RESILIENT SEAT GATE VALVE

MODEL: RSGV

DN50 - DN750

5

QAD#IM1055 REVD, 23.11.20

INSTALLATION, OPERATION AND MAINTENANCE

2.1 Preparaon before installaon of gate valve

Valves should be protected during transportaon. Collision and falling should be avoided during transportaon and installaon.

Liing the valve directly by the aached Key Cap or Hand Wheel is strictly prohibited.

Due to RSGV comprising rubber components, they are not to be stored exposed outdoors or exposed in sunshine for long

periods of me.

If the valve is installed in a pit, enough space shall be kept to accommodate the working personnel.

The pipelines shall be designed with supporng xtures such as support frames. It is strictly prohibited for the valve to support

the pipeline weight or external weight.

Prior to connecng the valve with the pipeline, the ange shall be welded to the pipe. It is strictly prohibited to clamp the valve

during the ange welding.

Foreign materials shall be cleared from the pipelines. It is strictly prohibited to leave weld slag, stones or other foreign

materials in the pipeline which could damage the valve.

Prior to installaon of the valve, prepare handling tools, spanners and other necessary tools, gaskets, bolts (or studs), nuts and

washers. Bolts and nuts shall meet the pipeline design requirements. It is strictly prohibited to use fasteners without

sucient strength.

2.2 Installaon of gate valve

When installing the gate valves, ensure that the seat and the ange faces are clean.

When valves are provided with liing lugs, plates or eye nuts, these must be used to li the valve.

To ensure adequate sealing it is important to select the correct type of gasket for the medium

concerned, gaskets with the correct ange size must be used.

Place valve between pipe anges and insert gaskets and bolts.

Tighten bolts loosely.

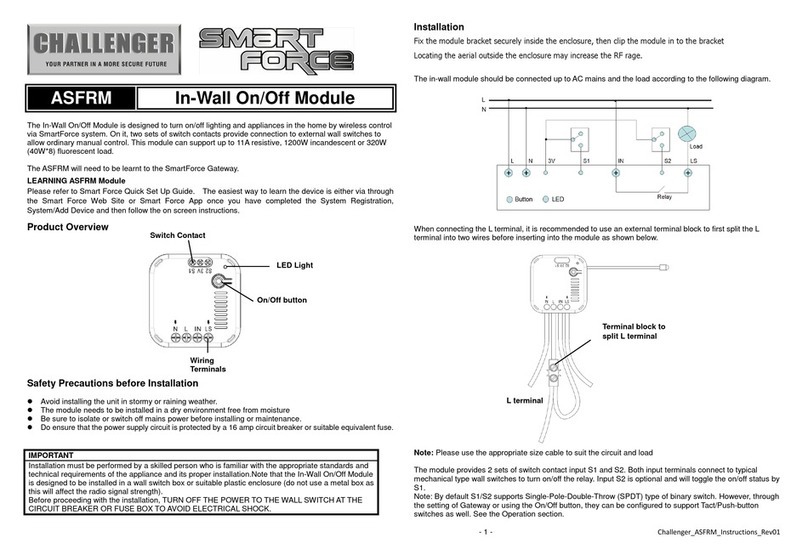

Tighten bolts in a diagonal sequence to ensure anges are pulled up parallel. As per bolng

sequence shown right (Figure 1).

Finally, ghten bolts to correct torque levels as recommended per WSA 109.

2.3 Maintenance of gate valve

The valve is to be maintained periodically.

No lubricaon is required as the medium lubricates all required parts.

Make sure all bonnet and ange bolts are ght at all mes.

Changing of Bonnet Gaskets

- Make sure no pressure is in the pipeline

- Remove bonnet fasteners

- Remove bonnet

- Remove and replace bonnet gasket

- Replace bonnet

- Ret fasteners and ghten.

1

2

11

8

3

10

5

12

7

4

9

6

Figure 1. Bolng Sequence