2

All Rights Reserved

Printed in the USA

2001 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause

cancer, birth defects, and other reproductive harm.

Warning

Important The engine in this product is not equipped

with a spark arrester muffler. It is a violation of California

Public Resource Code Section 4442 to use or operate this

engine on any forest-covered, brush-covered, or

grass-covered land as defined in CPRC 4126. Other states

or federal areas may have similar laws.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada.

Contents

Page

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 4. . . . . . . . . . . . . . . . . . . .

Supervisor’s Responsibilities 4. . . . . . . . . . . . . . . .

Before Operating 4. . . . . . . . . . . . . . . . . . . . . . . . .

While Operating 5. . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure Level 6. . . . . . . . . . . . . . . . . . . . . .

Vibration Level 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 7. . . . . . . . . . . . . . . .

Specifications 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 15. . . . . . . . . . . . . . . . . . . . .

Dimensions 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

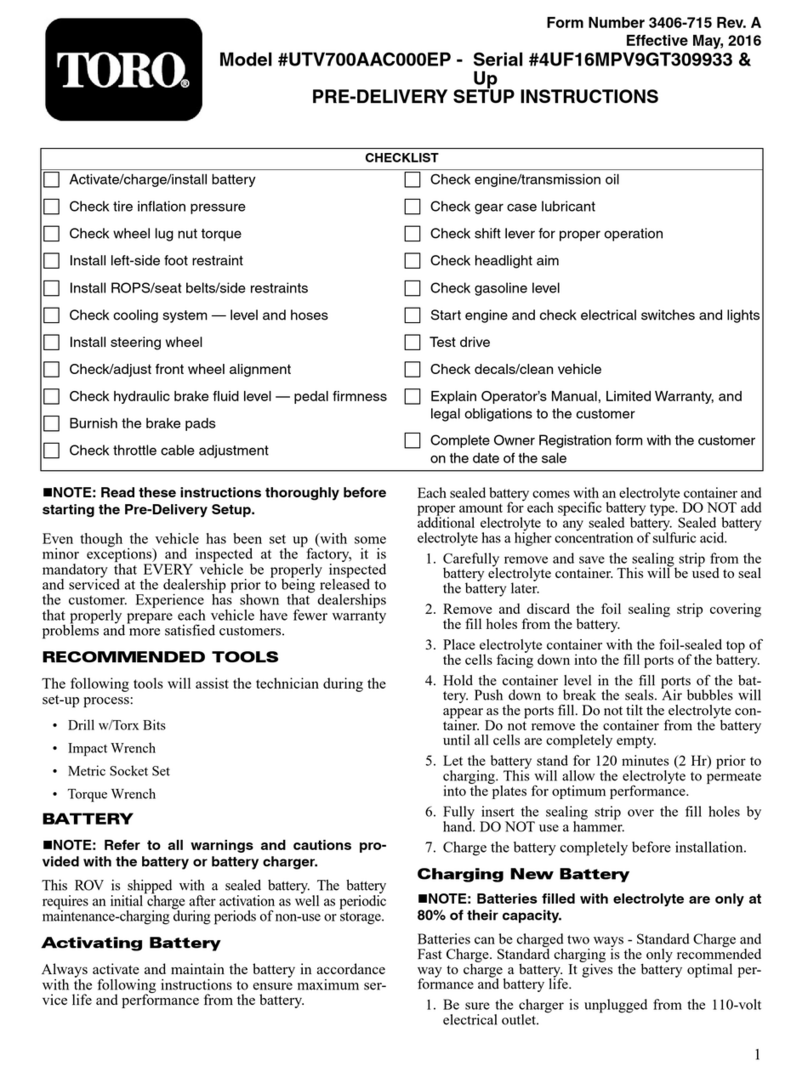

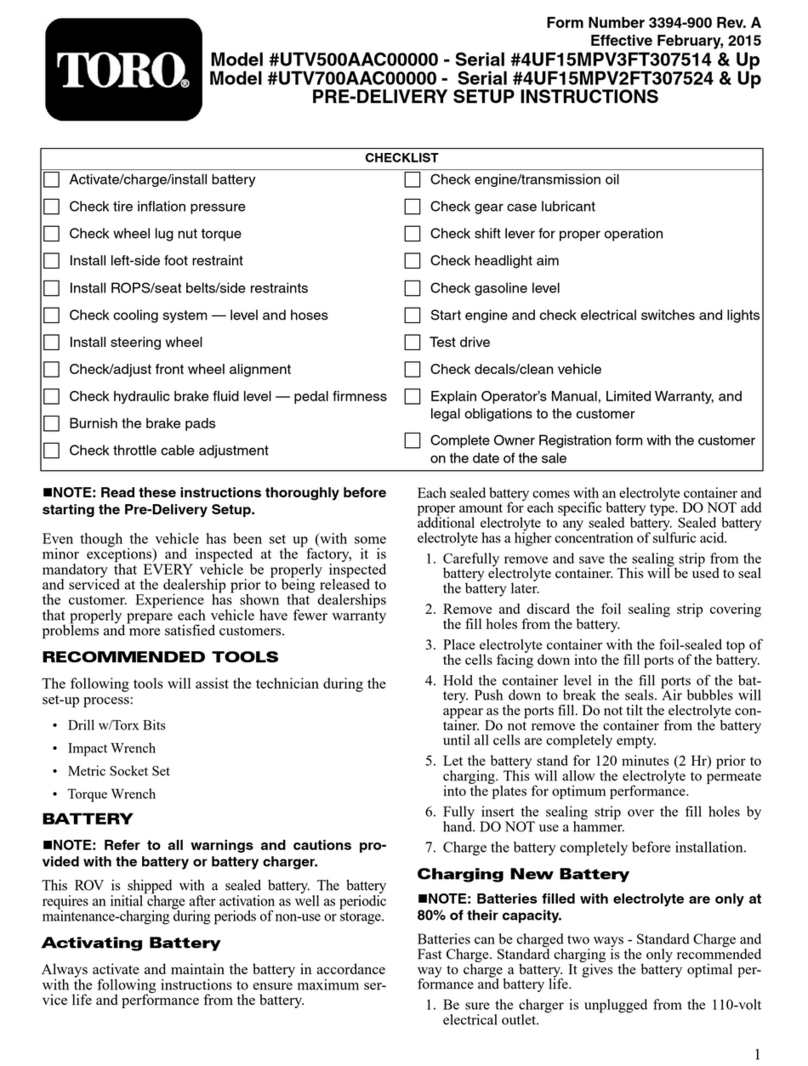

Setup 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Rear Fenders 18. . . . . . . . . . . . . . . . . . . . . . .

Install Wheels 18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Steering Wheel 18. . . . . . . . . . . . . . . . . . . . .

Install Front Fenders 19. . . . . . . . . . . . . . . . . . . . . . .

Install ROPS 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Activate and Charge Battery 19. . . . . . . . . . . . . . . . .

Full Bed Removal 21. . . . . . . . . . . . . . . . . . . . . . . . .

Re–Install Full Bed 21. . . . . . . . . . . . . . . . . . . . . . . .

Before Operating 23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Crankcase Oil 23. . . . . . . . . . . . . . . . . . . . . .

Fill Fuel Tank 24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Cooling System 24. . . . . . . . . . . . . . . . . . . . .

Check Transaxle / Hydraulic Fluid 25. . . . . . . . . . . .

Check Front Differential Oil 25. . . . . . . . . . . . . . . . .

Check Torque Of Wheel Nuts 25. . . . . . . . . . . . . . .

Check Tire Pressure 25. . . . . . . . . . . . . . . . . . . . . . .

Check Brake Fluid 26. . . . . . . . . . . . . . . . . . . . . . . .

Operation 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–starting Checks 30. . . . . . . . . . . . . . . . . . . . . . .

Starting Engine 30. . . . . . . . . . . . . . . . . . . . . . . . . . .

Bleeding Fuel System 31. . . . . . . . . . . . . . . . . . . . . .

Driving Vehicle 31. . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping Vehicle 31. . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping Engine 31. . . . . . . . . . . . . . . . . . . . . . . . . .

New Vehicle Break–in 31. . . . . . . . . . . . . . . . . . . . .

Check Interlock System 32. . . . . . . . . . . . . . . . . . . .

Operating Characteristics 32. . . . . . . . . . . . . . . . . . .

Passengers 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Braking 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tipovers 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hills 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading And Dumping 35. . . . . . . . . . . . . . . . . . . . .

Using The Differential Lock 35. . . . . . . . . . . . . . . .

Four Wheel Drive 36. . . . . . . . . . . . . . . . . . . . . . . . .

Transporting Vehicle 36. . . . . . . . . . . . . . . . . . . . . .

Towing Vehicle 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailer Towing 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Hydraulic Control 37. . . . . . . . . . . . . . . . . .

Maintenance 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 39. . . . . . . . . . . . . . . . . . . . . .

Greasing Bearings And Bushings 39. . . . . . . . . . . . .

Maintenance 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 41. . . . . . . . .

Daily Maintenance Checklist 42. . . . . . . . . . . . . . . .

Heavy Duty Operation 43. . . . . . . . . . . . . . . . . . . . .

Using Bed Safety Support 43. . . . . . . . . . . . . . . . . .

Jacking Vehicle 44. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Air Cleaner Maintenance Practices 44. . . . .

Servicing Air Cleaner 44. . . . . . . . . . . . . . . . . . . . . .

Changing Engine Oil And Filter 45. . . . . . . . . . . . . .

Fuel System 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bleeding Air From Injectors 46. . . . . . . . . . . . . . . . .

Removing Debris From Engine Cooling System 46.

Changing Engine Coolant 46. . . . . . . . . . . . . . . . . .

Adjusting Belts 47. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Bolts 48. . . . . . . . . . . . . . . . . . . . . . .

Engine Valve Clearance 48. . . . . . . . . . . . . . . . . . . .

Adjusting Accelerator Pedal 48. . . . . . . . . . . . . . . . .

Changing Transaxle / Hydraulic Fluid 48. . . . . . . . .

Replacing Hydraulic Filter 49. . . . . . . . . . . . . . . . . .