CH Hanson Norse 9681115 Instructions for use

6˝ x 9˝

Belt/Disc

Sander

Operating Instructions & Parts Manual

9643069.01 0518

Model 9681115

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 1

2

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NO SE Operating Manual & Parts List 9681115

Please read and save hese ins ruc ions. Read carefully before a emp ing o assemble, ins all,

opera e or main ain he produc described.

Pro ec yourself and o hers by observing all safe y informa ion. Failure o comply wi h ins ruc ions

could resul in personal injury and/or proper y damage! re ain ins ruc ions for fu ure reference.

Model #: ________________________

Serial #: _________________________

Purchase Da e: ___________________

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 2

GETTI G STARTED

Structural Requirements

Make sure all supporting structures and load attaching devices are

strong enough to hold your intended loads. If in doubt, consult a

qualified structural engineer.

Electrical Requirements

The power supply to the Sander needs to be 120 volt/ 8.0 amp,

single phase, 60 Hz. The standard allowable voltage variation is

plus or minus 10%.

Tools eeded:

Standard mechanic’s hand tool set.

U PACKI G

Be careful not to touch overhead power

lines, pipin , li htin , etc. if liftin

equipment is used. Sander wei hs approximately 88 lbs,

proper tools, equipment and qualified personnel should be

employed in all phases of unpackin and installation.

Cartons should be handled with care to avoid damage from

dropping, bumping, etc. Store and unpack cartons with correct side

up. After unpacking Sander, inspect carefully for any damage that

may have occurred during transit. Check for loose, missing or

damaged parts. If any damage or loss has occurred, claim must be

filed with carrier immediately. Check for completeness. Immediately

report missing parts to dealer.

Sander is shipped partially assembled. End user will need to

assemble loose parts to machine.

IMPOR AN : The tool has been coated with a protective coating.

In order to ensure proper fit and operation, the coating must be

removed. Remove coating with mild solvents such as mineral

spirits and a soft cloth. Nonflammable solvents are recommended.

After cleaning, cover all exposed metal surfaces with a light coating

of oil.

Never use hi hly volatile solvents. Avoid

ettin cleanin solution on paint as it

may tend to deteriorate these finishes. Use soap and water

on painted components.

Contents:

• Sander (1)

• Miter gauge assembly (1)

• Fence support (1)

• Table assembly (1)

• Hardware bag (1)

• Rubber foot (4)

• Hex wrench (1)

• Operating Instructions and Parts Manual (1)

Unpack:

• Carefully unpack Sander from carton. Do not discard packing

materials until after machine has been inspected for damage

and completeness. Locate loose parts and set aside.

Inspect:

• After unpacking the unit, carefully inspect for any damage that

may have occurred during transit. Check for loose, missing or

damaged parts. Shipping damage claims must be filed with the

carrier.

• All tools should be visually inspected before use, in addition to

regular periodic maintenance inspections.

• Be sure that the voltage labeled on the unit matches your

power supply.

• See General Safety Instructions, Cautions and

Warnings as shown.

SAFETY RULES

For your own safety, read all of the

instructions and precautions before

operatin tool.

PROPOSI ION 65 WARNING: Some dust created by

using power tools contain chemicals known to the state

of California to cause cancer, birth defects or other

reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry

products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area and work with approved safety

equipment. Always wear OSHA/NIOSH approved, properly fitting

face mask or respirator when using such tools.

Always follow proper operatin

procedures as defined in this manual even

if you are familiar with the use of this or similar tools.

Remember that bein careless for even a fraction of a

second can result in severe personal injury.

Be Prepared for Job

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI Z87.1.

Everyday glasses have only impact resistant lenses. They are

NO safety glasses.

3

NO SE Operating Manual & Parts List 9681115

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 3

SAFETY RULES (CO TI UED)

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

Prepare Work Area for Job

• Keep work area clean. Cluttered work areas invite accidents.

• Do not use power tools in dangerous environments. Do not

use power tools in damp or wet locations. Do not expose

power tools to rain.

• Work area should be properly lighted.

• Proper electrical receptacle should be available for tool. Three-

prong plug should be plugged directly into properly grounded,

three-prong receptacle.

• Extension cords should have a grounding prong and the three

wires of the extension cord should be of the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentional use of power tools.

Tool Should Be Maintained

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting

procedures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that

adjusting tools are removed before switching machine on.

• Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

• Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condition

that may affect a tool’s operation.

• A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs. (Use

parts list provided to order repair parts.)

Know How to Use Tool

• Use right tool for job. Do not force tool or attachment to do a

job for which it was not designed.

• Disconnect tool when changing the belt or abrasive disc.

• Avoid accidental start-up. Make sure that the tool is in the OFF

position before plugging in.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Keep hands away from moving parts and sanding surfaces.

• Never leave tool running unattended. Turn the power off and

do not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is tipped

or if blade is unintentionally contacted.

• Know your tool. Learn the tool’s operation, application and

specific limitations.

• Use recommended accessories. Use of improper accessories

may cause risk of injury to persons.

• Handle workpiece correctly. Protect hands from possible injury.

• Turn machine off if it jams. Belt jams when it digs too deeply

into workpiece. (Motor force keeps it stuck in the work.)

• Support workpiece with miter gauge, belt platen or work table.

• Maintain 1/16˝ maximum clearance between table and sanding

belt or disc.

Think safety! Safety is a combination of

operator common sense and alertness at

all times when tool is bein used.

Do not attempt to operate tool until it is

completely assembled accordin to

instructions.

SPECIFICATIO S

Belt size 6 x 48˝

Belt platen area 6 x 141⁄2˝

Belt drum dimensions 27⁄8x 61⁄8˝

Table dimensions 6 x 111⁄2˝

Table tilts 0 to 45º

Dust chute diameter 2˝

Belt speed 1836 SFPM

Disc diameter 9˝

Disc speed 2510 RPM

Base dimensions 12 x 181⁄8˝

Switch SP, Locking rocker

Motor 1 HP, 120 V, 8.0 Amps

Weight 72 lbs

Shipping weight 76 lbs

4

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NO SE Operating Manual & Parts List 9681115

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 4

ASSEMBLY

Do not attempt assembly if parts are

missin . Use this manual to order repair

parts.

the sander must NOT be plu ed in and

the power switch must be in the "OFF"

position until assembly is complete.

Installing the Foot Pads

Four rubber foot pads are supplied to protect your work surface,

and to reduce any vibration that may develop when the sander is

operating.

1. Tilt the sander up and slide the feet onto each of the four

corners of the sander. No hardware is needed. See Figure 1.

Installing the Sanding Belt Fences

The sander includes two fences for use with the sanding belt. The

small fence/platen attaches directly to the sanding belt frame, and

is used for supporting small items being sanded.

The larger fence/platen attaches onto the small fence. It gives a

larger support surface for sanding large work pieces.

NOTE: These parts may be pre-assembled at the time of delivery.

If not, follow the following parts assembly:

1. Install the small fence onto the sanding belt frame with the four

hex screws and washers. See Figure 2.

2. Insert two star-head screws through the countersunk holes in

the large fence and install the knobs on their threaded ends.

(Washers shown in Figure 3 are optional, not included with

sander).

3. Slide the large fence’s two screws with knobs over the two

slots in the small fence and fasten in place. Pending on the

material being sanded, the large fence can easily be removed

by just loosening the two knobs and sliding it off the small

fence. See Figure 3.

Installing the Disc Table

Refer to figures 4 and 5.

The larger worktable is used with the sanding disc. It should be

used to support workpieces in all sanding operations except inside

curve applications.

1. Locate worktable handles and washers in parts bag.

2. Place the worktable onto the sander frame, aligning the semi-

circle slot with the threaded hole.

3. Place a washer on threaded shaft of each worktable handle,

insert through semi-circular slot, and tighten into threaded hole.

Repeat on other side of table.

4. Adjust worktable to level or any angle between 0° and 45° for

sanding.

NOTE: Always check to make sure the handles are tight before

beginning any sanding operation.

5

NO SE Operating Manual & Parts List 9681115

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

Figure 2 - Install small fence.

Figure 3 - Install fence knobs.

Figure 4

Work Table

Washers

Lock Handle

Figure 1 - Install foot pads.

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 5

ASSEMBLY (CO TI UED)

Mounting PSA Sandpaper Disc

NOTE: The 6 x 9˝ Belt Disc Sander only uses 9˝ diameter abrasive

sanding discs with Pressure Sensitive Adhesive (PSA) backing. To

apply the sandpaper:

1. The metal disc plate is pre-installed on the machine. Locate the

9˝ PSA sandpaper disc and peel the protective backing off.

2. Center the sandpaper over the metal disc plate, then press the

sandpaper firmly in place. See Figure 6.

See page 9 for instructions on changing the sandpaper disc.

Before plu in in and turnin on the

machine, mount the sander and complete

all of the adjustments in the instructions that follow. This

will ensure that the sander is correctly set up for safe and

efficient operation.

I STALLATIO

The machine must not be plu ed in and

the power switch must be in the off

position until all adjustments are complete.

Mount Sander

NOTE: Although compact, the sander is heavy. At least two people

are required to lift from carton.

Choose a suitable location to mount the sander. The sander must

be installed in a place with ample lighting and correct power supply.

Make sure there is plenty of room for moving the workpiece. There

must be enough room that neither operators nor bystanders will

have to stand in line with the wood while using the tool. Allow room

so that belt assembly can be positioned horizontally.

Figure 7 shows the base dimensions, mounting holes and required

space to allow for table assembly and belt assembly in horizontal

position.

The sander must be bolted to a firm, level surface. Sander can be

installed on a workbench or a tool stand using bolts, lock washers

and hex nuts (not supplied).

6

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NO SE Operating Manual & Parts List 9681115

Figure 7 – Base dimension and required space.

171⁄2˝18˝

12˝

21˝

30˝

3/8˝

Dia.

81⁄2˝

Figure 5

Figure 6 - Mount sandpaper disc.

Lock Handle

Washer

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 6

I STALLATIO (CO TI UED)

Adjusting Disc Table Angle

Ensure sander is disconnected from the power supply prior to

commencing work.

1. To check the trueness of the 90º angle of the disc sanding

table, place a square or other measuring device on the table

with the other end against the sanding disc. See Figure 8.

2. Loosen the disc table adjustment handle, and adjust table

angle to 90º.

3. Re-tighten the disc table adjustment handle.

4. Adjust the angle scale pointer to 0°.

5. To adjust the disc table to another angle, loosen the disc table

adjustment handle.

6. Set the table at the desired angle using the angle scale pointer.

7. Re-tighten the disc table adjustment handle.

To avoid jammin the work piece or

fin ers between the table and sandin

surface, the table ed e should be set to a maximum of 1/16

inches away from sandin surface. See Fi ure 9.

Adjusting Belt Assembly Position

The sanding belt frame can be easily adjusted from a horizontal

position to a vertical position, or any other position to assist your

sanding operation.

1. Loosen the hex screw that pulls the split casting together. This

allow the sanding belt frame to be moved to the work angle

desired. See Figure 10.

2. Once the sanding belt frame is at the desired work angle, re-

tighten the hex screw to secure it in place.

3. In the horizontal position, there are two vertical padded hex

screws that support the sanding belt frame. These should be

checked and adjusted, if necessary, to make sure that they both

touch the sanding belt frame supports. These screws will help

relieve pressure on the casting during work. See Figure 11.

7

NO SE Operating Manual & Parts List 9681115

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

Figure 8 - Check disc trueness.

Figure 9

1/16˝

Figure 10

Figure 11

Sanding belt

frame supports.

Hex Screw

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 7

I STALLATIO (CO TI UED)

All electrical connections must be

performed by a qualified electrician.

Power Source

Connect sander to a supply circuit protected by a circuit breaker or

time-delay fuse.

The motor is designed for operation on the voltage and frequency

specified. Normal loads will be handled safely on voltages not more

than 10% above or below the specified voltage.

Running the unit on voltages which are not within the range may

cause overheating and motor burn-out. Heavy loads require that

the voltage at motor terminals be no less than the voltage specified.

Power supply to the motor is controlled by a single pole locking

rocker switch. Remove the key to prevent unauthorized use.

Grounding Instructions

Improper connection of equipment

roundin conductor can result in the risk

of electrical shock. Equipment should be rounded while in

use to protect operator from electrical shock.

Check with a qualified electrician if grounding instructions are not

understood or if in doubt as to whether the tool is properly

grounded.

This tool is equipped with an approved 3-conductor cord rated at

300V and a 3-prong grounding type plug (See Figure 15) for your

protection against shock hazards.

rounding plug should be plugged directly into a properly installed

and grounded 3- prong grounding-type receptacle, as shown

(Figure 12).

Do not remove or alter grounding prong in any manner. In the event

of a malfunction or breakdown, grounding provides a path of least

resistance for electrical shock.

Do not permit fin ers to touch the

terminals of plu when installin or

removin from outlet.

Plug must be plugged into matching outlet that is properly installed

and grounded in accordance with all local codes and ordinances.

Do not modify plug provided. If it will not fit in outlet, have proper

outlet installed by a qualified electrician.

Inspect tool cords periodically, and if damaged, have repaired by an

authorized service facility.

reen (or green and yellow) conductor in cord is the grounding

wire. If repair or replacement of the electric cord or plug is

necessary, do not connect the green (or green and yellow) wire to a

live terminal.

Where a 2-prong wall receptacle is encountered, it must be

replaced with a properly grounded 3-prong receptacle installed in

accordance with National Electric Code and local codes and

ordinances.

This work should be performed by a

qualified electrician.

A temporary 3-prong to 2-prong grounding adapter (See Figure 13)

is available for connecting plugs to a two pole outlet if it is properly

grounded.

Do not use a 3-prong to 2-prong grounding adapter unless

permitted by local and national codes and ordinances.

(A 3-prong to 2-prong grounding adapter is not permitted in

Canada.) Where permitted, the rigid green tab or terminal on the

side of the adapter must be securely connected to a permanent

electrical ground such as a properly grounded water pipe, a

properly grounded outlet box or a properly grounded wire system.

Many cover plate screws, water pipes and outlet boxes are not

properly grounded. To ensure proper ground, grounding means

must be tested by a qualified electrician.

Extension Cords

• The use of any extension cord will cause some drop in voltage

and loss of power.

• Wires of the extension cord must be of sufficient size to carry

the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W. .)

extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If the extension cord is worn, cut or damaged in any way,

replace it immediately.

Extension Cord Length

Length Wire Size A.W.G.

Up to 25 ft 18

25 – 50 ft 16

NOTE: Using extension cords over 50 ft. long is not

recommended.

8

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NO SE Operating Manual & Parts List 9681115

Figure 12 – 3-Prong receptacle

Properly grounded outlet.

rounding Prong

3-Prong Plug

Figure 13 – 2-Prong receptacle with adapter

rounding Lug

Adapter

3-Prong Plug 2-Prong

Receptacle

Make sure this is

connected to a known

grounded receptacle.

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 8

OPERATIO

Operation of any power tool can result in

forei n objects bein thrown into eyes

which can result in severe eye dama e. Always wear safety

o les complyin with United States ANSI Z87.1 before

commencin power tool operation. Safety o les are

available throu h your Grain er catalo .

Always observe the followin safety

precautions:

• Whenever adjusting or replacing any parts on the tool, turn

switch off and remove the plug from power source.

• Recheck table handles and bolt. They must be tightened

securely.

• Make sure all guards are properly attached and securely

fastened.

• Make sure all moving parts are free and clear of any

interference.

• Make sure all fasteners are tight and have not vibrated loose.

• With power disconnected, test operation by hand to verify

clearance and adjust if necessary.

• Always wear eye protection or face shield.

• Make sure abrasive belt tracks properly. Correct tracking gives

optimum performance.

• After turning switch on, always allow belt to come up to full

speed before sanding or grinding.

• Be sure disc turns counterclockwise. Abrasive belt must travel

downward.

• Keep your hands clear of abrasive belt, disc and all moving

parts.

• For optimum performance, do not stall motor or reduce speed.

Do not force the work into the abrasive belt or disc.

• Always support workpiece with table or work stop when

sanding with belt and with table when sanding with disc.

• Never push a sharp corner of workpiece rapidly against belt or

disc. Abrasive backing may tear.

• Replace abrasive belt or disc when they become loaded

(glazed) or frayed.

Before turnin on the machine, review all

safety precautions. Make sure that you

fully understand the features, adjustments and capabilities

of the machine that are outlined throu hout this manual.

O /OFF Switch

The ON/OFF locking switch needs to have the safety switch key

inserted before the switch can be used. This feature prevents

unauthorized use of the sander. See Figure 14.

Abrasive Belt Sanding

• Finishing flat surfaces: Hold workpiece firmly with both hands;

keep fingers away from abrasive belt.

Use table to position and secure work being sanded. Keep end

butted against table and move work evenly across abrasive

belt.

• Finishing long pieces: Use belt in horizontal position with work

stop. Apply only enough pressure to allow abrasive belt to

remove material.

Use work stop to position and secure work being sanded.

Keep end butted against work stop and move work evenly

across abrasive belt. Use extra caution when finishing very thin

pieces.

• Finishing curved edges: Finish outside curves on flat portion of

abrasive belt. Finish inside curves on idler drum portion of

abrasive belt.

• Finishing end grain: It is more convenient to finish ends of long

workpieces with the abrasive belt in a vertical position.

Position table on belt side of sander. Move work evenly across

abrasive belt. For accuracy, use miter gauge. Table may be

tilted for beveled work.

Abrasive Disc Sanding

• Abrasive disc sanding is well suited for finishing small flat

surfaces and convex edges.

• Move workpiece across down side (left) of abrasive disc. Hold

workpiece firmly with both hands; keep fingers away from

abrasive disc.

• Abrasive disc moves fastest and removes more material at

outer edge.

• For accuracy, use miter gauge.

9

NO SE Operating Manual & Parts List 9681115

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

Figure 14 - Remove safety key to prevent sander use.

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 9

OPERATIO (CO TI UED)

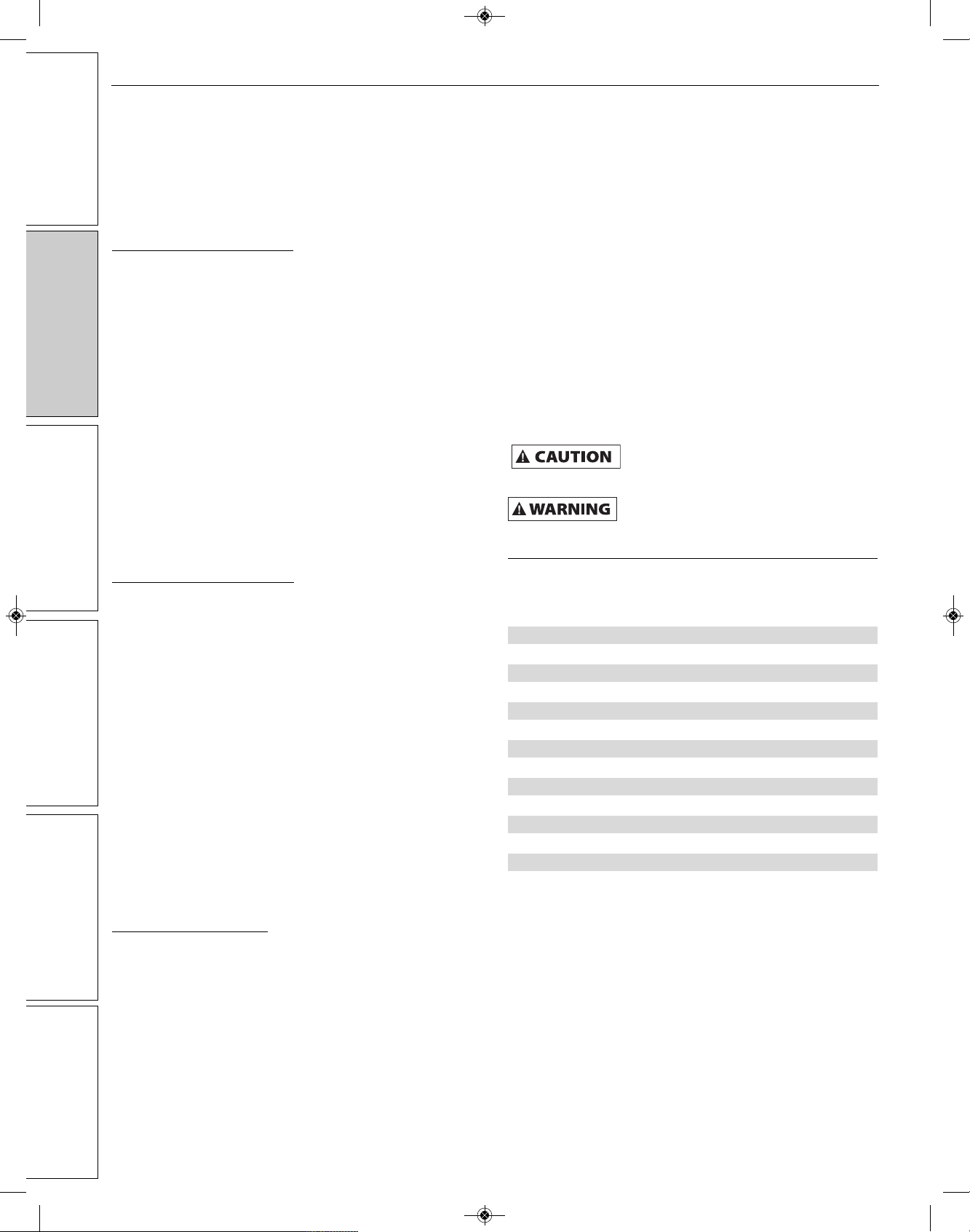

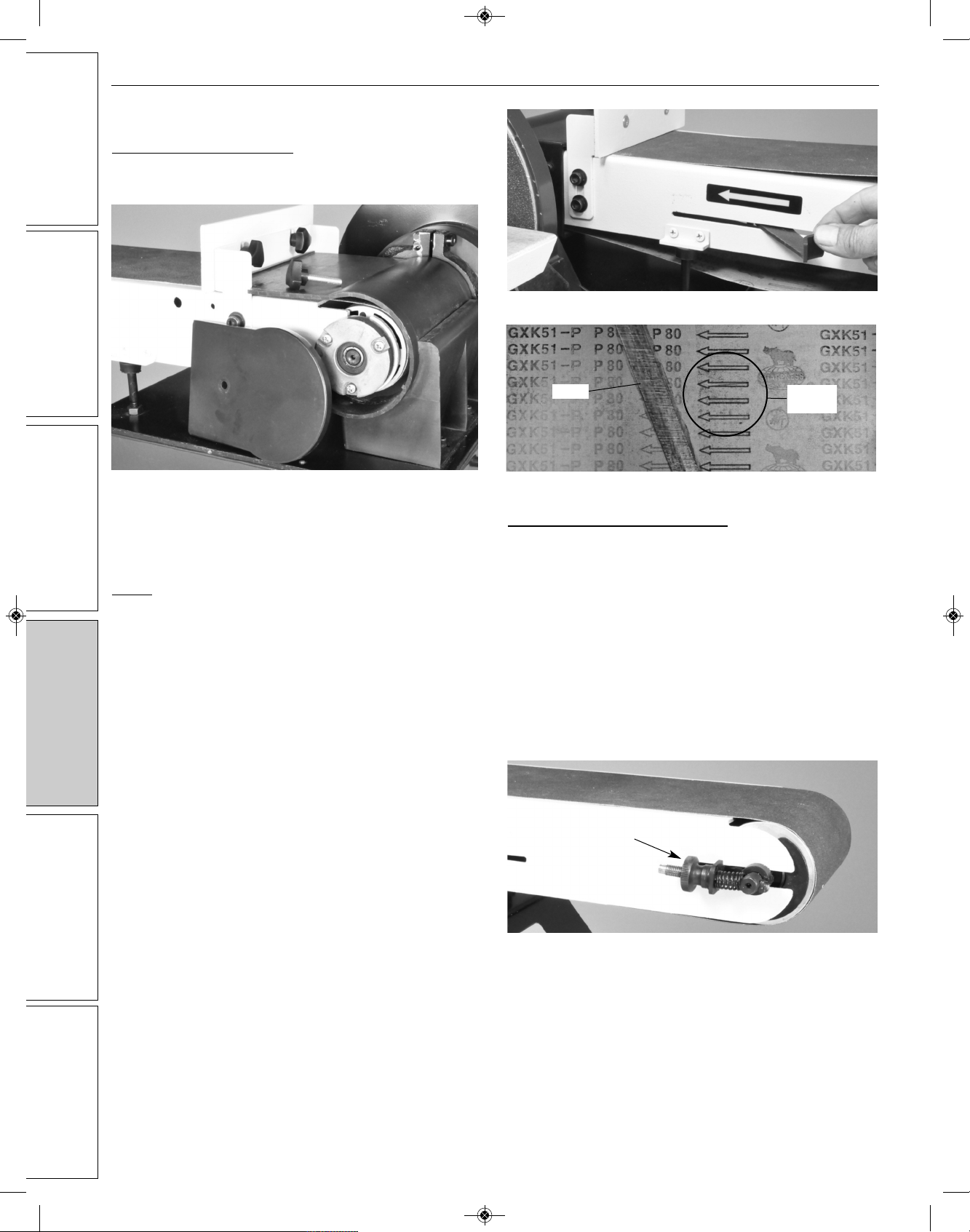

Changing the Sanding Belt

1. Remove the plastic side cover from the frame by unscrewing

the knob. See Figure 15.

2. Remove the small fence. See page 3 for instructions on

installing this part.

3. Slide tension lever to the right to release the belt tension. See

Figure 16.

NOTE: Above the tension lever, there is a direction arrow. The

sanding belt must run in the direction of this arrow so that the splice

does not come apart. See figures 16 and 17.

4. Remove the old belt by sliding it off to the left of the frame.

Place the new sanding belt over the drums with the direction

arrow pointing in the proper direction. See Figure 17. Make

sure the belt is centered on both drums.

5. Slide the tension lever to the left to apply tension to the belt.

See Figure 16.

6. Re-install the small fence and side cover onto the frame

(removed in Step 1 & 2).

7. Plug in the power cord. Turn the switch “ON” and note if the

belt tends to move to the right or left on the drums. The belt

should be running on the center of the drive drums. If it is not,

the belt tracking needs adjustment. See instructions on

sanding belt tracking.

Adjusting Sanding Belt Tracking

Refer to Figure 18.

1. Belt tracking on the center of the drive wheels is pre-set at the

factory. If an adjustment needs to be made, the sander must

be turned on.

a) If the sanding belt moves toward the disc, slowly turn the

tracking knob clockwise 1/4 turn.

b) If the sanding belt moves away from the disc, turn the

tracking knob slowly counterclockwise 1/4 turn.

2. Slowly turn the belt tracking knob noting the belt movement.

Re-adjust the tracking knob, as necessary, until the belt runs

true in the center of the drums.

10

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NO SE Operating Manual & Parts List 9681115

Figure 15

Figure 16

Figure 18

Figure 17

Direction

Arrows

Splice

Belt Tracking

Knob

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 10

OPERATIO (CO TI UED)

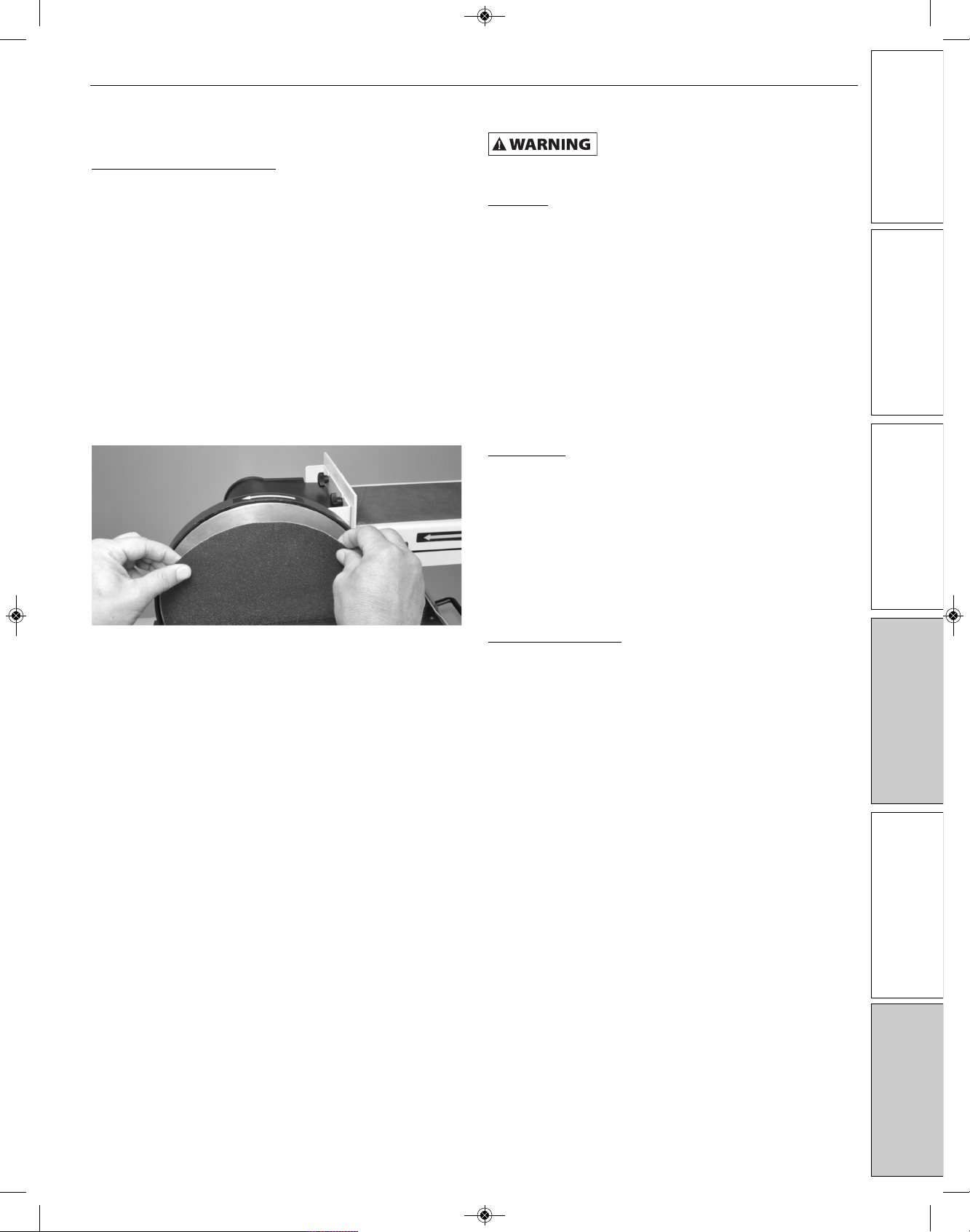

Changing the Sanding Disc

Refer to Figure 19.

The sandpaper disc can be removed with the table installed, or with

the table removed to give more working access to the disc, if

needed.

1. Peel the used abrasive disc from the metal disc plate. A putty

knife may help in this process.

2. Make sure that the disc plate is clean of any residue. Mineral

spirits will soften the PSA adhesives for its removal. Rotate the

disc by hand to access to all of the disc surface.

3. Peel the protective backing from the new PSA 9˝ abrasive

sanding disc, then center and press the sanding disc firmly

onto the metal disc plate. See page 4.

4. Replace the sanding table if it was removed.

MAI TE A CE

Make certain that the unit is

disconnected from power source before

attemptin to service or remove any component.

Cleaning

• Keep machine and workshop clean. Do not allow sawdust to

accumulate on the tool.

• Keep the drums clean. Dirt on drums will cause poor tracking

and belt slippage.

• Operate tool with dust collector to keep dust from

accumulating.

• Be certain motor is kept clean and is frequently vacuumed free

of dust.

• Use soap and water to clean painted parts, rubber parts and

plastic guards.

Lubrication

The shielded ball bearings in this tool are permanently lubricated at

the factory. They require no further lubrication.

• When operation seems stiff, a light coat of paste wax applied to

the belt and disc tables will make it easier to feed the work

while finishing.

• Do not apply wax to the belt platen. Belt could pick up wax and

deposit it on the drums causing belt to slip.

Keep Tool in Repair

• If power cord is worn, cut or damaged in any way, have it

replaced immediately.

• Replace worn abrasives when needed.

• Replace any damaged or missing parts. Use parts list to order

parts.

• Any attempt to repair motor may create a hazard unless repair

is done by a qualified service technician.

11

NO SE Operating Manual & Parts List 9681115

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

Figure 19

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 11

12

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NO SE Operating Manual & Parts List 9681115

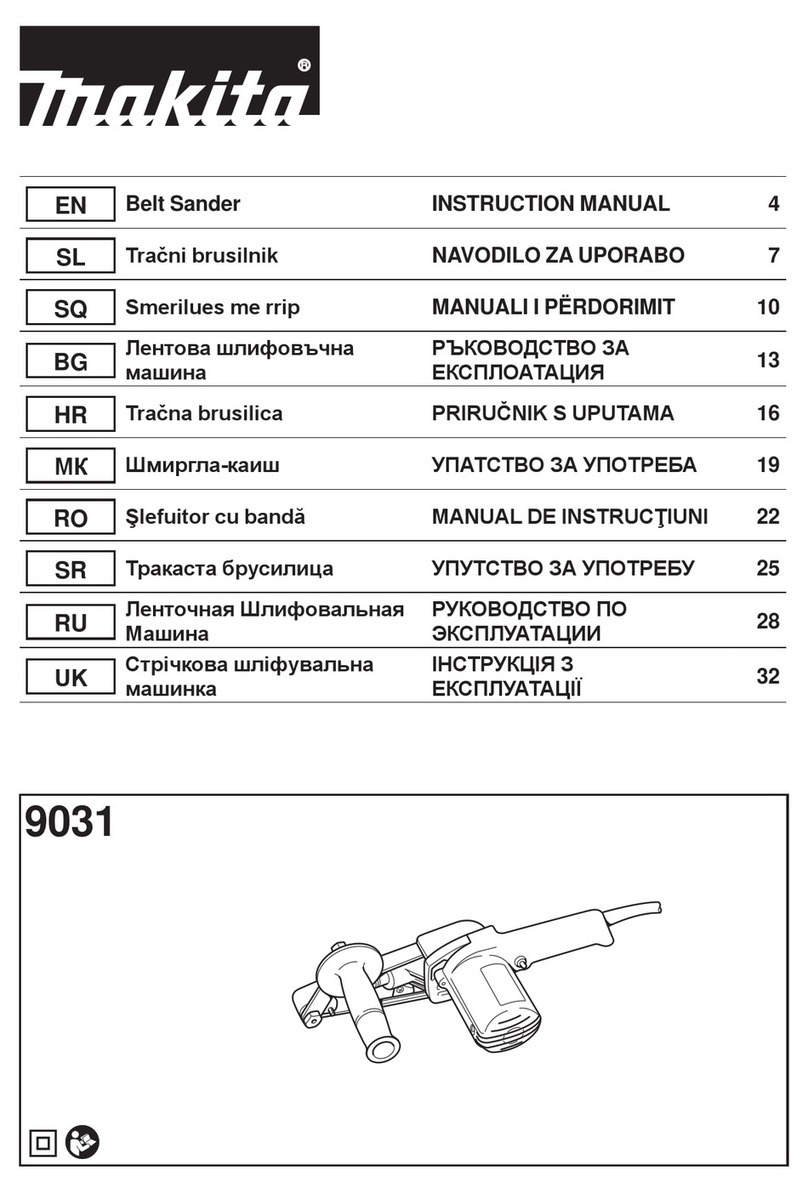

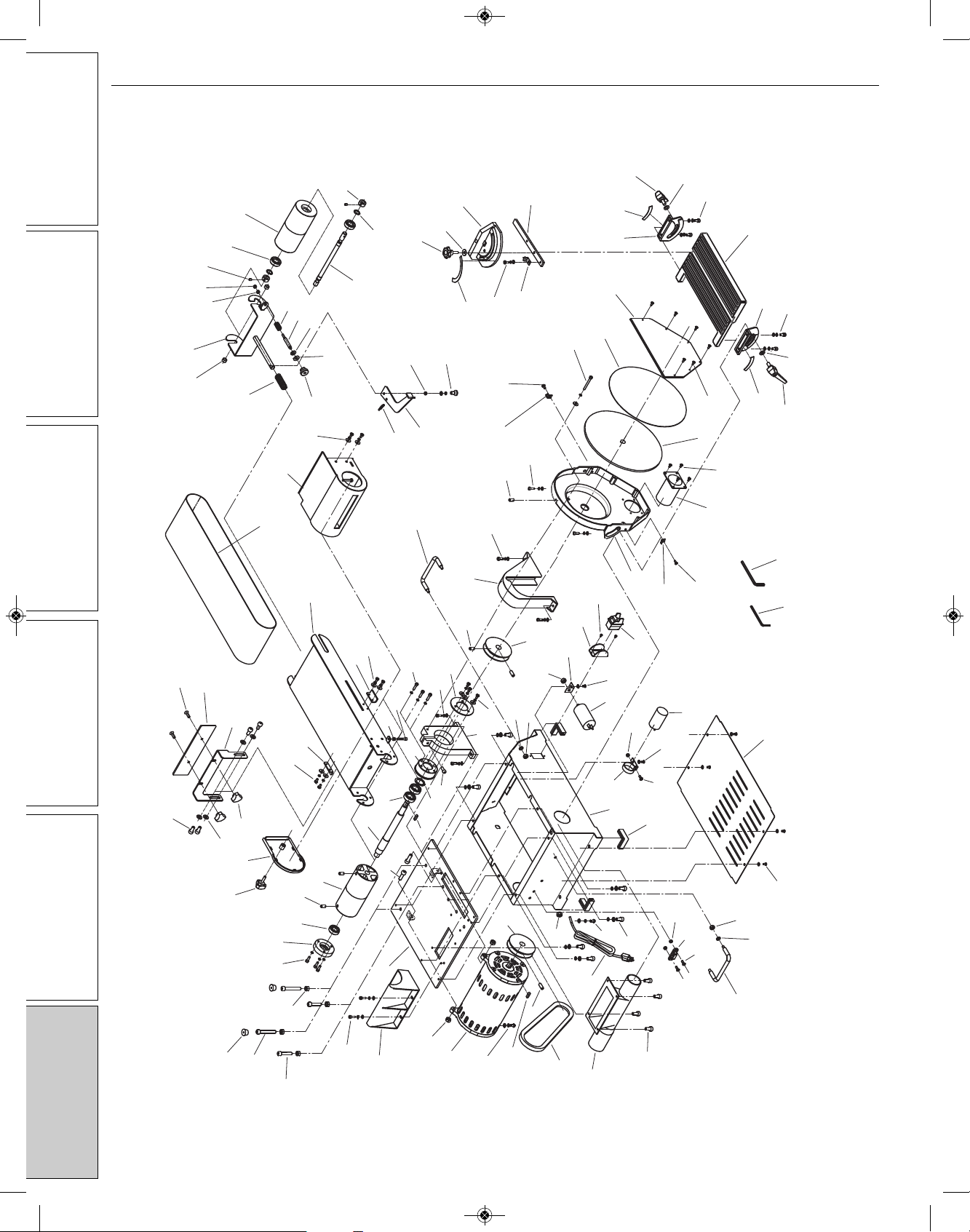

REPAIR PARTS ILLUSTRATIO FOR 9681115 6˝ X 9˝ BELT/DISC SA DER

18

49

16

15

13

12

11

8

9

14

10

6

2

4

16

105

106

90

89

107

104

7

2

25 82

11

48

47

46

61

49

32

50

26

43

89

107

19

44

939

90 71

70

72

108

45

51

51

52

53

41

43 66

58

67

68

69

76

62

63 64

32 65 74

21

77

78

96

80

73

43

43

55

78

28

58

57 56

54

60

42

59

19

61 20

21 22

23

24

79

81

84

91

33

101

22

38

16

92

93

94

2

36

2

1

3

32

35

30

29

31

28

19

99

101

33

100

33

98 33

86 85

34

17

5

102

103

95 88 87

5

17

34

40

97

83

Figure 26 - Parts Illustration

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 12

13

NO SE Operating Manual & Parts List 9681115

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

REPAIR PARTS LIST FOR 9681115 6˝ X 9˝ BELT/DISC SA DER

Ref. Part

o. Description o. Qty.

Ref. Part

o. Description o. Qty.

(∆) Not shown.

(*) Standard hardware item, available locally.

(NA) Not available as replacement part.

1 Philips screw + flat washer M4x6 * 4

2 Philips screw + spring washer + flat washer M4x8 * 4

3 Base Plate 9642862.01 1

4 Philips Screw M5x8 * 4

5 Lock handle 9642863.01 2

6 Power Cord 9624671.01 1

7 Dust hose 9642864.01 1

8 V-belt A580 9642865.01 1

9 Hex screw M6X8 * 5

10 Cord clip 6P4 * 1

11 Key A5X15 * 2

12 Motor 9624652.01 1

13 Nut M8 * 2

14 Driving pulley 9624653.01 1

15 Dust cover 9624637.01 1

16 Hex screw + spring washer + flat washer M5x10 * 10

17 Flat washer D8 * 2

18 Hex screw M8X55 * 2

19 Hex nut, I type M8 * 5

20 Bearing cap 9624631.01 1

21 Ball bearing 6201 * 3

22 Hex screw M8X12 * 3

23 Driving drum 9621434.01 1

24 Driving shaft 9624633.01 1

25 Supporting plate NA 1

26 Hex screw + spring washer + flat washer M8X30 * 2

27 Hex screw M8X16 * 4

28 Base NA 1

29 Rubber foot 9624672.01 4

30 Philips screw M5x12 * 1

31 Capacitor bracket 9642866.01 1

32 Hex nut, I type M5 * 3

33 Philips screw M4x10 * 11

34 Hex screw + spring washer + flat washer M6x12 * 4

35 Capacitor 20UF/125V 9642867.01 1

36 Capacitor 20UF/300V 9642868.01 1

37 Capacitor bracket 9642869.01 1

38 Hex screw + spring washer + flat washer M5x18 * 2

39 Belt cover 9624638.01 1

40 Disc table 9642870.01 1

41 Dust port 9642871.01 1

42 Philips screw + spring washer M5x25 * 3

43 Philips screw + spring washer + flat washer M5X12 * 9

44 Idler pulley 9624666.01 1

45 Fixing ring 9642872.01 1

46 Belt frame assembly base 9642873.01 1

47 Bearing cap 9624639.01 1

48 Ball bearing 6202 * 2

49 Hex screw M8x30 * 3

50 Hex screw M5x30 * 1

51 Supporting plate 9642874.01 2

52 Platen 9624628.01 1

53 Sanding belt (6 x 48") 9622173.00 1

54 Philips screw, M6x14 * 2

55 Fence 9642875.01 1

56 Fence support 9642876.01 1

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 13

14

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NO SE Operating Manual & Parts List 9681115

REPAIR PARTS LIST FOR 9681115 6˝ X 9˝ BELT/DISC SA DER (CO TI UED)

Ref. Part

o. Description o. Qty.

Ref. Part

o. Description o. Qty.

(∆) Not shown.

(*) Standard hardware item, available locally.

(N/A) Not available as replacement part.

57 Locking nut 9642877.01 2

58 Flat washer M8 * 5

59 Rubber foot 9642878.01 2

60 Dust port cover 9642879.01 1

61 Philips screw + spring washer M5x16 * 3

62 Tension spring 9621426.01 1

63 Bushing 9642880.01 2

64 Driven drum support 9642881.01 1

65 Nut M5 * 1

66 Belt tracking knob M8 9642882.01 1

67 Rubber washer 9642883.01 1

68 Adjustment rod 9642884.01 1

69 Adjustment spring 9642885.01 1

70 Spring Ⅱ9642886.01 1

71 Belt tension handle 9621428.01 1

72 Powder metal bushing 9642887.01 1

73 Position ring for driven shaft 9642888.01 2

74 Inner hex position screw M5X6 9642889.01 2

75 Spring washer for shaft M12 * 2

76 Driven shaft 9642890.01 1

77 Driven drum 9642891.01 1

78 Miter gauge knob 9642892.01 2

79 Miter gauge label 9642893.01 1

80 Miter gauge 9642894.01 1

81 Philips screw + spring washer + flat washer M5x8 * 1

82 Philips screw M8x25 * 2

83 Slide bar 9642895.01 1

84 Miter gauge pointer 9642896.01 1

85 Disc table left support 9642897.01 1

86 Left scale 9642898.01 1

87 Right scale 9642899.01 1

88 Disc table right support 9642900.01 1

89 Spring washer M6 * 4

90 Handle 9642901.01 2

91 Inner hex head screw M5X56 9642902.01 1

92 Switch guard 9642903.01 1

93 Star-head screw M3x10 * 2

94 Switch with key 9642904.01 1

95 Disc guard 9642905.01 1

96 Big washer M6 * 1

97 Sanding disc, 9" PSA 80 rit 9616731.00 1

98 Aluminum disc plate 9621446.01 1

99 Disc cover 9630671.01 1

100 Adapter 9642906.01 1

101 Pointer 9642907.01 2

102 Hex wrench S=4 NA 1

103 Hex wrench NA 1

104 Clip 9642908.01 1

105 Hex nut M5 * 2

106 Philips screw M5x10 * 2

107 Hex nut M6 * 4

108 Philips screw + outer tooth washer + flat washer M5x16 * 1

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 14

15

NO SE Operating Manual & Parts List 9681115

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

TROUBLESHOOTI G GUIDE

Symptom Possible Cause(s) Corrective Action

Motor will not start

Motor will not start; fuses blown

or circuit breakers tripped

Motor fails to develop full power

(power output of motor de-

creases rapidly with decrease in

voltage at motor terminals)

Motor overheats

Motor stalls

(resulting in blown fuses or

tripped circuit breakers)

Machine slows down while

operating

Abrasive belt runs off top wheel

1. Blown line fuse or tripped circuit

breaker

2. Low line voltage

3. Defective switch

4. Defective, blown capacitor

1. Overloading due to binding

2. Defective plug

3. Defective cord

4. Defective switch

5. Faulty internal wiring

1. Power line overloaded with lights,

appliances and other motors

2. Undersized wires or circuits too long

3. eneral overloading of power

company’s facilities

Motor overloaded

1. Short circuit in motor or loose

connections

2. Low voltage

3. Incorrect fuses or circuit breakers in

power line

4. Motor overloaded

1. Applying too much pressure to

workpiece

2. V-belt slipping

Not tracking properly

1. If fuse is blown, replace with fuse of proper size.

If breaker tripped, reset it

2. Check power supply for voltage and correct as

needed

3. Replace switch

4. Replace capacitor

1. Clean around wheels and shaft and/or replace

bearings

2. Replace plug

3. Replace cord

4. Replace switch

5. Contact authorized NORSE Service Center

1. Reduce load on power line

2. Increase wire sizes, or reduce length of wiring

3. Request a voltage check from power company

Reduce load on motor

1. Inspect connections in motor for loose or

shorted terminals or worn insulation on lead

wires

2. Correct the low line voltage conditions

3. Install correct fuses or circuit breakers

4. Reduce load on motor

1. Ease up on pressure

2. Increase V-belt tension

See operation section “Adjusting Sanding Belt

Tracking”, page 8.

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 15

ORSE Warranty

NO SE by C.H. Hanson warrants their products to be free of defects in material or workmanship. This

warranty does not cover defects due directly or indirectly to misuse, abuse, normal wear and tear, failure

to properly maintain the product, heated, ground or otherwise altered, or used for a purpose other than

that for which it was intended.

The warranty does not cover expendable and/or wear part (i.e. v-belts, screws, abrasives, jaws), damage to

tools arising from alteration, abuse or use other than their intended purpose, packing and freight. The

duration of this warranty is expressly limited to the terms noted below beginning from the date of

delivery to the original user.

The NO SE branded items carry the following warranties on parts:

All NO SE branded Tools and Accessories 1 YEA

The obligation of NO SE by C.H. Hanson is limited solely to the repair or replacement, at our option, at its

factory or authorized repair agent of any part that should prove inoperable. Purchaser must lubricate and

maintain the product under normal operating conditions at all times. Prior to operation become familiar

with product and the included materials, i.e. warnings, cautions and manuals.

Failure to follow these instructions will void the warrant .

This warranty is the purchaser's exclusive remedy against C. H. Hanson for any inoperable parts in its

product. Under no circumstances is C. H. Hanson liable for any direct, indirect, incidental , special or

consequential damages including loss of profits in any way related to the use or inability to use our

products. This warranty gives you specific legal rights which may vary from state to state.

SERVICE & REPAIR

1. If a NO SE product requires a repair or warranty service DO NOT return the product to

the place of purchase.

2. All warranty related work must be evaluated and approved by NO SE.

3. Prior to returning any item the user must obtain factory approval and a valid GA number.

4. For instructions and GA number call toll free (800) 827-3398.

NORSE - a C.H. Hanson brand

2000 N. Aurora Rd., Naperville, IL 60563 U.S.A.

or call: 1-800-827-3398

NO SE Operating Manual & Parts List 9681115

18-0307

NORSE - a C.H. Hanson brand

2000 N. Aurora Rd., Naperville, IL 60563 U.S.A.

or call: 1-800-827-3398

9681115_oipm_En012_9643069.01 0518 05/22/18 Page 16

Table of contents

Other CH Hanson Sander manuals