Chalmit NexLED Manual

I-NELE-11.doc Issue 05 18/07/2018 1

NEXLED EMERGENCY (IEx)

ENGLISH

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

NexLED – Emergency Bulkhead Luminaire

Important: Please read these instructions carefully before installing or maintaining this equipment.

Good electrical practices should be followed at all times and this data should be used

as a guide only.

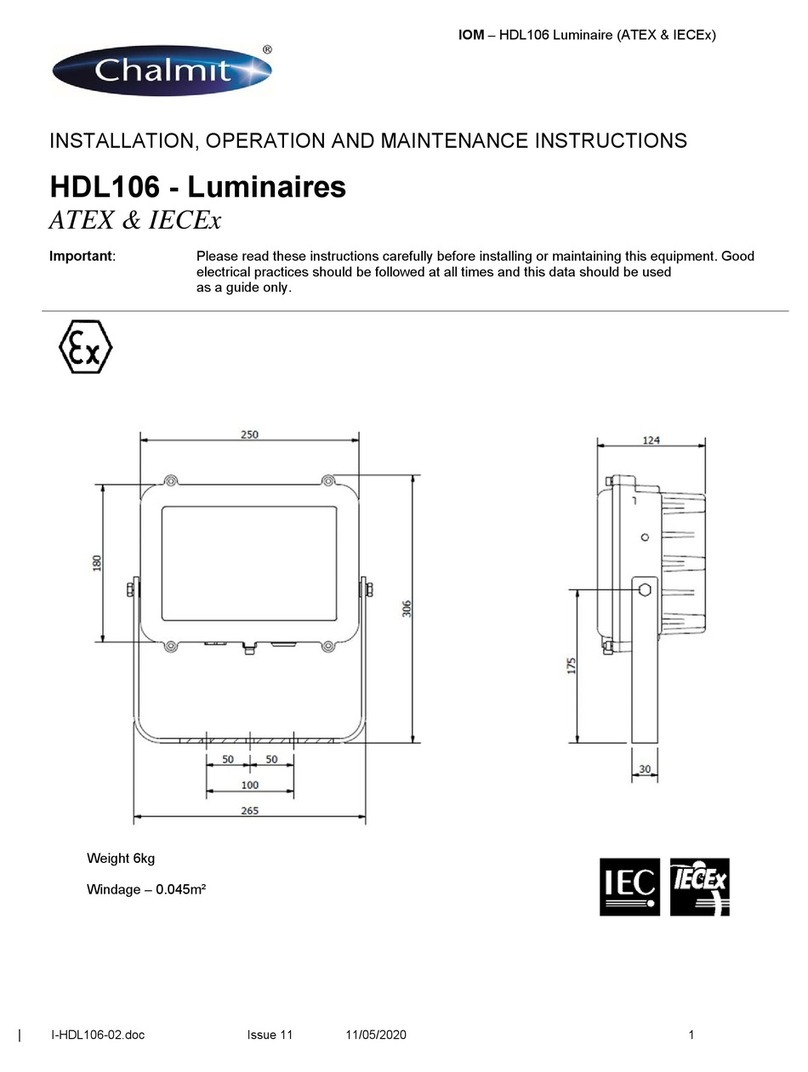

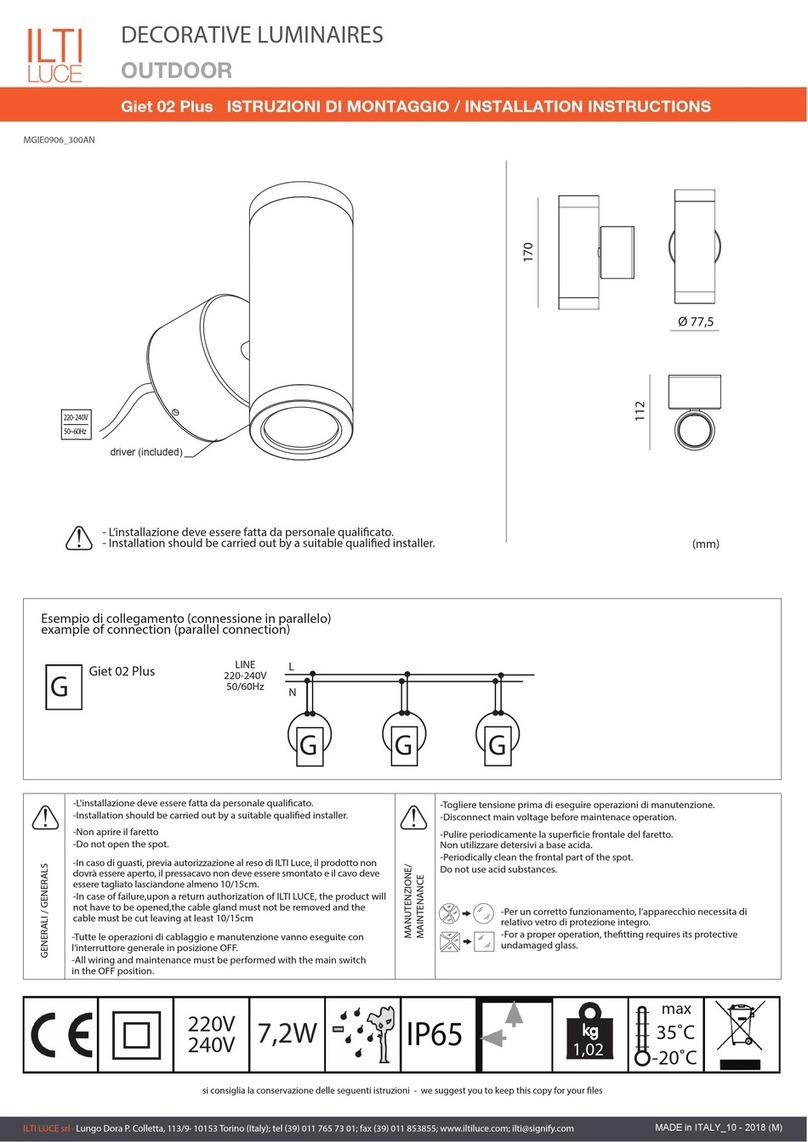

168

99

300

205

2 x M20

Entries

Type Of

Protection

Ex e ib mb (Increased safety, intrinsic safety, encapsulation)

Protection

Standards

ABNT NBR IEC 60079-0, 60079-7, 60079-11, 60079-18, 60079-1.

Area of

application

Zone 1 and Zone 21 areas to EN/IEC 60079-10-1 and 60079-10-2.

Installation EN60079-14

Certificate IEx 15.0299

Equipment

Coding

Ex e ib mb IIC T4 Gb -45oC ≤ Ta ≤ +55oC

Ex db e ib mb IIC T4 Gb (when fitted with flameproof

isolation switch).

Standard product -20°C to +55°C

Low Temp version down to -45°C Add

suffix /LT to Catalogue Code

Ingress

Protection

IP66/67

Laser safety Class 1 LED product

I-NELE-11.doc Issue 05 18/07/2018 2

NEXLED EMERGENCY (IEx)

ENGLISH

1.0 Introduction

The Chalmit NexLED emergency brings to hazardous areas the very latest in lighting technology. It is a compact

light source that uses ultra bright light emitting diodes to provide light from mains power. The LEDs are

maintenance free and can last up to 80000 hours or more. They are housed in an impact and corrosion resistant

marine grade aluminium enclosure with a toughened glass lens. The control gear is electronic with regulated

lamp output. The LEDs work equally well at very low temperatures as they do at high and produce a product with

very low overall power consumption. When the Nexled is specified for low temperature it should be fitted with a

battery pack heater to enable the battery pack to be kept at an optimum temperature for maximum reliability and

duration. The LEDs also emit no ultra-violet light and no forward heat.

The product is available with 2 or 6 LED Array and an accessory kit is available for exit signs.

Led 2 x 1

W

(/201) 6 x 1

W

(/801)

Voltage range AC 110 - 254V

Frequency range Hz 50/60/0Hz

Power Watts 220-254V 7W (15W) 11.1W (20.6W)

Current Amps 220-254V 51mA (82mA) 71.6mA (101.5mA)

Power Watts 110-130V 6W (15W) 10.6W (20.8W)

Current Amps 110-130V 52mA (127mA) 100.7mA (193.8mA)

* Figures brackets represent values when heater is in operation

The safety limit for surface temperature (T rating) is +/-10% on the rated voltage. Equipment should not be

operated continuously at more than +10/-10% of the rated voltage of the control gear.

Batteries 4.2V 4Ah NiCd (Battery Pack is disconnected for transportation)

Emergency Duration 90 minutes duration for the 6 x 1 Watt and

3 hours duration for the 2 x 1 Watt

Emergency Output 100%

Power Factor 0.85 minimum

EMC EN 61547 EN 55015

Over voltage 400V ac for 1 min

Looping The looping current rating is 16A. 4mm² terminals are standard (6mm² wiring

can be used in the terminals in accordance with the luminaire certificate)

Tamb Storage -40°C to +50°C

Storage Luminaires are to be stored in cool dry conditions preventing ingress of moisture

and condensation.

LED The LED used in the Nexled is the latest technology and is a class 1 LED

product.

Fuse and MCB Ratings Current consumption of an 6 LED unit is 66mA and for a 2 LED unit 49mA. It is

recommended that for selection of MCB's users should consult the MCB

manufacturer. MCB ratings can vary depending on the manufacturer and type

and the size of the installation, i.e. impedance of conductors, however type ‘C’

breakers are usually suitable. The electronic control gear has an inrush current

SPECIAL CONDITIONS FOR SAFE USE

None

I-NELE-11.doc Issue 05 18/07/2018 3

NEXLED EMERGENCY (IEx)

ENGLISH

of 12A for less than 1ms on 230V. These figures are worst case with low resistance connections with short

cables and low impedance supplies.

2.0 Storage

Luminaires and control gear boxes are to be stored in cool dry conditions preventing ingress of moisture and

condensation. Any specific instructions concerning emergency luminaires must be complied with.

Diagram showing fully specified circuit with optional heater.

3.0 Installation and Safety

3.1 General

There are no health hazards associated with this product whilst in normal use. However, care should be

exercised during the following operations. Installation should be carried out in accordance with ABNT NBR IEC

60079-14 or the local hazardous area code of practice, whichever is appropriate, and fitting of specified

insulating material to be adhered to where a specific fire resistance rating is required. In the UK the requirements

of the 'Health and Safety at Work Act' must be met.

Handling and electrical work associated with this product to be in accordance with the 'Manual Handling

Operations Regulations' and 'Electricity at Work Regulations, 1989'. Your attention is drawn to the paragraphs

(i) 'Electrical Supplies', (ii) 'Electrical Fault Finding and Replacement' and (iii) 'Inspection and Maintenance'.

The luminaires are class 1 and should be effectively earthed. Certification details on the rating plate must be

verified against the application requirements before installation.

The information in this leaflet is correct at the time of publication. The company reserves the right to make

specification changes as required.

3.2 Tools

No 1/2 Philips/Pozidriv/T20 Torx screwdrivers

3mm and 5mm flat blade screwdriver

Spanners for installing cable glands.

Pliers, knife, wire Strippers/cutters.

EARTH

LIVE CONSTANT

NEUTRAL

6 or 2 x 1W LED

ELECTRONIC

CONTROLLER

LIVE SWITCHED

BATTERY

PACK

HEATER

THERMISTOR

I-NELE-11.doc Issue 05 18/07/2018 4

NEXLED EMERGENCY (IEx)

ENGLISH

3.3 Electrical Supplies

The standard unit is rated for a nominal 110V-254V AC 50/60/0Hz. A maximum voltage variation of +6%/-6% on

the nominal is expected. (The safety limit for T rating is +10%). The lamp supply is regulated therefore the light

output over the supply range is constant.

The battery pack red wire should be the last connection made prior to energising supply power.

3.4 LED Array & Driver

This product is fitted with LED array that can last in excess of 80000 hours. Therefore in many applications

replacement of the LED array will be unnecessary. If replacement is required ensure mains supplies are isolated

before commencing work.

Open the front cover by unscrewing the 4 cheese head screws, and hang to the side.

Gain access to control gear & wire connections below the LED array, loosen the 4 Trox head screws, slide Array

plate out and hang to the side.

Disconnect the battery red wire and insulate bare conductor in a spare terminal.

Disconnect the flying lead wires from LED array at the terminal block.

Assembly is the reverse of disassembly.

The driver and batteries may be replaced, ensure the correct parts are ordered and that the cables are

reconnected correctly. Also ensure that the gasket/glass mating surfaces are clean and cables are not trapped.

Prior to any work internally the Red Battery wire should be disconnected and insulate bare conductor in

a spare terminal.

3.5 Mounting

Luminaires should be installed where access for maintenance is practical and in accordance with any lighting

design information provided for the installation. Mounting is by 4 holes in the base of the body casting external to

the gasket. These should be secured with lock washers or self-locking nuts and bolts and are accessed by

removing the front cover. Any mounting attitude may be used.

3.6 Cabling and Cable Glands

3.6.1 Cables

The maximum conductor size is 4mm². Internal earth point is provided next to the main terminal block. 300/500V

cable ratings are adequate and no special internal construction is necessary. The standard looping cable size is

up to 4mm². The selection of cable size must be suitable for the fuse rating. Terminals are supplied with

suitability for looping. Where looping is used the maximum current is 16A. Terminals are accessed by removing

the front cover and LED module. Maximum cable temperature rise is 20oC above ambient.

3.6.2 Cable Glands

The installer and user must take responsibility for the selection of cables, cable glands and seals. Three tapped

cable entries are provided, two with a plug and seal suitable for permanent use, the other with a travelling plug

not suitable for use in service. Sealing plugs are similarly rated and a tool must be used for their removal. Cable

entries are M20x1.5. Cable glands and sealing plugs must have “Generation E” approval.

The cable and gland assembly when installed must maintain a minimum of IP66/67 rating.

The cable glands must be suitable for the application. Where brass cable glands are used in a corrosive

environment, cadmium or nickel plating should be used.

3.8 Emergency Operation

When there is a disruption to the mains supply the Nexled will switch over to battery backup; as there is no

difference in light output this will be signalled by one blink at switchover. Following a full discharge, the LEDs will

blink periodically as the batteries regenerate.

It is recommend that the battery pack is charged for a 24 hour cycle, then fully discharged and re-charge so that

the full duration can be achieved. However if the battery pack has been fully discharged an additional cycle may

be required.

I-NELE-11.doc Issue 05 18/07/2018 5

NEXLED EMERGENCY (IEx)

ENGLISH

3.9 Battery Maintenance

The battery pack is a 4.2V 4Ah NiCad 4 cell pack. Periodic testing allowing full discharge will enable the cells to

remain in a healthy condition. Should the battery pack need to be replaced spares may be ordered from Chalmit

Lighting. The battery assembly must be protected from damage and water ingress then removed from any

potentially hazardous area as soon as practical.

The luminaire must not be operated without the battery connected. If the battery is removed and not replaced

the control gear supply must be disconnected at the mains terminal block and secured. Care must be taken to

connect the positive and negative terminals correctly.

3.9.1 Low temperature operation with battery heater

At temperatures near 0°C ambient the battery heater will switch on. This enables the batteries to be maintained

within their optimum temperature range down to -45°C.

4.0 Inspection and Maintenance

Visual inspection should be carried out at a minimum of 12 monthly intervals and more frequently are severe;

refer to ABNT NBR IEC 60079-17.

4.1 Electrical Fault Finding and Replacement

Any fault finding must be done by a competent electrician with the luminaire isolated and, if carried out with the

luminaire in place, under a permit to work. Fault finding is by substitution with known good components.

5.0 Routine Maintenance

Visual tests and checks should be carried out at intervals described by the appropriate regulations, ABNT NBR

IEC 60079-17, and should include the following:

Check that the LEDs are working.

Check for mechanical damage/corrosion.

Check for loose connections including earthing.

Check for undue accumulations of dust or dirt.

Verification of tightness of fixing, glands, blanking plugs etc.

Check for unauthorised modifications.

Check condition of enclosure gasket and fastenings.

Check for any accumulation of moisture.

Periodic inspection of the enclosure seal should be carried out to ensure that the seal is sound.

If the luminaire has been subject to abnormal conditions, for example, severe mechanical impact or chemical

spillage, it must be de-energised until it has been inspected by an authorised and competent person. If in doubt,

the unit should be returned to Chalmit for examination and, if necessary, replacement.

Before re-assembling, all connections should be checked and any damaged cable replaced.

Prior to any work internally the Red Battery wire should be disconnected and insulate bare conductor in

a spare terminal, and should be the last connection made prior to closing the unit.

6.0 Disposal of Material

Any disposal must satisfy the requirements of the WEEE directive [2012/19/EU] and therefore must not be

treated as commercial waste. The unit is mainly made from incombustible materials. The control gear contains

plastic resin and electronic components. All electrical components may give off noxious fumes if incinerated.

6.1 Battery Disposal

Nickel cadmium batteries are defined as 'controlled waste' under the hazardous waste regulations and the

person disposing needs to observe a 'duty of care'.

Batteries can be returned to the manufacturers for recycling. They must be stored and transported safely and

any necessary pollution control forms completed prior to transportation. Take care to fully discharge batteries

before transporting, or otherwise ensure that there can be no release of stored energy in transit. For further

details refer to our Technical Department

I-NELE-11.doc Issue 05 18/07/2018 6

NEXLED EMERGENCY (IEx)

ENGLISH

To comply with the Waste Electrical and Electronic Equipment directive 2012/19/EU the

apparatus cannot be classified as commercial waste and as such must be disposed of or

recycled in such a manner as to reduce the environmental impact.

Table of contents

Other Chalmit Lantern manuals

Popular Lantern manuals by other brands

IKEA

IKEA STRALA J2025 manual

Timeguard

Timeguard CLLED44PIRB Installation & operating instructions

J D Williams

J D Williams PD531 Assembly instructions

LIVARNO LUX

LIVARNO LUX 43174 Operation and safety notes

GOAL ZERO

GOAL ZERO Lighthouse Micro Charge user guide

HAMPTON BAY

HAMPTON BAY 32300-008-4pk Use and care guide