Charles Ischi AG AE-1 User manual

OME_306511 1

OPERATING INSTRUCTIONS

ABRASION AND

FRIABILITY TESTER

AE-1

Version 2.06

14.11.2006

Rights reserved for technical changes

OME_306511 2

TABLE OF CONTENTS

Page

1. START UP.................................................................................................................................3

2. USER GUIDANCE...................................................................................................................4

3. TECHNICAL DATA.................................................................................................................6

4. FINAL ASSEMBLY CONTROL TEST .................................................................................7

5. SERVICING...............................................................................................................................8

6. TROUBLESHOOTING............................................................................................................9

7. SPARE PART LIST...............................................................................................................10

8. CE –CONFORMITY DECLARATION................................................................................11

9. DECLARATION OF CONFORMITY WITH PH-EUR5.0/2005 AND USP29 NF2006.12

10. DRAWINGS.............................................................................................................................13

11. TECHNICAL INFORMATION –Install support 10° angle ............................................15

OME_306511 3

1. START UP

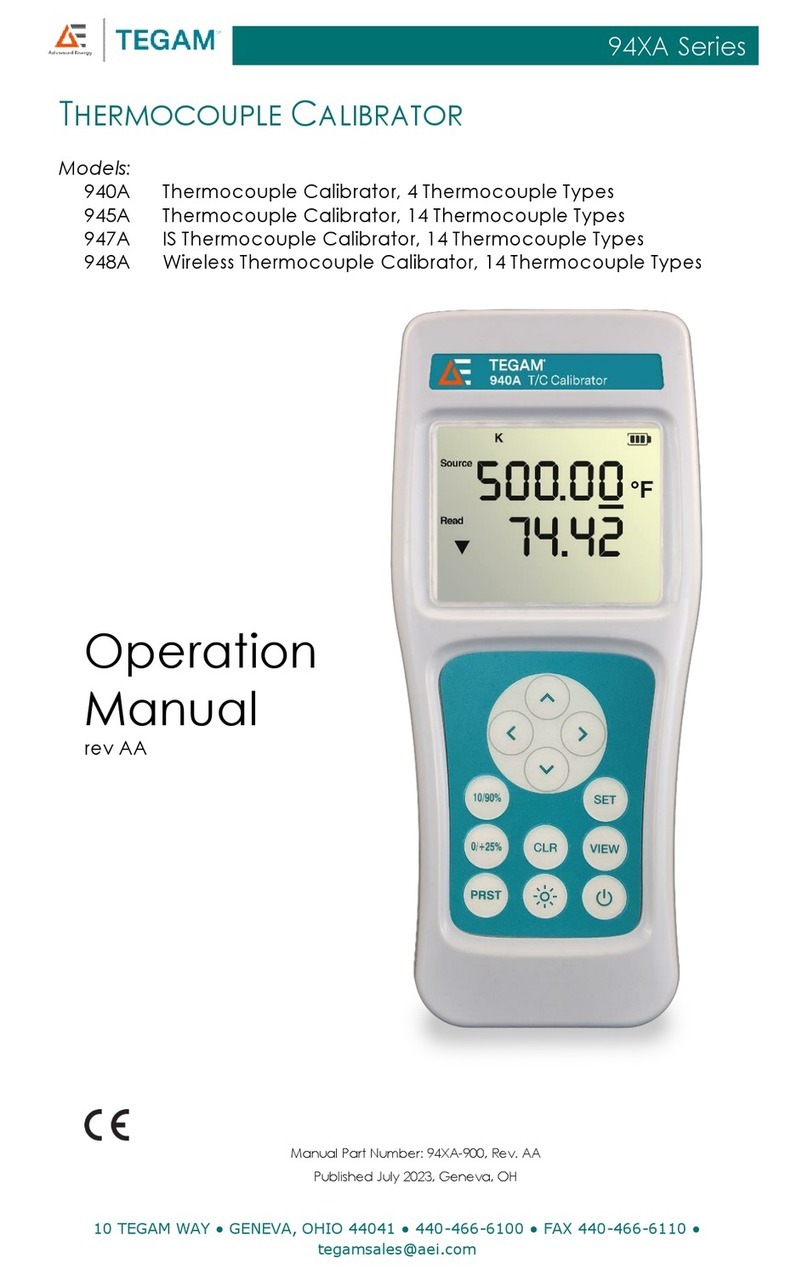

1. Operating voltage

Before plugging the machine in, check the voltage selector on the rear panel.

2. Mounting the test drums

The tester is delivered with power cable and operating manual. The test drums are

avaliable as an option in 2 versions: Friability test or abrasion test. The test drums are

prevented from rolling by tabs on the inside and a quick release nut on the outside of the

shaft.

3. Connectingpower

After the correct operating voltage ( point 1) has been selected the power cable can

be connected to the machine.

OME_306511 4

2. USER GUIDANCE

2.1.Switch machine on

After the machine is switched on the machine version is shown in the display first,

then the actual operating parameters:

Line 1: Preset rotation speed / PARAM *

Line 2: Time or total counts / START #

The machine can be operated using preset time or total counts, as desired.

2.2.Setting time or rotations:

Press * (PARAM) button

With the button # (R or TIME) you can chose the mode of operation

R = test with number of rotations

TIME = test with preset time

Press * (MODIFY) button

Chose the speed

Setting preset time or number of rotations

Press * (OK) button

OME_306511 5

2.3. Load test drums

By removing the quick release nut either the drum lid or the complete drum can be

removed from the machine. The tablets are loaded into the test drum and the drum

is held in place on the shaft by means of the quick release nut. The test drum is correctly

mounted and closed when the quick release nut snaps into the groove on the shaft.

2.4. Starting the test

Press # (START) button

The machine begins to test

The tester shows the residual time or number of rotations

2.5. Ending the test

At the end of the test time or total counts the machine stops. The preset time or number

of rotations will be restored.

The test can be stopped by the button # STOP or interrupted and be continued later at

any time, before the end of the testing time or number of rorations.

The preset parameters are retained in the machine when it is turned off by means of

a battery.

OME_306511 6

3. TECHNICAL DATA

Power connection 200-240V / 50-60Hz

Fuses 2x M1A/250V

Speed 10 –99 rpm

Preset time 1min –23h 59min

Number of rotations 10 –999999 r

Drums Friability drum

Abrasiondrum

OME_306511 7

4. FINAL ASSEMBLY CONTROL TEST

Each machine undergoes, as a minimum, a 12-hour final assembly control test prior to

delivery. During this test all machine functions are checked.

OME_306511 8

5. SERVICING

The servicing contains a periodical cleaning of the tester. There are no wearing parts. The

spare part list you can find under point 7.

OME_306511 9

6. TROUBLESHOOTING

Machine malfunctions should only be repaired by an authorized school trained technician. In

the case it is not possible to correct the malfunction, Charles Ischi AG,

or theresponsible representative should be contacted for repairs.

OME_306511 10

7. SPARE PART LIST

Description Art. no.

Base plate 310901

Cover 310902

Display complete 310903

Main board 310904

Front foil 310905

Display board 310906

Sensor speed 310907

Sensor rotations 310908

Motor 310909

Axis left 310910

Axis right 310911

Fixing / drum left 310912

Fixing / drum right 310913

Mortor holder 310914

Control system unit 310915

OME_306511 11

8. CE–CONFORMITY DECLARATION

Wir / We Charles Ischi AG

Langfeldstrasse 26

4528 Zuchwil

Schweiz / Switzerland

Erklären hiermit, in alleiniger Verantwortung, dass dieses Produkt,

Declare sole responsibility for our product,

Abriebs-und Friabilitäts-Testgerät

Abrasion-and Friability Tester

Typ AE-1

Auf die sich diese Erklärung bezieht, die Normen und normativen Dokumente der

EG-Richtlinien für Maschinen 89/392/EWG berücksichtigt wurden.

To which this declaration document relates is in conformity with the standardsand

norms for machines of the EC.

Zuchwil, 28.04.2004 ......................................................

Ort, Datum rechtsverbindliche Unterschrift

Place, Date Signature

OME_306511 12

9. DECLARATION OF CONFORMITYWITH PH-EUR5.0/2005 AND USP29 NF2006

Wir / We Charles Ischi AG

Langfeldstrasse 26

CH-4528 Zuchwil

Switzerland

Erklären hiermit, in alleiniger Verantwortung, dass dieses Produkt,

Declare sole responsibility for our product,

Abriebs-und Friabilitäts-Testgerät

Abrasion-andFriabilityTester

Typ AE-1

mit den Anforderungen der European Pharmacopoeia 2005 und USP29 NF2006

übereinstimmt, soweit diese für Abriebs-und Friabilitäts-Testgeräte anwendbar sind.

is conform with the requirements of the European Pharmacopoeia 2005 and USP29

NF2006, concerning the regulations forAbrasion-and Friability Testing.

Zuchwil, 14.11.2006......................................................

Ort, Datum rechtsverbindliche Unterschrift

Place, Date Signature

OME_306511 13

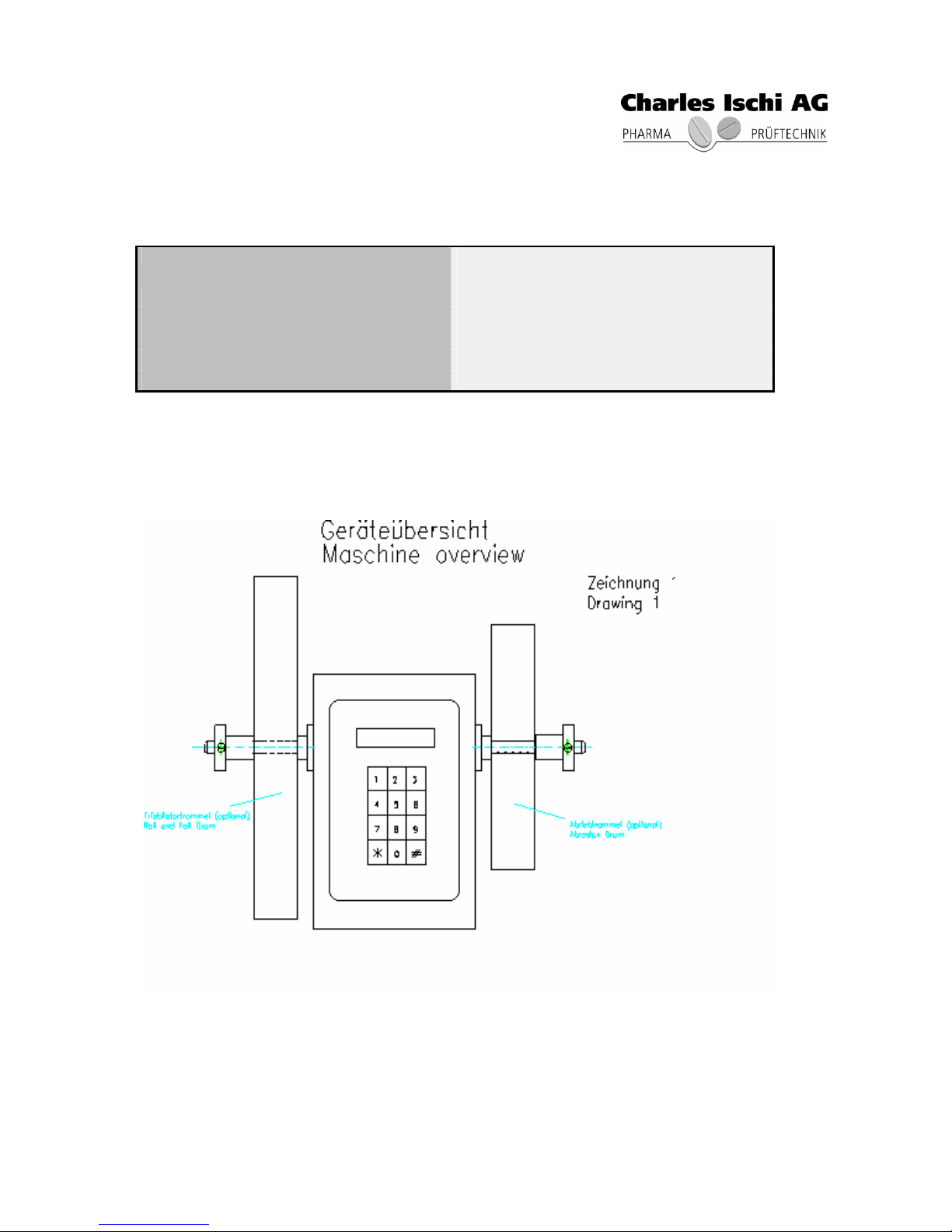

10.DRAWINGS

Drawing no.

1Machine overview

2Rear panel

OME_306511 14

OME_306511 15

11. TECHNICAL INFORMATION –Install support 10° angle

Machine with angle 10° angle with screw

Take out one of thesetwo screws left or Use the screw which we deliver with this

right and put on this place the 10° angle.angle, see on the picture in which

position you have to fasten the angle.

Table of contents

Popular Test Equipment manuals by other brands

Global Specialties

Global Specialties 3600 user manual

Tektronix

Tektronix TDS3000C Series Declassification and security instructions

Bante Instruments

Bante Instruments PHscan20S/F instruction manual

JDS Uniphase

JDS Uniphase Validator quick start guide

Fluke

Fluke 718Ex 300G Specifications

Reely

Reely 206964 operating instructions

HeartSciences

HeartSciences MyoVista Quick reference user guide

Valen

Valen RE856 Operation manual

Polar Instruments

Polar Instruments T1500A Operator's manual

Sonotec

Sonotec SONAPHONE E operating instructions

pico Technology

pico Technology ADC-100 user guide

Keysight Technologies

Keysight Technologies U2941A operating guide