CH Hanson NORSE 9681310 User manual

Operating Manual & Parts List

9681310 & 9681311

DISC SANDER

with Stand

Read carefully and follow all safety

rules and operating instructions before

first use of this product.

9644211.01-0519

Model #: ___________________

Serial #: ____________________

Purch. Date: ________________

3

NO SE Operating Manual & Parts List 9681310 & 9681311

GETTING STARTED

Save this manual

You will need this manual for the safety warnings and

precautions, assembly instructions, operating and maintenance

procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover.

Keep this manual and invoice in a safe and dry place for future

reference.

Structural requirements

Make sure all supporting structures and load attaching

devices are strong enough to hold your intended loads.

If in doubt, consult a qualified structural engineer.

Electrical requirements

The power supply to your specific Disc Sander is

determined by its model number. Model 9681310

requires 115V, 60Hz, 17.8 amps. Model 9681311

requires 230V, 60Hz, 11.2 amps single phase. The

standard allowable voltage variation is a plus or minus 10%.

UNPACKING

When unpacking, check to make sure all parts listed below are

included. If any parts are missing or broken, please contact your

local retailer.

Never use highly volatile solvents. Avoid

getting cleaning solution on paint as it

may tend to deteriorate these finishes. Use soap and water

on painted components.

IMPORTANT: Many unpainted steel surfaces will have been

coated with a protectant. To ensure proper fit and operation,

remove the coating. Coating can be easily removed with mild

solvents, such as mineral spirits and a soft cloth. Avoid getting

solution on paint or any of the rubber/plastic parts. Solvents may

deteriorate these finishes. Use soap and water on paint, plastic

or rubber components. After cleaning, cover all exposed surfaces

with a light coating of oil.

Contents:

• Disc Sander

• 5mm Hex Wrench

• Miter Guage

• Adhesive Backed Sanding Disc

• Anti-vibration Foot Pads

Unpack

Remove all the over packing materials, but leave unit

attached to its pallet. Do not discard packing materials

until after the machine has been inspected for damage and

completeness. Locate loose parts and set them aside.

Inspect

• After unpacking the unit, carefully inspect for any

damage that may have occurred during transit.

Check for loose, missing or damaged parts.

Shipping damage claims must be filed with the

carrier.

• All tools should be visually inspected before use, in addition

to regular periodic maintenance inspections.

• Be sure that the voltage labeled on the unit matches your

power supply.

SAFETY RULES

For your own safety, read all of the

instructions and precautions before

operating tool.

Always follow proper operating

procedures as defined in this manual even

if you are familiar with the use of this tool or similar

machines. Remember that being careless for even a fraction

of a second can result in severe personal injury.

PROPOSITION 65 WARNING: Some dust created by

using power tools contain chemicals known to the state

of California to cause cancer, birth defects or other

reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry

products

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area and work with approved

safety equipment. Always wear a OSHA/NIOSH approved,

properly fitting face mask or respirator when using such tools.

Preparing for your job

• Wear safety glasses complying with United States ANSI

Z87.1. Everyday glasses only have impact resistant lenses.

They are not safety glasses.

• Wear an ANSI approved dust mask.

• Wear proper apparel when using this tool. Do not wear loose

clothing, gloves, neckties, rings, bracelets or other jewelry

which may get caught up in moving parts of this machine.

• When using this machine, wear protective hair covering to

contain long hair.

• Wear safety shoes with non-slip soles.

• Bealert and think clearly. Never operate power tools when

tired, intoxicated or when taking medications that cause

drowsiness.

Preparing the work area for your job

• Keep your work area clean. Cluttered work areas invite

accidents.

• Do not set up or use the Disc Sander in dangerous

environments. Do not set up or use the Disc Sander in damp

or wet locations. Do not expose this machine to rain.

• Make sure your work area is properly lighted.

• Proper electrical connections should be set up for this

machine.

• Extension cords should have a grounding prong and the

4

NO SE Operating Manual & Parts List 9681310 & 9681311

4

three wires of the extension cord should be of the proper

gauge.

•Keep visitors at a safe distance from work area.

•Keep children out of the workplace. Make your workshop

childproof. Use padlocks, master switches or remove switch

keys to prevent any unintentional use of your power tools.

Maintaining your tool

•Always unplug the tool and remove it from its power source

prior to inspection. If your machine plugs into an electrical

outlet do not unplug the tool by pulling on the cord.

• Consult this manual for specific maintenance and adjustment

procedures.

•Keep the tool clean for safest operation. Metal or wood dust

build ups can become combustible.

• Check for damaged parts. A part that is damaged should

be properly repaired or replaced. Do not perform makeshift

repairs. Use the parts list in this manual to order repair parts.

Repairs must be made by a qualified technician.

Know how to use your tool

Dusty work environments may be

hazardous to your health. Always wear a

OSHA/NIOSH approved, properly fitting face mask or

respirator.

The operation of any machine can result

in foreign objects being thrown into the

eyes, which can result in severe eye damage. Always wear

safety goggles complying with United States ANSI Z87.1.

(shown on package) before commencing power tool

operation.

Think safety! Safety is a combination of

operator common sense and alertness at

all times when tool is being used.

•Know your tool. Learn the tool’s operation, application and

specific limitations.

•Keep your hands away from moving parts and sanding

surfaces.

•Never operate the machine without the disc guards in place.

• Completely disconnect this machine from its power source

when changing an abrasive disc.

• Use the right tool for the job. Do not force a tool or

attachment to do a job for which it was not designed.

•Toreduce the risk of electrical shock, never use the machine

in rain or allow it to become wet.

• Never attach the Disc Sander to a dust extraction unit used

for wood sanding if you are sanding metal. The sparks can

cause a fire or explosion.

•Turn the tool off immediately in the case of an emergency.

Completely remove the tool from its power source before

attempting to fix the issue.

• Never leave tool running unattended. Turn the power off and

do not leave tool until it comes to a complete stop.

• Do not use the tool as a toy or let children play with it. Care

should be taken when using the tool around children or

animals.

•Avoid accidental start-ups. Make sure that the power switch

is in the OFF position before plugging the machine in or

connecting it into an appropriate electrical resource.

• Do not overreach. Keep proper footing and balance.

• Never stand on the machine. Serious injury could occur if the

tool tips or if the sanding disc is unintentionally contacted.

•Only use recommended accessories. The improper use of

accessories may create a risk of operator injury.

• Handle workpieces correctly to help protect your hands from

possible injury.

•Support your workpiece with the supplied miter gauge or the

work table. Never “free-hand” sand a workpiece.

• Maintain a 1/16” maximum clearance or less between table

and sanding disc.

•Follow OSHA lock-out, tag-out procedures to prevent

accidental machine starts.

SPECIFICATIONS

Disc Sanding Machines

Model 9681310

Disc Sander

Model 9681311

Disc Sander

Electrical requirements

phase

230V, 60 Hz, single

phase

Amps AC 17.8A 11.2A

Motor Size 1.5 HP 2 HP

Disc speed (RPM) 1750 1750

Sanding disc diameter 16" 20"

Table size (L x W) 18.58" x 8.5” 22.68" x 8.5”

Table tilt-In angle 5˚ 5˚

Table tilt-out angle 45˚ 45˚

Dust collection port

diameter 4" 4"

Overall Dimensions

(L x W x H) 27.84" x 23.33" X 44.44"

Gross pkg. weight 266.76 lbs. 313.5 lbs.

115V, 60 Hz, single

27.75" x 27.68" x 46.44"

5

NO SE Operating Manual & Parts List 9681310 & 9681311

5

Electrical connections

Make sure the tool is off before plugging it

into a power source to prevent accidental

starts.

Do not permit fingers to touch the

terminals of plug when installing or

removing from outlet.

Electrical safety

• Double insulated tools are equipped with a polarizing three

pronged plug (one blade is wider than the other.) This plug

will fit in a polarized outlet only one way. If the plug does not

fit fully into the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician to install a polarized outlet. Do

not change the plug in any way.

• Double insulation eliminates the need for the three wire

grounded power cord and grounded power supply system.

Before plugging in the tool, be certain the outlet voltage

supplied is within the voltage marked on the nameplate.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased

risk of electric shock if your body is grounded. If operating

the power tool in damp locations is unavoidable, a Ground

Fault Circuit Interrupter must be used to supply the power to

your tool. Rubber soled footwear will further enhance your

personal safety.

4. Don’t expose this or any tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

5. Do not abuse the cord. Never pull on a cord to unplug it from

an outlet. Keep the cord away from heat, oil, sharp edges

or moving parts. Replace damaged cords immediately.

Damaged cords increase the risk of electric shock.

Extension cords

• The use of an extension cord will cause some drop in voltage

and loss of power.

• Wires of the extension cord must be of sufficient size to carry

the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W.G)

extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If the extension cord is worn, cut or damaged in any way,

replace it immediately.

Extension cord length

Wire Size A.W.G.

Up to 25 ft 16

25 to 100 ft 14

NOTE: Using extension cords over 100 ft long is not

recommended.

ASSEMBLY/INSTALLATION

This tool must be connected to or plugged

into a properly grounded outlet. Never

operate the machine if it is not properly grounded to help

prevent electrical shock.

Power source

• The motor on this machine is designed for operation on

the voltage and frequency specified. Normal loads will be

handled safely on voltages not more than 10% above or

below specified voltage.

• Running the unit on voltages which are not within the range

may cause overheating and motor burn-out. Heavy loads

require that the voltage at the motor terminals be no less

than the voltage specified.

Lifting and setting up the machine

1. Remove any crating or outer packing materials covering the

machine. Leave the machine attached to its pallet.

NOTE: Disc sanding machines are heavy. Be certain any hoists

or devices used to lift this machine are capable of

handling the weight. The machine may tip as it is lifted.

You can minimize this tipping by rigging an additional

slings over the machine as needed. Be careful

when using a sling to prevent it from damaging any

components on the machine. Carefully steady the

machine to prevent it from spinning, but do not stand

under the machine.

2. Remove all accessory items from the pallet or machine table.

Compare these items with those listed on page 3.

3. The machine must be placed on a solid concrete floor away

from any vibrations transmitted from adjacent machines.

Unless substantially constructed, and braced a wood floor

should be avoided.

4. Check all lock handles on the machine to ensure they are

tight.

5. Remove any nuts, bolts or fasteners securing the machine to

the pallet.

6. Center an overhead crane or other suitable lifting device and

sling arrangement over the machine.

7. Carefully lift the machine off the pallet. Raise the machine no

higher than necessary to clear the hold-down hardware and

pull the pallet out of the way. DO NOT place your hands or

feet underneath the machine when removing the pallet.

8. Place the machine into a final position on a flat surface

allowing adequate space around the machine for workpieces

and dust extraction connection. (see diagrams on pg. 6)

9. When the machine is being lowered into its final location,

level it using the supplied anti-vibration feet.

10. Use a highly accurate spirit or laser level for leveling the

machine. Leveling should be done on the top of the stand

since this is the reference standard for both side-to-side and

front-to-back leveling. It is important that the machine be

properly leveled and for optimum performance.

6

NO SE Operating Manual & Parts List 9681310 & 9681311

ASSEMBLY/INSTALLATION (CONTINUED)

Lifting and setting up the machine

Shown below are the dimensions for the disc sanding machines.

You can use the information below to place your machine into its

final position. Also, allow extra space around the machine for the

handing larger workpieces and dust extraction connections.

Front

L

H

Side

W

Length Width Height

Model 9681314 27.84” 23.33” 44.44”

Model 9681315 27.75” 27.68” 46.44”

Attaching the sander to a dust extraction unit

Never connect a disc sander being used

for metal sanding to a wood dust

extraction system. The sparks created from sanding metal

can cause the wood sawdust to catch fire or explode.

• Your disc sander machine can be attached to a dust

extraction system to keep your work shop cleaner.

Use of a dust extraction unit strongly recommended.

• This machine uses a 4” diameter dust port. Locate the dust

port on the left side of the machine. Slide a suitable hose

over the port and secure it with a hose clamp. Dryer vent

hosing material is not acceptable.

OPERATION

Dusty work environments may be

hazardous to your health. Always wear a

OSHA/NIOSH approved, properly fitting face mask or

respirator.

Always wear safety glasses complying

with U.S. ANSI Z87.1 before beginning any

sanding operation.

Make sure all disc guards are in securely

in place before starting the disc sanding

machine. Never operate the machine without the guards.

Completely disconnect the disc sanding

machine before making any adjustments

or changing abrasive sanding discs.

Installing an abrasive sanding disc

NOTE: While not required, it is much easier to make table

alignment adjustments while the abrasive sanding disc is

removed (see pg. 7).

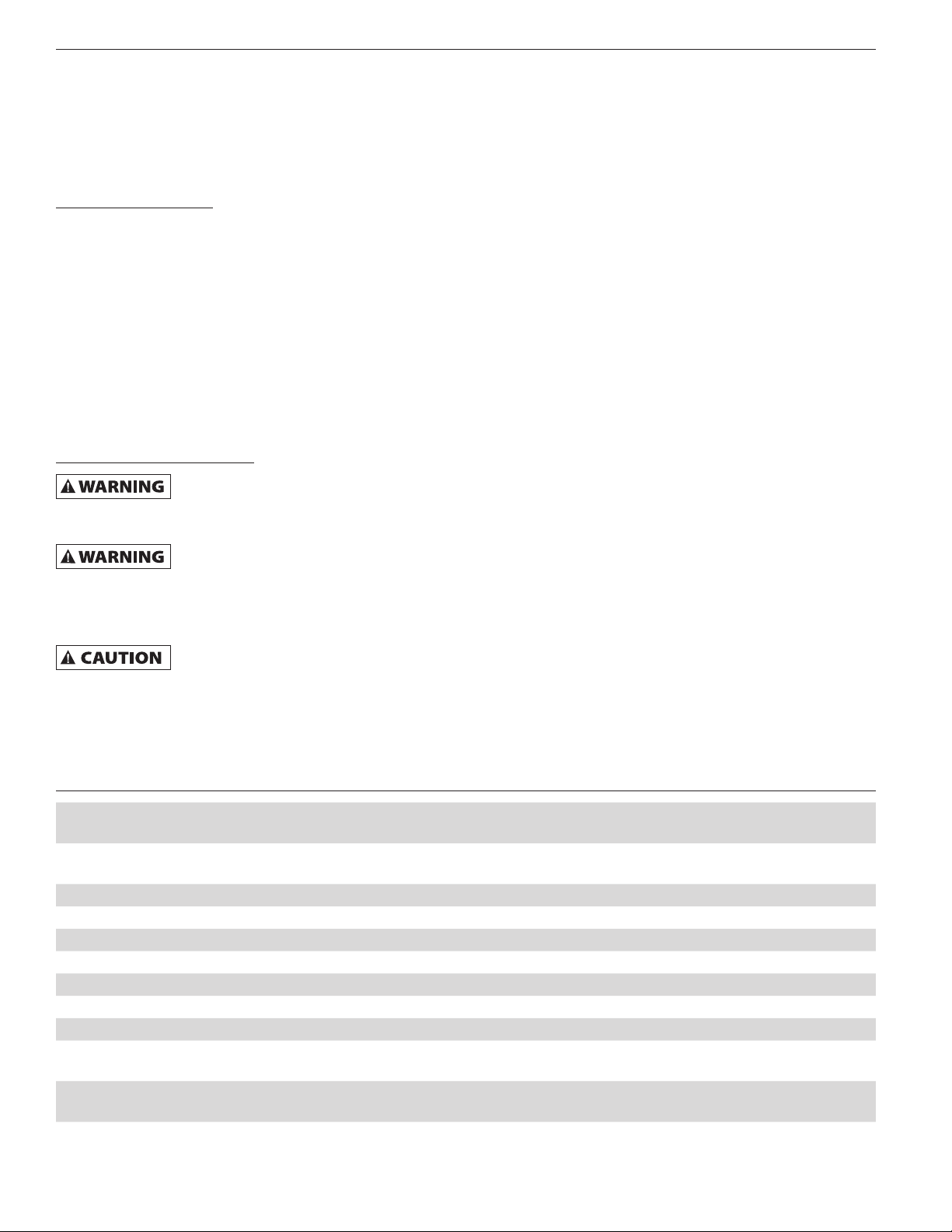

A

1. Remove the two knobs (A) holding the upper disc guard in

place.

B

3. Loosen and remove the four hex bolts (B) under the

workpiece table using the supplied 5 mm hex wrench.

Remove the workpiece table.

7

NO SE Operating Manual & Parts List 9681310 & 9681311

Table parallel alignment to disc

Table parallel alignment to disc

p

Table parallel alignment to disc

g

lel alignment to disc

v

Remove the lower guard.

remove the four hex bolts (C) holding on the lower guard.

Use the supplied 4 mm hex wrench attached to the base to3.

Remove the lower guard.

remove the four hex bolts (C) holding on the lower guard.

Use the supplied 4 mm hex wrench attached to the base to

remove the four hex bolts (C) holding on the lower guard.

Use the supplied 4 mm hex wrench attached to the base to

table can move.

Loosen the four bolts under the miter brackets enough so the1.

o set the table gap perform the following steps:

T

To set the table gap perform the following steps:

touch the sanding disc and has a clearance gap of 1/16” or less.

disc to ensure flush sanding.

The workpiece table must be properly aligned to the sanding

table can move.

Loosen the four bolts under the miter brackets enough so the

o set the table gap perform the following steps:

touch the sanding disc and has a clearance gap of 1/16” or less.

The table must be set to it does notdisc to ensure flush sanding.

The workpiece table must be properly aligned to the sanding

Loosen the four bolts under the miter brackets enough so the

o set the table gap perform the following steps:

touch the sanding disc and has a clearance gap of 1/16” or less.

The table must be set to it does not

The workpiece table must be properly aligned to the sanding

Remove the sanding disc from the flywheel disc.3.

Remove the sanding disc from the flywheel disc.

g

following steps:

o set a true 90º reference for your disc sander perform the

T

To set a true 90º reference for your disc sander perform the

performs accurate flush and angled miter sanding operations.

The workpiece table can be adjusted to ensure your disc sander

Setting the

during the process.

ighten the four bolts making sure the table does not moveT3.

consistently 1/16” or less from front to back.

Align the table so the gap between the disc and table is2.

g

following steps:

o set a true 90º reference for your disc sander perform the

performs accurate flush and angled miter sanding operations.

The workpiece table can be adjusted to ensure your disc sander

miter bracket to a 90º right angle

during the process.

ighten the four bolts making sure the table does not move

consistently 1/16” or less from front to back.

Align the table so the gap between the disc and table is

g

o set a true 90º reference for your disc sander perform the

performs accurate flush and angled miter sanding operations.

The workpiece table can be adjusted to ensure your disc sander

ht angle

ighten the four bolts making sure the table does not move

consistently 1/16” or less from front to back.

Align the table so the gap between the disc and table is

grease.

Clean the flywheel disc of any left-over adhesive, dirt or4.

Clean the flywheel disc of any left-over adhesive, dirt or

Clean the flywheel disc of any left-over adhesive, dirt or

removed.

alignment adjustments while the abrasive sanding disc is

While not required, it is much easier to make tableNOTE:

following steps:

alignment adjustments while the abrasive sanding disc is

While not required, it is much easier to make table

alignment adjustments while the abrasive sanding disc is

While not required, it is much easier to make table

Aligning the bottom of the disc and adheresanding disc.

Remove the adhesive backing from the top half of the5.

Aligning the bottom of the disc and adhere

Remove the adhesive backing from the top half of the

Aligning the bottom of the disc and adhere

Remove the adhesive backing from the top half of the

Use a machinist square or suitable tool and adjust the table2.

the workpiece table so it can move.

Slightly loosen the miter adjustment levers on both ends of1.

Use a machinist square or suitable tool and adjust the table

the workpiece table so it can move.

Slightly loosen the miter adjustment levers on both ends of

Use a machinist square or suitable tool and adjust the table

Slightly loosen the miter adjustment levers on both ends of

Replace the lower guard, table and upper guard.7.

ensure it is tightly adhered to the flywheel disc.

After the new abrasive disc is attached, press firmly on it to6

the abrasive sanding disc on the flywheel disc.

adhere the bottom of the sanding disc.

Then remove the bottom adhesive backing andthe top first.

Aligning the bottom of the disc and adheresanding disc.

Replace the lower guard, table and upper guard.

ensure it is tightly adhered to the flywheel disc.

After the new abrasive disc is attached, press firmly on it to

the abrasive sanding disc on the flywheel disc.

ake care

T

Take care to center

adhere the bottom of the sanding disc.

Then remove the bottom adhesive backing and

Aligning the bottom of the disc and adhere

After the new abrasive disc is attached, press firmly on it to

ake care to center

Then remove the bottom adhesive backing and

Aligning the bottom of the disc and adhere

Adjust the indicator pointer to 90º if required.4.

Carefully tighten the adjustment lever and recheck the table.3.

until the square rests flush on both the table and disc.

Use a machinist square or suitable tool and adjust the table2.

Adjust the indicator pointer to 90º if required.

Carefully tighten the adjustment lever and recheck the table.

until the square rests flush on both the table and disc.

Use a machinist square or suitable tool and adjust the table

7

Adjust the indicator pointer to 90º if required.

Carefully tighten the adjustment lever and recheck the table.

until the square rests flush on both the table and disc.

Use a machinist square or suitable tool and adjust the table

8

NO SE Operating Manual & Parts List 9681310 & 9681311

urn the pointer from the middle OFF position to the leftT3.

urn the pointer from the middle OFF position to the left

urn the pointer from the middle OFF position to the left

Setting the miter tool to a 90º right angle

Setting the miter tool to a 90º right angle

g

It is recommended that you sand your workpiece with the disc

Setting the

hand or knee.

position, or push the emergency stop button with either your

o stop the machine, turn the pointer back the middle OFF

T

To stop the machine, turn the pointer back the middle OFF

5.

direction.

The right REV position will rotate the disc in the clockwise4.

motion.

FOR position, and the disc will spin in the counter-clockwise

g

It is recommended that you sand your workpiece with the disc

e guards for forward or reverse rotation

hand or knee.

position, or push the emergency stop button with either your

o stop the machine, turn the pointer back the middle OFF

direction.

The right REV position will rotate the disc in the clockwise

FOR position, and the disc will spin in the counter-clockwise

urn the pointer from the middle OFF position to the left

It is recommended that you sand your workpiece with the disc

verse rotation

position, or push the emergency stop button with either your

o stop the machine, turn the pointer back the middle OFF

The right REV position will rotate the disc in the clockwise

FOR position, and the disc will spin in the counter-clockwise

g

Use a machinist square or suitable tool and adjust the face2.

Slightly loosen the miter tool adjustment push knob (E).1.

tool while the abrasive sanding disc is removed.

While not required, it is much easier to adjust the miterNOTE:

steps:

o set a true 90º refe

T

To set a true 90º reference for miter tool, perform the following

performs accurate flush and angled miter sanding operations.

The miter tool can be adjusted to ensure your disc sander

Setting the miter

g g

Use a machinist square or suitable tool and adjust the face

Slightly loosen the miter tool adjustment push knob (E).

tool while the abrasive sanding disc is removed.

While not required, it is much easier to adjust the miter

o set a true 90º reference for miter tool, perform the following

performs accurate flush and angled miter sanding operations.

The miter tool can be adjusted to ensure your disc sander

r tool to a 90º right angle

Use a machinist square or suitable tool and adjust the face

Slightly loosen the miter tool adjustment push knob (E).

While not required, it is much easier to adjust the miter

o set a true 90º reference for miter tool, perform the following

performs accurate flush and angled miter sanding operations.

The miter tool can be adjusted to ensure your disc sander

according to the rotation of the sanding disc.

depending on the guard’

and removing the two black knobs on the top and back (or front

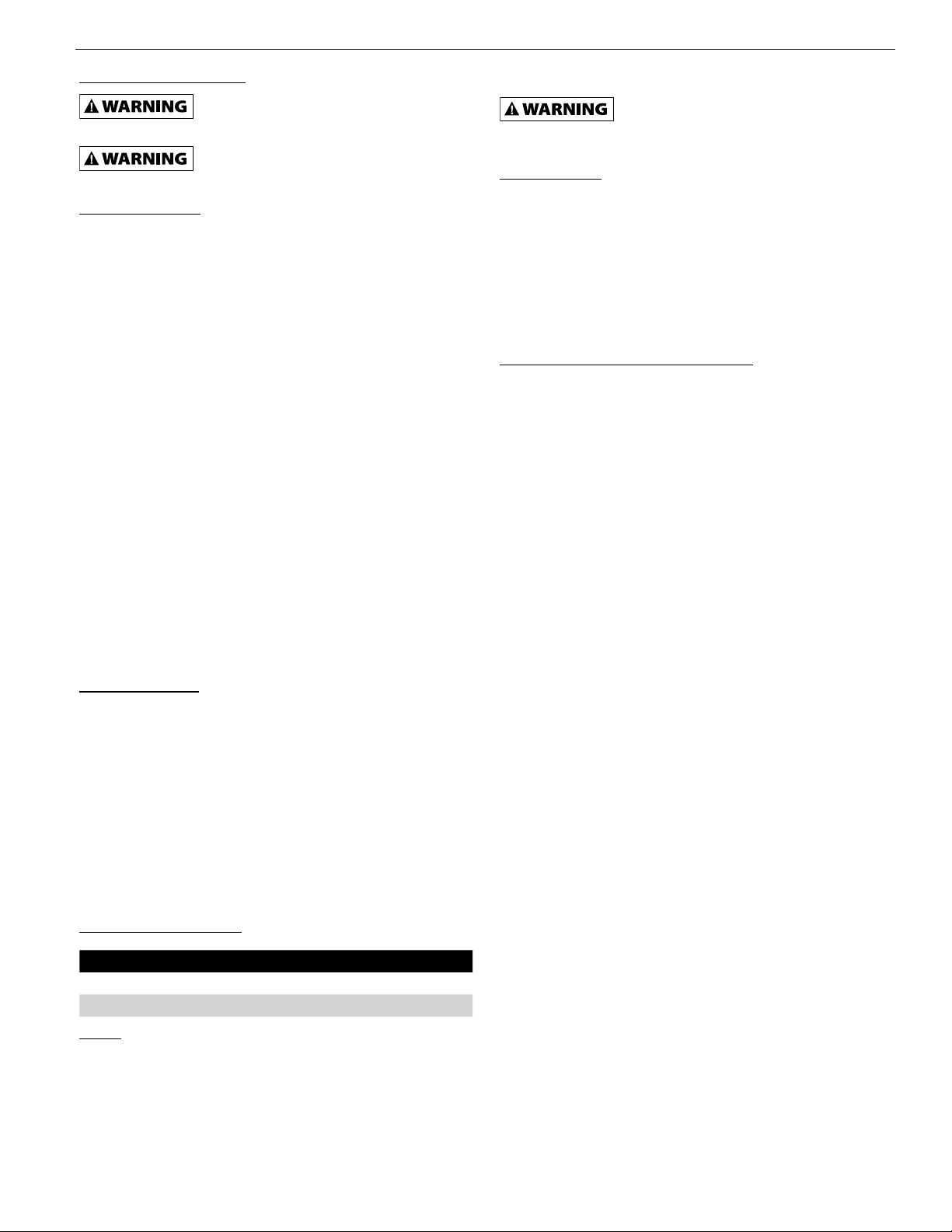

rear half of the sanding disc. Move the top guard by loosening

The top disc guard can be moved to expose either the front or

rotating down toward the workpiece to hold it against the table.

It is recommended that you sand your workpiece with the disc

o set up the machine for

T

To set up the machine for

rotation set up

Counterclockwise

according to the rotation of the sanding disc.

The guard’s set up).depending on the guard’

and removing the two black knobs on the top and back (or front

rear half of the sanding disc. Move the top guard by loosening

The top disc guard can be moved to expose either the front or

rotating down toward the workpiece to hold it against the table.

It is recommended that you sand your workpiece with the disc

o set up the machine for

rotation set up

Counterclockwise

Front

Machine

s position is setThe guard’

and removing the two black knobs on the top and back (or front

rear half of the sanding disc. Move the top guard by loosening

The top disc guard can be moved to expose either the front or

rotating down toward the workpiece to hold it against the table.

It is recommended that you sand your workpiece with the disc

g

out.

, and the emergency stop button is pulledelectrical supply

Ensure the machine is properly connected to a suitable1.

Turning on the sa

Adjust the indicator pointer (F) to 90º if required.4.

miter tool to ensure it is square.

Carefully tighten the adjustment push knob and recheck the3.

tool face and flywheel disc.

of the miter tool until the square rests flush on both the miter

g

, and the emergency stop button is pulled

Ensure the machine is properly connected to a suitable

anding disc machine

Adjust the indicator pointer (F) to 90º if required.

miter tool to ensure it is square.

Carefully tighten the adjustment push knob and recheck the

tool face and flywheel disc.

of the miter tool until the square rests flush on both the miter

, and the emergency stop button is pulled

Ensure the machine is properly connected to a suitable

Adjust the indicator pointer (F) to 90º if required.

Carefully tighten the adjustment push knob and recheck the

of the miter tool until the square rests flush on both the miter

portion of the disc.

set the disc guard to the back

counterclockwise rotation,

o set up the machine for

T

To set up the machine for

the back portion of the disc.

guard to the front and sand on

clockwise rotation set the disc

o set up the machine for

T

To set up the machine for

Clockwise rotation set up

portion of the disc.

set the disc guard to the back

counterclockwise rotation,

o set up the machine for

Front

Machine

the back portion of the disc.

guard to the front and sand on

clockwise rotation set the disc

o set up the machine for

Clockwise rotation set up

emergency stop button.

Locate the power and direction switch to the left of the2.

TROUBLESHOOTING GUIDE

Symptom

Sanding paper becomes glazed.

emergency stop button.

Locate the power and direction switch to the left of the

TROUBLESHOOTING GUIDE

Possible Cause(s)

Sanding paper becomes glazed. Sanding a painted or coated surface.

Locate the power and direction switch to the left of the

Corrective Action

grit.

Use open-end grain/flint sanding paper with a coarserSanding a painted or coated surface.

Possible Cause(s)

Corrective Action

Use open-end grain/flint sanding paper with a coarser

Use open-end grain/flint sanding paper with a coarser

orkpiece pulled fro

W

Workpiece pulled from hand.

.quickly

Sanding paper burns, or clogs

Burn marks on workpiece.

orkpiece pulled from hand.

Allow the disc to cut freely

hand sand workpieces.

No support for workpiece. Do not free

disc.

Sanding paper burns, or clogs

disc.

Do not force the workpiece into sanding

rong sanding paper surface.Burn marks on workpiece.

Forcing the workpiece into the sanding

ood is wet or g

W

W

Wood is wet or gummy

amounts of material in one pass.

table.

Use miter gauge. Keep workpiece firmly down against

hand sand workpieces.

No support for workpiece. Do not free

the disc to cut freely

Make several passes instead of trying to remove large

.Allow the disc to cut freely

Do not force the workpiece into sanding

Use coarser grit for stock removal.

Do not force the workpiece into sanding disc.Forcing the workpiece into the sanding

Use dif

rong sanding paper surface.

grit.

.ood is wet or gummy

amounts of material in one pass.

table.

Use miter gauge. Keep workpiece firmly down against

.

Make several passes instead of trying to remove large

Use coarser grit for stock removal.

the disc to cut freely

Do not force the workpiece into sanding disc.

ferent material.

grit.

e dif

fferent material.

Make several passes instead of trying to remove large

Use miter gauge. Keep workpiece firmly down against

AllowDo not force the workpiece into sanding disc.

8

Sanded edge is not square.

Sanded edge is not square.

sanding is not recommended.

able scale inacc

T

Table scale inaccurate.

Result of freehand sanding. Free hand

workpiece is square with sanding disc.

table angle if necessary

square. It should be 90 degrees.

Check table alignment to disc with a machinist’able scale inaccurate.

square edge is desired. Use miter gauge to ensure

Keep workpiece flat on table at all times when a

sanding is not recommended.

Result of freehand sanding. Free hand

workpiece is square with sanding disc.

.table angle if necessary

Adjust pointer andsquare. It should be 90 degrees.

Check table alignment to disc with a machinist’

square edge is desired. Use miter gauge to ensure

Keep workpiece flat on table at all times when a

workpiece is square with sanding disc.

Adjust pointer and

sCheck table alignment to disc with a machinist’

square edge is desired. Use miter gauge to ensure

Keep workpiece flat on table at all times when a

9

NO SE Operating Manual & Parts List 9681310 & 9681311

9

TROUBLESHOOTING GUIDE

Symptom Possible Cause(s) Corrective Action

Disc sander will not start or

restart. Machine trips circuit

breakers or blows fuses.

Disc sander is connected to an

inappropriate power source.

Confirm disc sander is connected to power and source

appropriate for the machine.

Blown fuse or tripped circuit breaker Replace blown fuse; reset circuit breaker.

Cord damaged. Replace damaged cord.

Extension cord too light or too long. Replace extension cord with one of adequate size for

its length.

Building fuse blows or circuit breaker

trips.

Confirm the building’s circuitry is large enough to

accommodate the disc sander. Check for a loose

electrical lead if circuitry is large enough.

Electrical connections loose. Check all electrical connections on the disc sander

including the motor connections. Confirm each

connection is tight. Visually check for signs of

electrical arcing which indicates loose connections or

circuit overload.

Switch or motor failure (troubleshooting

between the two).

Use a voltmeter to determine if the issue is a switch

or motor failure. First, verify that the incoming voltage

reads according to the rated voltage, and second,

check the voltage between switch and motor. This

voltage should also read according to rated voltage.

If incoming voltage is incorrect, the issue is power

supply problem. If voltage between switch and motor

is incorrect, the issue is a switch problem. If voltage

between switch and motor is correct, your issue is a

motor problem.

Motor failure. If the electrical supply and switch show correct

voltage, the motor is probably the issue. Have a

qualified electrician test the motor for function.

Replace motor as needed.

On/Off switch failure. Have a qualified electrician test the switch to ensure

it is functioning properly. Replace switch as needed

Disc does not come up to full

speed.

Extension cord too light or too long. Replace extension cord with one of adequate size for

its length.

Low voltage being supplied to the

machine.

Have a qualified electrician address the issue.

Excessive sanding friction or feed

pressure is too great.

Do not force the workpiece into sanding disc. Allow

the disc to cut freely.

Excessive replacement of

sanding paper.

Excessive pressure being used during

sanding operations.

Do not force the workpiece into sanding disc. Allow

the disc to cut freely.

Not using full width of disc. Stroke across the full width of the sanding disc.

Machine vibrates excessively. Sander base not level with floor. Level the machine using the supplied anti-vibration

feet.

Motor loose or improper motor

mounting.

Check and adjust motor mounting. Confirm all motor

mounting bolts are tight.

Sanding marks on workpiece. Sanding disc is too coarse based on

the material being sanded.

Use proper grit disc. Coarser grits remove stock

quicker and leave a rougher finish. Finer grits show

less marks and are used for finishing work.

Workpiece sanded across grain. When surface sanding, use fine sanding disc paper

then finish by hand, working in direction of grain.

Sanding granules quickly rub

off the sanding disc.

The sanding disc has lost its original

properties or is defective.

Never store sanding discs in extremely dry or high-

temperature areas which can damage the glue holding

the granules. Never fold sanding discs, store them flat.

10

NO SE Operating Manual & Parts List 9681310 & 9681311

10

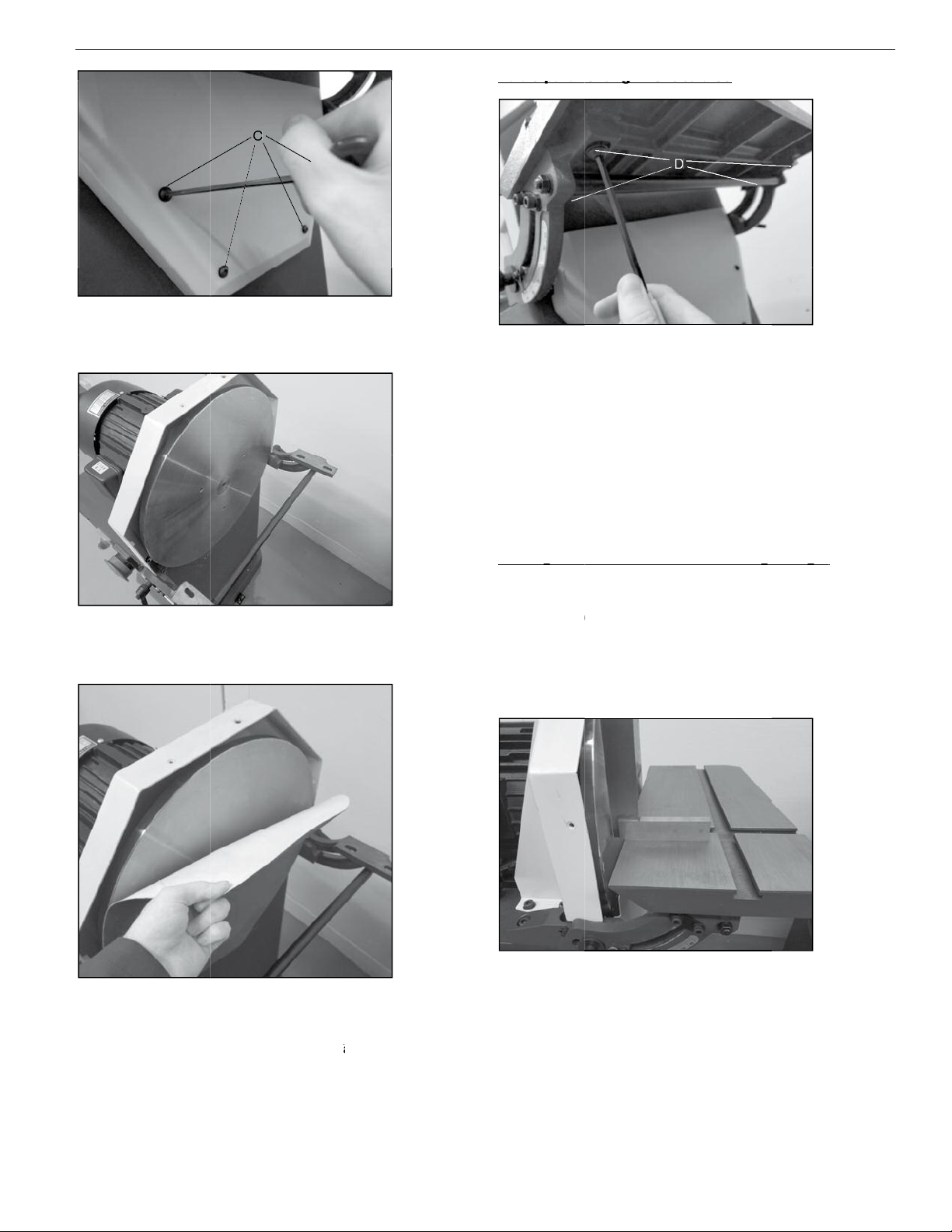

WIRING DIAGRAM - MODEL 9681314 - 16” DISC SANDER

Motor wire outlet

Power cord

outlet

Reversing Switch

Pressure

Switch

WIRING DIAGRAM - MODEL 9681310 - 16” DISC SANDER

11

NO SE Operating Manual & Parts List 9681310 & 9681311

11

WIRING DIAGRAM - MODEL 9681315 - 20” DISC SANDER

WIRING DIAGRAM - MODEL 9681311 - 20” DISC SANDER

12

NO SE Operating Manual & Parts List 9681310 & 9681311

14

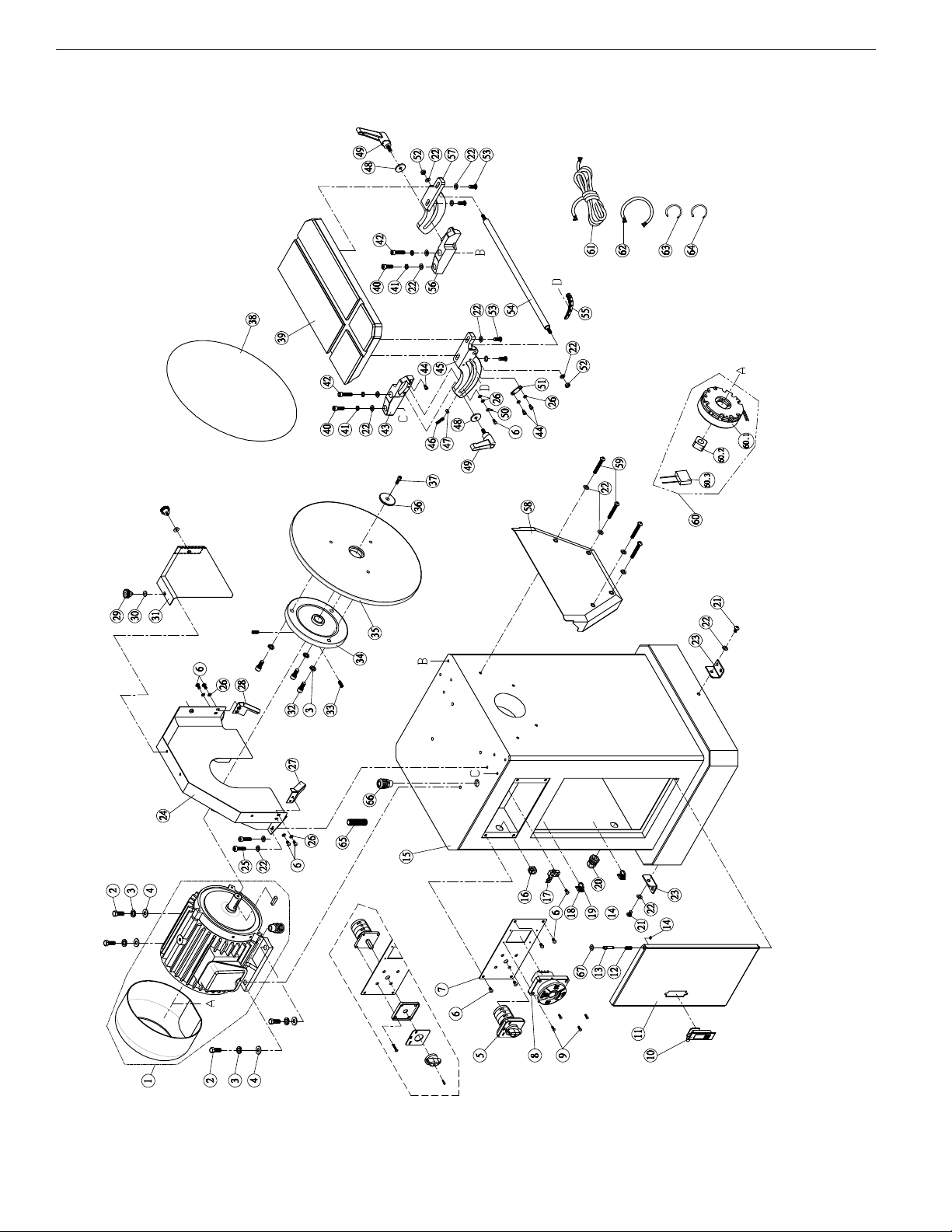

REPAIR PARTS ILLUSTRATION FOR MODEL 9681314 - 16” DISC SANDER

F

REPAIR PARTS ILLUSTRATION - MODEL 9681310 - 16” DISC SANDER

13

NO SE Operating Manual & Parts List 9681310 & 9681311

15

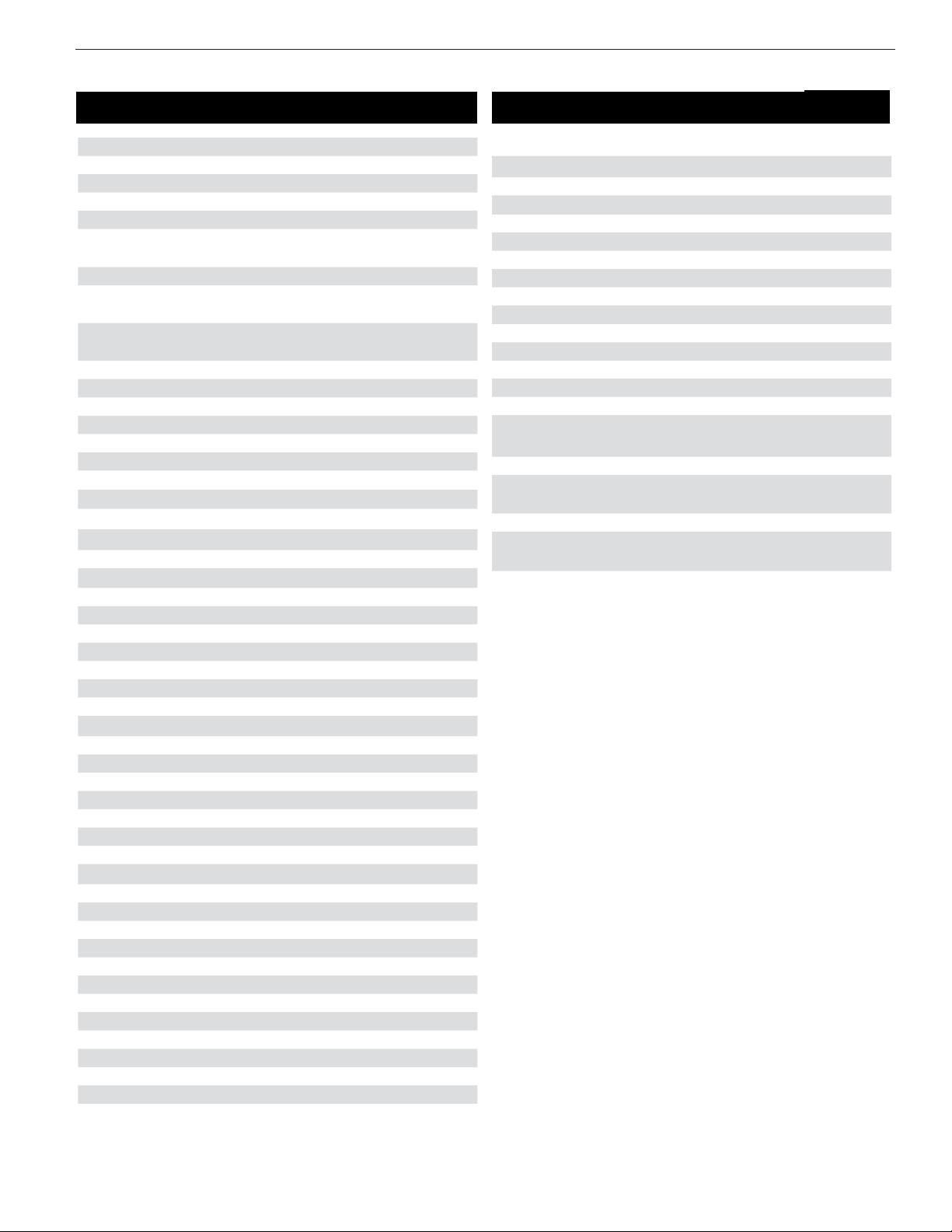

REPAIR PARTS LIST FOR MODEL 9681314 - 16” DISC SANDER

(6) Not Shown (*) Standard hardware item available locally (N/A) Not available as replacement part

1 Motor (1.5HP, 115V, 60Hz, 1PH, 4P) 9642598.01

1

2 Hex Screw (M10 x 1.5P x 25L ) * 4

3 Spring Washer (M10) * 7

4 Flat Washer (10.2 x 23 x 2t) *

4

5 Reversing Switch 9642599.01

1

6 Round Head Screw

(M5 x 1.0P x 12L)

*10

7 Switch Mount 9642600.01 1

8 Pressure Switch

(125V/35A 250V/20A)

9642601.01 1

9 Round Head Screw

(M4 x 0.7P x 12L)

*4

10 Door Buckle 9642602.01

1

11Door 9642603.011

12 Spring 9642604.01 1

13 Pin 9642605.01 1

14 E ring (ETW-4) * 1

15 Stand N/A 1

16 Strain Relief (SB8R-3) * 1

17 Ground Copper (3P) 9642606.01 1

18 Bracket 9642607.01 2

19 Wire Holder (ALT-165S 2.5Wx160L) 9642608.01 2

20 Cable Strain Relief (PG-13.5) 9642653.01 2

21 Round Head Screw (M8 x 1.25 x 12L) * 3

22 Flat Washer (8.2 x 16 x 1t) * 19

23 Anti-vibration Pad Bracket 9642609.01 3

24 Disc Guard 9642610.01 1

25 Cap Screw (M8 x 1.25 x 10L) *

4

26 Flat Washer (5.1 x 10 x 1t) *

8

27 Dust Chute Plate, Left 9642611.01 1

28 Dust Chute Plate, Right 9642612.01 1

29 Knob 9642613.01 2

30 Flat Washer (5.2 x 16 x 1.4t) * 2

31 Disc Guard, Front 9642614.01 1

32 Cap Screw (3/8"-16 UNC x 7/8"L ) * 3

33 Set Screw (5/16"-18 UNC x 3/4"L ) *

2

34 Hub 9642615.01

1

35 16" Disc 9642616.01 1

36 Wheel Washer 9642617.01 1

37 Cap Screw (1/4"-20 UNC x 3/4"L ) * 1

38 Abrasive Disc * 1

39 Table 9642619.01 1

40 Cap Screw (M8 x 1.25P x 30L) * 2

41 Spring Washer (M8) * 4

42 Cap Screw (M8 x 1.25P x 35L ) * 2

43 Trunnion Bracket, Left 9642620.01 1

44 Cap Screw(M5 x 0.8P x 8L) * 3

45 Trunnion, Left 9642621.01 1

46 Set Screw (M6 x 1.0P x 25L ) * 1

47 Hex Nut (M6 x 1.0P) * 1

48 Flat Washer (8 x 30 x 3t) * 2

49 Adjustment Knob (M8 x 1.25P x 20L) 9642622.01 2

Ref.

No. Description Part No. Qty.

Ref.

No. Description Part No. Qty.

50 Pointer 9642623.01 1

51 Angle Adjustment Plate 9642624.01 2

52 Hex Nut (M8 x 1.25P) * 2

53 Round Head Screw (M8 x 1.25 x 20L) * 4

54 Tie Rod 9642625.01 1

55 Angle Scale 9642626.01 1

56 Trunnion Bracket, Right 9642627.01 1

57 Trunnion, Right 9642628.01 1

58 Dust Chute 9642629.01 1

59 Round Head Screw (M8 x 1.25 x55L) * 4

60 Brake Assembly 9642630.01 1

60.1 Brake (9CB-18E) 9642631.01 1

60.2 Brake Block 9642632.01 1

60.3 5HFWL¿HU,1$&9287'&9 9642633.01 1

61 Motor Wire (14AWGx4Cx45cm) 9642634.01 1

62 Power cord (SJT 14AWG x 3C x

300cm + 110V(CSA))

9642635.01 1

63 Switch Wire (14AWG x 2C x 20cm) 9642636.01 1

64 Ground Cord

((600V) 14AWG x 1Cx60cm)

9642637.01 1

65 Hose NGN-12B 3/8" x 8cm 9642638.01 1

66 Strain Relief

(N-MGN20-15B-ST M20 x 1.5P)

*2

67 Foam washer * 1

REPAIR PARTS LIST - MODEL 9681310 - 16” DISC SANDER

14

NO SE Operating Manual & Parts List 9681310 & 9681311

16

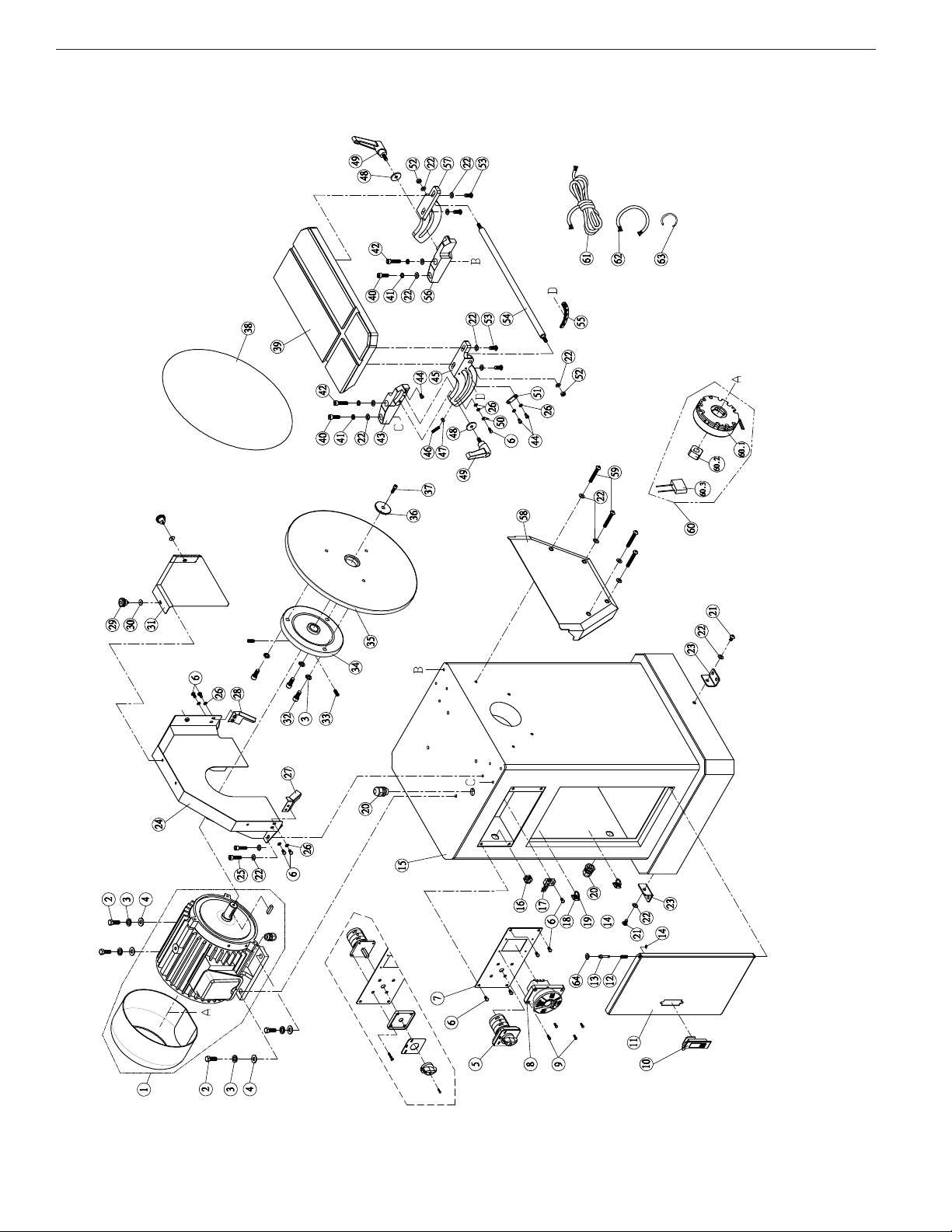

REPAIR PARTS ILLUSTRATION FOR MODELS 9681315, 9681316 AND 9681317 -

20” DISC SANDERS

REPAIR PARTS ILLUSTRATION - MODEL 9681311 - 20” DISC SANDER

15

NO SE Operating Manual & Parts List 9681310 & 9681311

17

REPAIR PARTS LIST FOR MODEL 9681315, 9681316 AND 9681317 - 20” DISC SANDERS

(6) Not Shown (*) Standard hardware item available locally (N/A) Not available as replacement part

1 Motor Model 9681315

(2HP, 230V, 60Hz, 1PH)

9642642.01

1

1Motor Model 9681316

(3HP, 230V, 60Hz, 3PH)

9642641.01

1

1 Motor Model 9681317

(3HP, 460V, 60Hz, 3PH)

9642685.01

1

2 Hex Screw (M10 x 1.5P x 25L ) * 4

3 Spring Washer M10) * 7

4 Flat Washer (10.2 x 23 x 2t ) * 4

5 Reversing Switch 9642643.01

1

6 Round Head Screw

(M5 x 1.0P x 12L )

*

10

7 Switch Mount 9642644.01 1

8 Pressure Switch 9642645.01 1

9 Round Head Screw

(M4 x 0.7P x 12L )

*4

10 Door Buckle 9642602.01 1

11Door 9642603.01

1

12 Spring 9642604.01 1

13 Pin 9642605.01 1

14 E Ring (ETW-4 ) * 1

15 Stand N/A 1

16 Strain Relief (SB8R-3) * 1

17 Earthing copper (3P) 9642606.01 1

18 Bracket 9642607.01 2

19 Wire Holder (ALT-165S 2.5W x 160L) 9642608.01 2

20 Cable Strain Relief (PG-13.5) 9642653.01 2

21 Round Head Screw

(M8 x 1.25 x 12L )

*3

22 Flat Washer (8.2 x 16 x 1t ) * 19

23 Anti-vibration Pad Bracket 9642609.01 3

24 Disc Guard 9642655.01 1

25 Cap Screw (M8 x 1.25P x 10L ) * 4

26 Flat Washer (5.1 x 10 x 1t ) *

8

27 Dust Chute Plate, Left 9642656.01

1

28 Dust Chute Plate, Right 9642657.01 1

29 Knob 9642613.01 2

30 Flat Washer (5.2 x 16 x 1.4t) * 2

31 Disc Guard, Front 9642659.01 1

32 Cap Screw (3/8"-16 UNC x 7/8"L) * 3

33 Set Screw (5/16"-18 UNC x 3/4"L ) * 2

34 Hub 9642615.01

1

35 20" Disc 9642661.01

1

36 Disc Washer 9642617.01 1

37 Cap Screw (1/4"-20UNC x 3/4"L ) * 1

38 Abrasive Disc (20"#100) * 1

39 Table 9642663.01 1

40 Cap Screw (M8 x 1.25P x 30L ) * 2

41 Spring Washer (M8) * 4

42 Cap Screw (M8 x 1.25P x 35L) * 2

43 Trunnion Bracket, left 9642620.01 1

44 Cap Screw (M5 x 0.8P x 8L ) * 3

Ref.

No. Description Part No. Qty.

Ref.

No. Description Part No. Qty.

45 Trunnion, Left 9642621.01 1

46 Set Screw (M6 x 1.0P x 25L ) * 1

47 Hex Nut (M6 x 1.0P) * 1

48 Flat Washer (8 x 30 x 3t) * 2

49 Adjustment Knob (M8 x 1.25P x 20L) 9642622.01 2

50 Pointer 9642623.01 1

51 Angle Adjustment Plate 9642624.01 2

52 Hex Nut (M8 x 1.25P) * 2

53 Round Head Screw (M8 x 1.25 x 20L) * 4

54 Tie Rod 9642669.01 1

55 Angle Scale 9642626.01 1

56 Trunnion Bracket, Right 9642627.01 1

57 Trunnion, Right 9642628.01 1

58 Dust Chute 9642673.01 1

59 Round Head Screw (M8 x 1.25 x 55L) * 4

60 Brake Assembly 9642674.01 1

60.1 Brake (CB-18E) 9642675.01 1

60.2 Brake Block 9642632.01 1

60.3 5HFWL¿HU,1$&9287'&9 9642677.01 1

61 Motor Wire 9642678.01 1

62 Power Cord 9642679.01 1

63 Switch Wire 9642680.01 1

64 Foam Washer * 1

REPAIR PARTS LIST - MODEL 9681311 - 20” DISC SANDER

16

NO SE Operating Manual & Parts List 9681310 & 9681311

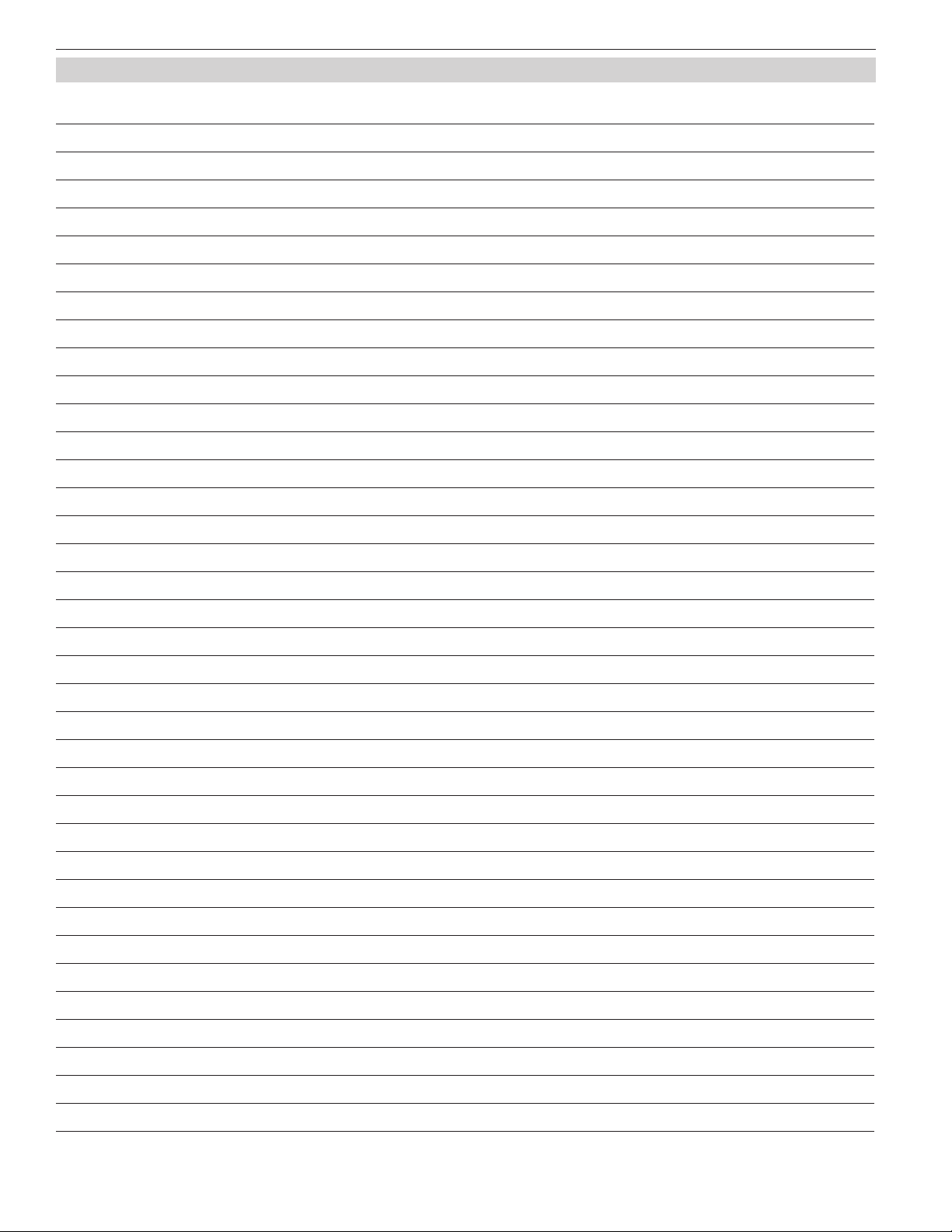

REPAIR PARTS ILLUSTRATION FOR MITER GAUGE,

MODELS 9681314, 9681315 AND 9681316 - DISC SANDERS

REPAIR PARTS ILLUSTRATION FOR MITER GAUGE -

MODELS 9681310 & 9681311 - DISC SANDERS

17

NO SE Operating Manual & Parts List 9681310 & 9681311

19

REPAIR PARTS LIST FOR MITER GAUGE - 9681314, 9681315, 9681316 AND 9681317 -

DISC SANDERS

(6) Not Shown (*) Standard hardware item available locally (N/A) Not available as replacement part

1Miter Gauge Assembly 9642639.01

1

1.1 Handle N/A 1

1.2 Miter Gauge N/A 1

1.3 Round Head Screw

(3/16"-24 UNC x 5/16"L )

N/A

1

Ref.

No. Description Part No. Qty.

Ref.

No. Description Part No. Qty.

1.4 Flat Washer (95.1 x 12 x 1.0t ) N/A

1

1.5 Pointer N/A 1

1.6 Bar N/A 1

1.7 Washer N/A 1

1.8 Phillips Screw

(1/4"-20 UNC x 5/16"L )

N/A 1

REPAIR PARTS LIST FOR MITER GAUGE -

MODELS 9681310 & 9681311 - DISC SANDERS

NOTES

18

NO SE Operating Manual & Parts List 9681310 & 9681311

NOTES

19

NO SE Operating Manual & Parts List 9681310 & 9681311

NO SE Operating Manual & Parts List 9681310 & 9681311

NO SE - a C.H. Hanson brand

2000 N. Aurora d., Naperville, IL 60563 U.S.A.

or call: 1-800-827-3398

NO SE by C.H. Hanson warrants their products to be free of defects in material or workmanship. This

warranty does not cover defects due directly or indirectly to misuse, abuse, normal wear and tear, failure

to properly maintain the product, heated, ground or otherwise altered, or used for a purpose other than

that for which it was intended.

The warranty does not cover expendable and/or wear part (i.e. v-belts, screws, abrasives, jaws), damage to

tools arising from alteration, abuse or use other than their intended purpose, packing and freight. The

duration of this warranty is expressly limited to the terms noted below beginning from the date of

delivery to the original user.

The NO SE branded items carry the following warranties on parts:

All NO SE branded Tools and Accessories 1 YEA

The obligation of NO SE by C.H. Hanson is limited solely to the repair or replacement, at our option, at its

factory or authorized repair agent of any part that should prove inoperable. Purchaser must lubricate and

maintain the product under normal operating conditions at all times. Prior to operation become familiar

with product and the included materials, i.e. warnings, cautions and manuals.

Failure to follow these instructions will void the warrant .

This warranty is the purchaser's exclusive remedy against C. H. Hanson for any inoperable parts in its

product. Under no circumstances is C. H. Hanson liable for any direct, indirect, incidental , special or

consequential damages including loss of profits in any way related to the use or inability to use our

products. This warranty gives you specific legal rights which may vary from state to state.

SERVICE & REPAIR

1. If a NO SE product requires a repair or warranty service DO NOT return the product to

the place of purchase.

2. All warranty related work must be evaluated and approved by NO SE.

3. Prior to returning any item the user must obtain factory approval and a valid GA number.

4. For instructions and GA number call toll free (800) 827-3398.

NORSE WARRANTY

18-0307

This manual suits for next models

1

Table of contents

Other CH Hanson Sander manuals

Popular Sander manuals by other brands

ULTRA TEC

ULTRA TEC ULTRAPOL Advance user manual

Far Tools

Far Tools BS 1200B Original manual translation

Central Pneumatic

Central Pneumatic 68152 Owner's manual and safety instructions

Toolshop

Toolshop 241-9801 Operator's manual

NUTOOL

NUTOOL RED NEP1200R Original Operating Instruction

Power Tec

Power Tec OS1000 owner's manual

Lumberjack

Lumberjack EBS100VS Safety and operating manual

Central Pneumatic

Central Pneumatic 42966 Assembly and operating instructions

Parkside

Parkside PEXS 270 C3 Translation of the original instructions

Triton

Triton TROS 125 Operating/safety instructions

Sthor

Sthor 79307 Original instructions

Ryobi

Ryobi CRO-180M user manual