Chalmit Sterling III Manual

IOM –STERLING III - ZONE 2 LED (ATEX, IECEx, Ex ec)

I-ST3N-01.doc Issue 8 December 2018 1

The

Sterling III - LED Luminaires (Ex ec)

ATEX, IECEx

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

GRP Standard body

Important:

Please read these instructions carefully before installing or maintaining this equipment.

Good electrical practices should be followed at all times and this data should be used

as a guide only.

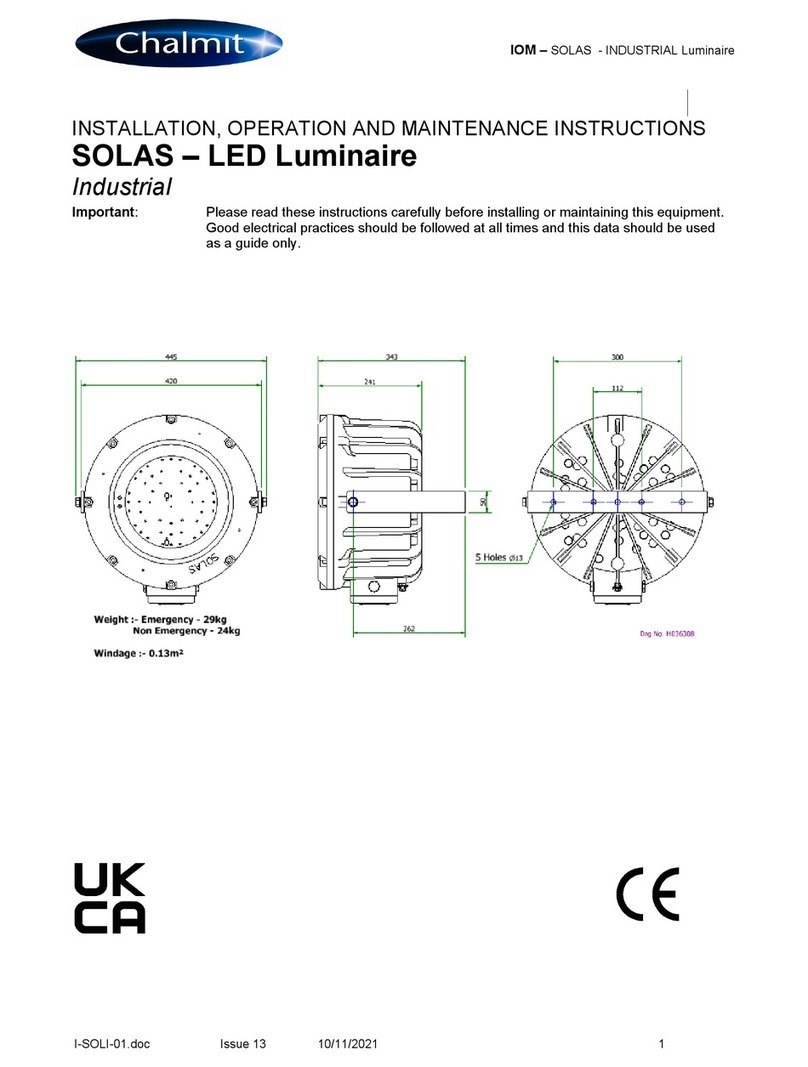

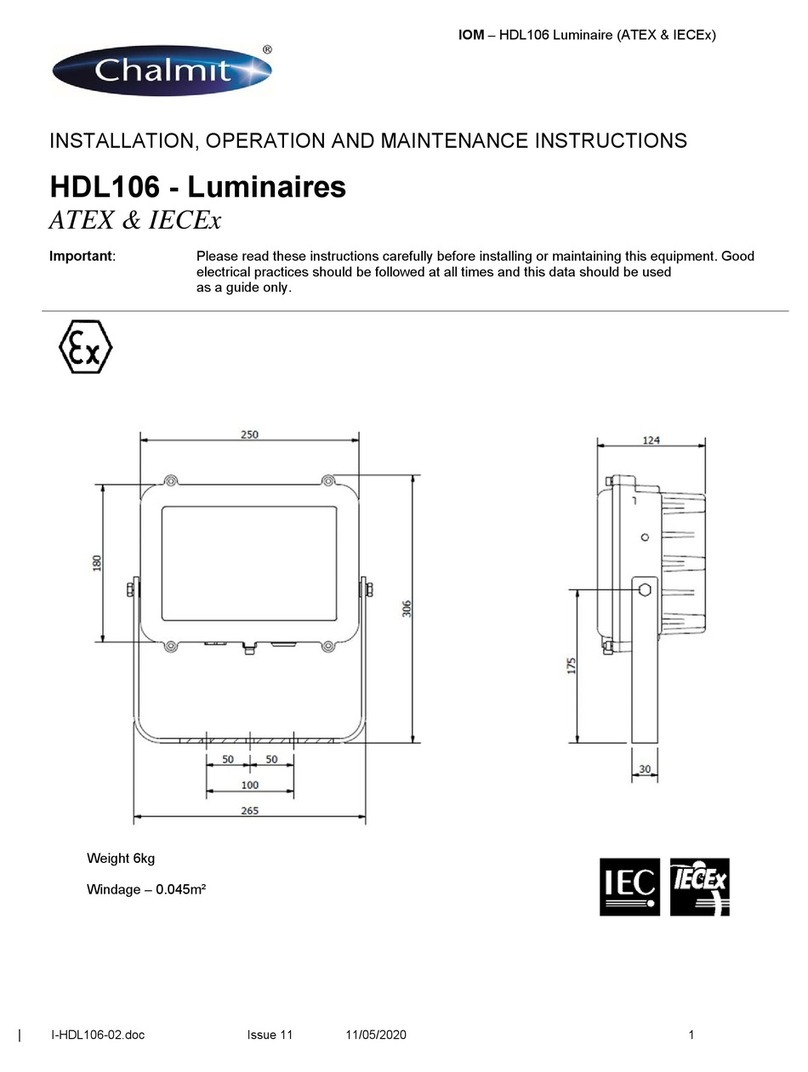

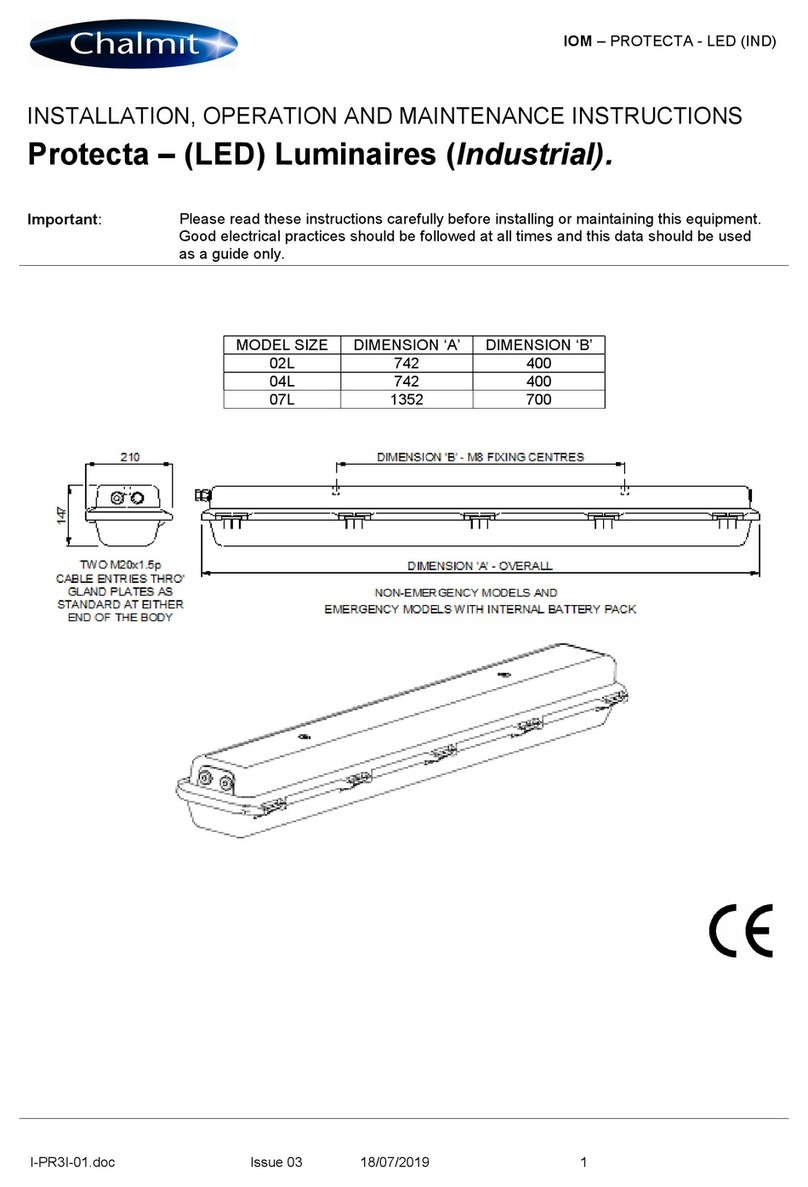

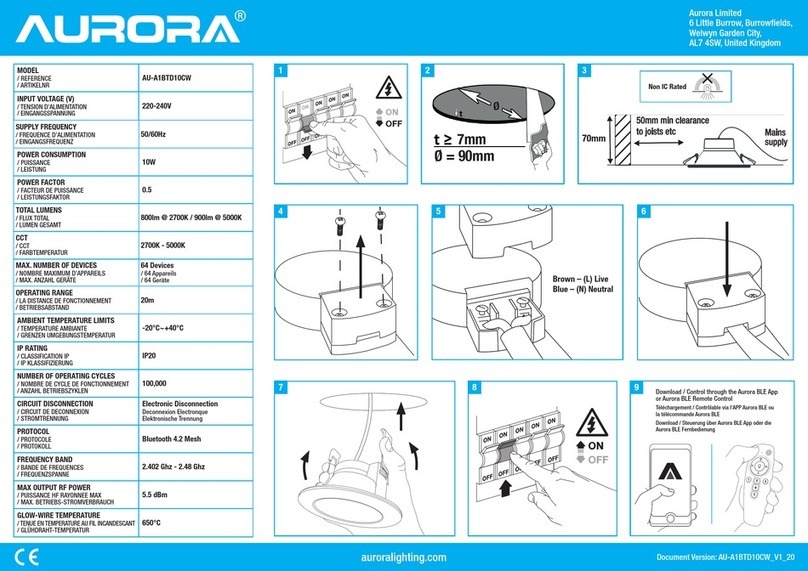

Technical Drawing:

IOM –STERLING III - ZONE 2 LED (ATEX, IECEx, Ex ec)

I-ST3N-01.doc Issue 8 December 2018 2

0.0 Specification

Type Of Protection

Ex ec, (non-sparking). Ex tc,

Protection Standards

EN/IEC 60079-0, EN/IEC 60079-7, EN/IEC 60079-31

Area Classification

Zone 2 areas to EN/IEC 60079-10-1,

Zone 22 areas to EN/IEC 60079-10-2.

Installation

EN/IEC 60079-14

Certificate

Type Examination Certificate CML 16ATEX 4101X

IEC Ex Type Certificate No. IECEx CML 16.0044X

Equipment Coding

Ex ec lIC T4 Gc

Ex tc IIIC T76°C Dc IP6X, (ambient values see tables below for details)

ATEX Coding

II 3GD

Ingress Protection

IP65 to EN/IEC 60529

CE Mark

The CE marking of this product applies to "The Electrical Equipment (Safety) Regulations

2006", "The Electromagnetic Compatibility Regulations 2004", the “Waste Electrical and

Electronic Equipment Regulations 2006” and the "Equipment and Protective Systems intended

for use in Explosive Atmospheres Regulations 1996". [This legislation is the equivalent in UK

law of EU directives 2014/35/EU, 2014/30/EU, 2012/19/EU and 2014/34/EU respectively].

The Equipment is declared to meet the provisions of the ATEX directive (2014/34/EU) by

reason of the EU Type Examination and compliance with the Essential Health and Safety

Requirements.

M Poutney Technical Manager

1.0 Introduction –Zone 2 & Zone 22, Ex ec, Ex tc LED Luminaire

General

The type of protection is Ex ec and Ex tc. The Zone 2 & Zone 22 series LED luminaires are surface mounted or

suspended, utilising the two holes on the base of the body. They are mainly used in harsh environments, and are

constructed using a corrosion resistant glass reinforced polyester body, attached to an injection moulded

polycarbonate diffuser by stainless steel toggle clips. The control gear and LED’s are mounted on a removable

tray that for maintenance purposes has hanging straps.

Note: The ratings are listed in TABLES A & B.

1.1 Application

The luminaire is designed to be safe in normal operation. The luminaire should not be used where there are

environmental, vibration or shock conditions above the normal for fixed installations. The gaskets should not be

exposed to hydrocarbons in liquid or high concentration vapour states.

The luminaire is suitable for applications where Category 3 apparatus can be used. The type examination does

not address suitability for portable applications.

2.0 Storage

Luminaires are to be stored in cool dry conditions preventing ingress of moisture and condensation.

SPECIAL CONDITIONS FOR SAFE USE

The Luminaire shall only be installed where there is a low risk of mechanical damage.

When refitting the diffuser, the fixing clamps are to be re-secured with the original or replacement self

tapping screws.

Fasteners through the enclosure used for mounting purpose shall be fitted with appropriate sealing

washers to maintain the ingress protection rating of the enclosure.

IOM –STERLING III - ZONE 2 LED (ATEX, IECEx, Ex ec)

I-ST3N-01.doc Issue 8 December 2018 3

3.0 Installation and Safety

3.1 General

There is no health hazards associated with this product whilst in normal use. However, care should be exercised

during the following operations. Installation should be carried out in accordance with relevant EN / IEC standard or

the local hazardous area code of practice, whichever is appropriate.

These instructions should be read carefully before attempting to install the luminaire. Copies of these instructions

should be held in a safe place for future reference.

It is the responsibility of the installer to ensure that the apparatus selected is fit for its intended purpose and that

the installation, operation and maintenance of the apparatus complies with regulations, standards or codes of

practice applicable.

Any specific installation instructions must be referred to. In the UK, the requirements of the Health and Safety at

Work Act must be met and electrical work associated with this product must be in accordance with the "Manual

Handling Operations Regulations" and "Electricity at Works Regulations 1989". Your attention is drawn to the

paragraphs (i) 'Electrical Supplies', (ii) 'Electrical Fault Finding and Replacement' and (iii) 'Inspection and

Maintenance'. The luminaires are Class 1 and should be effectively earthed.

The luminaires are quite heavy and suitable means of handling on installation must be provided.

Certification details on the rating plate must be verified against the application requirements before installation.

The information in this leaflet is correct at the time of publication. The manufacturer reserves the right to make

specification changes as required.

The GRP body & polycarbonate diffuser presents a potential source of ignition by electrostatic electricity. The

diffuser should only be cleaned using a damp cloth. The luminaire should not be mounted very near to any

probable location of fast moving stream of dry air, steam etc. which could generate a propagating brush static

discharge

3.1.1 Use in Combustible Dust Atmospheres

Where the equipment is used in ignitable dust atmospheres reference must be made to the selection and

installation standards in order that the equipment is used correctly. In particular this applies to the de-rating of

surface temperature for use where dust clouds may be present. Dust layers should not be allowed to accumulate

on the fitting surface and good housekeeping is required for safe operation. Dust in layers has the potential to

form ignitable clouds and to burn at lower temperatures.

Self tapping screws are supplied with the luminaire to lock the diffuser clamps. These must be fitted to maintain

the certification.

Refer to EN/IEC 60079-10-2 & EN/IEC 61241-14 for additional details of selection, installation and maintenance.

3.1.2 Hybrid Mixtures –Gas plus Dust

Where Hybrid mixtures exist as defined in EN/IEC1127 as a potentially explosive atmosphere, consideration

should be given to verifying that the maximum surface temperature of the luminaire is below the ignition

temperature of the hybrid mixture.

3.1.3 Cleaning

The body of the luminaire may be cleaned with a mild solution of household detergent and water, after cleaning

the body should be washed and wiped with clean water. The diffuser should not be polished or wiped with a dry

cloth, as a risk of explosion due to electrostatic discharge may result. Cleaning of the diffuser with any chemical or

hydrocarbon solvent based cleaner may result in severe damage.

3.1.4 Aggressive substances

If the equipment is likely to come into contact with aggressive substances, then it is the responsibility of the user to

take suitable precautions that prevent it from being adversely affected, thus ensuring that the type of protection

provided by the equipment is not compromised.

Aggressive substances: e.g. acidic liquids or gases that may attack metals or solvents that may affect polymeric

materials.

Suitable precautions: e.g. regular checks as part of routine inspections or establishing from the material’s data

sheets that it is resistant to specific chemicals.

IOM –STERLING III - ZONE 2 LED (ATEX, IECEx, Ex ec)

I-ST3N-01.doc Issue 8 December 2018 4

3.2 Tools

Suitable spanners for installing cable glands.

3mm flat blade screwdriver. 12mm flat blade screwdriver. No. 6 pozidrive

Pliers, knife, wire strippers/cutters.

3.3 Electrical Supplies

The supply voltage and frequency should be specified when ordering. A maximum voltage variation of +6%/-6%

on the nominal is expected. (The safety limit for T rating is +10%). Luminaires should not be operated

continuously at more than +6%/-6% of the rated supply voltage of the control gear.

Warning: Luminaires are assessed and/or tested for EMC requirements. This is based on the disposition

of entry cables and, where appropriate, through wiring arrangements as supplied or specified.

Users must take care not to introduce wiring into parts of the apparatus materially different to that

which could be reasonably inferred from the disposition of fixed supply terminals and specified wiring.

3.4 Light Emitting Diode (LED)

LED’s are supplied in 3000, 6000 or 9000 Lumen options with the colour temperature of 4000K or 5000K

(Check nameplate for colour temperature)

3.5 Mounting

Luminaires should be installed where access for maintenance is practical and in accordance with any lighting

design information provided for the installation. The mounting attitudes are restricted to ceiling, pendant, outreach

pole (lamps facing down or horizontally outward) and horizontal wall mount. The luminaire is mounted using the

DIA 8.2mm mounting holes on the rear of the body.

On mounting the luminaire by using the holes, it is the responsibility of the user to ensure that an adequate seal is

made, to maintain the IP rating of the enclosure. Sealing Washers are provided.

3.6 Cabling and Cable Glands

3.6.1 Cables

The GRP models have facility for through wiring but do not have a facility for looping.

The temperature conditions of the supply cable entry point are such that 70ºC (ordinary PVC) cable can be used..

300/500V cable ratings are adequate and no special internal construction is necessary.

An internal earth tag can be fitted to the cable gland.

Note: Through wiring when used, is subject to a maximum current of 16A.

3.6.2 Cable Gland Types

The installer and user must take responsibility for the selection of cables, cable glands and seals.

The product is dual certified for ATEX and IECEx and to comply with the certification for installation cable glands

and sealing plugs must be ATEX or IECEx certified (or both) depending on site requirements.

Cable glands and sealing plugs when installed must reliably maintain the IP rating of the enclosure.

The cable gland must withstand an impact value of 7Nm where the risk of mechanical damage is high or 4Nm

where the risk of mechanical damage is low.

The cable should be reliably clamped externally to the apparatus or surrounding fixture within 200mm of the cable

gland.

Where brass cable glands are used in a corrosive environment cadmium or nickel plating should be used.

20 DIA cable entry clearance holes suitable for M20 cable glands are standard.

3.6.3 Earthing

On GRP bodied luminaires, all internal metal parts are earthed through the Metal gear tray. The Metal gear tray is

earthed via supplied cable to incoming terminal block.

It is the installer’s responsibility to ensure proper earth supply to the luminaire and to ensure any metal cable

glands are properly earthed. Cable gland earth kits are available from the manufacturer.

IOM –STERLING III - ZONE 2 LED (ATEX, IECEx, Ex ec)

I-ST3N-01.doc Issue 8 December 2018 5

3.6.4 Cabling

Access for cabling is via diffuser cover; care is to be taken, as there is no suspension of diffuser cover. The

diffuser clip screws are removed and the diffuser clips are undone and the diffuser laid aside. The gear tray is

dropped down after unclipping the steel mounting clips. The tray can be removed by undoing the spring clips on

the suspension cables. Any earth tag connections should be fitted.

The connecting terminals are identified and the conductors should be bared back so that they make full contact in

the terminals, but the bare conductor should not be more than 1mm beyond the terminal. Unused terminal screws

should be tightened. The cores must be identified by polarity and connected in accordance with the terminal

markings. Before re-fitting the cover, a final check on the correctness of connections should be made.

3.7 Replacing LED’s

Before opening the diffuser cover, ensure that the luminaire is isolated from mains supply. Access is via the

diffuser cover; care is to be taken, as there is no suspension facility for the diffuser cover.

It is recommended on failure of LED’s an entire geartray kit including driver should be fitted. This will maximise the

lifetime of the product.

Note: The diffuser cover must be refitted in its original orientation to maintain the IP rating & diffuser clips

snapped into place.

Self-tapping screws are supplied with the luminaire to lock the diffuser clamps. These must be fitted to maintain

the certification.

Refer to EN/IEC 60079-10-2 & EN/IEC 61241-14 for additional details of selection, installation and maintenance.

3.8 Inspection and Maintenance

Visual inspection should be carried out at a minimum of 12 monthly intervals and more frequently if conditions are

severe. The time between lamp changes could be very infrequent and this is too long a period without inspection.

3.8.1 Routine Examination

The equipment must be de-energised before opening. Individual organisations will have their own procedures.

What follows are guidelines based on EN/IEC 60079-17 and on our experience:

1 Ensure LED’s are lit when energised by mains supply.

2 Visually check diffuser cover for damage. This should only be cleaned using a damp cloth to avoid static

and only use recommended detergents for polycarbonate. If the polycarbonate is discoloured or damaged,

a new diffuser cover must be fitted.

3 When de-energised and left to cool, there should be no significant sign of internal moisture. If there are

any signs of water ingress, the luminaire should be opened up, dried and any likely ingress points

eliminated by re-gasketing or other replacements. If the diffuser cover is removed, its orientation must be

noted and it must be refitted in the original orientation.

4 Check cable gland for tightness and nip up if required.

5 Check any external and internal earths.

6 Check all terminations are firmly screwed down, tighten if necessary.

7 Check clips visually for any damage and replace, if necessary.

8 If it has been suspected that the luminaire has suffered mechanical damage, a stringent workshop check

on all components should be made. All components can be removed from the luminaire for inspection.

9 Avoid the build up of dust layers by regular cleaning and again clean only using a damp cloth.

3.8Electrical Fault Finding and Replacement (Refer EN / IEC 60079-19)

The supply must be isolated before opening the luminaire.

Any live fault finding must be done by a competent electrician and, if carried out with luminaire in place, under a

permit to work.

The electronic drivers are approved components.

On re-assembly, all faulty/damaged wiring should be replaced and connections checked.

IOM –STERLING III - ZONE 2 LED (ATEX, IECEx, Ex ec)

I-ST3N-01.doc Issue 8 December 2018 6

4.0 Overhaul (Refer EN / IEC 60079-19)

Components to be incorporated into or used as replacement parts of the equipment shall be fitted by suitably

trained personnel and other than the fuse are to be purchased from the manufacturer as to ensure that

certification is not invalidated. The certification of this equipment relies upon the following materials used in its

construction: Glass re-enforced polyester body, polycarbonate diffuser, stainless steel clips and EPDM rubber

gasket.

The unit is largely made of materials that are very corrosion resistant. This allows the unit to be completely

stripped, cleaned and then re-built with new electrical parts as required. The internal wiring is 0.8mm² solid core,

HTPVC insulated. All the spares required are available. Please state the model identification string e.g.

ST3N/03L/LE.

The seal is between the polycarbonate diffuser and the base. The diffuser is retained by stainless steel clips. If the

sealing gasket has deteriorated by softening or permanent set, a new sealing gasket should be fitted, which can

be obtained from the manufacturer. To fit this, care is needed, the old gasket should be removed and remaining

adhesive scraped off. The gasket is fixed in place to the body with a small amount of silicone RTV.

It is the end users responsibility to ensure the materials of construction and the product certification as detailed on

the product label is suitable for intended installation location.

5.0 Fuse Ratings

With the availability of MCB's with a wide range of characteristics, the individual engineer can make a better

judgement of what is required. Use MCB's suitable for inrush currents to reduce ratings. Where MCB's are used,

the type with the higher short time tripping current ratio used for motor starting and lighting should be specified.

The inrush current can be calculated where circuit conditions are known. The inrush currents can be obtained

from the manufacturer.

The fuse ratings for LED strips in circuits need to take account of the Driver within the construction of the

Luminaire. All calculations must satisfy wiring regulations.

Note: Line currents for 230V, 50Hz are as indicated in Table B.

6.0 Disposal of Material

Any disposal must satisfy the requirements of the WEEE directive [2012/19/EU] and therefore must not be treated

as commercial waste. The unit is made from combustible materials; the control gear contains plastic parts and

electronic components. All electrical components and the body parts may give off noxious fumes if incinerated.

Take care to render these fumes harmless or avoid inhalation. Any local regulations concerning disposal must be

complied with.

6.1 LED’s

LED’s in modest quantities are not "special waste". They should be broken in a container to avoid possible injury

from fragmentation. Avoid inhaling dust. This applies to the UK; there may be other regulations on disposal

operating in other countries.

Important: Do not incinerate LED’s.

To comply with the Waste Electrical and Electronic Equipment directive 2012/19/EU the

apparatus cannot be classified as commercial waste and as such must be disposed of or recycled

in such a manner as to reduce the environmental impact.

IOM –STERLING III - ZONE 2 LED (ATEX, IECEx, Ex ec)

I-ST3N-01.doc Issue 8 December 2018 7

Tables A and B

TABLE A - SCHEDULE –LED CONTROL GEAR –NON EMERGENCY –120 to 277Vac –127 to 300Vdc

Note: for Dust Ratings Refer to Max Surface Temperatures.

Light

Source

Body

Type

Nominal

Volts

LED

Driver

Ambient

Temperature

T

Rating

Max Surface

Temperature

(Dust)

3365 Lumen

2ft Twin

120-277Vac

127-300Vdc

26W

-20°C < Ta < +55°C

T4

76°C

6218 Lumen

4Ft Twin

120-277Vac

127-300Vdc

60W

-20°C < Ta < +50°C

T4

76°C

8953 Lumen

4Ft Twin

120-277Vac

127-300Vdc

96W

-20°C < Ta < +45°C

T4

76°C

Typical Standard LED Wiring Diagram

Note: For other Wiring Diagrams, please contact the manufacturer

Table B - Series Circuit.

No. Off

LED Strips

Gear Type

Lumen

Nominal Circuit Power (W)

Line

Current

2 x 560mm

LED Driver

3365

24

0.100

2 x 1120mm

6218

44

0.190

2 x 1120mm

8953

64

0.290

IOM –STERLING III - ZONE 2 LED (ATEX, IECEx, Ex ec)

I-ST3N-01.doc Issue 8 December 2018 8

EU-Declaration of conformity

UE-Déclaration de conformité

EU-Konformitätserklärung

Manufacturer

Chalmit

Address

388 Hillington Road, Glasgow. G52 4BL Scotland UK

Product

Sterling lIl LED

Type Examination Certificate

CML 16ATEX 4101X

Notified Body

CML 2503

ATEX Coding

II 3 GD

ATEX Classification

Group II Category 3 GD

Equipment Coding

Ex ec IIC T4 Gc, Ex tc IIIC T76°C Dc IP6X

Ingress Protection

IP65

The technical basis, with respect to equivalence of

La base technique, en ce qui concerne l'équivalence de

Die technische Grundlage hinsichtlich der Normen

Protection Standards EN 60079-0, EN 60079-7, EN 60079-31

Area Classification EN 60079-10-1, EN 60079-10-2.

of compliance with the EHSRs is valid as there are no changes which materially affect the state of technological progress of the product.

en conformité avec les EESS est valide puisqu'il n'y a aucun changement qui affecte matériellement l'état de l'évolution technologique du

produit.

zur Erfüllung der GSGA ist gegeben, da keine Änderungen erfolgt sind, die einen Einfluss auf den technischen Stand des Produkts haben.

Terms of the directive:

Standard & Date Certified to

Standards Date Declared to

Prescription de la directive:

Standard & date certifiée à

Normes date Déclaré

Bestimmungen der Richtlinie:

Standard & Datum

Zertifiziert nach

Standards Datum erklärt

2014/34/EU

Equipment and protective systems intended for use in

potentially explosive atmospheres.

EN 60079-0: 2012

EN 60079-7: 2015

2014/34/UE

Appareils et les systèmes de protection destinés à être

utilisés en atmosphères potentiellement explosibles.

EN 60079-31: 2014

2014/34/EU

Geräte und Schutzsysteme zur bestimmungs-

gemäßen Verwendung in explosionsfähigen Bereichen.

2014/30/EU

Electromagnetic compatibility

EN 55015 : 2013

2014/30/UE

Compatibilité électromagnétique

EN 61547 : 2009

2014/30/EU

Elektromagnetische Verträglichkeit

EN 61000-3-2 : 2014

2014/35/EU

Low voltage equipment

EN 60598-1 : 2015

2014/35/UE

Équipements électriques à bas voltage

EN 60598-2-5 : 2015

2014/35/EU

Niederspannungsgeräte / -systeme

EN 60529 : 1992

2012/19/EU

Waste of electrical and electronic equipment

2012/19/UE

Déchets d'équipements électriques et électroniques

2012/19/EU

Entsorgung der elektrischen und elektronischen Geräte

/ Systeme

2011/65/EU

RoHS II Directive

IOM –STERLING III - ZONE 2 LED (ATEX, IECEx, Ex ec)

I-ST3N-01.doc Issue 8 December 2018 9

On behalf of the Chalmit, I declare that, on the date the equipment accompanied by this declaration is placed on the market, the equipment

conforms to all technical and regulatory requirements of the above listed directives.

En tant que représentant du fabricant Chalmit, je déclare qu'à la date où les équipements accompagnant cette déclaration sont mis sur le

marché, ceux-ci sont conformes à toutes les dispositions réglementaires et techniques des directives énumérées ci-dessus.

Hiermit bestätige ich, im Namen von Chalmit, dass am Tag der Lieferung des Produkts/der Produkte zusammen mit dieser Erklärung das

Gerät/die Geräte alle technischen und regulativen Anforderungen der oben aufgeführten Direktiven erfüllt.

Name and Date

Mark Poutney

30/08/2018

Technical Manager

Nom et Date

Directeur technique

Name und Datum

Technischer Leiter

Quality Assurance Notification by:

Baseefa Ltd.

Quality Management System Acreditation:

ISO 9001

Notification d'assurance qualité par:

1180

Système de Management Qualité Accréditation:

Qualitätssicherungsnotifikation durch:

Qualitätsmanagementsystem Akkreditierung:

Environmental Management System.

ISO 14001

Système de gestion de l'environnement.

by/par/durch

Umwelt kontroll system.

Loyd's Register

Certificate No./Certificat N°/Zertifikat Nr.

LRQ 4005876

Table of contents

Other Chalmit Lantern manuals