CH Hanson PALMGREN 9681061C User manual

Operating Manual & Parts List 9681061C

2 x 6"

belt and disc

Sander

Read carefully and follow all safety rules and operating instructions before

first use of this product.

9631694.01-1117

2

Palmgren Operating Manual & Parts List 9681061C

GETTING STARTED

STRUCTURAL REQUIREMENTS

Make sure all supporting structures and load attaching devices are

strong enough to hold your intended loads. If in doubt, consult a

qualified structural engineer.

ELECTRICAL REQUIREMENTS

The power supply to the Sander needs to be 120 volt/ 3.5 amp, sin-

gle phase, 60 Hz. The standard allowable voltage variation is plus or

minus 10%.

TOOLS NEEDED:

Standard mechanic’s hand tool set.

UNPACKING

WARNING: Be careful not to touch overhead power lines, piping,

lighting, etc. if lifting equipment is used. Sander weighs approxi-

mately 32 lbs, proper tools, equipment and qualified personnel

should be employed in all phases of unpacking and installation.

Carton should be handled with care to avoid damage from drop-

ping, bumping, etc. Store and unpack carton with correct side up.

After unpacking Sander, inspect carefully for any damage that may

have occurred during transit. Check for loose, missing or damaged

parts. If any damage or loss has occurred, claim must be filed with

carrier immediately. Check for completeness. Immediately report

missing parts to dealer.

Sander is shipped partially assembled. End user will need to assem-

ble loose parts to machine.

IM ORTANT: The tool has been coated with a protective coating. In

order to ensure proper fit and operation, the coating must be re-

moved. Remove coating with mild solvents such as mineral spirits

and a soft cloth. Nonflammable solvents are recommended. After

cleaning, cover all exposed metal surfaces with a light coating of

oil.

CAUTION: Never use highly volatile solvents. Avoid getting clean-

ing solution on paint as it may tend to deteriorate these finishes.

Use soap and water on painted components.

CONTENTS:

• 2 x 6" Belt and Disc Sander (1)

• Disc table (1)

• Abrasive disc (1)

• Mater gauge assembly (1)

• Belt table (1)

• Parts bag (1) includes: work stop; two knobs; one 10-1.5 x

16mm socket head bolt; one 10mm flat washer; two 6mm wash-

ers; one each 5, 6 and 8mm hex wrenches and one 12mm open

end wrench.

• Operating Instructions and Parts Manual (1)

UN ACK:

•Do not discard packing materials until after machine has been in-

spected for damage and completeness. Locate loose parts and set

aside.

INS ECT:

•After unpacking the unit, carefully inspect for any damage that

may have occurred during transit. Check for loose, missing or dam-

aged parts. Shipping damage claims must be filed with the carrier.

• All tools should be visually inspected before use, in addition to

regular periodic maintenance inspections.

• Be sure that the voltage labeled on the unit matches your

power supply.

SEE GENERAL SAFETY INSTRUCTIONS, CAUTIONS AND

WARNINGS AS SHOWN.

SAFET RULES

WARNING: For your own safety, read all of the instructions and

precautions before operating tool.

RO OSITION 65 WARNING: Some dust created by

using power tools contain chemicals known to the state

of California to cause cancer, birth defects or other repro-

ductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry

products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area and work with approved safety

equipment. Always wear OSHA/NIOSH approved, properly fitting

face mask or respirator when using such tools.

WARNING: Always follow proper operating procedures as defined

in this manual even if you are familiar with the use of this or similar

tools. Remember that being careless for even a fraction of a second

can result in severe personal injury.

BE RE ARED FOR JOB

• Wear proper apparel. Do not wear loose clothing, gloves, neck-

ties, rings, bracelets or other jewelry which may get caught in

moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI Z87.1.

Everyday glasses have only impact resistant lenses. They are

NOT safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools when tired,

intoxicated or when taking medications that cause drowsiness.

RE ARE WORK AREA FOR JOB

• Keep work area clean. Cluttered work areas invite accidents.

• Do not use power tools in dangerous environments. Do not use

power tools in damp or wet locations. Do not expose power

tools to rain.

• Work area should be properly lighted.

• Proper electrical receptacle should be available for tool. Three-

prong plug should be plugged directly into properly grounded,

three-prong receptacle.

• Extension cords should have a grounding prong and the three

wires of the extension cord should be of the correct gauge.

• Keep visitors at a safe distance from work area.

• Keep children out of workplace. Make workshop childproof. Use

padlocks, master switches or remove switch keys to prevent any

unintentional use of power tools.

3

Palmgren Operating Manual & Parts List 9681061C

SAFET RULES (CONTINUED)

TOOL SHOULD BE MAINTAINED

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting proce-

dures.

• Keep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that ad-

justing tools are removed before switching machine on.

• Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their in-

tended function.

• Check for damaged parts. Check for alignment of moving parts,

binding, breakage, mounting and any other condition that may

affect a tool’s operation.

• A guard or other part that is damaged should be properly re-

paired or replaced. Do not perform makeshift repairs. (Use parts

list provided to order repair parts.)

KNOW HOW TO USE TOOL

• Use right tool for job. Do not force tool or attachment to do a

job for which it was not designed.

• Disconnect tool when changing abrasive belt or disc.

• Avoid accidental start-up. Make sure that the tool is in the OFF

position before plugging in.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Use of improper accessories may cause risk of injury to persons.

• Handle workpiece correctly. Protect hands from possible injury.

• Turn machine off if it jams. Belt jams when it digs too deeply

into workpiece. (Motor force keeps it stuck in the work.)

• Never leave tool running unattended. Turn power off and do

not leave tool until it comes to a complete stop.

• Do not overreach. Keep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is tipped

or if belt or disc is unintentionally contacted.

• Keep hands away from moving parts and sanding surfaces.

• Know your tool. Learn its operation, application and specific lim-

itations.

• Support workpiece with miter gauge, work stop or work table.

• Maintain 1/16˝ maximum clearance between table and sanding

belt or disc.

CAUTION: Think safety! Safety is a combination of operator com-

mon sense and alertness at all times when tool is being used.

WARNING: Do not attempt to operate tool until it is completely

assembled according to instructions.

SPECIFICATIONS

Belt size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 x 42˝, 80 grit

Belt platen area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

⁄4x 2˝

Belt table dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

⁄4x 9˝

Belt table tilts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to 60º

Belt speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4480 FPM

Disc diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6˝, 80 grit

Disc table dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

⁄8x 8˝

Disc table tilts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 to 45º

Disc dust collection chute . . . . . . . . . . . . . . . . . . . . . . . . . . 11

⁄2˝ diameter

Disc speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3590 RPM

Base dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

⁄8x 9˝

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SP, locking rocker

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120V, 3.5 AMPS

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 lbs

Shipping weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35 lbs

ASSEMBL

Refer to Figures 1 through 3.

CAUTION: Do not attempt assembly if parts are missing. Use this

manual to order repair parts.

ATTACH ABRASIVE DISC TO ALUMINUM DISC

1. Remove dust chute by loosening screws and bolts.

2. Remove the adhesive cover from the back of the abrasive disc.

3. Center abrasive on aluminum disc and press to paste.

4. Make sure abrasive is pasted evenly on the aluminum disc.

5. Replace dust chute.

ASSEMBLE DISC TABLE

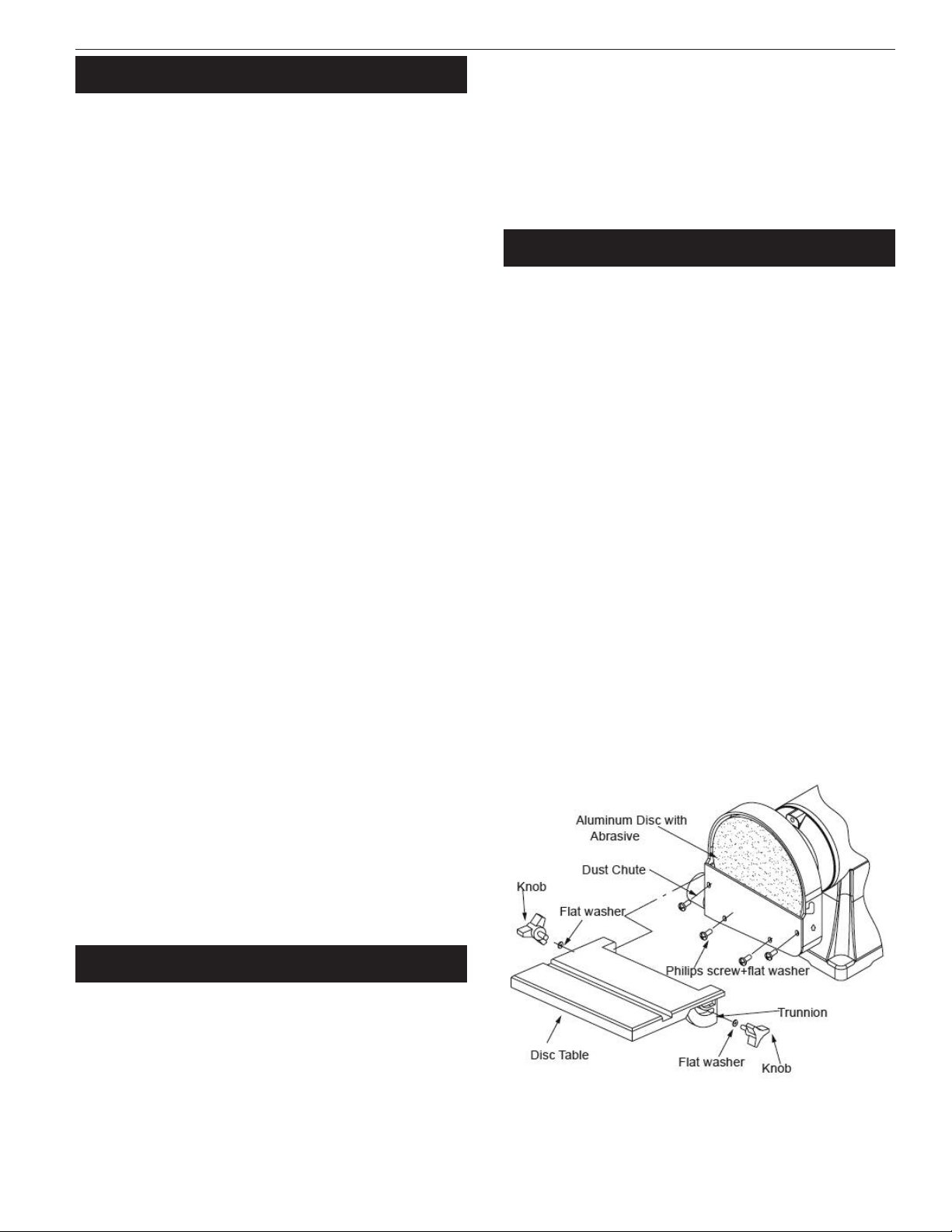

Refer to Figure 1.

1. Slide table onto disc guard as shown.

2. Set the disc table at right angle to the aluminum disc and se-

cure the table position using two knobs and flat washers

ADJUST DISC TABLE ANGLE

Refer to Figure 1.

1. The disc table is adjustable from 0 to 45 degree for beveled

work. To adjust disc table, loosen 2 knobs and flat washers and

adjust to desired angle

2. Use scale on disc table trunnions to set disc table from 0 to 45

degree to abrasive disc

3. When disc table is at desired angle, lock into position by tight-

ening the knobs

Figure 1 - Assemble and adjust disc table.

4

Palmgren Operating Manual & Parts List 9681061C

ASSEMBL (CONTINUED)

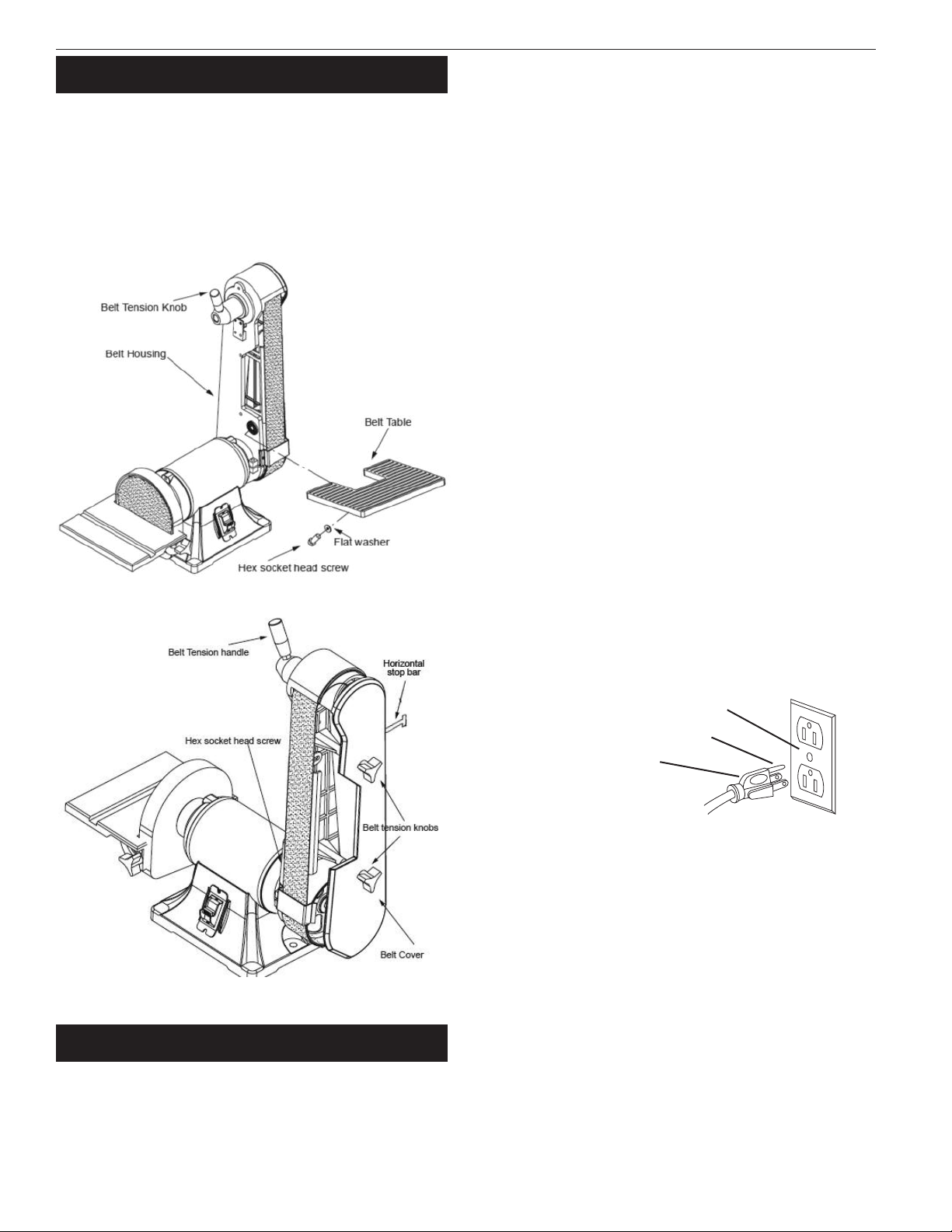

ASSEMBLE BELT TABLE

Refer to Figure 2.

1. Mount belt table to left side of belt housing using hex socket

head screw and flat washer.

2. Set the belt table at right angle to the belt

3. Be sure gap between table and belt is 1/16˝ or less. Tighten

socket head screw to secure table position.

INSTALLATION

Refer to Figures 4 and 5.

WARNING: Operation of any power tool can result in foreign ob-

jects being thrown into eyes which can result in severe eye damage.

Always wear safety goggles complying with United States

ANSI Z87.1 before commencing power tool operation.

ELECTRICAL CONNECTIONS

WARNING: All electrical connections must be performed by a

qualified electrician. Make sure tool is off and disconnected from

power source while motor is mounted, connected, reconnected or

anytime wiring is inspected.

WARNING: All electrical connections must be performed by a

qualified electrician.

WARNING: Do not connect sander to the power source until all

assembly steps have been completed.

OWER SOURCE

1. The motor is designed for operation on the voltages and fre-

quency specified.

2. Normal loads will be handled safely on voltages not more than

10% above or below the specified voltage.

3. Running the unit on voltages which are not within the range

may cause overheating and motor burnout.

4. Heavy loads require the voltage at motor terminals be not less

than the voltage specified. Power supply to the motor is con-

trolled by a single pole locking rocker switch. Remove the key to

prevent unauthorized use.

GROUNDING INSTRUCTIONS

Refer to Figures 4 and 5.

WARNING: Improper connection of equipment grounding con-

ductor can result in the risk of electrical shock. Equipment should

be grounded while in use to protect operator from electrical shock.

Check with a qualified electrician if grounding instructions are not

understood or if in doubt as to whether the tool is properly

grounded.

This equipment is for use on less than 150V, and is equipped with

an approved 3-conductor cord and a 3-prong, grounding type plug

(see Figure 4) for your protection against shock hazards.

rounding plug should be plugged directly into a properly in-

stalled and grounded 3- prong grounding-type receptacle.

Do not remove or alter grounding prong in any manner. In the

event of a malfunction or breakdown, grounding provides a path of

least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals or plug

when installing or removing from outlet.

Plug must be plugged into matching outlet that is properly in-

stalled and grounded in accordance with all local codes and ordi-

nances. Do not modify plug provided. If it will not fit in outlet, have

proper outlet installed by a qualified electrician.

Inspect tool cords periodically, and if damaged, have repaired by an

authorized service facility.

reen (or green and yellow) conductor in cord is the grounding

wire. If repair or replacement of the electric cord or plug is neces-

sary do not connect the green (or green and yellow) wire to a live

terminal.

Where a 2-prong wall receptacle is encountered, it must be re-

placed with a properly grounded 3-prong receptacle installed in

accordance with National Electric Code and local codes and ordi-

nances.

Figure 2 - Assemble belt table.

Figure 3 - Horizontal stop bar.

Figure 4 – 3- rong receptacle

Properly grounded outlet

rounding prong

3-Prong plug

5

Palmgren Operating Manual & Parts List 9681061C

INSTALLATION (CONTINUED)

WARNING: This work should be performed by a qualified

electrician.

A temporary 3-prong to 2-prong grounding adapter (See Figure 5)

is available for connecting plugs to a two pole outlet if it is properly

grounded.

Do not use a 3-prong to 2-prong grounding adapter unless permit-

ted by local and national codes and ordinances.

(A 3-prong to 2-prong grounding adapter is not permitted in

Canada.) Where permitted, the rigid green tab or terminal on the

side of the adapter must be securely connected to a permanent

electrical ground such as a properly grounded water pipe, a prop-

erly grounded outlet box or a properly grounded wire system.

Many cover plate screws, water pipes and outlet boxes are not

properly grounded. To ensure proper ground, grounding means

must be tested by a qualified electrician.

EXTENSION CORDS

• The use of any extension cord will cause some drop in voltage

and loss of power.

• Wires of extension cord must be sufficient in size to carry and

maintain adequate voltage.

• Do not use extension cords over 25 ft. Cord must be at least 18

A.W. .

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If the extension cord is worn, cut or damaged in any way, re-

place it immediately.

EXTENSION CORD LENGTH

Wire Size A.W.G.

Up to 25 ft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

NOTE: Using extension cords over 25 ft. long is not recommended.

OPERATION

Refer to Figures 6 and 7.

WARNING: Operation of any power tool can result in foreign ob-

jects being thrown into eyes which can result in severe eye dam-

age. Always wear safety goggles complying with United States

ANSI Z87.1 before commencing power tool operation.

CAUTION: Always observe the following safety precautions:

• Whenever adjusting or replacing any parts on the sander turn

power off and remove the plug from power source.

• Recheck table knobs and bolts, they must be tightened securely.

• Make sure all guards are properly attached. All guards should be

securely fastened.

• Make sure all moving parts are free and clear of any interference.

• Make sure all fasteners are tight and have not vibrated loose.

• With power disconnected, test operation by hand for clearance

and adjust if necessary.

• Always wear eye protection or face shield.

• Make sure abrasive belt tracks properly. Correct tracking gives

optimum performance.

• After turning switch on, always allow belt to come up to full

speed before sanding or grinding.

• Be sure motor runs clockwise on disc side. Abrasive belt must

travel down.

• Avoid kickback by sanding in accordance with the directional

arrows.

• Keep your hands clear of abrasive belt, disc and all moving parts.

• For optimum performance do not stall motor or reduce speed.

Do not force the work into the abrasive.

• Support workpiece with belt table when sanding with belt, with

disc table when sanding with disc.

• Never push a sharp corner of workpiece rapidly against belt or

disc. Abrasive backing may tear.

• Replace abrasives when they become loaded (glazed) or frayed.

• When grinding metal, move workpiece across abrasive to pre-

vent heat build-up.

• Never attempt wet sanding. If work-piece becomes too hot to

handle, cool it in water.

BELT INSTALLATION

Refer to Figure 6.

Sanding belt should be replaced when worn, torn, or glazed.

1. Release belt tension by pulling down on tension handle. Slide

old belt off the drive and tracking wheels.

2. Pull down on the tension handle and slide new belt over the

drive and tracking wheels, center belt on wheels.

3. Replace lower guard and tighten bolt.

4. Replace belt cover and knobs.

5. Rotate belt by hand to check tracking, belt should ride centered

on drive and tracking wheels. Adjust socket head bolt at top of

tracking bracket to track belt properly. Be sure to secure socket

head bolt with hex nut.

ADJUST BELT TABLE

Refer to Figure 6.

1. To adjust belt table angle, loosen socket head bolt.

2. Tilt belt table to desired position and secure by tightening

socket head bolt.

Figure 5 – 2- rong receptacle with adapter

rounding lug

Adapter

3-Prong plug 2-Prong re-

ceptacle

Make sure this is con-

nected to a known

grounded receptacle

Figure 6 – Operation

Tracking Bracket Knob

Disc Table

Belt Table

Lower

uard

Work Stop

Release Belt Cover

Belt Platen Screws

Knob Belt Housing Bolt

6

Palmgren Operating Manual & Parts List 9681061C

OPERATION (CONTINUED)

ADJUST BELT ASSEMBLY OSITION

Refer to Figure 6, page 5.

The sanding belt assembly can be adjusted from vertical to hori-

zontal position.

1. Loosen the belt housing bolt that clamps belt housing to motor

assembly.

2. Tilt belt assembly to desired position (from vertical to horizontal).

Secure belt assembly position by tightening belt housing bolt.

WORK STO

Refer to Figure 6, page 5.

The work stop can be used instead of the belt table.

1. Remove socket head bolt and washers holding belt table on

sander. Remove belt table.

2. Mount work stop to sander using the socket head bolt and

washer.

NOTE: Position work stop properly so gap between work stop and

belt is 1/16˝ or less. Tighten socket head bolt and washers.

CONTOUR SANDING

Refer to Figure 6,, page 5.

1. Belt platen can be removed for contour sanding. Remove belt

cover knobs and belt cover.

2. Remove socket head bolts and washers holding platen to belt

housing. Remove belt platen.

3. Replace belt cover and belt cover knobs. When contour sanding

is complete, replace belt platen. Position belt platen as close to

belt as possible so that platen does not contact belt.

ABRASIVE BELT FINISHING

Refer to Figure 7, page 8.

1. Finishing flat surfaces: Hold workpiece firmly with both hands,

keep fingers away from abrasive belt.

Use work stop. Work stop is used to position and stabilize work.

Keep end butted against workstop and move work evenly across

abrasive belt. Use extra caution when finishing very thin pieces.

For finishing long pieces: remove work stop. Apply only enough

pressure to allow abrasive belt to remove material.

2. Finishing curved edges: Finish outside curves on flat portion of

abrasive belt. Finish inside curves on drive wheel portion of

abrasive belt.

3. Finishing end grain: It is more convenient to finish ends of long

workpieces with abrasive belt in a vertical position.

RE LACING ABRASIVE DISC

Refer to Figure 7, page 8.

1. Loosen and remove knobs (Ref. No. 28).

2. ently press down on disc table and slide out disc table.

3. Remove old abrasive disc by peeling it from aluminum disc. Re-

moving aluminum disc from motor shaft is not necessary.

4. Clean aluminum disc if necessary. Select proper abrasive disc

and apply to aluminum disc.

5. Replace disc table.

ABRASIVE DISC FINISHING

1. Abrasive disc sanding is well suited for finishing small end sur-

faces and convex edges.

2. Move workpiece across down side (right) of face of

abrasive disc.

3. Abrasive disc moves fastest and removes more material at outer

edge.

4. For accuracy, use the miter gauge.

USING MITER GAUGE

Refer to Figure 7, page 8.

1. The miter gauge is used on disc table. Use the miter gauge for

securing the work and holding the proper angle while sanding.

2. Adjust the angle by repositioning the protractor scale and lock-

ing it into place with knob.

3. Check accuracy of miter gauge scale.

4. Use a combination square to adjust miter gauge square to face

of disc. Loosen screw and reposition indicator if necessary.

MAINTENANCE

WARNING: Make certain that the unit is disconnected from power

source before attempting to service or remove any component.

CLEANING

1. Keep machine and workshop clean. Do not allow sawdust to ac-

cumulate on the belt and disc sander.

2. Keep the wheels clean. Dirt on wheels will cause poor tracking

and belt slippage.

3. Operate sander with dust collector to keep dust from accumu-

lating.

WARNING: After sanding wood or non-metallic material, always

clean dust collector and guards of sawdust before grinding metal.

Sparks could ignite debris and cause a fire.

4. Be certain motor is kept clean and is frequently vacuumed free

of dust.

5. Use soap and water to clean painted parts, rubber parts and

plastic guards.

LUBRICATION

1. The shielded ball bearings in this sander are permanently lubri-

cated at the factory. They require no further lubrication.

2. When operation seems stiff, a light coat of automobile-type wax

applied to the belt table and disc table will make it easier to

feed the work while finishing.

3. Do not apply wax to the belt platen. Belt could pick up wax and

deposit it on wheels causing belt to slip.

KEE SANDER IN RE AIR

1. If power cord is worn, cut or damaged, have it replaced

immediately.

2. Replace worn abrasives when needed.

3. Replace any damaged or missing parts. Use parts list to

order parts.

TROUBLESHOOTING

SYM TOM OSSIBLE CAUSE(S) CORRECTIVE ACTION

Motor will not start

Motor will not start; fuses blown or

circuit breakers tripped

Motor fails to develop full power

(power output of motor decreases

rapidly with decrease in voltage at

motor terminals)

Motor overheats

Motor stalls

(resulting in blown fuses or

tripped circuit breakers)

Machine slows down

while operating

Abrasive belt runs off top wheel

1. Blown line fuse or tripped circuit breaker

2. Low line voltage

3. Defective switch

4. Defective, blown capacitor

1. Overloading due to binding

2. Defective plug

3. Defective cord

4. Defective switch

5. Motor wired for different

line voltage

6. Faulty internal wiring

1. Power line overloaded with lights, appli-

ances and other motors

2. Undersized wires or circuits too long

3. eneral overloading of power company’s

facilities

Motor overloaded

1. Short circuit in motor or loose connections

2. Low voltage

3. Motor wired for different line voltage

4. Incorrect fuses or circuit breakers in power

line

5. Motor overloaded

Applying too much pressure to

workpiece

Not tracking properly

1. If fuse is blown, replace with fuse of proper size. If

breaker tripped, reset it

2. Check power supply for voltage and correct as

needed

3. Replace switch

4. Replace capacitor

1. Clean around wheels and shaft and/or replace

bearings

2. Replace plug

3. Replace cord

4. Replace switch

5. Rewire motors as per line voltage

(See “Electrical Connections”, page 4)

6. Contact authorized Dayton Service Center

1. Reduce load on power line

2. Increase wire sizes, or reduce length of wiring

3. Request a voltage check from power company

Reduce load on motor

1. Inspect connections in motor for loose or shorted

terminals or worn insulation on lead wires

2. Correct the low line voltage conditions

3. Rewire motor as per line voltage

4. Install correct fuses or circuit breakers

(See “Electrical Connections”, page 4)

5. Reduce load on motor

Ease up on pressure

See “Belt Installation”, page 5

7

Palmgren Operating Manual & Parts List 9681061C

8

Palmgren Operating Manual & Parts List 9681061C

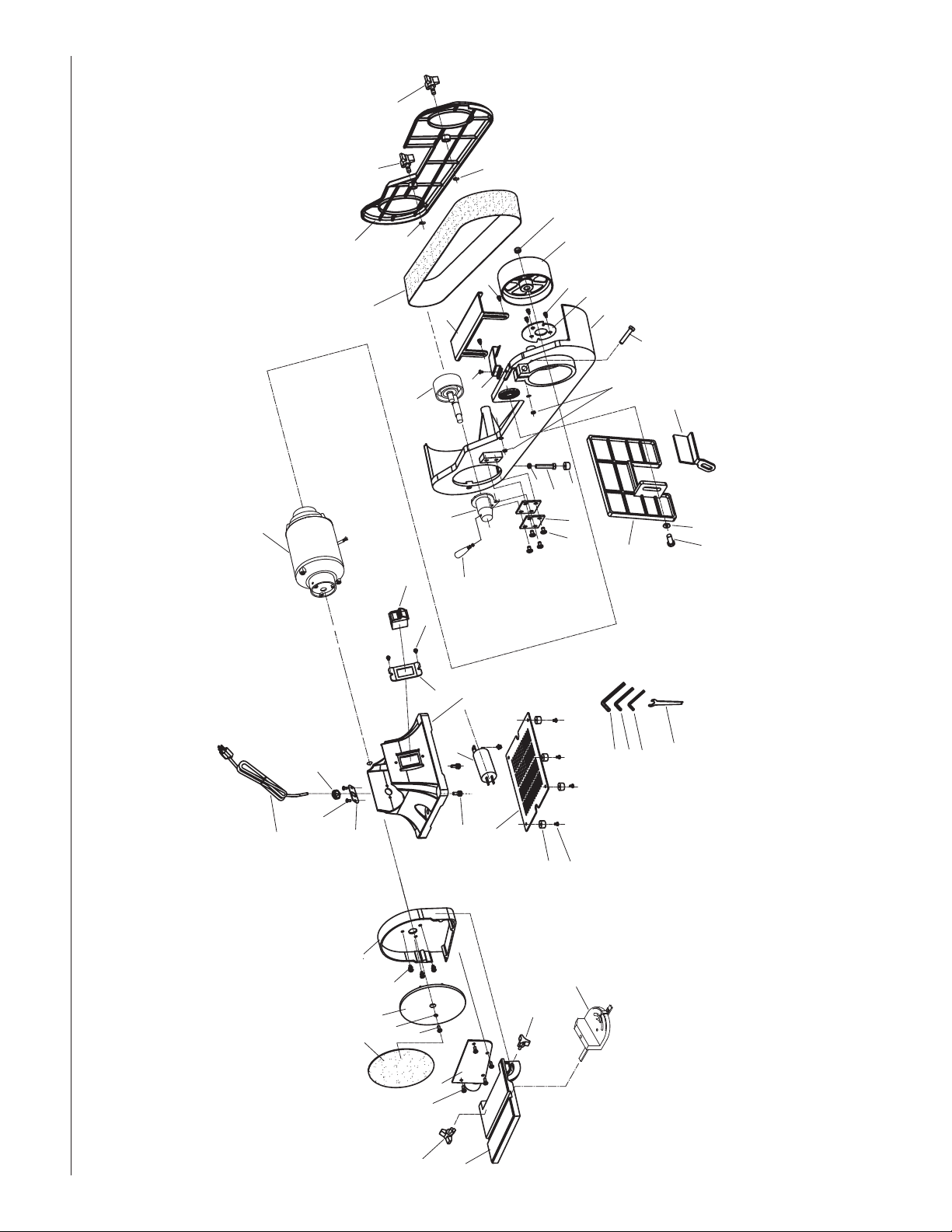

Figure 7 - arts illustration for 2 x 6˝ Belt and Disc Sander.

32

11

10

9

8

7

6

45

2

3

1

2

23

25

24

21

22 20

14

13

12

15

53

52

51

50

19

14

17

16

35

36

37

34

33

26

27

43

41 42

3818

28

54

44

49 45

46

10 47 48

39

40

29

31

30

32

30

9

Palmgren Operating Manual & Parts List 9681061C

1 Miter gauge assembly 9642315.01 1

2 Disc table knob 9642316.01 2

3 Disc table 9642317.01 1

4 Philips screw and flat washer 4 x 6mm * 4

5 Dust chute 9642318.01 1

6 Disc paper 6˝ PSA 9603126.00 1

7 Hex screw 9642319.01 1

8 Outer toothed washer 6mm dia. * 1

9 Disc 9642320.01 1

10 Philips screw and spring washer 5 x 10mm * 6

11 Disc guard 9642321.01 1

12 Power cord 9642322.01 1

13 Cord fixing plate 9642323.01 1

14 Philips screw 5 x 8mm * 4

15 Cord clip 9642324.01 1

16 Motor assembly 9642325.01 1

17 Locking switch 9642326.01 1

18 Philips screw 4 x 8mm * 1

19 Switch plate 9642327.01 1

20 Base N/A 1

21 Capacitor 9642328.01 1

22 Philips screw and spring washer 6 x 20mm * 2

23 Base plate 9642329.01 1

24 Rubber foot 9642330.01 4

25 Philips screw and flat washer 4 x 12mm * 4

26 Tension handle 9642331.01 1

27 Tension handle assembly 9642332.01 1

28 Eccentric shaft assembly 9642333.01 1

29 Belt, abrasive 2 x 42˝ 80x 9608901.00 1

30 Retaining ring 9642334.01 2

31 Belt cover 9642335.01 1

32 Belt tension knob 9642336.01 2

33 Philips screw, spring washer and flat washer 5 x 10mm * 4

34 Spring plate 9642337.01 4

35 Support 9642338.01 1

36 Hex bolt 8 x 90mm * 1

37 Hex nut 8mm * 1

38 Belt cover support 9642339.01 1

39 Hex screw and toothed washer 6 x 16mm * 2

40 Belt platen 9642340.01 1

41 Hex screw 10 x 16 * 1

42 Flat washer 10mm dia. * 1

43 Belt table 9642341.01 1

44 Hex screw 8 x 25mm * 1

45 Belt housing 9642342.01 1

46 Stop bracket 9642343.01 1

47 Drive wheel 9642344.01 1

48 Hex nut 12mm * 1

49 Hex nut 6mm * 2

50 Hex wrench 5mm * 1

51 Hex wrench 6mm * 1

52 Hex wrench 8mm * 1

53 Wrench * 1

54 Work stop 9642345.01 1

∆ Operating Instructions & Parts Manual 9631694.01

REPLACEMENT PARTS LIST FOR 2 X 6" BELT AND DISC SANDER

∆ Not Shown.

* Standard hardware item available locally.

Ref.

No. Description art No. Qty.

Ref.

No. Description art No. Qty.

NOTES

10

Palmgren Operating Manual & Parts List 9681061C

NOTES

11

Palmgren Operating Manual & Parts List 9681061C

WARRANT

Palmgren warrants their products to be free of defects in material or workmanship. This warranty does not cover defects due directly or

indirectly to misuse, abuse, normal wear and tear, failure to properly maintain the product, heated, ground or otherwise altered, or used for a

purpose other than that for which it was intended. The warranty does not cover expendable and/or wear parts (i.e. v-belts, coated screws,

abrasives), damage to tools arising from alteration, abuse or use other than their intended purpose, packing and freight. The duration of this

warranty is expressly limited to one year parts and labor, unless otherwise noted below beginning from the date of delivery to the original

user. The Palmgren products carry the following warranties on parts with a 1 year warranty on labor:

• USA Machine vises – Lifetime

• IQ Machine vises – Lifetime

• Bench vises – Lifetime

• Positioning tables – Lifetime

• Bench grinders & buffers – 3 years

• Tapping machines – 3 years

• Drilling machines – 3 years

• Finishing machines – 3 years

• Band saws – 3 years

• Work stands – Lifetime

• Arbor presses – Lifetime

• Metal forming equipment – 3 years

• Accessories – 1 year

The obligation of Palmgren is limited solely to the repair or replacement, at our option, at its factory or authorized repair agent of any part

that should prove deficient. Purchaser must lubricate and maintain the product under normal operating conditions at all times. Prior to

operation become familiar with product and the included materials, i.e. warnings, cautions and manuals. Failure to follow these

instructions will void the warranty.

This warranty is the purchaser’s exclusive remedy against Palmgren for any deficiency in its products. Under no circumstances is Palmgren

liable for any direct, indirect, incidental, special or consequential damages including lost profits in any way related to the use or inability to

use our products. This warranty gives you specific legal rights which may vary from state to state.

SERVICE & RE AIR

1. If a Palmgren product requires a repair or warranty service DO NOT return the product to the place of purchase.

2. All warranty related work must be evaluated and approved by Palmgren.

3. Prior to returning any item the user must obtain factory approval and a valid R A number.

4. For instructions and R A number call toll free (800) 827-3398.

Palmgren Operating Manual & Parts List 9681061C

11 2017

Table of contents

Other CH Hanson Sander manuals

Popular Sander manuals by other brands

Amano

Amano American Sanders 3DS Operator's manual

Makita

Makita PV301DZJ instruction manual

Black & Decker

Black & Decker KA110 instruction manual

Makita

Makita 9031 instruction manual

Alpha Professional Tools

Alpha Professional Tools VSP-320 instruction manual

Chicago Pneumatic

Chicago Pneumatic CP35 Series Operator's manual