Charger WS15P Quick start guide

Water Specialist

WS15P Control Valve

Parts and Service Manual

HYDROCARBONS SUCH AS VASELINE®, PETROLEUM JELLY, KEROSENE, BENZENE,

GASOLINE, ETC., WILL DAMAGE PRODUCTS THAT CONTAIN O-RINGS OR PLASTIC

COMPONENTS. EXPOSURE TO SUCH HYDROCARBONS MAY CAUSE THE PRODUCTS

TO LEAK. DO NOT USE CLACK CONTROL VALVE PRODUCT(S) ON WATER SUPPLIES

THAT CONTAIN HYDROCARBONS SUCH AS KEROSENE, BENZENE, GASOLINE, ETC.

Page 2 WS15P Parts and Service Manual

WS15P Parts and Service Manual Page 3

Table of Contents

General Specifications ................................................................................................................................ 4

Drive Cap Assembly, Pistons, Stack Assembly, Main Body ....................................................................... 5

Regenerant Components............................................................................................................................. 6

Injectors...................................................................................................................................................... 7

Injector Flow Graphs - U.S. Units............................................................................................................. 8

Injector Flow Graphs - Metric Units ......................................................................................................... 9

Fitting Kits................................................................................................................................................ 10

Drain Line Flow Control Washers............................................................................................................ 11

Troubleshooting Procedures...................................................................................................................... 12

Page 4 WS15P Parts and Service Manual

General Specications

Minimum/Maximum Operating Pressures 20 – 125 psi (138 kPa – 862 kPa)

Minimum/Maximum Operating Temperatures 40° - 110° F (4° - 43° C)

Power Adapter:

Supply Voltage

Supply Frequency

Output Voltage

Output Current

U.S.

100VAC to 120VAC

50/60 Hz

15VDC

500 mA

International

200VAC to 240VAC

50/60 Hz

15VDC

500 mA

Service ow rate 60 gpm @ 15 psi drop (227 lpm, 13.6 m3/h)

Backwash ow rate 43 gpm @ 25 psi drop (163 lpm, 9.8 m3/h)

Meter:

Accuracy

Flow Range

+5%

0.75 – 75 gpm (2.8 – 284 lpm)

Inlet/Outlet 1.5” Male NPT or BSPT

Drain line 1” Male Elbow NPT or 1" BSPT

Brine line ½” OD polytube compression

Tank connection 4”-8 UN

Height from top of tank 10.75”

PC board memory Nonvolatile EEPROM

Valve material Glass lled composite

Regenerant/chemical compatibility Sodium chloride, potassium chloride, potassium

permanganate, sodium bisulte, chlorine and chloramines

Regeneration Downow or upow

Tank applications 12” – 24” diameter

WS15P Parts and Service Manual Page 5

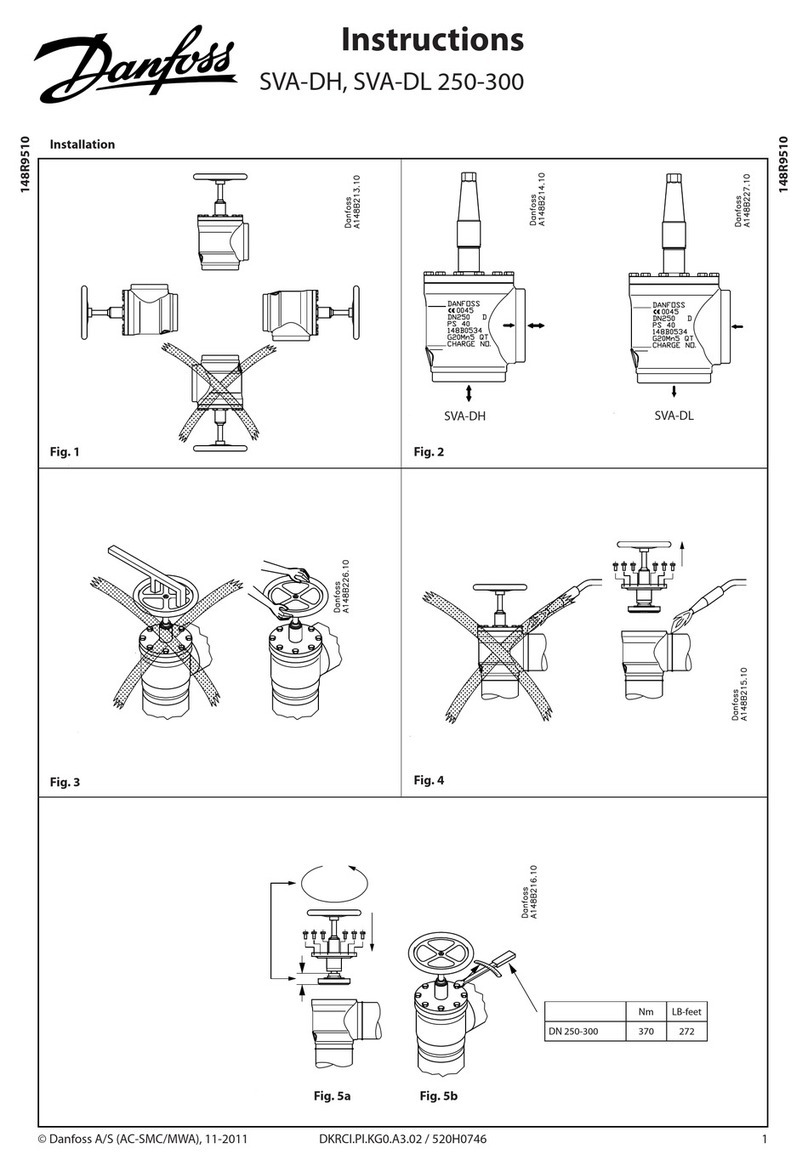

Drawing No. Order No. Description Quantity

1 V3004 WS1 DRIVE CAP ASSEMBLY 1

2 V3135 O-RING 228 1

3V3407 WS125/15 PISTON DOWNFLOW ASSEMBLY (AMBER) 1

V4042 WS112/15 PISTON UPFLOW ASSEMBLY (BLACK)

4 V3174* WS1 REGENERANT PISTON 1

5 V3430-01 WS1.5 SPACER STACK ASSEMBLY 1

6 D1300 TOP BAFFLE DIFFUSER 1.5/55MM 1

7 V3419 O-RING 347 1

8V4400-NPT WS15P NPT BODY ASSEMBLY 1

V4400-BSPT WS15P BSPT BODY ASSEMBLY

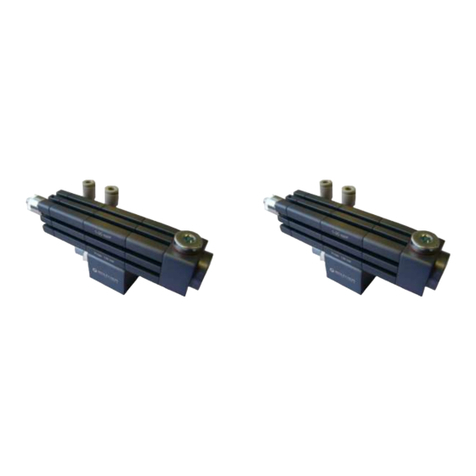

9V4430-01** WS15P FTG ASY QC TO NPT 1 set of 2

V4430-02** WS15P FTG ASY QC TO BSPT

10 V3641 O-RING 225 FOR VALVE BODIES WITH NPT THREADS 1

V3441 O-RING 226 FOR VALVE BODIES WITH BSPT THREADS 1

*V3174 Regenerant Piston not used for Backwash Only valves. Use V3010-15Z Injector Plug and V3195-01 Rell Port Plug Assembly.

** Inlet/Outlet tting kits are sold separate, see page 10 for tting selection.

WS1.5P Drive Cap Assembly, Pistons, Stack Assembly, Main Body

1234

5

9

8

9

10

7

6

Black o-ring retainer is NPT

Grey o-ring retainer is BSPT

Page 6 WS15P Parts and Service Manual

WS15P Regenerant Components

1

Drawing No. Order No. Description Quantity

1 H4615 RETAINING CLIP 1

2 V3498 WS15 BRINE ELBOW ASY W/RFC ½ 1

3 V3195-01 REFILL PORT PLUG ASY 1

4V4430-04NPT WS15P NPT DRAIN KIT 1

V4430-04BSPT WS15P BSPT DRAIN KIT

2

3

4

WS15P Parts and Service Manual Page 7

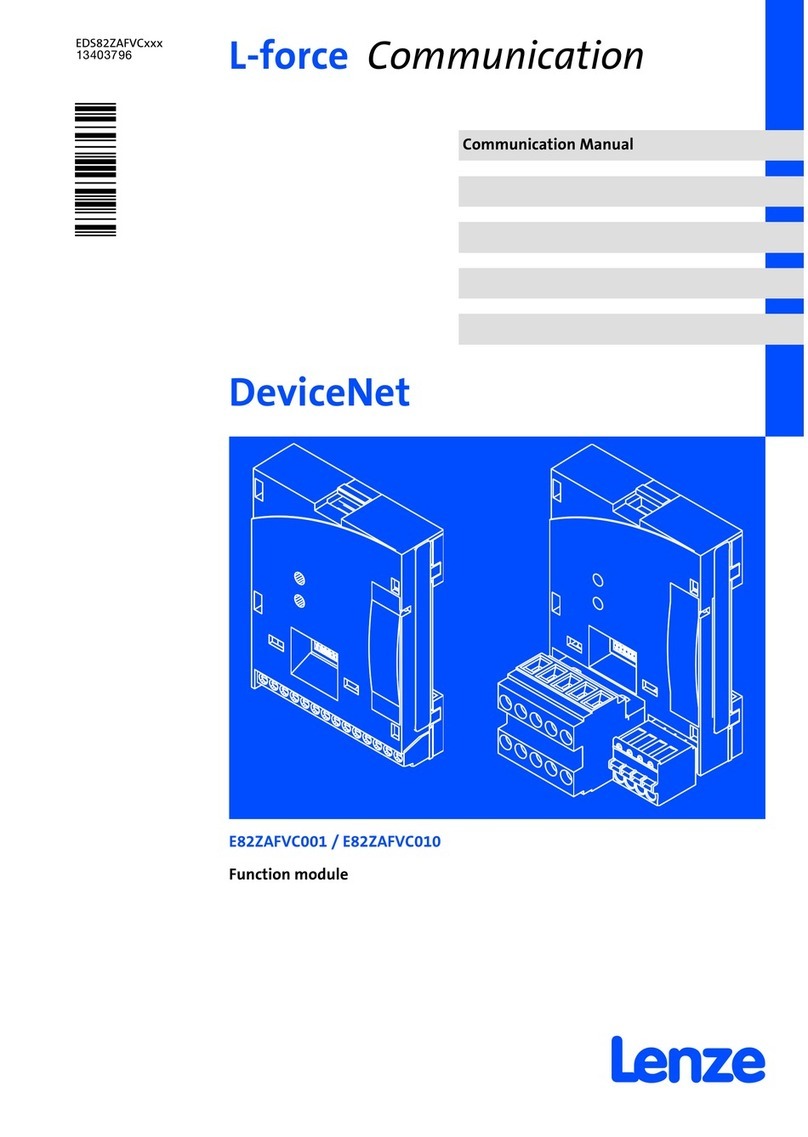

WS 1.5” Injectors

WS15P Regenerant Components

Drawing No. Order No. Description Quantity

1 V4349 WS15P INJECTOR CAP 1

2 V3152 O-RING 135 1

3 V4120 INJECTOR SCREEN 1

4 V4350-15Z WS15P INJECTOR FEED PLUG 1

5 V3010-15Z WS15 INJECTOR PLUG ASY 1 or 2

6 V3010-15X WS15 INJECTOR ASY 1 or 0

4

1

2

3

5

6

1

2

Drawing

No. Order No. Description Nozzle Color

Downflow

Typical Tank

Diameter1

Quantity

1

V3010-15B WS1.5 Injector Asy B Violet 12”

1

V3010-15C WS1.5 Injector Asy C Red 13”

V3010-15D WS1.5 Injector Asy D White 14”

V3010-15E WS1.5 Injector Asy E Blue 16”

V3010-15F WS1.5 Injector Asy F Yellow 18”

V3010-15G WS1.5 Injector Asy G Green 21”

V3010-15H WS1.5 Injector Asy H Orange 24”

2 V3010-15Z WS1.5 Injector Plug NA

V3010-15B through V3010-15H injectors include one V3416 o-ring 012 (lower) and one V3171 o-ring

013 (upper).

For upflow brine applications, it is recommended that the injector be downsized two tank sizes

minimum. Refer to the injector graphs for verifying proper selection.

Page 8 WS15P Parts and Service Manual

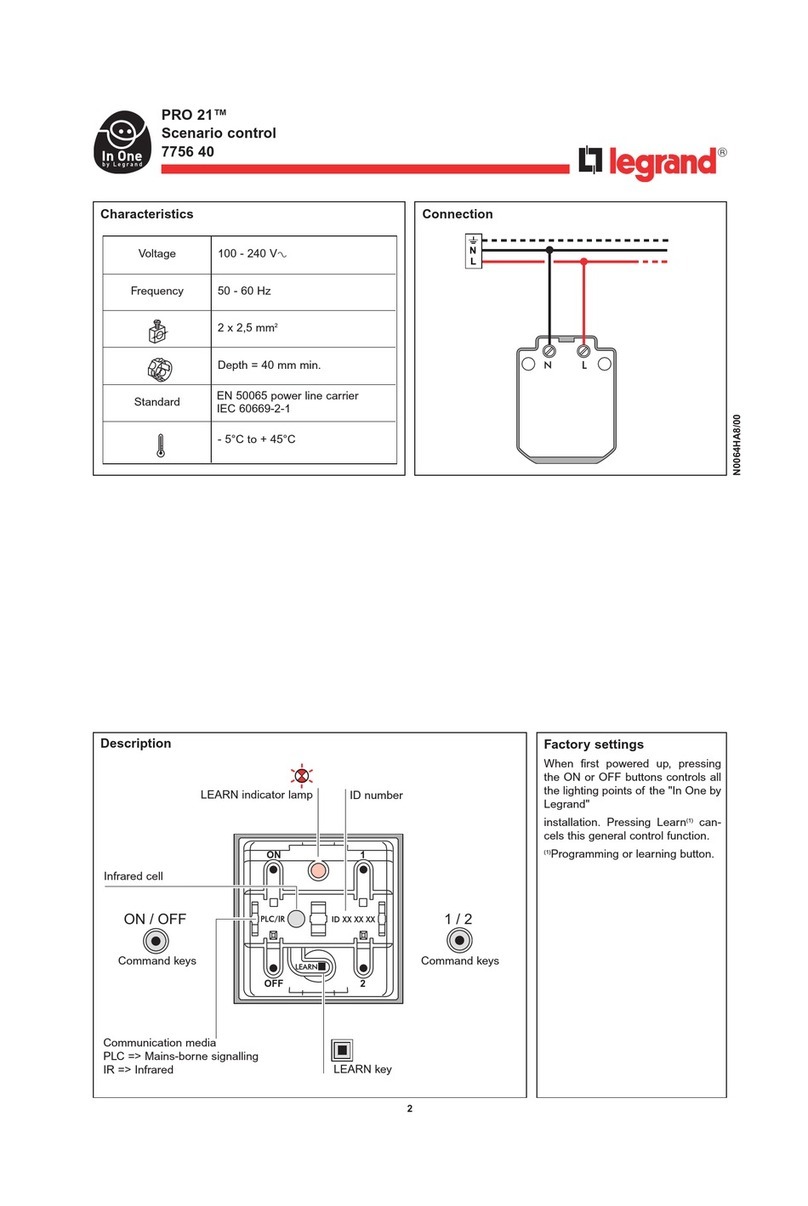

VIOLET, ORDER NO. V3010-15B

US Units

0.2

0.4

0.6

0.8

1

1.2

1.4

20 40 60 80 100 120

Pressure (psi)

Flow Rate (gpm)

Draw

Total

Slow Rinse

RED, ORDER NO. V3010-15C

US Units

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

20 40 60 80 100 120

Pressure (psi)

Flow Rate (gpm)

Slow Rinse

Total

Draw

ORDER NO. V3010-15B

VIOLET

WS 1.5” Injector Flow Graphs - U.S. Units

ORDER NO. V3010-15C

RED

ORDER NO. V3010-15D

WHITE

WHITE, ORDER NO. V3010-15D

US Units

0.5

1

1.5

2

2.5

3

20 40 60 80 100 120

Pressure (psi)

Flow Rate (gpm)

Total

Slow Rinse

Draw

ORDER NO. V3010-15E

BLUE

ORDER NO. V3010-15B

VIOLET

ORDER NO. V3010-15F

YELLOW

ORDER NO. V3010-15G

GREEN

BLUE, ORDER NO. V3010-15E

US Units

0.5

1

1.5

2

2.5

3

20 40 60 80 100 120

Pressure (psi)

Flow Rate (gpm)

Draw

Slow Rinse

Total

YELLOW, ORDER NO. V3010-15F

US Units

1

1.5

2

2.5

3

3.5

4

4.5

20 40 60 80 100 120

Pressure (psi)

Flow Rate (gpm)

Draw

Slow Rinse

Total

GREEN, ORDER NO. V3010-15G

US Units

1

2

3

4

5

6

20 40 60 80 100 120

Pressure (psi)

Flow Rate (gpm)

Draw

Slow Rinse

Total

ORANGE, ORDER NO. V3010-15H

US Units

1

2

3

4

5

6

7

20 40 60 80 100 120

Pressure (psi)

Flow Rate (gpm)

Draw

Slow Rinse

Total

ORDER NO. V3010-15H

ORANGE

WS15P Parts and Service Manual Page 9

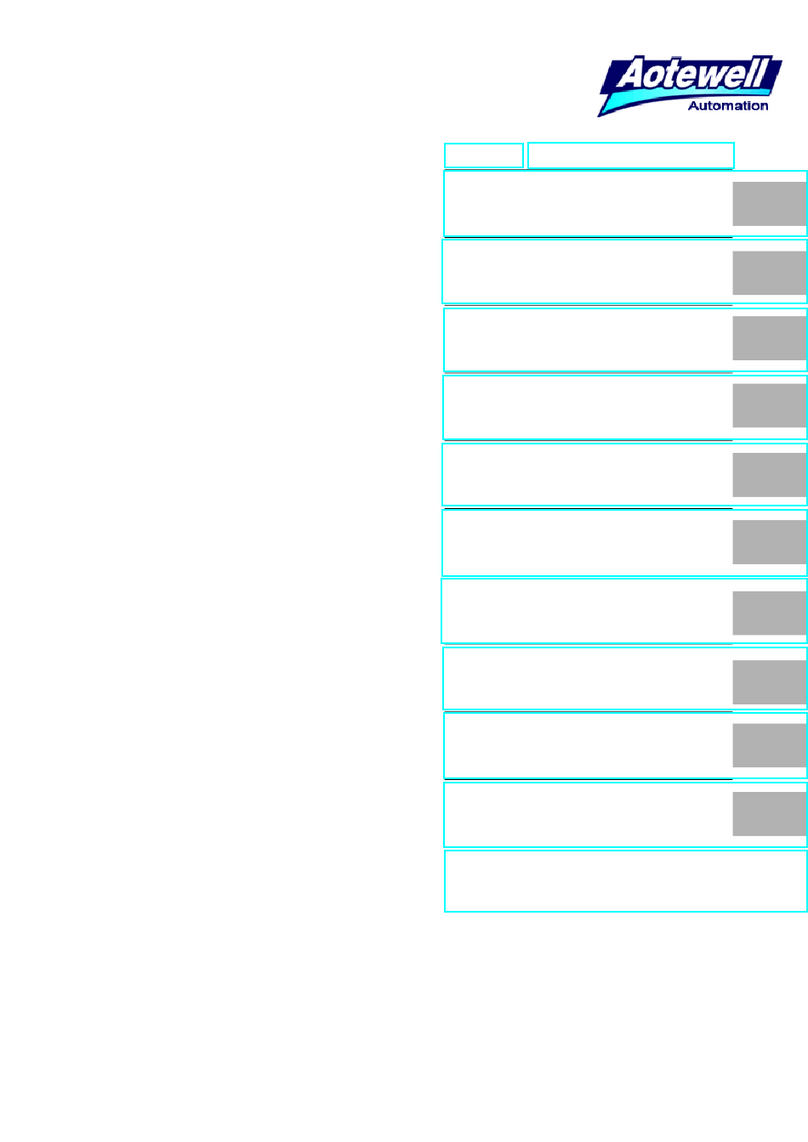

ORDER NO. V3010-15B

VIOLET

WS 1.5” Injector Flow Graphs - Metric Units

ORDER NO. V3010-15C

RED

ORDER NO. V3010-15D

WHITE

ORDER NO. V3010-15E

BLUE

ORDER NO. V3010-15F

YELLOW

ORDER NO. V3010-15G

GREEN

ORDER NO. V3010-15H

ORANGE

VIOLET, ORDER NO. V3010-15B

Metric Units

0.5

1.5

2.5

3.5

4.5

5.5

100 200 300 400 500 600 700 800 900

Pressure (kPa)

Flow Rate (lpm)

Draw

Total

Slow Rinse

RED, ORDER NO. V3010-15C

Metric Units

1

2

3

4

5

6

100 200 300 400 500 600 700 800 900

Pressure (kPa)

Flow Rate (lpm)

Slow Rinse

Total

Draw

WHITE, ORDER NO. V3010-15D

Metric Units

2

4

6

8

10

100 200 300 400 500 600 700 800 900

Pressure (kPa)

Flow Rate (lpm)

Total

Slow Rinse

Draw

BLUE, ORDER NO. V3010-15E

Metric Units

2

4

6

8

10

100 200 300 400 500 600 700 800 900

Pressure (kPa)

Flow Rate (lpm)

Draw

Slow Rinse

Total

YELLOW, ORDER NO. V3010-15F

Metric Units

2

4

6

8

10

12

14

16

100 200 300 400 500 600 700 800 900

Pressure (kPa)

Flow Rate (lpm)

Draw

Slow Rinse

Total

GREEN, ORDER NO. V3010-15G

Metric Units

4

8

12

16

20

100 200 300 400 500 600 700 800 900

Pressure (kPa)

Flow Rate (lpm)

Draw

Slow Rinse

Total

ORANGE, ORDER NO. V3010-15H

Metric Units

5

9

13

17

21

25

100 200 300 400 500 600 700 800 900

Pressure (kPa)

Flow Rate (lpm)

Draw

Slow Rinse

Total

Page 10 WS15P Parts and Service Manual

Fitting Installation Instructions:

• Installation ttings are designed to accommodate minor plumbing misalignments, but are not designed to support the weight of a system or the plumbing.

• Teon tape must be used on the tting threads.

• Slide nut on rst, then the split ring and o-ring.

• Hand tighten the nut only.

HYDROCARBONS SUCH AS VASELINE®, PETROLEUM JELLY, KEROSENE, BENZENE,

GASOLINE, ETC., WILL DAMAGE PRODUCTS THAT CONTAIN O-RINGS OR PLASTIC

COMPONENTS. EXPOSURE TO SUCH HYDROCARBONS MAY CAUSE THE PRODUCTS TO

LEAK. DO NOT USE CLACK CONTROL VALVE PRODUCT(S) ON WATER SUPPLIES THAT

CONTAIN HYDROCARBONS SUCH AS KEROSENE, BENZENE, GASOLINE, ETC.

Clack Order No. V4430-01

Description: WS15P QC to NPT Fitting Kit

Drawing No. Order No. Description Quantity

1 V4353 WS15P QC TO NPT FITTING 2

2 V4344 WS15P QC NUT 2

3 V4345 WS15P SPLIT RING 2

4 V4367 O-RING 222 2

2

3

4

1

Clack Order No. V4430-02

Description: WS15P QC to BSPT Fitting Kit

Drawing No. Order No. Description Quantity

1 V4355 WS15P QC TO BSPT FITTING 2

2 V4344 WS15P QC NUT 2

3 V4345 WS15P SPLIT RING 2

4 V4367 O-RING 222 2

2

3

4

1

Clack Order No. V4430-03

Description: WS15P QC to QC Fitting Kit

Drawing No. Order No. Description Quantity

1 V4354 WS15P QC TO QC FITTING 1

2 V4344 WS15P QC NUT 2

3 V4345 WS15P SPLIT RING 2

4 V4367 O-RING 222 2

2

3

4

1

Fitting Kits

Clack Order No. V4430-07

Description: WS1.5 PLASTIC ELBOW QC TO NPT

Drawing No. Order No. Description Quantity

1 V4432NPT 1.5 PLASTIC QC TO NPT ELBOW 2

2 V4367 O-RING -222 2

3 V4345 1.5 SPLIT RING 2

4 V4344 QC NUT 1.5 PLASTIC 2

4

3

2

1

Clack Order No. V4430-08

Description: WS1.5 PLASTIC ELBOW QC TO BSPT

Drawing No. Order No. Description Quantity

1 V4432BSPT 1.5 PLASTIC QC TO BSPT ELBOW 2

2 V4344 QC NUT 1.5 PLASTIC 2

3 V4345 1.5 SPLIT RING 2

4 V4367 O-RING -222 2

2

3

4

1

Clack Order No. V4430-09

Description: WS1.5 PLASTIC ELBOW QC TO QC

Drawing No. Order No. Description Quantity

1 V4432QC 1.5 PLASTIC QC TO QC ELBOW 1

2 V4345 1.5 SPLIT RING 2

3 V4344 QC NUT 1.5 PLASTIC 2

4 V4367 O-RING -222 2

4

3

2

1

WS15P Parts and Service Manual Page 11

Drain Line Flow Control Washers

5/8"

Flow Rate

Identication

Tooling

Identication

V3162-xx

Proper DLFC orientation

directs water ow towards

the washer face with rounded

edge & identication.

1"

Flow Rate

Identication

Tooling

Identication

V3190-xx

Proper DLFC orientation

directs water ow towards

the washer face with rounded

edge & identication.

Drain Line Flow Controls

Order No. Description

V3162-007 .7 GPM Drain line flow control

V3162-010 1.0 GPM Drain line flow control

V3162-013 1.3 GPM Drain line flow control

V3162-017 1.7 GPM Drain line flow control

V3162-022 2.2 GPM Drain line flow control

V3162-027 2.7 GPM Drain line flow control

V3162-032 3.2 GPM Drain line flow control

V3162-042 4.2 GPM Drain line flow control

V3162-053 5.3 GPM Drain line flow control

V3162-065 6.5 GPM Drain line flow control

V3162-075 7.5 GPM Drain line flow control

V3162-090 9.0 GPM Drain line flow control

V3162-100 10.0 GPM Drain line flow control

All DLFC housings ship without DLFC installed.

Up to 5 x V3162-XXX DLFC may be installed in V4430.

Select 1-5 flow controls from table for proper backwash flow,

based on media manufacturer's recommendations.

V3162-XXX

Clack Order No. V4430-04NPT OR V4430-04BSPT

Description: WS15P 1.5 Drain Elbow

Drawing No. Order No. Description Quantity

1A V4358 WS15P DRAIN ELBOW 1" NPT 1

1B V4359 WS15P DRAIN ELBOW 1" BSPT 1

2 V4345 WS15P SPLIT RING 1

3 V4344 QC NUT 1.5 PLASTIC 1

4 V4367 O-RING 222 1

5 V4351 FLOW CONTROL HOUSING 1

6 V4352 FLOW CONTROL RETAINER 1

7 V4364 O-RING 129 1

2

43

5

7

6

1A 1B

Page 12 WS15P Parts and Service Manual

Troubleshooting Procedures

Problem Possible Cause Solution

1. No Display on PC Board

a. No power at electric outlet a. Repair outlet or use working outlet

b. Control valve Power Adapter not plugged into

outlet or power cord end not connected to PC

board connection

b. Plug Power Adapter into outlet or connect

power cord end to PC Board connection

c. Improper power supply c. Verify proper voltage is being delivered to

PC Board

d. Defective Power Adapter d. Replace Power Adapter

e. Defective PC Board e. Replace PC Board

2. PC Board does not display correct time of day

a. Power Adapter plugged into electric outlet

controlled by light switch

a. Use uninterrupted outlet

b. Tripped breaker switch and/or tripped GFI b. Reset breaker switch and/ or GFI switch

c. Power outage c. Reset time of day. If PC Board has battery

back up present the battery may be

depleted. See Front Cover and Drive

Assembly drawing for instructions.

d. Defective PC Board d. Replace PC Board

3. Display does not indicate that water is flowing.

Refer to user instructions for how the display

indicates water is flowing

a. Bypass valve in bypass position a. Turn bypass handles to place bypass in

service position

b. Meter is not connected to meter connection on

PC Board

b. Connect meter to three pin connection

labeled METER on PC Board

c. Restricted/ stalled meter turbine c. Remove meter and check for rotation or

foreign material

d. Meter wire not installed securely into three pin

connector

d. Verify meter cable wires are installed

securely into three pin connector labeled

METER

e. Defective meter e. Replace meter

f. Defective PC Board f. Replace PC Board

4. Control valve regenerates at wrong time of day

a. Power outage a. Reset time of day. If PC Board has battery

back up present the battery may be

depleted. See Front Cover and Drive

Assembly drawing for instructions.

b. Time of day not set correctly b. Reset to correct time of day

c. Time of regeneration set incorrectly c. Reset regeneration time

d. Control valve set at ”on 0” (immediate

regeneration)

d. Check programming setting and reset to

NORMAL (for a delayed regen time)

e. Control valve set at ”NORMAL + on 0” (delayed

and/ or immediate)

e. Check programming setting and reset to

NORMAL (for a delayed regen time)

5. Time of day flashes on and off

a. Power outage a. Reset time of day. If PC Board has battery

back up present the battery may be

depleted. See Front Cover and Drive

Assembly drawing for instructions.

6. Control valve does not regenerate

automatically when the REGEN button is

depressed and held.

a. Broken drive gear or drive cap assembly a. Replace drive gear or drive cap assembly

b. Broken Piston Rod b. Replace piston rod

c. Defective PC Board c. Defective PC Board

7. Control valve does not regenerate

automatically but does when the REGEN button

is depressed and held.

a. Bypass valve in bypass position a. Turn bypass handles to place bypass in

service position

b. Meter is not connected to meter connection on

PC Board

b. Connect meter to three pin connection

labeled METER on PC Board

c. Restricted/ stalled meter turbine c. Remove meter and check for rotation or

foreign material

d. Incorrect programming d. Check for programming error

e. Meter wire not installed securely into three pin

connector

e. Verify meter cable wires are installed

securely into three pin connector labeled

METER

f. Defective meter f. Replace meter

g. Defective PC Board g. Replace PC Board

WS15P Parts and Service Manual Page 13

Problem Possible Cause Solution

8. Hard or untreated water is being delivered

a. Bypass valve is open or faulty a. Fully close bypass valve or replace

b. Media is exhausted due to high water usage b. Check program settings or diagnostics for

abnormal water usage

c. Meter not registering c. Remove meter and check for rotation or

foreign material

d. Water quality fluctuation d. Test water and adjust program values

accordingly

e. No regenerant or low level of regenerant in

regenerant tank

e. Add proper regenerant to tank

f. Control fails to draw in regenerant f. Refer to Trouble Shooting Guide number 12

g. Insufficient regenerant level in regenerant tank g. Check refill setting in programming. Check

refill flow control for restrictions or debris

and clean or replace

h. Damaged seal/stack assembly h. Replace seal/stack assembly

i. Control valve body type and piston type mix

matched

i. Verify proper control valve body type and

piston type match

j. Fouled media bed j. Replace media bed

9. Control valve uses too much regenerant

a. Improper refill setting a. Check refill setting

b. Improper program settings b. Check program setting to make sure they are

specific to the water quality and application

needs

c. Control valve regenerates frequently c. Check for leaking fixtures that may be

exhausting capacity or system is undersized

10. Residual regenerant being delivered to service

a. Low water pressure a. Check incoming water pressure – water

pressure must remain at minimum of 25 psi

b. Incorrect injector size b. Replace injector with correct size for the

application

c. Restricted drain line c. Check drain line for restrictions or debris

and clean

11. Excessive water in regenerant tank

a. Improper program settings a. Check refill setting

b. Plugged injector b. Remove injector and clean or replace

c. Drive cap assembly not tightened in properly c. Re-tighten the drive cap assembly

d. Damaged seal/ stack assembly d. Replace seal/ stack

e. Restricted or kinked drain line e. Check drain line for restrictions or debris

and or un-kink drain line

f. Plugged backwash flow controller f. Remove backwash flow controller and clean

or replace

g. Missing refill flow controller g. Replace refill flow controller

12. Control valve fails to draw in regenerant

a. Injector is plugged a. Remove injector and clean or replace

b. Faulty regenerant piston b. Replace regenerant piston

c. Regenerant line connection leak c. Inspect regenerant line for air leak

d. Drain line restriction or debris cause excess back

pressure

d. Inspect drain line and clean to correct

restriction

e. Drain line too long or too high e. Shorten length and or height

f. Low water pressure f. Check incoming water pressure – water

pressure must remain at minimum of 25 psi

13. Water running to drain

a. Power outage during regeneration a. Upon power being restored control will

finish the remaining regeneration time.

Reset time of day.

b. Damaged seal/ stack assembly b. Replace seal/ stack assembly

c. Piston assembly failure c. Replace piston assembly

d. Drive cap assembly not tightened in properly d. Re-tighten the drive cap assembly

Page 14 WS15P Parts and Service Manual

Problem Possible Cause Solution

14. E1, Err – 1001, Err – 101 = Control unable to

sense motor movement

a. Motor not inserted full to engage pinion, motor

wires broken or disconnected

a. Disconnect power, make sure motor is

fully engaged, check for broken wires,

make sure two pin connector on motor is

connected to the two pin connection on the

PC Board labeled MOTOR. Press NEXT

and REGEN buttons for 3 seconds to

resynchronize software with piston position

or disconnect power supply from PC Board

for 5 seconds and then reconnect.

b. PC Board not properly snapped into drive

bracket

b. Properly snap PC Board into drive bracket

and then Press NEXT and REGEN buttons

for 3 seconds to resynchronize software

with piston position or disconnect power

supply from PC Board for 5 seconds and

then reconnect.

c. Missing reduction gears c. Replace missing gears

15. E2, Err – 1002, Err – 102 = Control valve

motor ran too short and was unable to find the

next cycle position and stalled

a. Foreign material is lodged in control valve a. Open up control valve and pull out piston

assembly and seal/ stack assembly for

inspection. Press NEXT and REGEN

buttons for 3 seconds to resynchronize

software with piston position or disconnect

power supply from PC Board for 5 seconds

and then reconnect.

b. Mechanical binding b. Check piston and seal/ stack assembly,

check reduction gears, check drive bracket

and main drive gear interface. Press NEXT

and REGEN buttons for 3 seconds to

resynchronize software with piston position

or disconnect power supply from PC Board

for 5 seconds and then reconnect.

c. Main drive gear too tight c. Loosen main drive gear. Press NEXT

and REGEN buttons for 3 seconds to

resynchronize software with piston position

or disconnect power supply from PC Board

for 5 seconds and then reconnect.

d. Improper voltage being delivered to PC Board d. Verify that proper voltage is being supplied.

Press NEXT and REGEN buttons for 3

seconds to resynchronize software with

piston position or disconnect power supply

from PC Board for 5 seconds and then

reconnect.

16. E3, Err – 1003, Err – 103 = Control valve

motor ran too long and was unable to find the

next cycle position

a. Motor failure during a regeneration a. Check motor connections then Press NEXT

and REGEN buttons for 3 seconds to

resynchronize software with piston position

or disconnect power supply from PC Board

for 5 seconds and then reconnect.

b. Foreign matter built up on piston and stack

assemblies creating friction and drag enough to

time out motor

b. Replace piston and stack assemblies. Press

NEXT and REGEN buttons for 3 seconds

to resynchronize software with piston

position or disconnect power supply from

PC Board for 5 seconds and then reconnect.

c. Drive bracket not snapped in properly and out

enough that reduction gears and drive gear do

not interface

c. Snap drive bracket in properly then Press

NEXT and REGEN buttons for 3 seconds

to resynchronize software with piston

position or disconnect power supply from

PC Board for 5 seconds and then reconnect.

17. Err – 1004, Err – 104 = Control valve motor

ran too long and timed out trying to reach home

position

a. Drive bracket not snapped in properly and out

enough that reduction gears and drive gear do

not interface

a. Snap drive bracket in properly then Press

NEXT and REGEN buttons for 3 seconds

to resynchronize software with piston posi-

tion or disconnect power supply from PC

Board for 5 seconds and then reconnect.

WS15P Parts and Service Manual Page 15

Problem Possible Cause Solution

18. Err -1006, Err – 106,

Err - 116 = MAV/ SEPS/ NHBP/ AUX MAV

valve motor ran too long and unable to find the

proper park position

Motorized Alternating Valve = MAV

Separate Source = SEPS

No Hard Water Bypass = NHBP

Auxiliary MAV = AUX MAV

a. Control valve programmed for ALT A or b,

nHbP, SEPS, or AUX MAV with out having a

MAV or NHBP valve attached to operate that

function

a. Press NEXT and REGEN buttons for 3

seconds to resynchronize software with

piston position or disconnect power supply

from PC Board for 5 seconds and then

reconnect. Then re-program valve to proper

setting.

b. MAV/ NHBP motor wire not connected to PC

Board

b. Connect MAV/ NHBP motor to PC Board

two pin connection labeled DRIVE. Press

NEXT and REGEN buttons for 3 seconds

to resynchronize software with piston

position or disconnect power supply from

PC Board for 5 seconds and then reconnect.

c. MAV/ NHBP motor not fully engaged with

reduction gears

c. Properly insert motor into casing, do not

force into casing Press NEXT and REGEN

buttons for 3 seconds to resynchronize

software with piston position or disconnect

power supply from PC Board for 5 seconds

and then reconnect.

d. Foreign matter built up on piston and stack

assemblies creating friction and drag enough to

time out motor

d. Replace piston and stack assemblies. Press

NEXT and REGEN buttons for 3 seconds

to resynchronize software with piston

position or disconnect power supply from

PC Board for 5 seconds and then reconnect.

19. Err – 1007, Err – 107,

Err - 117 = MAV/ SEPS/ NHBP/ AUX MAV

valve motor ran too short (stalled) while looking

for proper park position

Motorized Alternating Valve = MAV

Separate Source = SEPS

No Hard Water Bypass = NHBP

Auxiliary MAV = AUX MAV

a. Foreign material is lodged in MAV/ NHBP valve a. Open up MAV/ NHBP valve and check

piston and seal/ stack assembly for foreign

material.PressNEXTand REGENbuttons

for 3 seconds to resynchronize software

with piston position or disconnect power

supply from PC Board for 5 seconds and

then reconnect.

b. Mechanical binding b. Check piston and seal/ stack assembly, check

reduction gears, drive gear interface, and

check MAV/ NHBP black drive pinion on

motor for being jammed into motor body.

Press NEXT and REGEN buttons for 3

seconds to resynchronize software with

piston position or disconnect power supply

from PC Board for 5 seconds and then

reconnect.

Page 16 WS15P Parts and Service Manual

WS15P Parts and Service Manual Page 17

Page 18 WS15P Parts and Service Manual

WS15P Parts and Service Manual Page 19

Revision History:

2/26/2020

PAGE 11:

1A V4358 WS15P DRAIN ELBOW 1" NPT 1

1B V4359 WS15P DRAIN ELBOW 1" BSPT 1

3/16/2020

PAGE 11:

Removed V3190 series of DLFC from table and V3190-XXX drawing.

7/6/2020

PAGE 11:

All DLFC housings ship without DLFC installed. Up to 5 x V3162-XXX DLFC may be installed in V4430. Select 1-5 flow controls

from table for proper backwash flow, based on media manufacturer's recommendations.

2/22/2021

PAGE 20:

changed header to read “SOFTENER AND FILTER CONTROLS LIMITED WARRANTY”

4/21/2022

PAGE 5:

9V4430-01** WS15P FTG ASY QC TO NPT 1 set of 2

V4430-02** WS15P FTG ASY QC TO BSPT

** Inlet/Outlet tting kits are sold separate, see page 10 for tting selection.

PAGE 10:

Added V4430-07, V4430-08 and V4430-09 ttings.

Page 20 WS15P Parts and Service Manual

CLACK CORPORATION

SOFTENER AND FILTER CONTROLS

LIMITED WARRANTY

Clack Corporation (”Clack”) warrants to OEM that its Softener and Filter Control

Valves will be free from defects in material and workmanship under normal use

and service for a period of five years from the date of shipment of such Valves from

Clack’splantinWindsor,Wisconsinwheninstalledandoperatedwithinrecommended

parameters. No warranty is made with respect to defects not reported to Clack within

the warranty period and/or defects or damages due to neglect, misuse, alterations,

accident, misapplication, physical damage, or damage caused by fire, acts of God,

freezing or hot water or similar causes. For outdoor installations where the Softener

and Filter Control Valves are not under cover, the weather cover must be utilized for

the warranty to be valid.

Clack’sobligation to OEM underthis LimitedWarrantyshall be limited,atits option,

to replacement or repair of any Softener and Filter Control valve covered by this

LimitedWarranty.PriortoreturningaControlValve,OEMmustobtainareturngoods

authorizationnumber fromClackand return theControlValve freight prepaid.If any

Control Valve is covered under this Limited Warranty, Clack shall return the Control

Valve repaired, or its replacement, prepaid to the original point of shipment.

CLACK GIVES THIS WARRANTY TO OEM IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT

LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE AND HEREBY EXPRESSLY

DISCLAIMS ALL OTHER SUCH WARRANTIES. CLACK’S LIABILITY

HEREUNDER SHALLNOT EXCEED THE COST OFTHE PRODUCT. UNDER

NO CIRCUMSTANCES WILL CLACK BE LIABLE FOR ANY INCIDENTAL

OR CONSEQUENTIAL DAMAGES OR FOR ANY OTHER LOSS, DAMAGE

OR EXPENSE OF ANY KIND, INCLUDING LOSS OF PROFITS, ARISING

IN CONNECTION WITH THE INSTALLATION OR USE OR INABILITY

TO USE THE CONTROL VALVES OR ANY WATER TREATMENT SYSTEM

THE CONTROL VALVE IS INCORPORATED INTO.

Form No. V3435-15P – 4/21/2022 U.S. Patent: 6,776,901

Charger Water Treatment Products

8150 N. Lehigh Ave, Morton Grove, IL 60053

www.chargerwater.com/FAQ

Table of contents

Other Charger Control Unit manuals

Popular Control Unit manuals by other brands

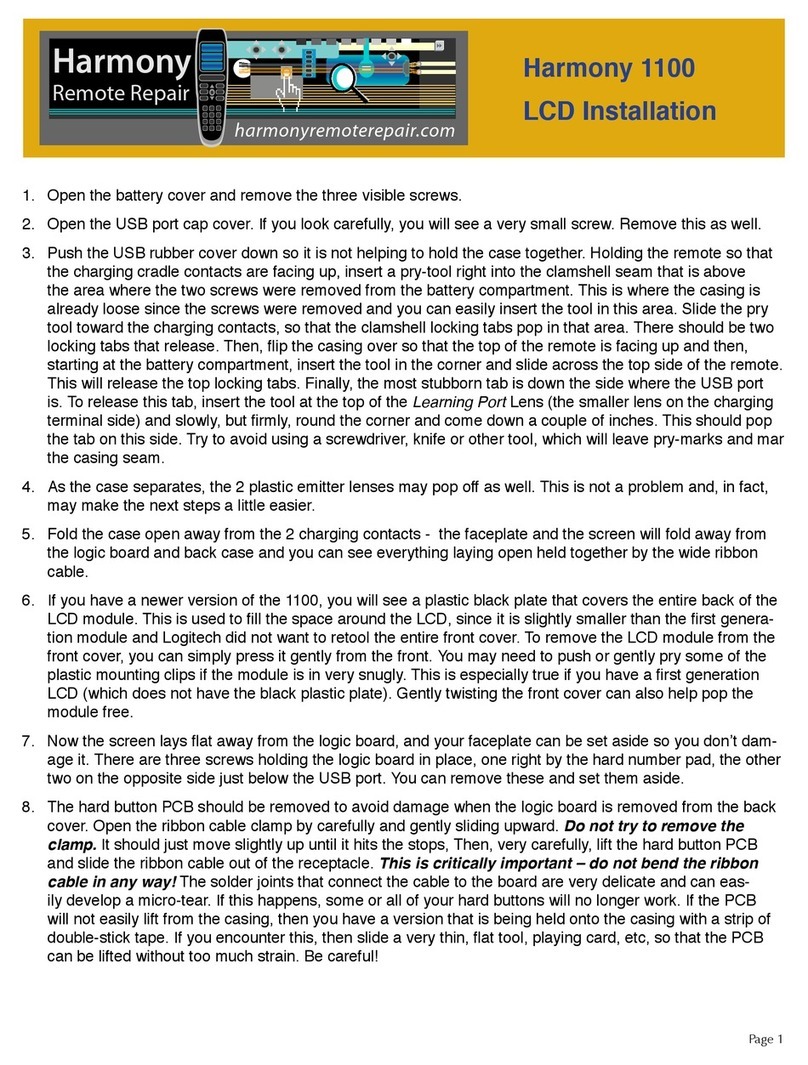

Logitech

Logitech Harmony 1100 Remote Repair

RabbitCore

RabbitCore RCM3100 Series Getting started manual

Teledyne

Teledyne 5800 Removal and Replacement

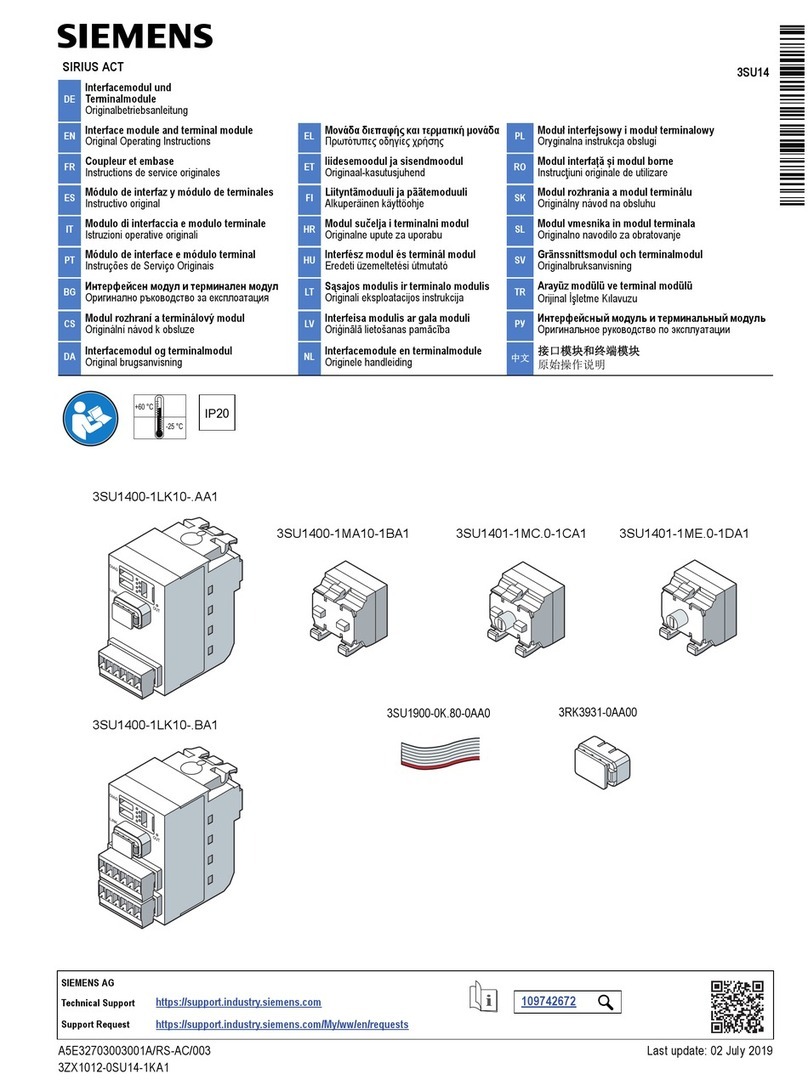

Siemens

Siemens SIRIUS ACT 3ZX1012-0SU14-1KA1 Original operating instructions

Asutec

Asutec ASUEL-150 operating manual

ASCO Valves

ASCO Valves 8222 Series Installation & maintenance instructions

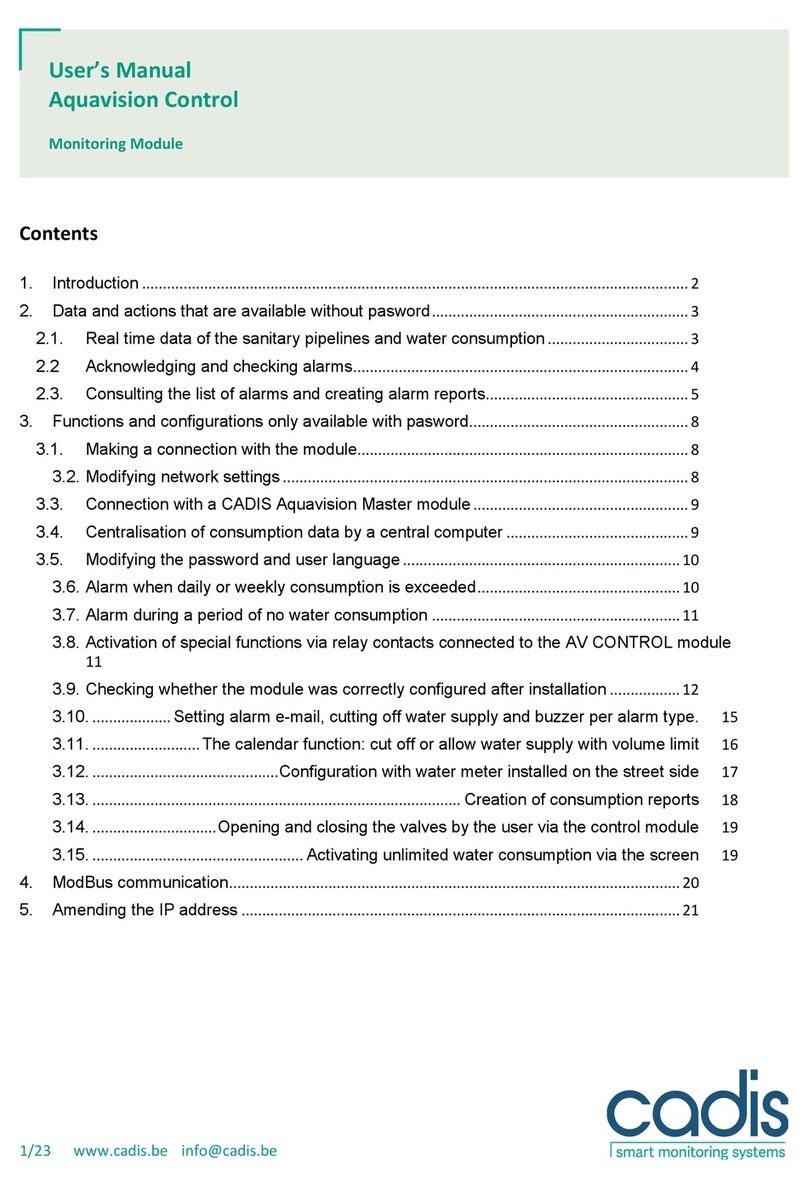

Cadis

Cadis Aquavision Control user manual

VAT

VAT 612 Series Installation, operating, & maintenance instructions

CKD

CKD 3KA1 instruction manual

Omron

Omron SYSMAC C200H-NC111 Operation manual

DeZurik

DeZurik VPB V-PORT instruction manual

Walther Systemtechnik

Walther Systemtechnik WDV-01 Assembly & instruction manual