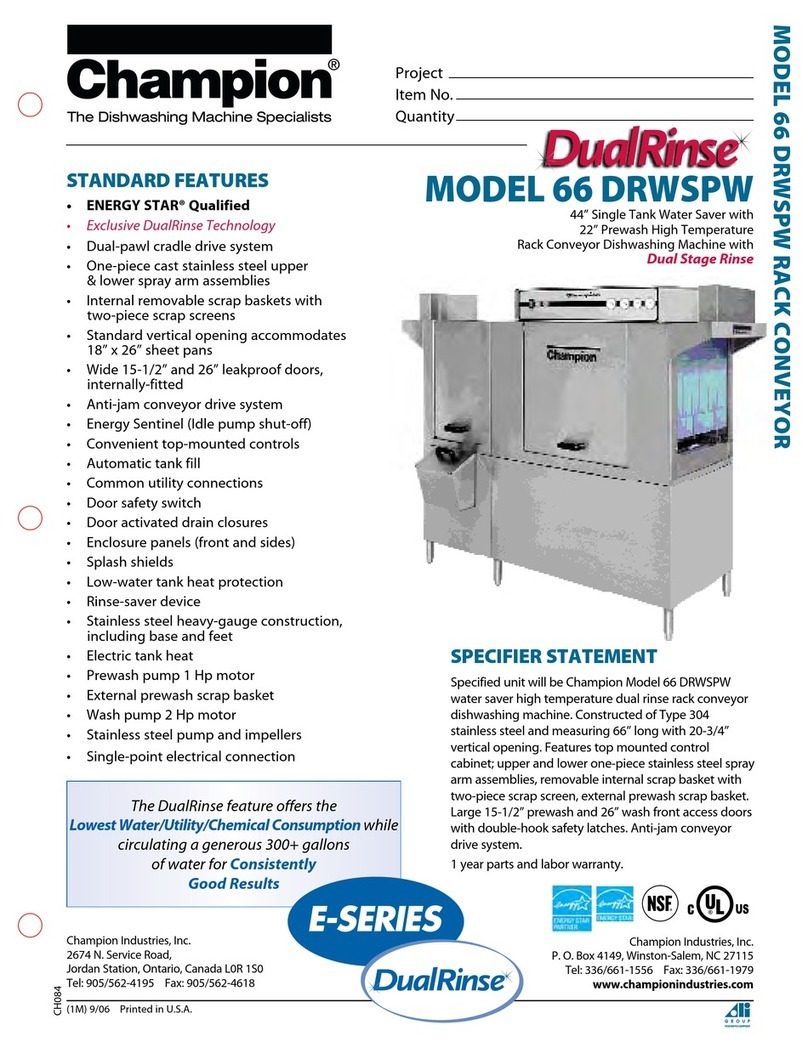

Door-type High Temperature

Extended Hood Warewashing Machine with Booster

D-H1T Without Booster

DHBT DOORTYPE

Due to an ongoing value analysis program at Champion, specifications contained in this catalog are subject to change without notice.

Champion Industries, Inc., P. O. Box 4149, Winston-Salem, NC 27115 • 336-661-1556 • Fax: 336/661-1979 • www.championindustries.com

2674 N. Service Road, Jordan Station, Ontario, Canada L0R 1S0 • 800/263-5798 • Fax: 905/562-4618

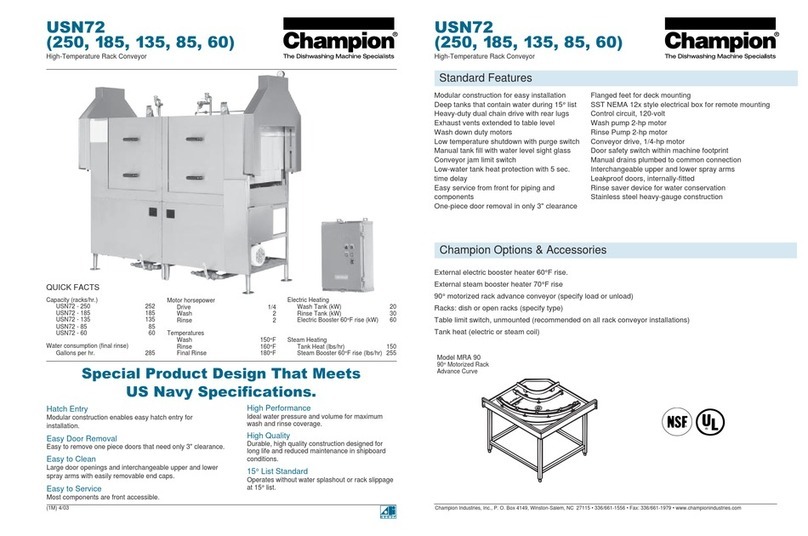

SPECIFICATIONS

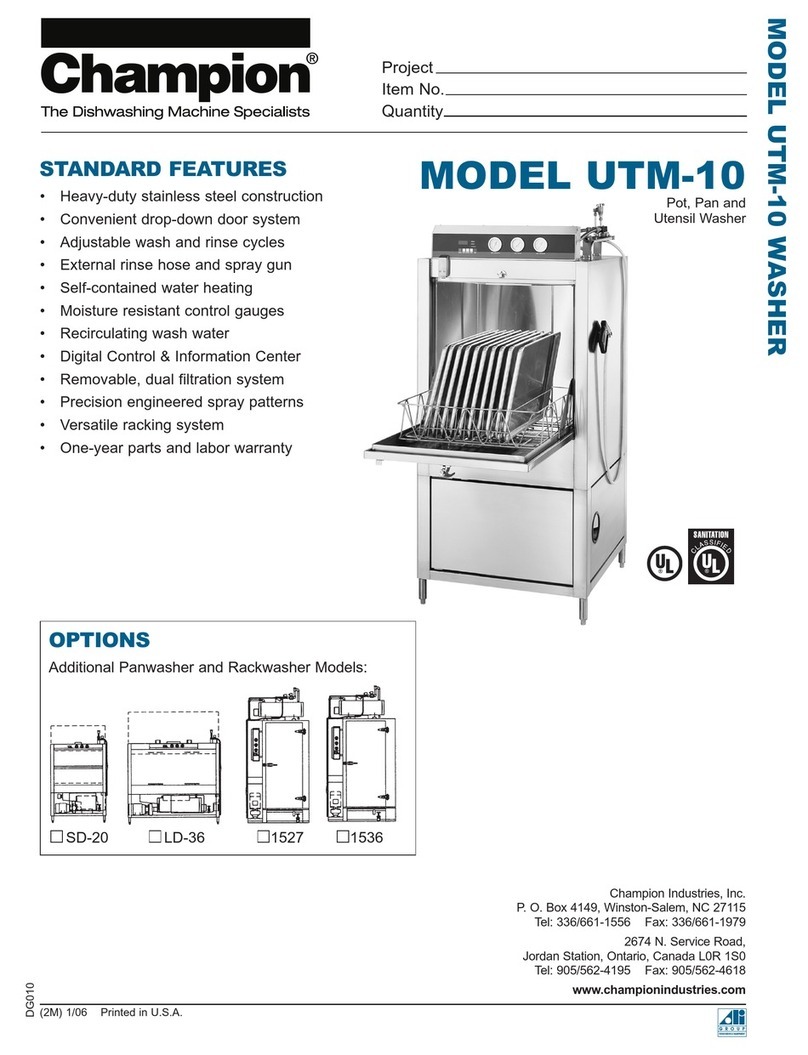

Capacities

Wash tank US gal. 9

Dishwasher Mode:

NSF Rated Racks per hr. 49/29

Pot/Pan Washer Mode:

NSF Rated Racks per hr. 19/10

Motor horsepower

2

Water consumption

Gal. per rack

US gal./liters 0.9/3.4 1.34/5.1

Gal. per hr.

(max. use) US gal. 44 36/99

Temperature°F

Wash 150

Rinse 180

Heating

Tank heat, electric (kW) 4.7

Tank heat, steam (lbs. per hr

required at 15 psi flow pressure) 25

Electric booster

(kW required for 40°F rise) 9

Electric booster

(kW required for 70°F rise) 13

Steam booster (internally mounted)

(lbs. per hr. required

for 40°F rise) 50

Steam booster (internally mounted)

(lbs. per hr. required for 70°F rise) 65

Time cycle in seconds

Dishwasher Mode Pot/Pan Washer Mode

Wash 44 96 Wash 156 336

Rinse 10 10 Rinse 13 13

Dwell 14 14 Dwell 11 11

Total 68 120 Total 180 360

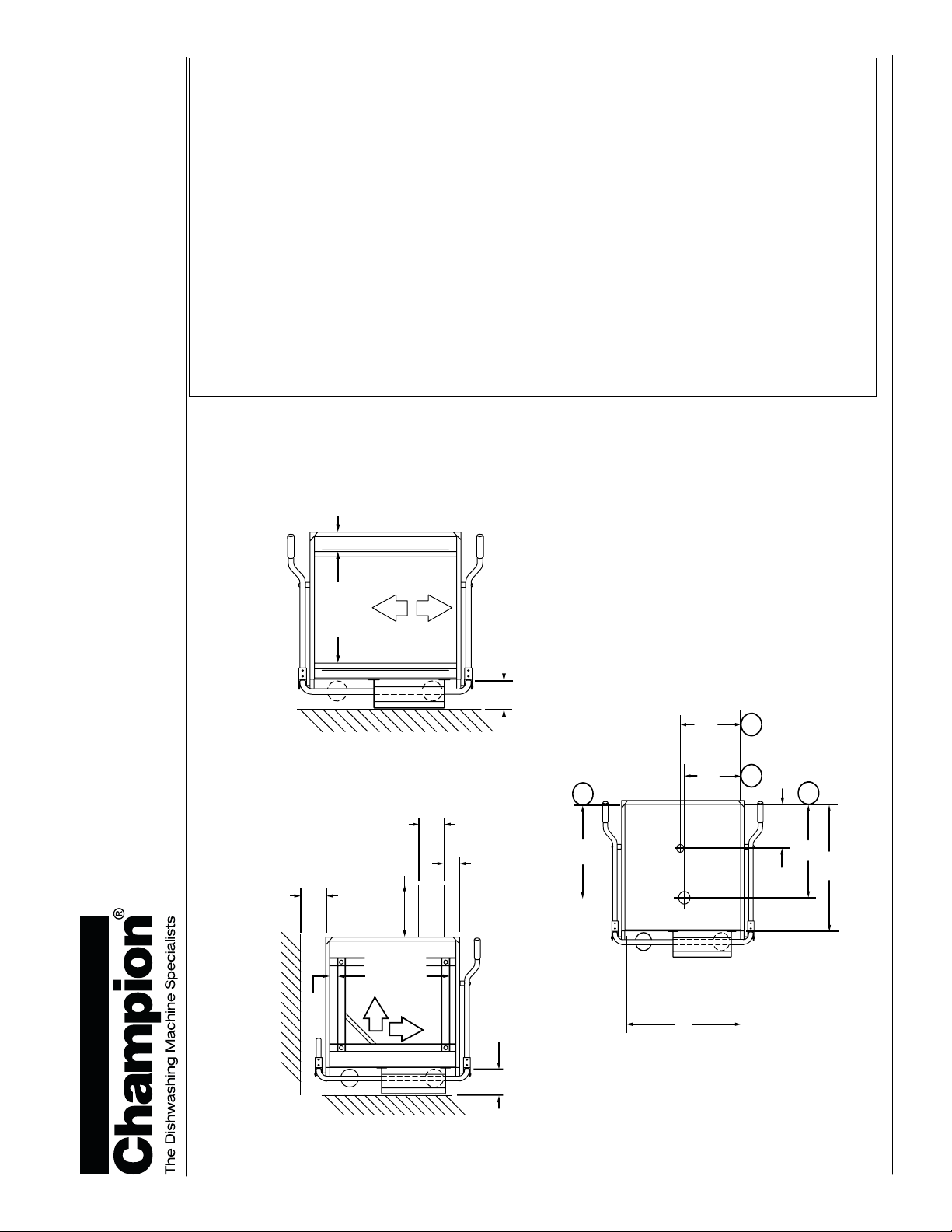

Corner Configuration

Warning: Plumbing and electrical connection

should be made by qualified personnel who will

observe all the applicable plumbing, sanitary and

safety codes and the National Electrical Code.

Plumbing Notes: Because of the variation in

house supplied water pressure, a water pressure

regulating valve (PRV) is needed. The PRV is

supplied by Champion and has been installed on

the machine prior to shipment.

Note: Water Hammer Arrestor (meeting ASSE-

1010 standard or equivalent) to be supplied (by

others) in common water supply line at service

connection.

Dimensions shown in inches [and millimeters]

A A

12-1/2" [318]

8-7/8" [225]

132

34" [864]

Load

Height

27" [686]

Clearance

67-1/2" [715]

Mach.

Height

92-1/2" [2302]

Door

Removal

Wash Pump 2 Hp

86" [2184]

Doors

Up

13-3/4"

[343]

26" [660]

13"

[330]

25"

[635]

9"[229]

19"

[483]

26"

[660]

1

23

3

Front

5-1/4" [133] Min.

20-1/8"

[511]

Inside

Tracks

2-7/8"

[73]

Front

5-1/4" [133] Min.

3-1/4" [83]

9-1/4" [235]

1-1/4" [32] Roll

1-1/8"

[29]

2-1/8" [54]

7-1/4" [184]

20-7/8"

[530]

24-1/4"

[616]

5" [127]

Control

Cabinet

Front

20-1/8"

[511]

Inside Tracks

2-7/8" [73]

5-1/4" [133] min

Front

20-1/4"

Inside Tracks

2-7/8"

5-1/4" min

Plan View

Dishwasher Pot/Pan Washer

A A

12-1/2" [318]

8-7/8" [225]

132

34" [864]

Load

Height

27" [686]

Clearance

67-1/2" [715]

Mach.

Height

92-1/2" [2302]

Door

Removal

Wash Pump 2 Hp

86" [2184]

Doors

Up

13-3/4"

[343]

26" [660]

13"

[330]

25"

[635]

9"[229]

19"

[483]

26"

[660]

1

23

3

Front

5-1/4" [133] Min.

20-1/8"

[511]

Inside

Tracks

2-7/8"

[73]

Front

5-1/4" [133] Min.

3-1/4" [83]

9-1/4" [235]

1-1/4" [32] Roll

1-1/8"

[29]

2-1/8" [54]

7-1/4" [184]

20-7/8"

[530]

24-1/4"

[616]

5" [127]

Control

Cabinet

Front

20-1/8"

[511]

Inside Tracks

2-7/8" [73]

5-1/4" [133] min

Front

20-1/4"

Inside Tracks

2-7/8"

5-1/4" min

Straight-through Configuration

A A

12-1/2" [318]

8-7/8" [225]

132

34" [864]

Load

Height

27" [686]

Clearance

67-1/2" [715]

Mach.

Height

92-1/2" [2302]

Door

Removal

Wash Pump 2 Hp

86" [2184]

Doors

Up

13-3/4"

[343]

26" [660]

13"

[330]

25"

[635]

9"[229]

19"

[483]

26"

[660]

1

23

3

Front

5-1/4" [133] Min.

20-1/8"

[511]

Inside

Tracks

2-7/8"

[73]

Front

5-1/4" [133] Min.

3-1/4" [83]

9-1/4" [235]

1-1/4" [32] Roll

1-1/8"

[29]

2-1/8" [54]

7-1/4" [184]

20-7/8"

[530]

24-1/4"

[616]

5" [127]

Control

Cabinet

Front

20-1/8"

[511]

Inside Tracks

2-7/8" [73]

5-1/4" [133] min

Front

20-1/4"

Inside Tracks

2-7/8"

5-1/4" min

Mode Mode