Chapman TF350 User manual

Page 2

Contents

Introduction ......................................................................................................................................3

HSE Information.........................................................................................................................4

Important Safety Information...........................................................................................................8

Safety Information........................................................................................................................8

Transportation Safety ...................................................................................................................9

Operating Safety...........................................................................................................................9

Description......................................................................................................................................10

Identification...............................................................................................................................10

Specification...............................................................................................................................10

Implement Decals.......................................................................................................................12

Attachment......................................................................................................................................13

Before Attaching the Machine....................................................................................................13

Attaching the Machine................................................................................................................13

Drop Size Adjustment & Calibration .............................................................................................14

Spring Change / Replacement ........................................................................................................15

Sensor Change / Adjustment ..........................................................................................................17

Control Box ....................................................................................................................................20

2 Button Model (UNTIL October 2015) ....................................................................................20

4 Button Model (FROM October 2015).....................................................................................21

Operating Limits & Recommendations..........................................................................................23

Forward Speed............................................................................................................................23

Storage........................................................................................................................................23

Troubleshooting..............................................................................................................................24

Warranty.........................................................................................................................................25

The Chapman Warranty..............................................................................................................25

Warranty Conditions...................................................................................................................25

Transfer of Warranty..................................................................................................................26

Page 3

Introduction

By purchasing a Chapman Machinery Ltd TF Series Trailed Feeder you have purchased a product de-

signed to give a long and trouble free service life.

A variety of options are available from the factory, and many of these are also suitable for retro-fitment if

your requirements change, or you purchase this machine used, and wish to use a different set-up. We are

more than happy to offer advice & support throughout the lifetime of the machine.

This manual also contains important Health & Safety Executive information and guidelines.

NOTICE:

THIS MANUAL MUST BE HANDED TO THE OPERATOR BEFORE USE. THE OPERATOR MUST

UNDERSTAND FULLY THE CONTENT OF THIS HANDBOOK BEFORE USING THE MACHINE

FOR THE FIRST TIME. OF THE IMPLEMENT IS RESOLD, THIS MANUAL MUST ACCOMPANY

THE MACHINE.

Note:

The information contained in this manual is correct at the time of going to press. However, in the course of

development, changes in specification are inevitable. Should you find the information given differs from

your machine, please contact Chapman Machinery Ltd direct for advice.

Chapman Machinery Ltd

Hele Barton

Week St.

Mary

Holsworthy

Devon

EX22 6XR

Tel:01288 308149

Page 4

HSE information sheet

Safe use of all-terrain vehicles (ATVs)

in agriculture and forestry

HSE Information

Agriculture Information Sheet No 33

Introduction

This information sheet gives advice on the safe use of

ATVs. It covers the two main types used in off-road

working in agriculture and forestry, which are:

●

sit-astride ATVs: any motorised vehicle designed

to travel on four low-pressure tyres on unpaved

surfaces, with a seat designed to be straddled by

the operator and handlebars for steering control.

They are intended to be used by a single operator

with no passenger. However, this type also

includes ATVsintended for use by a single

operator, but with a special seat for a passenger

behind the operator. These vehicles are generally

called ATVsin agriculture, quad bikes in leisure

use and all-terrain cycles (ATCs) in forestry;

●

sit-in machines: side-by-side mini-utility vehicles,

usually with a steering wheel, where the driver sits

in a conventional seat and there is generally

seating for one or more passengers. These are

often called ATVs in both agriculture andforestry.

The ATVs covered by this sheet are those designed for

off-road use only. However, agricultural, horticultural

and forestry users can register an ATV as a light

agricultural vehicle for limited on-road use in

connection with their business (see road use).

Accidents

Both types of machine are designed to cope with a

wide variety of terrain types, including steep slopes, but

if used outside their safe operating parameters they

can very rapidly become unstable. This is why most

ATV accidents involveoverturning.

On average, two people die each year in ATV

accidents. Non-fatal accidents are estimated to amount

to over 1000 serious injuries per year. The underlying

causes of accidents were usually one or more of the

following:

●

lack of structured training and/orexperience;

●

incorrect/lack of protectiveclothing;

●

excessive speed;

●

carrying a passenger or an unbalanced load;

●

tipping on a bank, ditch, rut or bump;

●

a steep slope combined with other factors,

e.g. ground or load conditions;

●

towing excessive loads with unbrakedequipment.

Route planning and stability

Most accidents with these machines have occurred

where they have either been driven on new routes over

steep ground for the first time, or have been carrying or

dragging destabilising loads. When travelling over

rough terrain, get to know your own ground and stick to

planned routes where possible. Walk new routes if

necessary to check for hidden obstructions. Allow for

changes in ground conditions and for the destabilising

effect of loads orattachments.

Sit-astride ATVs (quad bikes/ATCs)

REMEMBER - GET PROPERLY TRAINED AND

ALWAYS WEAR HEAD PROTECTION

Training

Under the Provision and Use of Work Equipment

Regulations 1998 (PUWER), there is a legal

requirement for employers to provide adequate training,

and to ensure that only employees who have received

appropriate training in their safe use, including the use

of any towed equipment or attachments, are permitted

to ride ATVs. The same requirements apply to the self-

employed. HSE regards training provided by

recognised training providers as being adequate for the

purposes of PUWER.

You can get details of suitable training courses from

franchised ATV dealers, manufacturers websites, EASI

(European ATV Safety Institute), the Forestry

Commission and Lantra Awards. Training is also

available from agricultural trainers and colleges

accredited by these bodies.

Page 5

Protective clothing

More than half of all ATV riders have been thrown off at

some time. As these machines are not fitted with either

a cab or roll bar, your only protection is what you wear.

●

Head protection is vital. The majority of ATV

fatalities in the UK in the last ten years have been

caused by head injuries. Nobody who died from

head injuries was wearing a helmet. Helmets

would certainly have prevented most, if not all, the

deaths. You should always wear a helmet when

riding an ATV. Helmet types suitable for ATV

operations, depending on the circumstances, are

motorcycle helmets to BS 6658:1985 or UN ECE

regulation 22.05, equestrian helmets to BS EN

1384:1997, including specialist ATVhelmets, cycle

helmets to BS EN 1078:1997 and mountaineering

helmets to BS EN 12492:2000. All helmets should

have a chinstrap and be capable of being used

with suitable eye protection. The type of helmet

chosen should be based on an assessment of the

circumstances in which the ATV will be used, eg

the types of surface travelled over and anticipated

speeds. The harder the surface and higher the

speed the greater the degree of protection

needed. NB: Forestry helmets and industrial

hard hats are not acceptable for any ATV

operations.

●

Wear clothing that is strong and covers your arms

and legs. Gloves are useful for protection and to

keep hands warm in cold weather for good control

of the ATV.Wear sturdy, ankle-covering footwear,

eg boots or wellingtons that are strong, supportive

and have good wet grip.

●

Protect your eyes from insects and branches with

either a visor or goggles.

Passengers

Never carry a passenger on a sit-astride ATV unless

it has been designed for, and is suitable for, that

purpose. The long seat is for operators to shift their

body weight backwards and forwards for different slope

conditions, not for carrying passengers. Passengers on

specially adapted ATVs must wear a safety helmet. Do

not carry a passenger in a trailer behind an ATV as any

movement can make the machine unstable, particularly

with independent rear suspension and trailers with

axles wider than the ATV.

Safety checks and maintenance

Off-road use is especially harsh on equipment so it is

essential to carry out safety checks and maintenance in

accordance with the manufacturerʼs recommendations.

In particular, pre-ride safety checks should always

include:

●

tyre pressures. These are low, eg around 2-7 psi,

so even a 1 psi (0.07 kg/cm2) difference in

pressure can cause vehicle control problems.

Use a gauge that is designed for measuring and

displaying low pressures –usually supplied with

the ATV;

●

brakes and throttle. Check that the brakes give a

safe straight stop and that the throttle operates

smoothly in all steering positions. Brakes can

have a relatively short life in farming or forestry

environments and need frequent cleaning, regular

adjustment and propermaintenance.

Safe driving methods

ATVs are rider-active machines, so rider positioning is

vital to operate them correctly. The position of the rider

on the machine needs to be changed depending on the

terrain and motion. Riders must have the ability to

move and balance the momentum of the ATVwith their

own body weight. Plan routes (and review the plan if

the route is used regularly) to assess risks.

The following advice is no substitute for formal

training.

●

Most ATVs have no differential and so do not

handle in the same way as other machines. This

means that when you turn, the ATVtries to keep

going in a straight line.

●

When cornering on an ATVwith no differential or

with the differential lock engaged, where your

body weight needs to be positioned depends on

how sharp the corner is and on how fast you are

going. Correct body position allows you to transfer

weight to the outside of the turn through the

footrests while maintaining balance with the torso.

This lets the inside wheels skid slightly allowing

the ATV to make the turn properly.

●

You must understand how the transmission

system of your machine will affect engine braking

for both riding, and recovery of stalled ATVs, on

slopes.

●

When riding across a slope, keep your weight on

the uphill side of the ATV.

●

When going downhill, slide your weight

backwards, select a low gear and use engine

braking, reducing the need to use the brakes.

●

When going uphill, it is important to review the

route before starting the climb. Move your weight

forwards and maintain a steady speed. It is

important to shift your body weight forwards as

much as possible. If necessary stand up and lean

forward, keeping both feet on the footrests at all

times and always maintain momentum.

●

Avoid sudden increases in speed, as this is a

common cause of rearward overturning accidents,

even from a standing start on flat ground where

there is good grip.

Page 6

●

Never put your foot onto the ground to

stabilise an ATV when riding, but shift your

weight across the ATV away from the imbalance.

●

Always read the owner’s manual.

Trailed equipment and loads

Ensure all riders know the manufacturers

recommended towing capacity and drawbar loading

limit. Always operate within these requirements.

Remember that your ability to control the ATV by your

body movements will be considerably reduced when

carrying a load or towing a trailer.

●

When selecting trailed equipment look for:

-

over-run brakes;

-

a swivel hitch drawbar;

-

bead lock rims on wheels;

-

a low centre of gravity and a wide wheel

track;

-

a long drawbar; and

-

attachment points for securing a load.

●

Check the weight ratio between your ATVand its

trailed load. This needs to be assessed for each

operation. As a general guide, on level ground,

braked trailed equipment can be a maximum of

four times the unladen weight of the ATV.For

unbraked trailed equipment the maximum should

be twice the unladen weight. These loads should

be reduced when working on slopes, uneven

ground or poor surface conditions. Follow the

manufacturers advice for your particular machine.

●

Weight transfer is also important. Stability and

resistance to jack-knifing is improved if some load

is transferred onto the ATVʼs drawbar.

Approximately 10% of the gross weight of the

loaded trailer is recommended, but this should not

exceed the manufacturers drawbar loading limit.

Remember that weight transfer can change

dramatically when you start going up or down hill.

●

When selecting mounted equipment, make sure it

is within the manufacturers approved weight limit,

with a low centre of gravity, and controls which are

easy to operate but do not create a hazard. Where

equipment is added to one end of the machine,

add ballast at the other end to maintain stability.

●

Loads carried on racks must be well secured, e.g.

with ratchet straps, and be evenly balanced

between the front and rear, except where they are

deliberately altered to aid stability when going up

or down a slope.

●

Only tow a load from the hitch point. Loads towed

from other points such as the rear rack have

caused sudden rear overturning even on slight

slopes or with slight acceleration. Ropes or chains

should not be used to drag a load where they can

become caught on a wheel. This may lead to

entanglement with the brake cable, causing

unexpectedbraking.

Using sprayers

●

Pesticides should be used in accordance with the

Code of Practice for using plant protection

products published by Defra. (Available from

Defra Publications, ADMAIL 6000, London SW1A

2XX Tel: 08459 556000.)

●

Sprayers should meet the requirements of BS EN

907 and be fitted with an induction hopper unless

the filling point is less than 1.5 m from the ground

and within 0.3 m from the edge of the sprayer. A

separate clean water tank for washing must be

provided containing at least 15 litres of clean

water and a tap that allows the water to run

without being continuously pressed.

●

When buying a sprayer look for a low centre of

gravity and internal baffles to reduce liquid surge

to improve stability when turning on slopes.

●

ATVs should only be used with rear-mounted

spray booms or other equipment that reduces the

risk of pesticide exposure to the operator.

●

Do not hold a spraying lance while riding your

ATV,as two hands are needed for safe control.

Accessories

Beware of the potential dangers of accessories which

are not approved by manufacturers, e.g. home-made

gun racks and boxes. Either use accessories

supplied/approved by manufacturers or seek their

advice as to the suitability of those sourced elsewhere.

Any weight added above the centre of gravity will

decrease the ATVʼs stability.

Children

●

Never carry a child as a passenger. It is illegal and

will reduce your ability to control the ATV.

●

Children under 13 are prohibited from using an

ATV at work. Over 13 they should only ride ATVs

of an appropriate size and power, after formal

training on a low-power ATV.

●

Check and adhere to the manufacturer’s

minimum age recommendations for your ATV.

The ratio of a child’s weight to that of the ATV is

significant, as weight transfer is the key to safe

handling.

●

Always refer to the owner’s manual and warning

labels on the machine.

Roll bars, lap straps and weather cabs

●

Roll bars are not recommended for sit-astride

ATVs. Research has shown that they are more

likely to increase injuries by obstructing the rider,

either when thrown off or when jumping off during

an overturn. This causes the rider to fall to the

ground alongside the ATV and increases the

likelihood of injury. PUWER does not require roll

bars where they would increase the overall risk.

Page 7

●

Lap straps should not be fitted. They prevent

active riding and would be potentially lethal

without a full cab or roll cage.

●

Weather cabs restrict a riders ability to jump clear

in an overturn. The rider is likely to be crushed

within the cab unless it is strong enough to

withstand the forces involved. Carefully assess the

risks for your particular conditions of use before

fitting any such structure and consult the

manufacturer forinformation.

Road use

For road use, ATVs and trailers have to comply with the

Road Vehicles Construction and Use Regulations 1986

(as amended) and the Road Vehicles Lighting

Regulations 1989 (both enforced by the police) and be

licensed in the appropriate class. They do not require

an MOT and the maximum permitted speed is 20 mph.

The minimum age for drivers is 17 and they need a

Category B licence.

Sit-in ATVs

Sit-in ATVs include the Mule, Rhino, Argocat, Scot-

Track, Gator, Ranger, Hiler, Goblin and other similar

machines. They all have conventional sit-in seats and

the driver does not use weight transfer to steer or

control stability, although load balance is important in

this respect. They range from machines designed for

purely rough terrain to utility vehicles, which are also

commonly used fully off-road.

Training

The legal requirements for training are the same as for

the sit-astride ATVs. You should request advice on

training from your suppliers, the training providers

previously mentioned or, for forestry operations, from

the Forestry Commission.

Rollover protection and seat belts

The requirements for these machines are quite different

to those of sit-astride ATVs.

●

Where there is a risk of the machine rolling over,

PUWER requires an employer to fit some device

to protect employees (the self-employed have the

same duty to themselves). This would normally be

a cab, rollover frame or roll bar. Such a structure

could either be provided as part of the original

machine or, if added afterwards, should be CE

marked and approved by a recognised test body.

●

Restraining devices such as seat belts should be

fitted and worn by the driver and passengers

where a roll bar or cab is fitted.

●

Where a machine is amphibious and used on

deep water as opposed to marshland, then the

seat restraints (and possibly roll frame) could

increase the overall risk rather than reduce it. In

this case, do not use seat restraints while on the

water. Assess the risk from the roll frame

according to its design and the likelihood of

trapping the occupants if the machine should sink.

●

If there is a risk of overturning, employees at work

who are carried in the rear of sit-in ATVs should

be protected by rollover protection and seat

restraints.

●

Children should only be carried in these vehicles if

they are in a passenger seat and wearing a

properly designed and fitted seatbelt.

Parking

If you have to park on a slope, always park across it

unless it is too steep. Accidents have occurred where

machines have run down slopes because of poor brake

maintenance or application, particularly while they are

being loaded, and movement or the increase in weight

sets the machine into motion.

Further information

HSE priced and free publications are available by mail

order from HSE Books, PO Box 1999, Sudbury, Suffolk

CO10 2WA Tel: 01787 881165 Fax: 01787 313995

Website: www.hsebooks.co.uk (HSE pricedpublications

are also available from bookshops and free leaflets can

be downloaded from HSEʼs website: www.hse.gov.uk.)

For information about health and safety ring HSEʼs

Infoline Tel: 0845 345 0055 Fax: 0845 408 9566

Text phone: 0845 408 9577 e-mail:

hse.infoline@natbrit.com or write to HSE Information

Services, CaerphillyBusiness Park, Caerphilly CF83 3GG.

© Crown copyright This publication may be freely

reproduced, except for advertising, endorsement or

commercial purposes. First published 05/99. Please

acknowledge the source as HSE.

This leaflet contains notes on good practice which are not

compulsory but which you may find helpful in considering

what you need to do.

Page 8

Important Safety Information

Always read this manual before fitting or operating the machine –whenever any doubt exists contact your

dealer or the Chapman Machinery Service Department for advice and assistance.

Use only Chapman Genuine Service Parts on Chapman Machinery and Machines

DEFINITIONS

The following definitions apply throughout this manual:

WARNING

An operating procedure, technique etc., which –

can result in personal injury or loss of life if not observed carefully.

CAUTION

An operating procedure, technique etc., which –

can result in damage to either machine or equipment if not observed carefully.

NOTE

An operating procedure, technique etc., which –

is considered essential to emphasis.

LEFT & RIGHT HAND

This term is applicable to the machine when attached to the towing vehicle and is

viewed from the rear –this also applies to tractor references.

Safety Information

-Do not operate this equipment unless you have studied this manual in full

-Only use this machine for its designated task - improper use is both highly dangerous and damaging to

machine components

- Both operators & maintenance fitters should be familiar with the machine and fully aware of dangers sur-

rounding improper use or incorrect repairs

-Before starting, carry out a visual check on both machine & towing vehicle as regards functionality,road

safety & accident prevention rules

-Even when using the machine correctly, accidents can occur. It is imperative that nobody stand withinthe

danger area. If working near roads, buildings or animals, special attention must be taken to ensure safety at

all times.

Page 9

-Never wear loose clothing which could get caught in rotatingequipment

-Never carry passengers on the towing vehicle

-Do not stand near the machine when operating

-Damaged or missing safety decals must be replaced immediately

Transportation Safety

-When transporting, especially over rough ground, reduce speed to prevent damage to machine.

-This machine is not road legal in its standard form. DO NOT tow on public highways unless you have

specified the road-legal model, and checked that this and the towing vehicle comply with local highway

regulations in place.

Operating Safety

-Pay special attention when working with the machine not to harm livestock if crowding around the ma-

chine occurs.

-If anything should become entangled in the mechanism, or blocked in the chute, stop the machine and

disconnect the power before attempting to clear the blockage.

Page 10

Description

The TF Series Trailed Feeders are designed for feeding livestock, through deposition of pre-defined drops of

feed, onto clear ground.

The TF Series operate with an electric motor mechanism, ensuring accurate disposition, and industry lead-

ing ground clearance. The rotor and wiring mechanism are all IP67 rated, to ensure trouble-free usage in

even the toughest winter conditions.

The TF350 has approximately 350kg carrying capacity (feed material dependant), a galvanised metal

hopper and PVC cover. Standard wheels are 22x11x8” flotation, with optional heavy duty 24x12x12”

traction or road going tyres available.

These machines should however only be used to perform tasks for which they were designed - use of the

machine for any other function may be both dangerous to persons, and potentially damaging to components.

Use of the machine beyond the stated usage may invalidate any applicable warranty, as well as being poten-

tial in breach of applicable safety regulations.

Identification

Each machine is fitted with a serial plate which details the following:

1. Model

2. Date of Manufacture (DOM)

3. Serial Number

4. Mass

When enquiring regarding spares or additional equipment, ensure you have this information to hand.

Specification

Width (m)

Height (m)

Length (m)

Mass Ap-

prox.(kg)

Drops per

minute

Ground

Clearance

TF350

1.52

1.05

1.80

135

25

300-

350mm

Page 11

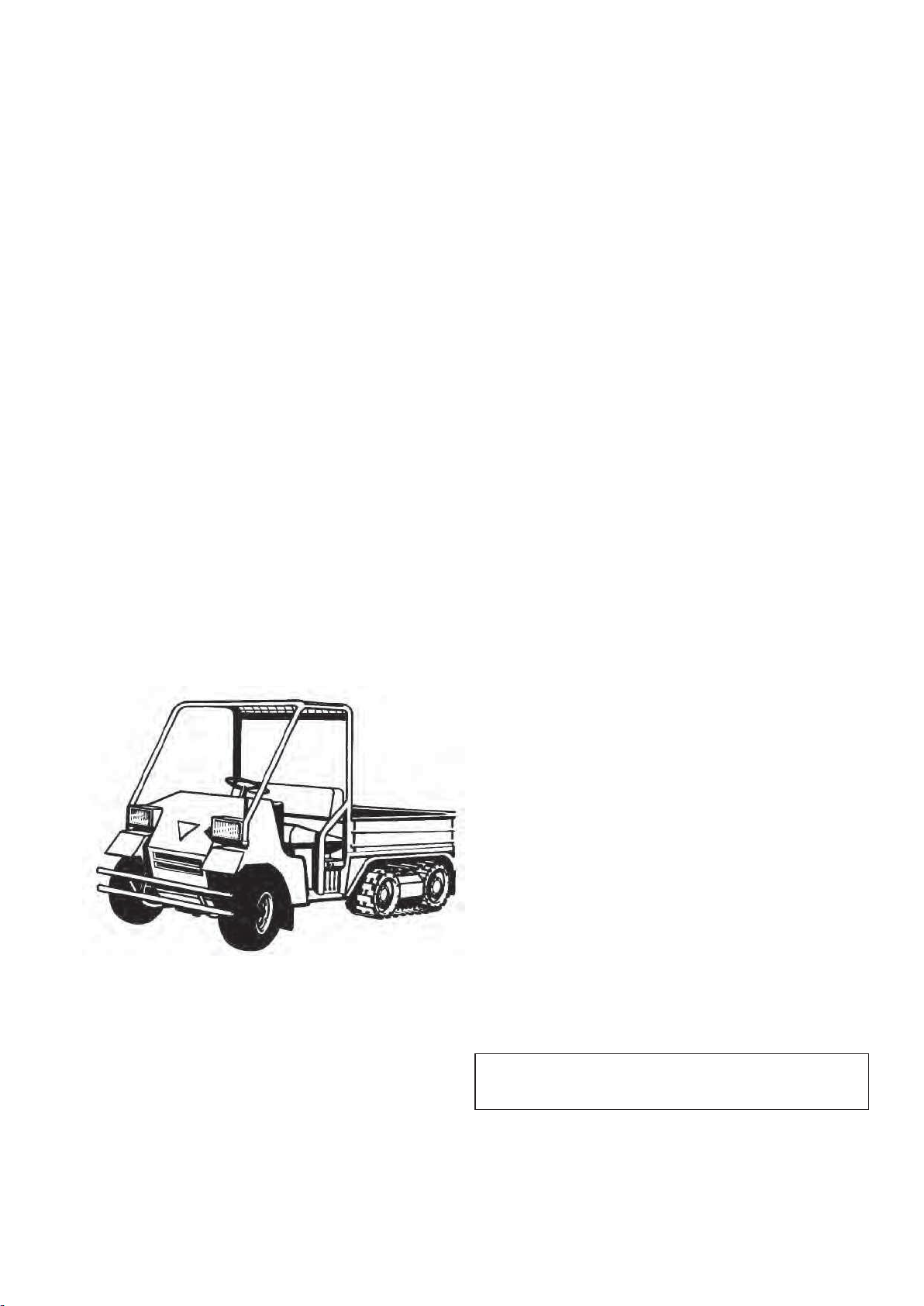

Component Identification

Optional Equipment

-Traction Tyres

-Extension Sides

-Livestock Fender Bar

-TwinAxle

-Hard TopBale Rack

-Road legal kit

-Additional ControlBox

Contact your distributor or Chapman Machinery for more information on optional equipment.

Page 12

Implement Decals

If your implement does not contain all of the decals shown below, please contact Chapman Engineering for

replacement decals before use.

Note: All decals must be present and visible. It is imperative that these are replaced if damaged to prevent

potential harm to users.

* Carefully read operators manual before handling this machine. Observe instructions and safety rules when

operating.

*Caution - Entanglement Hazard. Keep hands away from moving parts

Page 13

Attachment

Before Attaching the Machine

Before attachment, ALWAYS ensure the following:

- All safety guards & decals are in good working order and correctly fitted

- Lubrication points have been lubricated as per scheduled maintenance period

- The tyres are free of damage and inflated to the correct pressure

- Electrical connections are free of dirt and moisture

Attaching the Machine

NOTE: This machine is designed to attach to the towing vehicle through a 50mm diameter ball hitch.

1. Reverse the towing vehicle up to the machine.

2. Attach the machine onto the towing vehicle’s coupling.

3. Attach the control cable to the control socket fitted on the towing machine, ensuring a secure connection.

WARNING: ENSURE CONTROL EQUIPMENT IS SECURELY ATTACHED TO THE TOWING

VEHICLE BEFORE USE!

4. If required, check and adjust the drop size to suit the material being distributed.

1. Wire Plug

a. Wire Plug supplied with kit –cut approx. 30mm of outer sheath off and shorten BROWN

cable by 8mm. Wiring Code:

i. Brown = 7 = Motor –

ii. Red = 3 = Motor +

iii. Green = 5 = Sensor Brown Cable

iv. White = 1 = Sensor White Cable.

b. 2x 40mm lengths of black heat shrink tubing will be required as the plug is designed for a

larger cable diameter than is being used on these machines, so 2 pieces of heat shrink must be

heat shrunk onto the cable at the right point to allow the cable grip to function!

Page 14

Drop Size Adjustment & Calibration

Initially set the Feed adjustment plate to setting 4, as indicated by the arrow on the drop adjustment plate.

Toadjust, loosen BOTH hand wheels, and slide the unit forwards or backwards to the desired value. Tighten

securely.

Setting 1: Minimum drop size Setting 8: Maximum dropsize

Fill the hopper 50% full of the feed to be distributed. With the machine attached to the towing vehicle and

on level ground, switch the control box on and deposit 10 drops of feed into a bucket. Measure the weight of

the deposited feed, and divide by the number of drops (in this case 10) to give the weight per drop.

Adjust the feed adjustment plate as required to increase or decrease the drop size, checking after each ad-

justment for the average drop size. Individual drop sizes can vary, especially with large granular materials

(eg. cobs) or with feedstuff containing molasses, so it is important to average the drop size over a number of

drops.

It is recommended that the feed be deposited in round numbers, ie. 1kg, 1.5kg, 2kg etc. This allows easy

calculation of required number of drops for different livestock numbers.

The drop setting will differ between feedstuff, due to the different particulate size and any binding agents

such as molasses. Its is strongly recommended to re-calibrate if you change feed make-up or consistency.

Once you have set the machine to the desired drop size, securely tighten the two retaining handwheels to

ensure this does not change during use.

Page 15

Spring Change / Replacement

If you are using the TF350 for a molasses based feed, cobs or rolls. You will need to change the spring which

is used to open/close the shutter.

1. REMOVE THE GUARD WHICH IS LOCATED UNDER THE DRAW BAR USING A 17MM SOCKET

2. THERE WILL BE A SPRING ALREADY ATTACHED (SEE BELOW) THIS SPRING IS USED FOR A

MORE FINER FEED SUCH AS CORN AND ROLLED BARLEY

Page 16

3. REMOVE THE SPRING BY UNHOOKING IT FROM BOTH END

4. REPLACE THIS WITH THE STRONGER SPRING.

Page 17

Sensor Change / Adjustment

If your control box is showing an F1 error and not counting correctly, you may have a problem with

the connectors and/or the sensor may need adjustment.

First, check the plug and socket connection between the control box and the feeder –THIS IS THE

MOST COMMON CAUSE OF PROBLEMS! If required check continuity with a multi-meter.

Plug/socket wiring; Brown = 7 = Motor –

Red = 3 = Motor +

Green = 5 = Sensor Brown Cable

White = 1 = Sensor White Cable.

If the connectors are functioning correctly then the unit may need adjustment of the sensor and

magnet located within the machine.

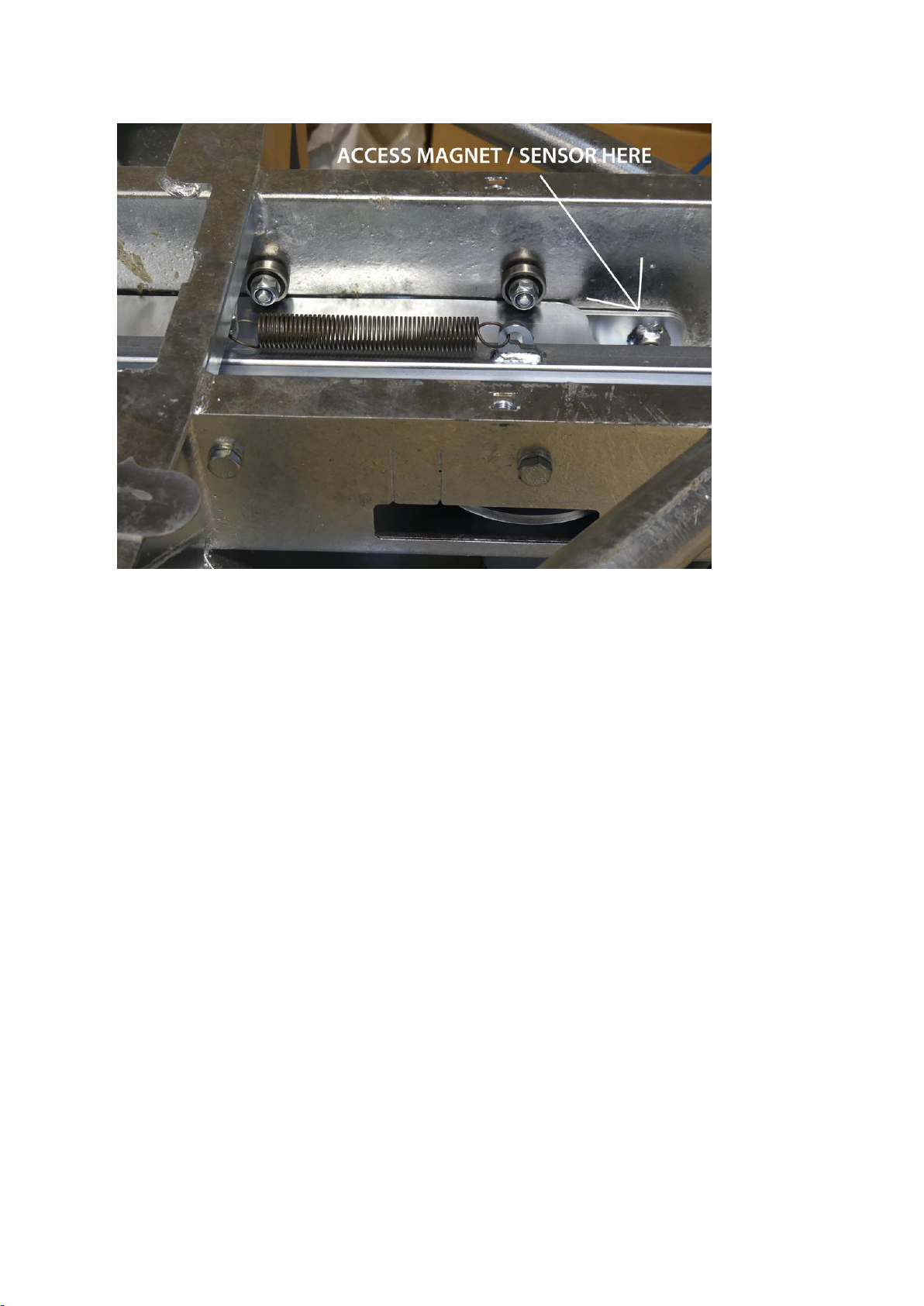

Procedure

1. Tilt the drawbar upwards so the machine is resting on the wheels and end of the mudguards,

this will allow easier access. Remove the belly plate using a 17mm socket on the 8 bolts.

2. The sensor can be accessed though the recess in the slide plate shown in the RH corner of

the image below. You should not need to remove the slide plate to access the sensor. If you

do need to remove the slide plate for access, this can be achieved by unclipping the spring

from the slide plate and removing the 5 x bearings and associated bolts which locate the

Page 18

plate. TAKE NOTE OF THE NUMBER OF WASHERS AS THESE NEED TO BE RE-FITTED

IN THE SAME ORDER TO ENSURE THE SLIDE MOVES SMOOTHLY.

3. In the Picture below you can see the sensor (with the wire) and the magnet (fitted to the disc)

are facing each other with approximately 2mm gap between them. The sensors also need to

be aligned vertically (so that they are approximately level with each other).

If required you can bend the sensor support bracket up or down to get vertical alignment, and

you can move the sensor in or out on the slotted holes to get horizontal alignment.

FOR MACHINES USED WITH DUSTY FEED OR FEED WITH ADDITIVES SUCH AS

MOLLASES, BUILD UP OF DIRT CAN AFFECT THE SENSOR OPERATION –IN THIS

CASE CLEAN WITH A LOW-PRESSURE WATER JET.

Page 19

4. Parts are re-fitted as a reverse of removal, taking care to ensure all bolts are secure and

tight. If adjustments have been made to the sensor, ensure the cable is secured with cable

ties or similar to prevent accidental damage.

Once this has been checked and all dirt removed, your problem should be resolved.

we will be more than happy to help.

Page 20

Control Box

2 Button Model (UNTIL October 2015)

The TF Series control box has a two-button operation, and a three-digit display, capable of counting up to

999 drops.

The LH button switches the unit on, and a subsequent press of the LH button will start operation of the unit.

Afurther single press will pause operation. Holding the LH button for three seconds will reset the counter to

zero. The RH Button switches the unit off fully, with negligible powerconsumption.

NOTE: The unit MUST be stopped before switching off, as this allows the unit to ‘park’ in the correct

position. Switching the unit off without stopping may result in feed being spilt if the slider stops in the

open position!

The unit also contains a 15amp fuse. This can be seen mounted on the circuit board below the counter mod-

ule. If the fuse blows, the unit will light up to indicate the fault.

Specification

Supply Voltage: 12V DC nominal, 16V MAXIMUM

Power Consumption: 300mA + Motor power consumption when running

Operating Temperature: -20°C to +50°C

Fuse: 15A Automotive blade fuse with integrated failure LED

Operating life: 100,000 cycles

Protection rating: IP67

Incorrect polarity protection: Yes, diode.

Operation

1. Press the LH switch to turn the unit on. The display will perform a self-test for approximately 3

seconds. Once the default count (zero) shows, the unit is ready to use.

2. Tostart the motor, press LH switch. The counter will update from 0 to 999 as the motor operates. Themo-

tor and counter will continue to operate until it is paused or switchedoff.

Other manuals for TF350

1

This manual suits for next models

1

Table of contents

Other Chapman Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

FEATHERLITE TRAILERS

FEATHERLITE TRAILERS Horse Trailer owner's manual

Egholm

Egholm City Ranger 2250 Operator's manual

Woodland Mills

Woodland Mills PATHLANDER Operator's manual

Silver Eagle

Silver Eagle VAST-20W Operation, service & parts manual

Toro

Toro Workman 07347 Operator's manual

Toro

Toro 7213 Operator's manual