4.

Hydrostatic Testing of DDX-LP Valves and DDX-

LP Systems

As required by NFPA 13, re sprinkler systems with working

pressures up to and including 150 psi are to be hydrostatically

tested at a water pressure of 200 psi. Fire sprinkler systems with

working pressures above 150 psi are required to be hydrostati-

cally tested at 50 psi above the system working pressure. In ad-

dition to the hydrostatic tests described above, dry pipe systems

require an additional low pressure air test.

In some cases, hydrostatic testing (in accordance with the

NFPA 13 requirements noted above) will result in pressures that

exceed the working pressure of the valve and trim kit for the two-

hour test period.

The valve and applicable trim kit have been tested, approved

and listed under these conditions and as such, hydrostatic test-

ing in accordance with NFPA 13 is acceptable. In addition, the

clapper can remain in the closed position and the trim kit need

not be isolated, as each has been designed to withstand hydro-

static testing as required by NFPA 13.

Subjecting the valve and trim to pressures higher than their

rating is limited to the hydrostatic test as referenced by NFPA13.

It does not address the occurrence of a “water hammer” effect,

which may damage the valve. A “water hammer” in the water

supply piping of the valve can create pressures in excess of the

rated pressure and should be avoided by all necessary means.

This condition may be created from improper re pump set-

tings, underground construction work, or an improper venting

of trapped air in the water supply piping.

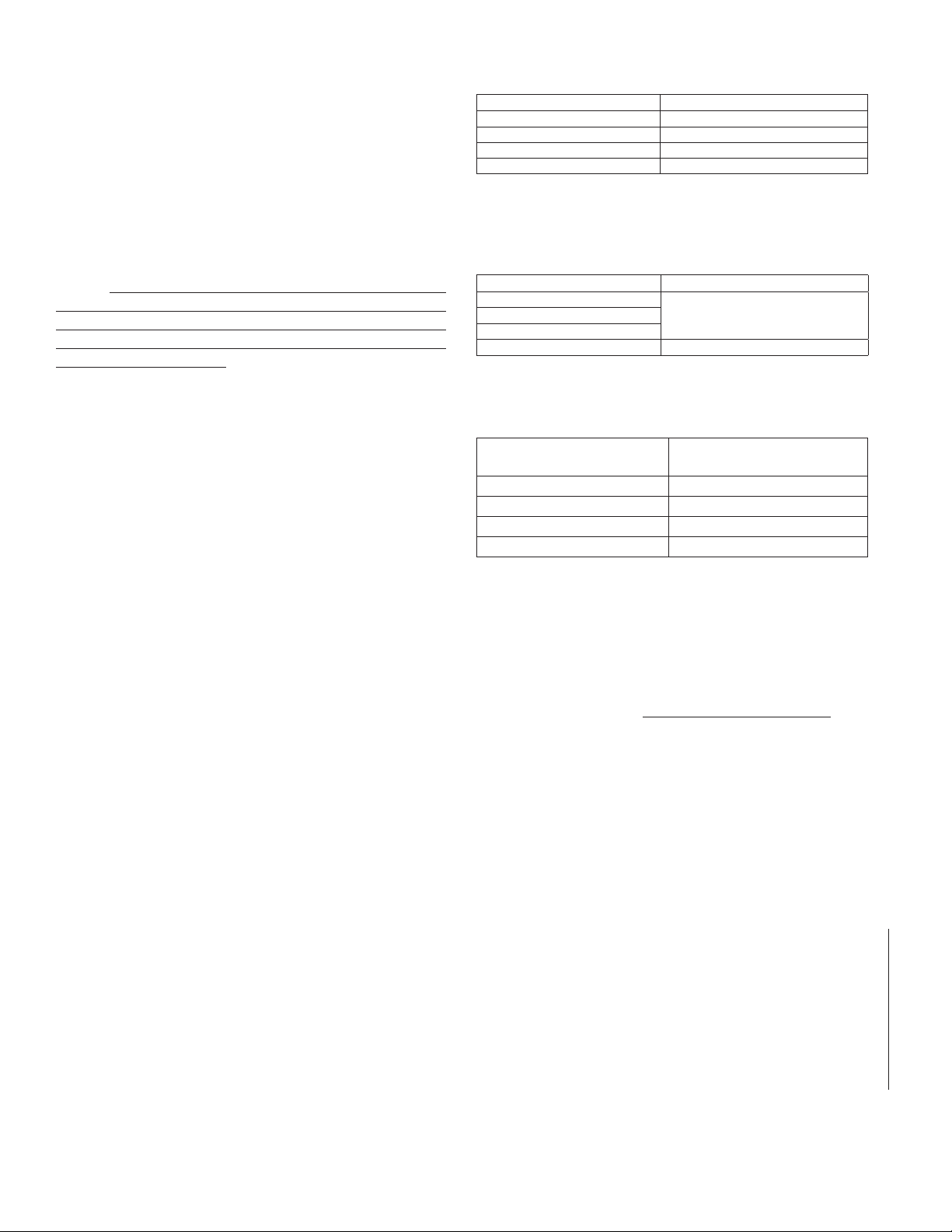

System Supervisory Pressure Requirements

The DDX-LP PrePaK system includes gauges indicating the

air/nitrogen and water pressures on the Model DDX-LP sys-

tem. Table A species the air or nitrogen pressure to be main-

tained in the sprinkler system piping based on the water supply

pressure. The factory installed Pressure Maintenance Device

in the unit automatically regulates makeup air or nitrogen flow

to maintain pressure with normal leakage from system piping,

while restricting the flow of makeup air or nitrogen to the sys-

tem. Please note that when the optional Model B1 Accelerator

is to be utilized to expedite water-delivery time, the air or nitro-

gen pressure must be not less than 15 psi (1.0 bar).

The factory-installed system low air pressure switch may need

on-site adjustment to correspond with the air pressure values

found in Table A. Adjustment, if required, should be made ac-

cording to Potter Bulletin 5401564 included with the switch.

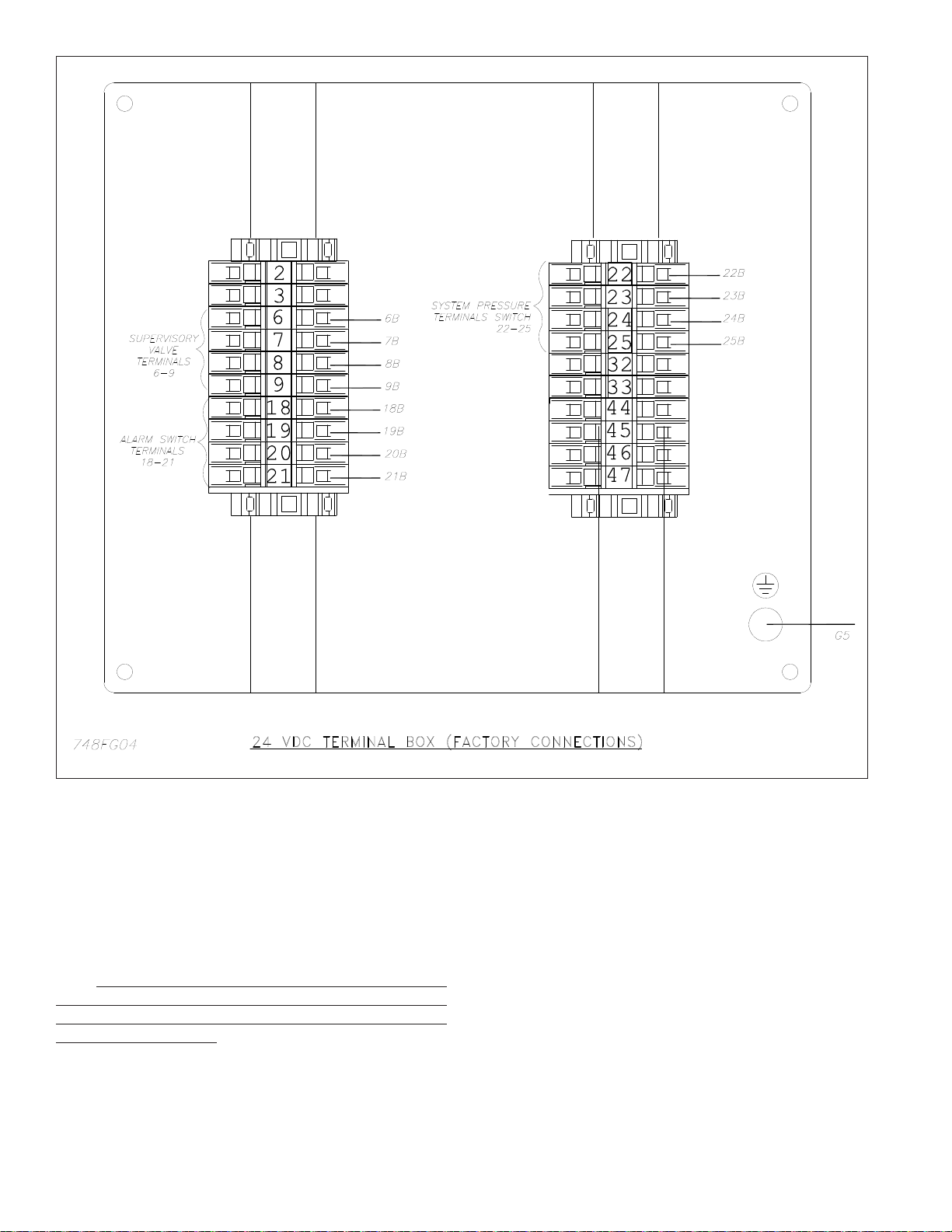

System Electrical Requirements

All 24 VDC electrical connections in the Reliable Model DDX-

LP PrePaK system are translated to a water tight terminal box

mounted on the inside of the enclosure. All eld wiring connec-

tions are made at this terminal box.

A separate power connection is provided for the optional air

compressor.

Note: The air compressor must be connected to a grounded

metallic, permanent wiring system, or an equipment grounding

terminal or lead on the product. Power supply wiring must con-

form to all required safety codes and be installed by a qualied

person. Check that the supply voltage agrees with that listed on

compressor nameplate.

Maintenance

The Reliable DDX-LP PrePaK system and associated equip-

ment shall periodically be given a thorough inspection and test.

NFPA 25, Standard for Inspection, Testing and Maintenance of

Water Based Fire Protection Systems, provides minimum main-

tenance requirements. Systems should be tested, operated,

cleaned and inspected at least annually, and parts replaced as

required. Periodically open the condensate drain valve beneath

the air tank to drain any condensate accumulation. Reliable

Technical Bulletins 338 and 519 provide additional information

for maintaining the Model DDX-LP Deluge Valve.

System Setup (Refer to Figure 2)

1. Close the main valve controlling water supply to the Model

DDX-LP deluge valve. Also, close the two ¼” valves sup-

plying air or nitrogen to the system.

2. Close the pushrod chamber supply valve.

3. Open the main drain valve and drain the system.

4. Open all drain valves and vents at low points throughout

the system, closing them when flow of water has stopped.

5. Open the Manual Emergency Release valve. Note: The

above steps accomplish the relieving of pressure in the

pushrod chamber of the deluge valve.

6. Push in the plunger of ball drip valve to force the ball from

its seat, and drain any water in the alarm line.

7. Push in and rotate the deluge valve’s external reset knob

counter-clockwise (when facing valve) until you hear a dis-

tinct clicking noise, indicating that the clapper has reset.

Note: The reset knob can be rotated only after pressure

in the pushrod chamber is reduced to atmospheric condi-

tions (0 psig).

Water Pressure psi (bar) System Air or Nitrogen Pressure

psi (bar)

Maximum Not Less Than

20 (1.4) 8 (0.6)

30 (2.1) 10 (0.7)

50 (3.4) 12 (.8)

75 (5.2) 13 (.9)

100 (6.9) 15 (1.)

125 (8.6) 16 (1.1)

150 (10.3) 17 (1.2)

175 (12.1) 18 (1.2)

200 (13.8) 19 (1.3)

225 (15.5) 21 (1.4)

250 (17.2) 22 (1.5)

275 (19.0) 23 (1.6)

300 (20.7) 24 (1.7)

Table A

Notes:

1. Supervisory air or nitrogen pressure should not exceed 30 psi (2.1 bar).

Excess pressure may result in damage to the actuator.

2. Fastest valve operation is achieved with supervisory air or nitrogen

pressure indicated; however, pressure must never be less than the

minimum specied in the table above.

3. Air maintenance devices that maintain a constant pressure are

recommended; however, if a tank-less compressor is used, the

“compressor on” setting of the pressure switch must never be lower than

the minimum pressure in the table above.