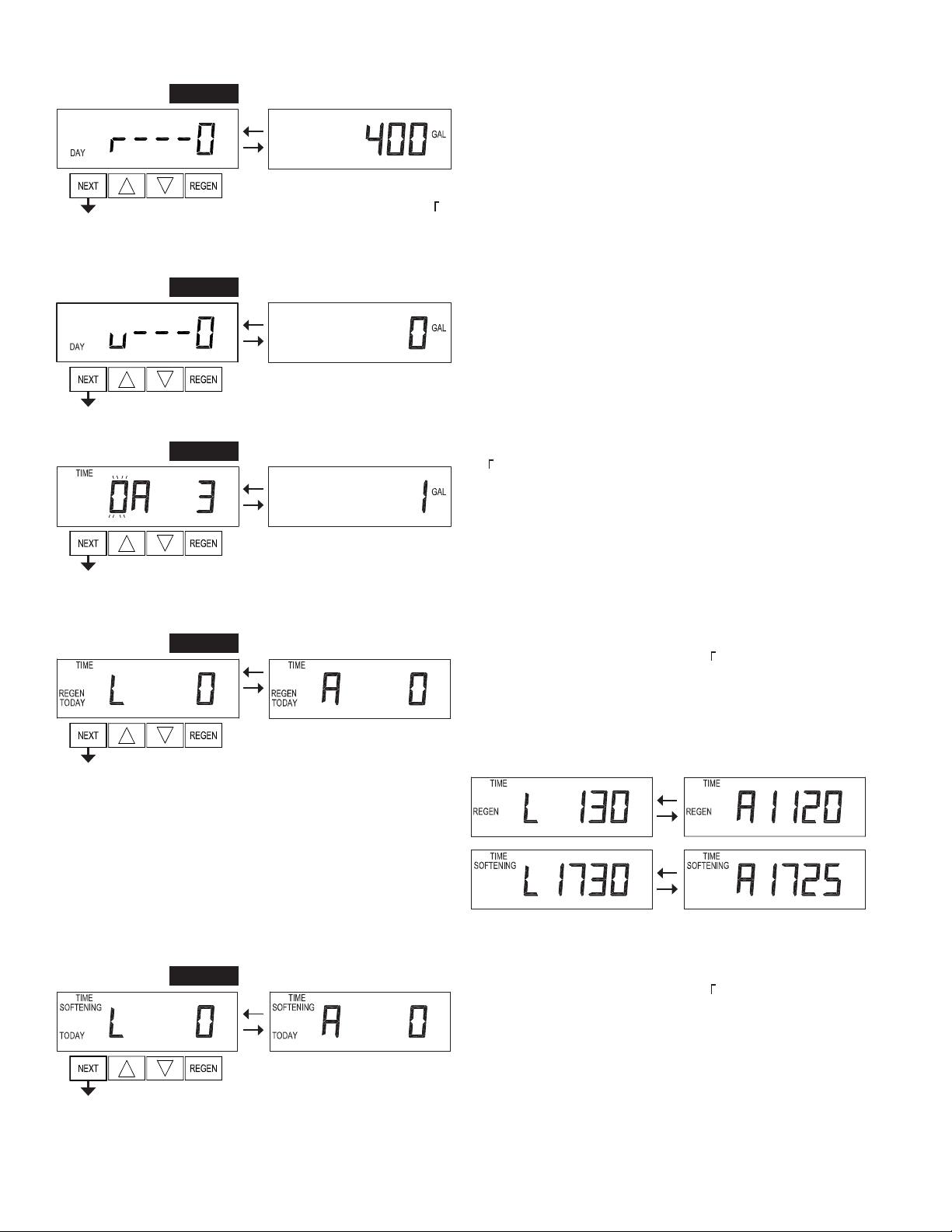

Step9D– Volume, reserve capacity used for last 7 days: If the valve is

setupasasoftener,ameterisinstalled,andSetVolumeCapacityisset

to“Auto,”thisdisplayshowsday0(fortoday)andflashesthereserve

capacity. Pressing will show day 1 (which would be yesterday) and

flashes the reserve capacity used. Pressing again will show day 2

(the day before yesterday) and the reserve capacity. Keep pressing

to show the capacity for days 3, 4, 5 and 6. can be pressed to move backwards in the day series. This

displaydoesnotappearif 1.0 issetinStep2CS,ifALTA orALT BareselectedinStep5CS,oranytime

the reserve capacity is not determined by the control.

Press NEXT at any time to go to Step 10D. Press REGEN to return to previous step.

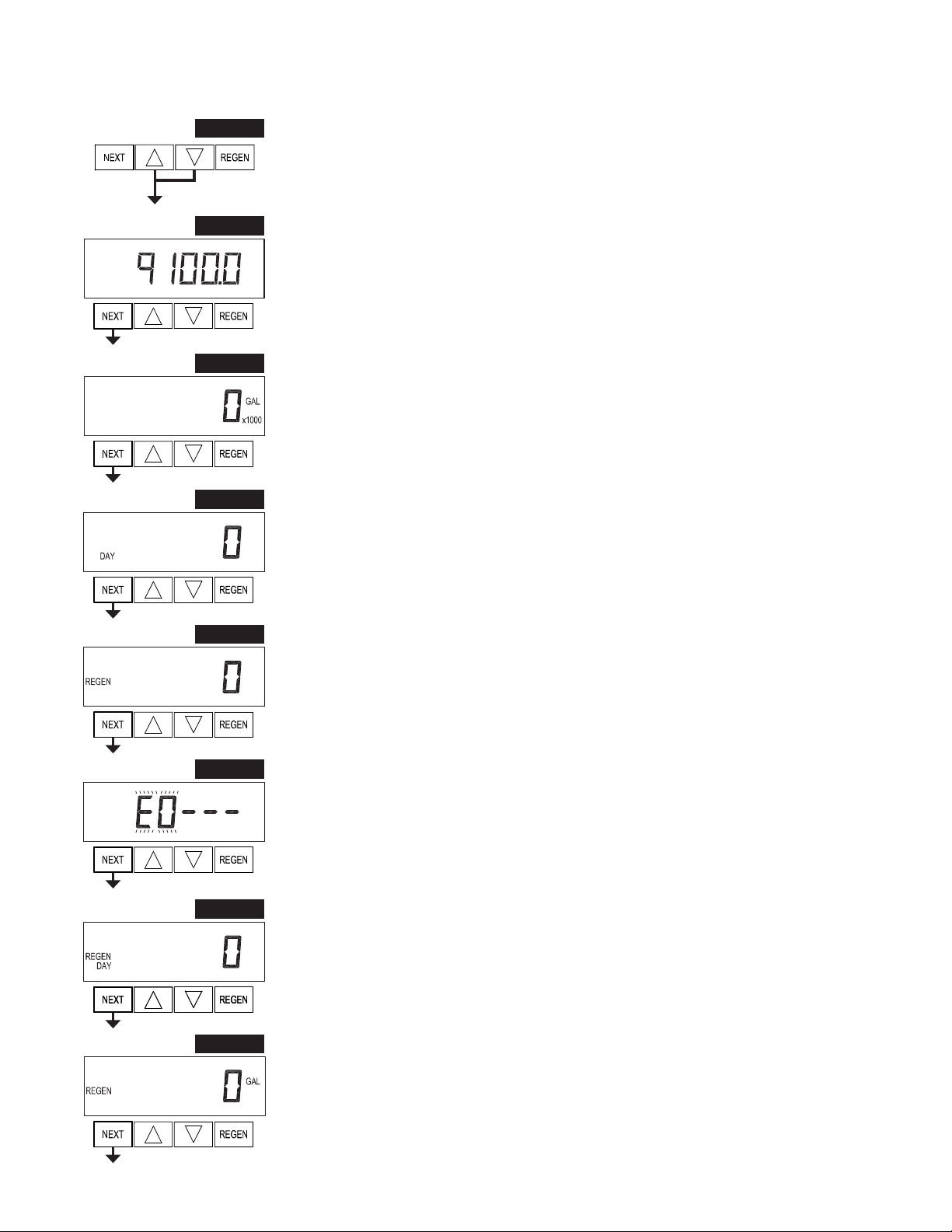

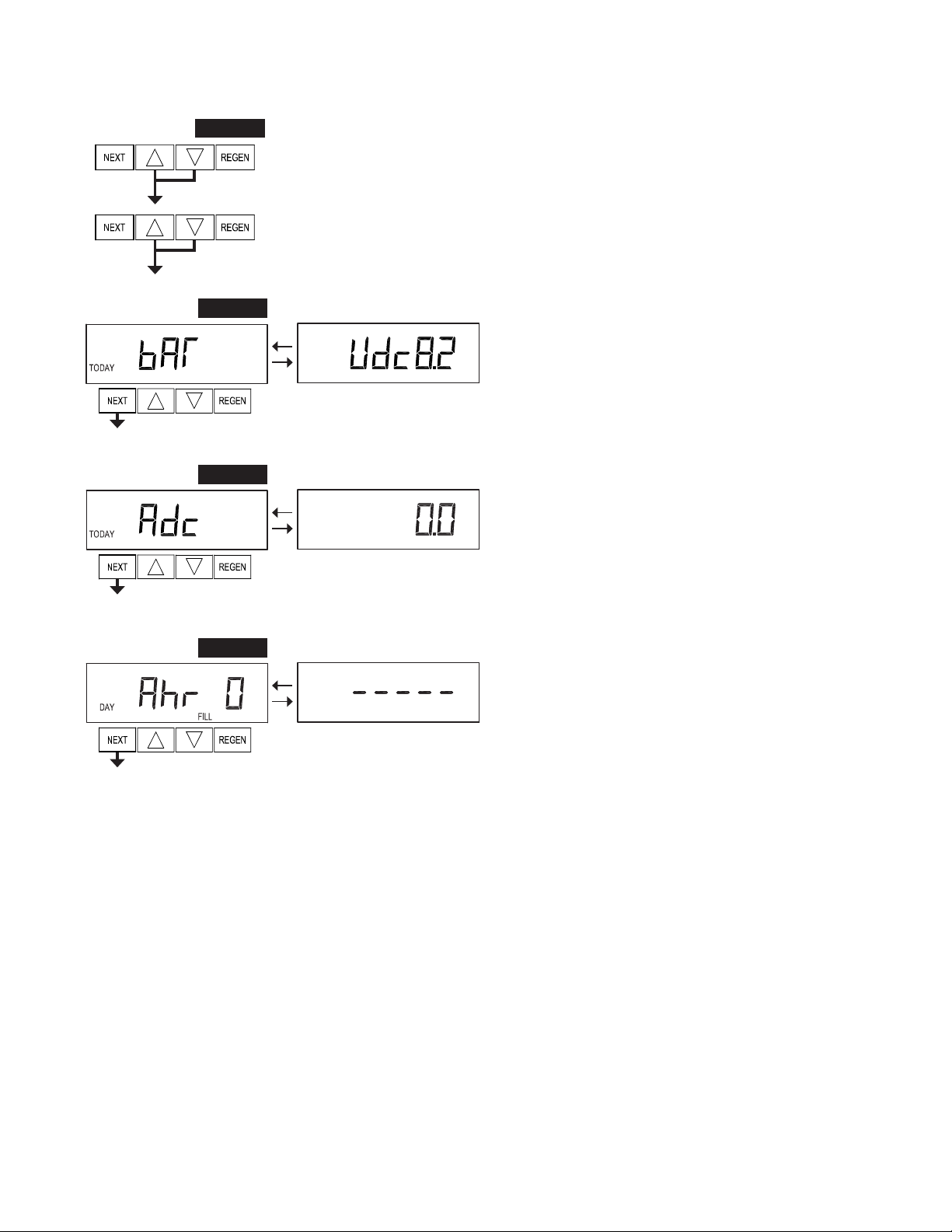

Step 10D – Volume, 63-day usage history: This display shows day 0

(for today) and flashes the volume of water treated today. Pressing

willshowday1(whichwouldbeyesterday)andflashesthevolumeof

water treated on that day. Continue to press toshow the maximum

volumeofwatertreatedforthelast63days.Ifaregenerationoccurred

onthedaytheword“REGEN”willalsobedisplayed.Thisdisplaywill

show dashes if a water meter is not installed.

Press NEXT at any time to go to Step 11D. Press REGEN to return to previous step.

Step 11D – Twin Tank Valve transfer history: only displays when

1.0 was selected in Step 2CS. Use or to scroll through the last

10 tank transfers. The first position in the display ranges from 0 to 9

with the lowest number being the most recent transfer. The second

position in the display will be either “A” or “b”. If “A” then the tank

withthevalveonitwasinservice,if“b”the tankwiththein/outhead

onitwasinservice.Thenextthreedigitsrepresentthenumberofhoursagothatthetransferoccurred.The

displayalternateswiththevolumethatwastreatedbeforethetanktransferred.PressNEXTatanytimeto

go to Step 12D. Press REGEN to return to previous step.

Step 11D

Step13D–MAVDriveHistoryinthedirectionofextendedpistonrod

position.Displaywillonlybeshownif1.0 isselectedinStep2CS,or

OFF is not selected in Step 4CS. Up to a four digit number

willappearafterthe“L”whichstandsforlatestand“A”whichstands

foraverage. Drivetimeis measuredin 1/100ofa second;i.e.,a 17.15

second move is displayed as “1715”. Press and hold and for 3

secondswhileinStep 13D to reset the MAV drive history in both the extended and retracted pistonrod

position. To view the old MAV drive history data see Step 12D.

Press NEXT at any time exit Diagnostics. Press REGEN to return to previous step.

Step 13D

EXIT DIAGNOSTICS

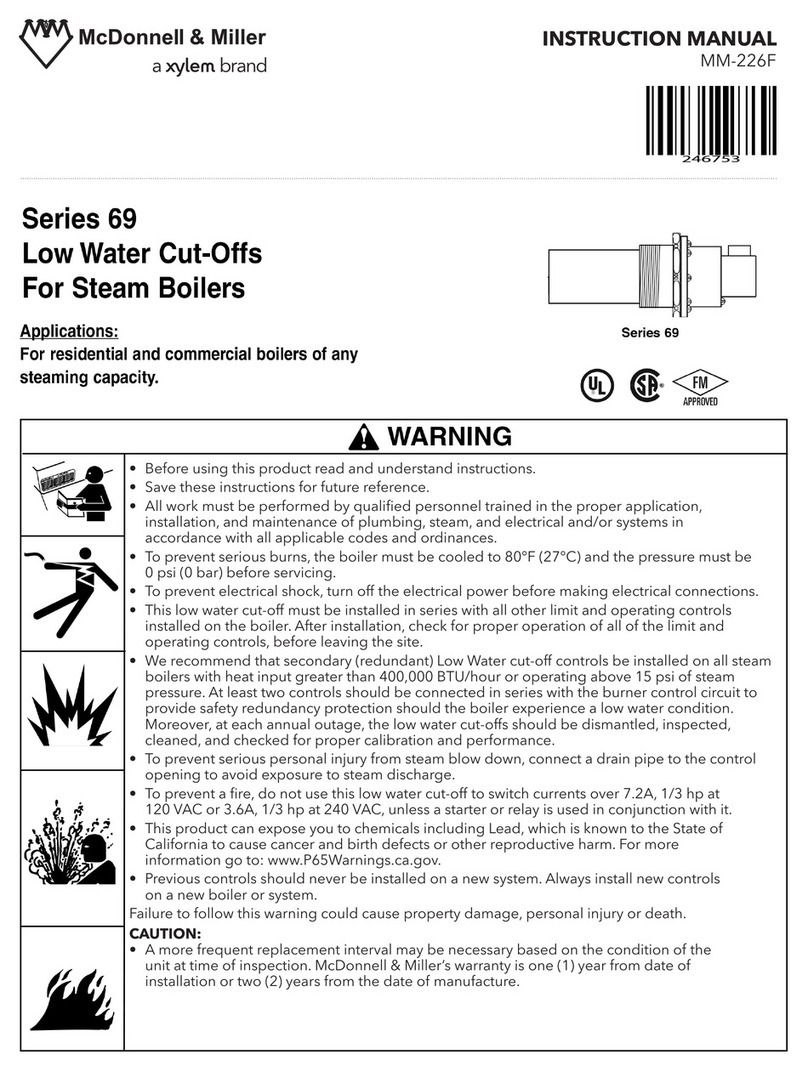

Step12D–MAVDriveHistoryinthedirectionofretractedpistonrod

position.Displaywillonlybeshownif1.0 isselectedinStep2CS,or

OFFisnotselectedinStep5CS.Uptoafourdigitnumberwillappear

afterthe“L”whichstandsforlatestand“A”whichstandsforaverage.

Drivetimeismeasuredin1/100ofasecond;i.e.,a17.10secondmove

is displayed as “1710”. Press NEXT at any time to go to Step 13D.

Press REGEN to return to previous step.

Step 12D

Press and hold and buttons for 3 seconds while in Step 12D to

resettheMAVdrivehistoryinboththeretractedandextendedpiston

rod position. To view the old MAV drive history data for retracted

and extended rod position press and hold REGEN and while in

Step 12D. Press NEXT to advance display to the old MAV drive

history.

Step 9D

Step 10D