Charles 31929E Dimensional drawing

Section 319–29E–202

Equipment Issue 2

Third Printing, June 1999Charles Industries, Ltd.

1999Charles Industries Ltd.

CLEI is a trademark of Bell Communications Research, Inc.

All rights reserved. Printed in United States of America.

The availability of features and technical specifications herein subject to change without notice. Page 1 of 14

STS 3192–9E Powering T1 Network Interface Unit (NIU)

CLEICode: T1STETT1AA

Recognized under Underwriters Laboratories Standard 1459, Second Edition*

CONTENTS PAGE

Part 1. GENERAL 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 2. APPLICATION ENGINEERING 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 3. CIRCUIT DESCRIPTION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 4. INSPECTION 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 5. MOUNTING 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 6. OPTIONS 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 7. TESTING 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 8. TECHNICAL ASSISTANCE 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 9. WARRANTY & CUSTOMER SERVICE 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 10. SPECIFICATIONS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

R

C

V

WESCOM

PWRG

T1

NIU

3192–9E

X

M

T

91–31929E

0.6V

ISS. 2

FA

ESF

R

P

T

M

O

N

NET

LOS

LB

CI

R

P

T

M

O

N

MLB

LOS

Figure 1. 3192–9E Powering T1 NIU

Section 319–29E–202

2

1. GENERAL

1.1 Document Purpose

This document provides general, circuit, and testing information for the Charles Industries Span Termination Sys-

tem (STS) 3192–9E Powering T1 Network Interface Unit (NIU), shown in Figure 1. The 3192–9E is a member of

the Charles Industries STS–3192 family of high density span termination equipment. For additional information on

the STS–3192 System, see sections 319–211–100 and 319–211–200.

1.2 Document Status

This practice is reprinted to correct Figure 4 and related text. The Issue 2 equipment provides one additional loop

up code and one additional loop down code over the Issue 1 equipment; form remains unchanged.

1.3 Equipment Function

The 3192–9E combines the functions of a Powering T1 Office Repeater plus a T1 Network Interface Unit con-

forming to Bellcore TR–TSY–000312 in a single high density plug-in module. When equipped in the 3192–11 23

inch mounting shelf, up to 28 3192–9E units can be provided in 5.25 inches of vertical equipment space. The

3192–9E can be intermixed with other plug in units of the STS-3192 Family in the shelf assembly.

Field repairs/modifications may void compliance with Underwriters Laboratories Standard 1459 – 2nd

Edition. Compliance is restricted to inside plant wiring.

CAUTION

1.4 Equipment Mounting/Location

The 3192–9E is fully qualified for operation over a –40 to 65C temperature range, and can be deployed in out-

side plant electronics cabinets or indoor building Remote Terminals, typically in Span Termination System

(STS–3192) Mounting Shelves.

Lightwave

Multiplexer

3192–11 STS

Equipment Shelf

e/w 28 ea. 3192–9E

Customer CPE

Equipment

DSX-1 Crossconnect

Network

Interface

Fiber

Facility

To LEC

Network

Building Remote Terminal

ÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇ

ÇÇÇÇ

Ç

Ç

Ç

Ç

21 dB loss max.

Figure 2. 3192–9E T1 Powering NIU Typical Configuration

Section 319-29E-202

3

2. APPLICATION ENGINEERING

The 3192–9E is ideally suited for use in provisioning T1 High Capacity Digital Service (HCDS) from lightwave-fed

building Remote Terminals located at customer premise locations. See Figure 2 for a typical application. The

3192–9E, used as adjunct equipment to the Lightwave Multiplexer, provides transmission loopback for mainte-

nance activities. In addition, the 3192–9E can be optioned to provide a 60mA constant current power source to-

wards the network interface, which can be used to power the customers’ Channel Service Unit (CSU). This ser-

vice arrangement is typical in MPOP (Minimum Point Of Presence) applications.

The 3192–9E is intended to be co-located with the lightwave transport equipment and serves to extend the nor-

mal DSX range of that equipment. The 3192–9E provides a fixed DSX pre-equalizer for 0 to 110 feet of cable. In

the transmit direction the unit provides variable pads for level coordination toward the CPE. The 3192–9E can

accommodate up to 21dB of cable loss between the customer’s CSU and the 3192–9E.

Figure 3 shows a typical 3192–9E application with associated transmission levels.

Note: Range is limited to maximum cable loss of 21.0db. See table below for maximum cable length at

various cable gauges.

–1.5dB

–1.5 To

–22.5dB

Pre

Equalizer

0.0

DSX–1

Lightwave

Multiplexer

3192–9E Powering T1 NIU 0.0

T1 CSU

LBO

LEC Equipment CPE Equipment

Customer

Wiring

Maximum

Loss 21.0dB

(See NOTE)

–1.5dB

-1.5 To

-22.5dB

Customer

Network

Interface

Note:

Signal Levels Referenced

To 3V Base-To-Peak

CABLE @ 130 F

AERIAL - PIC MAXIMUM

LENGTH -KF TOTAL DCR

@ MAXIMUM REFERENCE

LOSS - dB/KF REFERENCE

LOSS - OHMS/

KF

REFERENCE

MAXIMUM

LOSS

22 GA-CU 4.29 KF 78 OHMS 4.9 dB/KF 18.3 OHMS 21.0dB

24 GA-CU 3.44 KF 100 OHMS 6.1 dB/KF 29.2 OHMS 21.0dB

26 GA-CU 2.56 KF 119 OHMS 8.2 dB/KF 46.7 OHMS 21.0dB

Figure 3. 3192–9E T1 Powering NIU Typical Configuration

2.1 Customer Interface Powering Options

The 3192–9E provides three, switch-selectable, CI (Customer Interface) side power modes: line powering, seal-

ing current, and looped simplex. See Part 6 for more information.

2.2 System Power Engineering

The 3192–9E generates all necessary voltages for its operation from a –48V (nominal) battery input source. The

3192–9E contains an internal high efficiency DC–DC converter to minimize input current, and consequently, maxi-

mize battery reserve time in the remote terminal assembly.

Section 319–29E–202

4

The 3192–9E input current is highly dependent on application. Those applications that require the 3192–9E to

power a customer’s CSU will require a greater input current.

Table 1 shows input current and heat release versus the equivalent series simplex resistance (at 60mA) present

on the CI side of the unit.

Table 1. 3192–9E Power Consumption and Heat Release

Typical Application Option S1

Position Equivalent

External

Simplex

–42.5 Volt

Battery 48.0 Volt Bat-

tery 56.0 Volt Bat-

tery

Simple

x

Resistance I W I W I W

Non-CPE Powering S1 = LP N/A 0.07 2.86 0.06 2.87 0.06 3.00

Sealing Current Only S1 = SC 0 Ohms 0.08 3.35 0.07 3.53 0.07 3.77

S1 = PWR 200 Ohms 0.10 2.91 0.08 3.02 0.07 3.12

S1 = PWR 400 Ohms 0.11 3.04 0.10 3.12 0.08 3.18

Powering Co-located 24V CSU S1 = PWR 600 Ohms 0.13 3.09 0.11 3.12 0.10 3.13

S1 = PWR 800 Ohms 0.14 3.18 0.13 3.13 0.11 3.14

S1 = PWR 1000 Ohms 0.16 3.22 0.14 3.18 0.13 3.15

Powering Co-located 68V CSU S1 = PWR 1200 Ohms 0.18 3.32 0.16 3.22 0.14 3.22

S1 = PWR 1400 Ohms 0.20 3.45 0.18 3.23 0.16 3.28

S1 = PWR 1600 Ohms 0.22 3.55 0.20 3.38 0.18 3.39

Note: W = Heat release in watts

I = Input current in amps

2.3 Maintenance Loopback

The 3192–9E provides a signal path Loopback feature, which can be used to differentiate circuit problems on ei-

ther side of the network interface.

The 3192–9E will respond to Loopback control codes in either SF or ESF protocols. SF control codes are re-

ceived as 5 or 6 bit inband repeating patterns, while ESF codes are via 16 bit messages in the ESF framing data

link. The operation of this feature is automatic, that is, when the unit is passing unframed or SF framed traffic it

will recognized the 5 or 6 bit inband SF Loop codes, when the unit is passing ESF traffic it will only recognize the

ESF data link Loopback control codes.

When the 3192–9E is in the maintenance loopback state, it will send an AIS (all ones) signal toward the Custom-

er Interface.

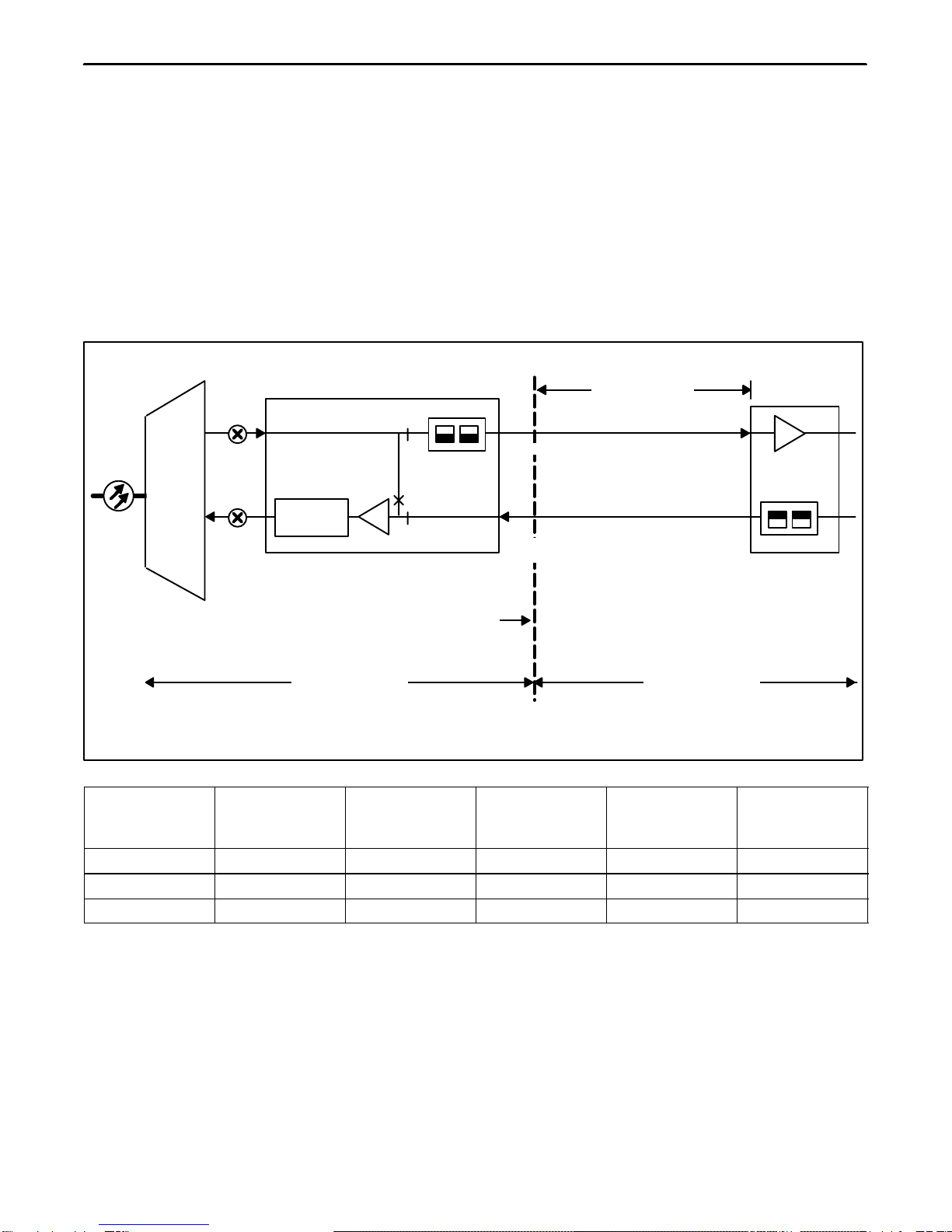

3. CIRCUIT DESCRIPTION

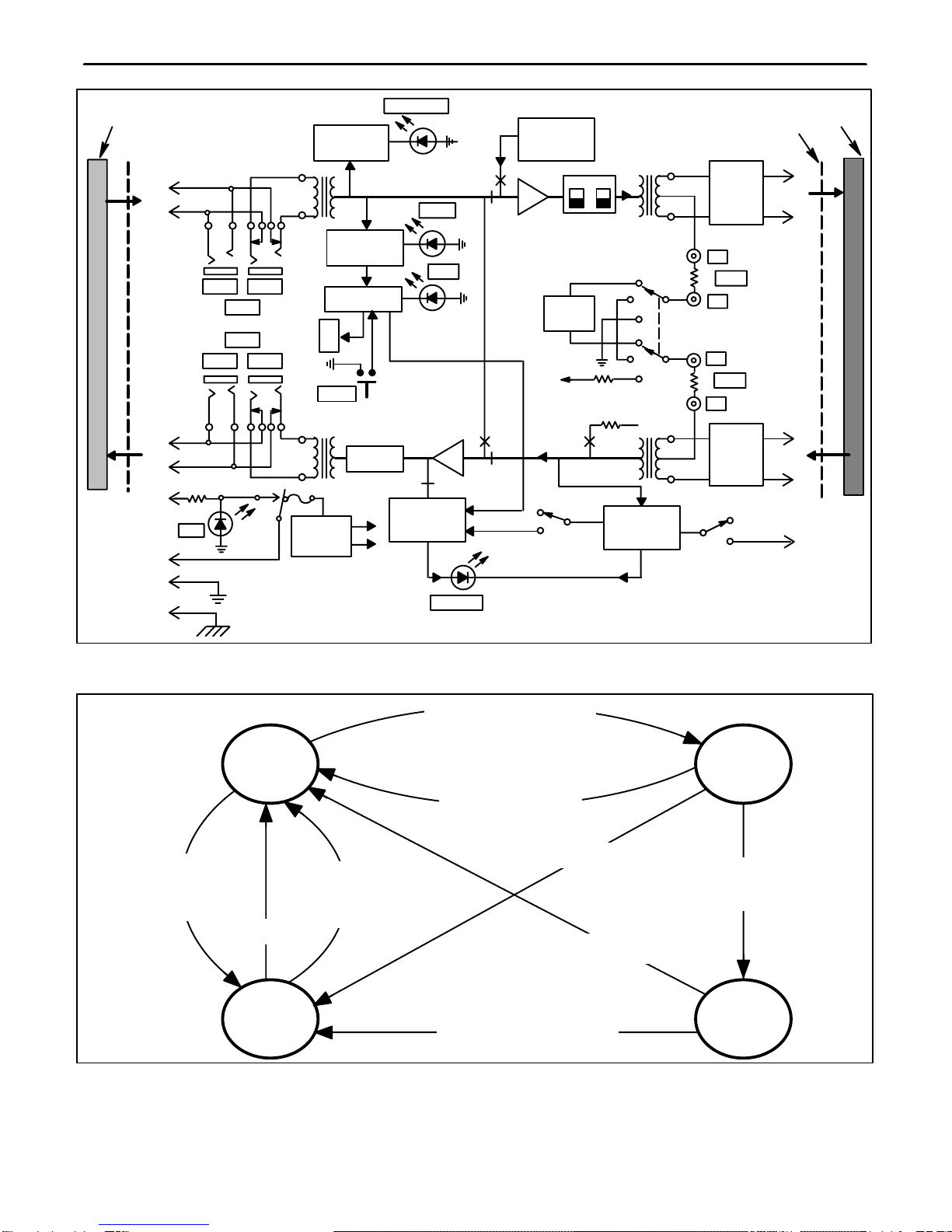

Refer to Figure 4, the 3192–9E Block Diagram, Figure 5, the 3192–9E State Table, and Figure 6, Front Panel

Features and Options Location, when reading the following circuit description.

Section 319-29E-202

5

+

-

7.5 7.5

XMT LBO

LOOPDOWN

CONTROL

MON RPT

RCV

MON RPT

XMT

DSX

PREEQ

SIGNAL

REGEN

LOS ALM

LIGHTWAVE

MULTIPLEXER

S3-1

DISABLE

NETWORK

SIGNAL

DETECTOR

NET LOS

LOOPBACK

CODE

DETECTOR

ESF

LB

CONTROL

LOGIC

LB

MLB

+

-

ASPR

0-96V

-48V 4K

PWR

LP

SC

BUFFER

AMP

-

RCV

+

XMT

SURGE

PROTEC

TION

SURGE

PROTEC

TION

AIS

GENERATOR

LB

LB

CPE

EQUIPMENT

CSU

NETWORK

INTERFACE

F

6

K

9

A

1

B

2

HLOS

ALM

100

LB

10

8

FA

DISABLE

ENABLE

POWER

SUPPLY

LB

CUSTOMER

INTERFACE

SIGNAL

DETECTOR

FLASH = SENDING AIS

STEADY = CI LOS

CI LOS

STEADY = LOS

FLASH = AIS

DISABLE

AIS

S3-2

S1

5

GND

J

FRA

MEGND

AIS

GENERATOR

FA

-BATT

S2

S4

Network

Side

DSX

CI

Side

Figure 4. 3192–9E T1 Powering NIU Block Diagram

DETECT SIGNAL PRESENT

CUSTOMER INTERFACE

IDLE

STATE 1

CI LOS

NOTIFI-

CATION

STATE 3

CI LOS

CUT-THRU

STATE 4

LOOPBACK

STATE 2

DETECT LOS FROM

CUSTOMER INTERFACE

RECEIVE

LOOPDOWN

SIGNAL FROM

NETWORK

RECEIVE LOOPUP SIGNAL

FROM NETWORK

RECEIVE LOOPUP SIGNAL

FROM NETWORK

DETECT SIGNAL PRESENT

CUSTOMER INTERFACE

20 MIN.

TIMEOUT

RECEIVE

LOOPDOWN

SIGNAL FROM

NETWORK

OR MLB

RECEIVE

LOOPUP SIG-

NAL FROM

NETWORK

OR MLB

Figure 5. 3192–9E Operational State Table

Section 319–29E–202

6

S3

12

S4

DISABLE

A

I

S

S1

PWR

7.5 7.5

1 2

O

N

LP SC

S2

LOS

ALM

R

C

V

X

M

T

R

P

T

M

O

N

R

P

T

M

O

N

WESCOM

PWRG

T1

NIU

3192-9E

91-31929E

0.6V

ISS. 2

FA

ESF

NET

LOS

LB

CI

LOS

MLB

Figure 6. 3192–9E Front Panel Features and Options Location

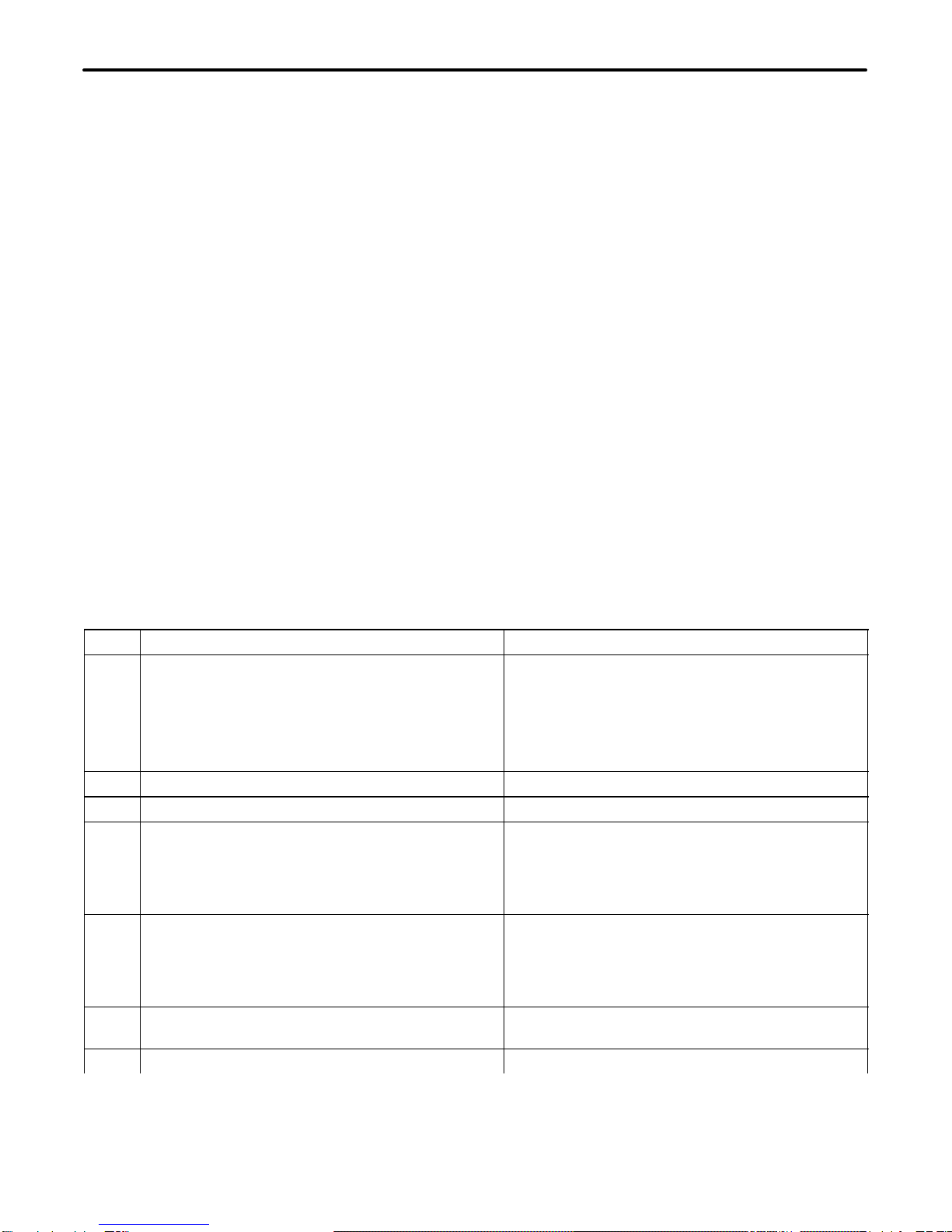

Table 2. 3192–9E Front Panel Options Description

Feature/Option Location Description Function

FA (Fuse Alarm) Front Panel Red LED Indicates that the internal fuse on the 3192-9E has opened. The internal fuse is

not field replaceable.

NET LOS (Loss of

Signal) Front Panel Red LED Continuous: Indicates LOS (Loss Of Signal) from the network side.

Flash: Indicates receipt of AIS from the network side.

CI LOS (Loss of

Signal) Front Panel Red LED Continuous: Indicates loss of signal from the customer interface side.

Flash: Indicates sending of AIS to the network side.

LB (Loopback) Front Panel Amber LED Indicates that the unit is in the Loopback State.

ESF (Extended

Superframe) Front Panel Green LED Indicates ESF Framed signal from the network.

RCV RPT Front Panel Bantam Jack Isolates the DSX allowing access to repeater RCV DSX (OUT).

RCV MON Front Panel Bantam Jack RCV DSX (OUT) monitor jack.

+ Test Pins Front Panel Pin Jack Used for measuring span current and voltage.

– Test Pins Front Panel Pin Jack Used for measuring span current and voltage.

XMT RPT Front Panel Bantam Jack Isolates the DSX, allowing access to repeater XMT DSX (IN).

XMT MON Front Panel Bantam Jack XMT DSX (IN) monitor jack.

S1 PC Board 3 Position Slide

Switch 3position switch to select either PWR (line powering), SC (Sealing Current) or

LP (Looped Simplex) CI side power modes.

S2 Front Panel Front Panel Push-

button Switch S2 is the recessed front panel MLB (Manual Loopback) pushbutton switch to

manually activate or deactivate loopback.

S3 PC Board 2 Section Dip

Switch S3–1 enables or disables a LOS condition alarm detected by CI side.

S3–2 enables or disables the operation of the Customer Receive Side AIS gen-

erator.

S4 PC Board 2 Section Switch Adjusts the transmit pad, allowing a transmit path loss of 0, 7.5 or 15 dB.

Section 319-29E-202

7

3.1 Signal Transmission Paths

In the idle (Looped down) mode, the signal from the network is coupled to the unit and routed through the trans-

mit pad circuit. Switch S4 mounted on the circuit pack is used to adjust the transmit pad which consists of two

cascaded 7.5dB sections, allowing transmit path losses of 0, 7.5 and 15dB.

The signal from the customer is routed through the receive side of the 3192–9E. This side contains a signal re-

generator with a wide range ALBO, accommodating signal levels from 0 to –35dB. After regeneration, the signal

is passed through a fixed DSX–1 pre-equalizer which will accommodate up to 110 feet of 22ga or 90 feet of 24ga

cable to the DSX–1 point.

3.2 Signal Loopback Operation

The signal from the network is continually monitored by the Loopback Code Detector for Loopback control se-

quences from the network. The detector will automatically configure itself to recognize either inband (SF) or data

link (ESF) control sequences. When the detector detects ESF framed traffic, it will only recognize Loopback con-

trol sequences in the ESF data link. In addition, when ESF traffic is present, the unit’s front panel ESF indicator

(green) will light.

3.3 Loopback Activation (State 1 State 2)

To activate loopback utilizing the SF protocol, a repetitive pulse pattern of two ones followed by three zeros

(11000) or one one followed by five zeros (100000) is applied to the line. The Code Detector will reject the pulse

pattern if it is less than 5 seconds in duration or if its error rate is greater than 10-. The circuitry will accept a

pulse pattern if it is greater than 5 seconds in duration.

To activate loopback utilizing the ESF protocol, the Code Detector monitors the 4kHz Data Link Channel of the T1

bit stream for the following repetitive pulse pattern; 0 001001 0 11111111 where the rightmost bit is transmitted

first. The pattern is acknowledged as valid when it has been received by the Code Detector four consecutive

times. This corresponds to 16ms.

The unit can manually be placed in the loopback state by momentarily operating the recessed front panel MLB

pushbutton switch.

After the code pattern is detected for the proper duration or a MLB pushbutton operation is detected, the Loop-

back Controller will operate the LB Relay.

3.3.1. Loopback Mode (State 2)

When the unit is in the loopback state, the CPE equipment is disconnected from the network and terminated in

100 ohms. The signal from the network is looped back toward the network. The front panel LB LED (amber) is on

and an AIS (all ones) signal is sent toward the Customer Interface.

3.3.2. Loopback Timeout/Retrigger

The 3192–9E provides a fixed 20 minute loopback timeout. Normally after 20 minutes the loopback state will

timeout and release. When the 3192–9E is in loopback, a reapplication of any of the loopback activation se-

quences will reset the timer for a new 20 minute period.

3.4 Loopback Deactivation (State 2 State1)

To deactivate loopback utilizing the SF protocol, a repetitive pulse pattern of 3 ones followed by 2 zeroes (11100)

or 1 one followed by 2 zeroes (100) is applied to the line. The Loopback Code Detector will reject the pulse pat-

tern if it is less than 5 seconds in duration or if its error rate is greater than 10-. The Loopback Code Detector will

accept a pulse pattern if it is greater than 5 seconds in duration.

To deactivate loopback utilizing the ESF protocol, the Code Detector monitors the 4kHz Data Link Channel of the

T1 bit stream for the following repetitive pulse pattern; 0 010010 0 11111111 where the rightmost bit is trans-

mitted first. The pattern is acknowledged as valid when it has been received by the Code Detector four consecu-

tive times. This corresponds to 16ms.

To deactivate loopback manually, the front panel MLB push button switch is momentarily operated.

When loopback is deactivated, the Loopback Controller releases the LB relay, restoring the thru transmission path

from network to CPE, extinguishing the LB LED, and removing the AIS signal that was being sent toward the

Customer Interface.

Section 319–29E–202

8

3.5 Transmit And Receive Signal Detectors

The 3192–9E provides Monitoring Signal Detectors on the transmission paths. These detectors provide a mainte-

nance aid for installation and troubleshooting.

3.6 Network Side Signal Detector

This detector monitors the unit’s transmit path and looks for signal activity from the network. When a LOS (Loss

Of Signal) is detected, as indicated by receipt of 175 +75 consecutive zeros, it will illuminate the front panel NET

LOS LED. When an AIS (all ones) signal is detected, the unit will flash the front panel NET LOS LED.

3.7 Customer Interface Signal Detector And Receive Side AIS Generator

The Customer Interface Signal detector and receive side AIS generator are used together and provide several

important maintenance features that can sectionalize problems across the customer interface. Operation of this

AIS generator feature is controlled by switch S3–2 (another AIS generator, not controlled by S3–2, sends AIS

toward the CI upon loopback). The Customer Receive Side AIS generator is enabled by placing S3–2 in the AIS

position and disabled when S3–2 is in the DISABLE position.

3.8 Customer Interface LOS (AIS Enabled)

The Customer Interface Signal detector continuously monitors the unit’s receive path. If a LOS (Loss Of Signal) is

detected, as indicated by receipt of 175 +75 consecutive zeros from the customer’s equipment, a LOS is de-

clared. This is shown as the transition from State 1 to State 3 (see Figure 5). In State 3, the unit will now send an

AIS signal toward the network as an indication that the customer equipment is disconnected or not operational.

The CI LOS LED will flash since the unit is sending AIS.

3.9 Loss Of Customer Interface Signal Alarm

When the Customer Interface (CI) Side Signal detector has declared a LOS condition, it will also forward a signal

to the shelf LOS bus, which is summarized by the 3192–9F module mounted in the far right hand position of the

STS shelf assembly. This alarm output can be disabled by placing switch S3–1 in the DISABLE position. To allow

the LOS alarm from the 3192–9E to be forwarded to the shelf alarm buss, place S3–1 in the LOS ALM position.

3.10 AIS Override (State 3 State 4)

With the unit in State 3 it is possible to override the AIS signal generator and cause the unit’s receive path to be

cut-thru from the customer equipment to the network. This override is accomplished by sending the unit a Loop-

down signal in the SF, or ESF formats as previously described. When the loopdown signal is received, the unit

will stop sending AIS and enter State 4. If the CI signal subsequently returns, the unit will transition back to State

1 (idle). Alternately, the unit can be placed in the loopback state by receipt of a valid loopback code. This is

shown as the State 4 to State 2 transition.

3.11 Customer Interface LOS (AIS Disabled)

When the AIS feature is disabled (S3–2 in the DISABLE position), the CI LOS detector monitors the unit’s receive

path and looks for signal activity from the customer equipment. When a LOS (Loss Of Signal) is detected, as indi-

cated by receipt of 175 +75 consecutive zeros, it will illuminate the front panel CI LOS LED (LOS LED will not

flash). When the CI signal returns, the CI LOS LED will extinguish.

3.12 Signal Test Access Jacks

The 3192–9E provides both splitting and monitor bantam jack access on the DSX side of the unit. The splitting

jacks provide access looking toward the 3192–9E and are labeled RPT (repeater).

3.13 Span Current Test Points

The 3192–9E provides front panel test points that can be used to measure the CI side simplex current. When the

unit is in the POWER mode (S1 in the PWR position), the reading across both the RCV and XMT sides should be

0.6 +0.03V indicating 60mA of span current. If only sealing current is supplied on the CI loop (S1 in the SC posi-

tion), the voltage reading should be approximately 0.12 volts (i.e. 12mA across 10 ohms).

Section 319-29E-202

9

4. INSPECTION

Inspect the equipment thoroughly upon delivery. If the equipment has been damaged in transit, immediately re-

port the extent of damage to the transportation company.

Wescom equipment is identified by a model and issue number imprinted on the front panel or located elsewhere

on the equipment. Each time a major engineering design change is made on the equipment, the issue number is

advanced by one number on any subsequent models that are manufactured. Therefore, be sure to include both

the model number and its issue number when making inquiries about the equipment.

Each module is shipped in static-protective packaging to prevent electrostatic charges from damaging static-sen-

sitive devices. Use approved static-preventive measures, such as static-conductive wrist straps and a static-dissi-

pative mat, when handling modules outside of their protective packaging. A module intended for future use should

be tested as soon as possible and returned to its original protective packaging for storage.

Do not ship or store modules near strong electrostatic, electromagnetic, or magnetic fields. Use the

original static-protective packaging for shipping or storage.

STATICSENSITIVE

5. MOUNTING

The 3192–9E is fully qualified for operation in a –40 to 65C temperature range, and can be deployed in outside

plant electronics cabinets or indoor building Remote Terminals, typically in Wescom Span Termination System

(STS–3192) Mounting Shelves.

Complete the optioning in Part 6 before installing the 3192–9E unit into a shelf or assembly.

Installation and removal of modules should be done with care. Do not force a module into place. If

excessive resistance is encountered while installing a module, remove the module and check the

card guides and connector to verify proper alignment and the absence of foreign material.

CAUTION

6. OPTIONS

6.1 SI—Power Mode

S1 (see Figure 6) is a 3-position slide switch used to select CI side power modes: line powering (PWR), sealing

current (SC), and looped simplex (LP).

6.1.1. Line Powering, S1 = PWR

In this mode the 3192–9E provides an Automatic Span Power Regulator (ASPR) circuit that automatically gener-

ates up to 96V of regulated span voltage at a constant 60mA of current. This power source can be used to power

the customer’s CSU and/or intermediate span line repeaters as long as the total voltage drop does not exceed 96

volts or 1600 ohms of equivalent simplex resistance at 60mA. Note that the customer’s terminal equipment (CSU)

plus wiring can require up to 68V per FCC P.68 rules.

6.1.2. Sealing Current, S1 = SC

In this mode the 3192–9E provides approximately 12mA of sealing current toward the customer equipment. The

CPE equipment must be locally powered and should be optioned to provide a looped simplex path toward the

3192–9E.

6.1.3. Looped Simplex, S1 = LP

In this mode the 3192–9E loops the CI side simplex leads. This mode can be used if the CPE equipment provides

a sealing current source toward the network, or if no sealing current is provided across the interface.

Section 319–29E–202

10

6.2 S2 — Front Panel MLB Push Button

S2 is a recessed, front-panel push-button switch used to manually activate or deactivate loopback. Momentarily

depress the MLB (Manual Loopback) push-button switch to activate or deactivate a loopback condition.

6.3 S3 — LOS ALM and AIS Enable/Disable

S3 is a two-section dip switch that interacts with the transmit and receive signal detectors on the 3192–9E.

6.3.1. S3–1 — LOS ALM

S3–1 is used to enable or disable sending a LOS (Loss of Signal) condition alarm to the shelf alarm buss. The

LOS condition is detected by the Customer Interface Side Signal detector. For more information, see Paragraphs

3.10 and 3.11, and Figure 6.

6.3.2. S3–2 — AIS Generator

S3–2 is used to enable or disable operation of the Customer Receive Side AIS generator that sends AIS toward

the network upon LOS from the CI.

6.4 S4 — XMT Pad dB

S4 is a 2-section switch used to adjust the transmit pad, allowing transmit path losses of 0, 7.5 and 15dB. See

Figure 6.

7. TESTING

The procedure shown in Table 3 can be used to verify operation of the 3192–9E for pre-service checkout.

Table 3. 3192–9E Verification of Operation and Performance Test Procedure

Note: Requires TBERD209 Digital Transmission Test Set or Equivalent.

Step Action Action

1. Option the 3192–9E as follows:

Set Switch S3–2 (AIS) to the DISABLE position.

Set Switch S3–1 (LOS ALM) to the DISABLE posi-

tion.

Set Switch S1 (PWR) to the LP position.

Set Switch S4 (XMT LBO) for 7.5dB.

2. Insert the 3192–9E into the shelf assembly.

3. Disconnect the CPE at the Network Interface.

4. Connect the Digital Transmission Test Set

(TBERD-209) to the 3192–9E via its front panel

jacks as follows:

TBERD-209 SEND to XMT RPT.

TBERD-209 RCV to RCV RPT.

5. Set the TBERD-209 to transmit an all Zeros pat-

tern. All the 3192–9E front panel LEDs should be off

except for the NET LOS and CI LOS LEDs which

should be on. This indicates NO signal from the

network or CPE equipment. The TBERD-209

should be receiving a NO signal condition.

6. Condition the TBERD-209 to send an AIS (all

ones) signal. The 3192–9E NET LOS LED should flash.

7. Change the TBERD-209 to send a QRSS pattern. The 3192–9E NET LOS LED should extinguish.

Section 319-29E-202

11

Step ActionAction

8. Momentarily operate the 3192–9E front panel MLB

pushbutton switch. The 3192–9E front panel LB LED should light indi-

cating that the unit is in Loopback and the

TBERD-209 should be receiving the looped back

QRSS pattern.

9. Momentarily operate the 3192–9E front panel MLB

push-button switch. The 3192–9E front panel LB LED should extin-

guish and the TBERD-209 shows no signal.

10. Connect the TBERD-209 RCV to the Network In-

terface OUT or ‘Transmit’ (this point will vary by

installation. The intent is to access pins F and 6 of

the 3192–9E card-edge-connector).

The TBERD-209 should see the QRSS pattern

attenuated by 7.5dB.

11. Condition the TBERD-209 to send the inband

loop-up code (11000 or 100000) for greater than 5

seconds, and then return to QRSS.

The 3192–9E front panel LB LED should light and

the TBERD-209 should receive an AIS (all ones)

signal from the 3192–9E.

12. Condition the TBERD-209 to send the inband

loop-down code (11100 or 100) for more than 5

seconds, then return to QRSS.

The 3192–9E front panel LB LED should extin-

guish & the TBERD-209 shows the QRSS signal

down 7.5dB.

13. Connect the TBERD-209 SEND to the Network

Interface IN or ‘Receive’ (this point will vary by

installation. The intent is to access pins K and 9 of

the 3192–9E card-edge-connector).

Reconnect the TBERD-209 RCV to the 3192–9E

front panel jack RCV RPT. Verify that the test set

is still sending QRSS.

The 3192–9E front panel CI LOS LED should be

extinguished and the TBERD-209 should be re-

ceiving the QRSS signal.

14. Disconnect all test set connections. Back out the

3192–9E, set S1 (PWR) to the PWR position. Set

S3–2 to the AIS position and reinsert the unit.

CAUTION: The customer interface will now have

up to 96V on the pairs.

Connect the TBERD-209 SEND to the 3192–9E

front panel XMT RPT jack. Connect the

TBERD–209 RCV to the 3192–9E front panel RCV

RPT jack.

The 3192–9E front panel CI LOS LED should flash

indicating that the unit has detected a customer

Loss-Of-Signal (LOS) and is sending AIS. The

TBERD-209 should be receiving AIS (all ones).

15. Condition the TBERD-209 to send the loop-down

code (11100 or 100). The 3192–9E front panel CI LOS LED should

change from flashing to steady and the

TBERD-209 should read NO signal.

16. Condition the TBERD-209 to send NO signal (all

zeros).

CAUTION: The customer interface will now have

up to 96V on the pairs

.

At the Customer Network Interface, connect the

receive pair to the transmit pair which will close the

simplex loop.

Using a Voltmeter, measure the voltage across the

front panel XMT + and – pin jacks. The voltage

should be approximately 0.6V indicating proper

operation of the ASPR circuit (delivering 60mA to

the load). Repeat this test across the RCV + and –

pins jacks and verify approximately 0.6V.

17. This completes the basic test of the 3192–9E. Dis-

connect all test equipment and test leads. Discon-

nect the loop setup which connected the receive

pair to the transmit pair. Set all switch options to

their design/application settings and perform any

additional end to end circuit checks per local pro-

cedure.

Section 319–29E–202

12

8. TECHNICAL ASSISTANCE

8.1 Technical Assistance — U.S.

If technical assistance is required, contact Charles Industries’ Technical Services Center at:

847–806–8500

847–806–8556 (FAX)

800–607–8500

[email protected] (e-mail)

8.2 Technical Assistance — Canada

Canadian customers contact:

905–821–7673 (Main Office)

905–821–3280 (FAX)

9. WARRANTY & CUSTOMER SERVICE

9.1 Warranty

Charles Industries, Ltd. offers an industry-leading, 5-year warranty on products manufactured by Charles Indus-

tries. Contact your local Sales Representative at the address or telephone numbers below for warranty details.

The warranty provisions are subject to change without notice. The terms and conditions applicable to any specific

sale of product shall be defined in the resulting sales contract.

Charles Industries, Ltd.

5600 Apollo Drive

Rolling Meadows, Illinois 60008–4049

Telephone: 847–806–6300 (Main Office)

847–806–6231 (FAX)

9.2 Field Repairs (In-Warranty Units)

Field repairs involving the replacement of components within a unit are not recommended and may void the war-

ranty and compatibility with any applicable regulatory or agency requirements. If a unit needs repair, contact

Charles Industries, Ltd. for replacement or repair instructions, or follow the

Repair Service Procedure

below.

9.3 Advanced Replacement Service (In-Warranty Units)

Charles Industries, Ltd. offers an “advanced replacement” service if a replacement unit is required as soon as

possible. With this service, the unit will be shipped in the fastest manner consistent with the urgency of the situa-

tion. In most cases, there are no charges for in-warranty repairs, except for the transportation charges of the unit

and for a testing and handling charge for units returned with no trouble found. Upon receipt of the advanced re-

placement unit, return the out-of-service unit in the carton in which the replacement was shipped, using the pre-

addressed shipping label provided. Call your customer service representative at the telephone number above for

more details.

9.4 Standard Repair and Replacement Service (Both In-Warranty and Out-Of-Warranty Units)

Charles Industries, Ltd. offers a standard repair or exchange service for units either in- or out-of-warranty. With

this service, units may be shipped to Charles Industries for either repair and quality testing or exchanged for a

replacement unit, as determined by Charles Industries. Follow the

Repair Service Procedure

below to return units

and to secure a repair or replacement. A handling charge applies for equipment returned with no trouble found. To

obtain more details of this service and a schedule of prices, contact the CI Service Center at 217–932–5288 (FAX

217–932–2943).

Repair Service Procedure

1. Prepare, complete, and enclose a purchase order in the box with the equipment to be returned.

Section 319-29E-202

13

2. Include the following information:

– Company name and address

– Contact name and phone number

– Inventory of equipment being shipped

– Particulars as to the nature of the failure

– Return shipping address

3. Ship the equipment, purchase order, and above-listed information, transportation prepaid, to the ser-

vice center address shown below.

CI Service Center

Route 40 East

Casey, IL 62420–2054

4. Most repaired or replaced units will be returned within 30 or 45 days, depending on the product type

and availability of repair parts. Repaired units are warranted for either 90 days from the date of repair

or for the remaining unexpired portion of the original warranty, whichever is longer.

10. SPECIFICATIONS

10.1 Electrical Specifications

The electrical characteristics of the 3192-9E are as follows:

(a) REPEATER TYPE: Passive transmit;

regenerative receive.

(b) LINE SIGNAL TYPE: Bipolar at 1.544Mbps +200bps.

(c) TRANSMIT PATH PAD: Selectable 0.0dB, 7.5dB, or 15.0dB.

(d) DSX PRE-EQUALIZER: Fixed 0–110 feet, 22ga; 0–90 feet, 24ga.

(e) REPEATER LINE SIGNAL PULSE WIDTH: 324nsec +30nsec.

(f) REPEATER LINE SIGNAL PULSE WIDTH UNBALANCE: 15nsec maximum.

(g) REPEATER LINE SIGNAL PULSE OVERSHOOT: 10 to 30 percent of pulse height, 20 percent nomi-

nal.

(h) REPEATER LINE SIGNAL PULSE RISE AND FALL TIME: 100 nsec maximum.

(i) INPUT/OUTPUT IMPEDANCE: 100 ohms (nominal) at 772kHz.

(j) RECEIVE AUTOMATIC LINE BUILD-OUT: 0 to 35dB.

(k) TIMING JITTER: Meets the Jitter Transfer Specifications as described in TR-TSY-000312 .

(l) LONGITUDINAL BALANCE: Greater than 35dB from 50kHz to 1.5 mHz.

(m) INSERTION LOSS: Transmit path 1.5dB nominal.

(n) LOSS-OF-SIGNAL THRESHOLD: 175 +75 consecutive zeros.

10.1.1. Loopback

(a) LOOPBACK ERROR THRESHOLD: 10–error rate or better.

(b) LOOPBACK CODE:

SF: Framed or unframed 2 in 5 (11000) or 1 in 6 (100000) to loop up (approximately 5 seconds); 3 in

5 (11100) or 1 in 3 (100) to loop down (approximately 5 seconds).

Section 319–29E–202

14

(c) ESF DATA LINK: The bit-oriented command and response message 0 001001 0 11111111 for 16 milli-

seconds to loop up. The bit-oriented command and response message 0 010010 0 11111111 for 16

milliseconds to loop down.

(d) LOOPBACK TIMEOUT: 20 Minutes

10.1.2. Power

(a) INPUT: Voltage Requirements, –42.5 to 56Vdc; Current Requirements, see Table 1.

10.2 Physical Specifications

The physical specifications of the 3192-9E are as follows:

Table 4. Physical Specifications

Feature U.S. Metric

Height 4.75 inches 12.06 cm

Width 0.687 inches 1.746 cm

Depth 10.5 inches 26.67 cm

Weight 12 oz. 198 g

Temperature –40to 149 F–40to 65C

Humidity To 95% (no condensation)

This manual suits for next models

1

Table of contents

Popular Network Card manuals by other brands

Solartron Metrology

Solartron Metrology Orbit PCI Mk 2 user manual

Compaq

Compaq iPAQ IA-2 Quick setup

FP InovoLabs

FP InovoLabs FP S-Compact LAN Installation and safety

Texas Instruments

Texas Instruments TLV320DAC3202EVM user guide

NetComm

NetComm NP1020 Technical specifications

Honeywell

Honeywell RMWIFI-M3 user guide

eWON

eWON FLX3101 installation guide

REXROTH

REXROTH efc series instruction manual

Delta Electronics

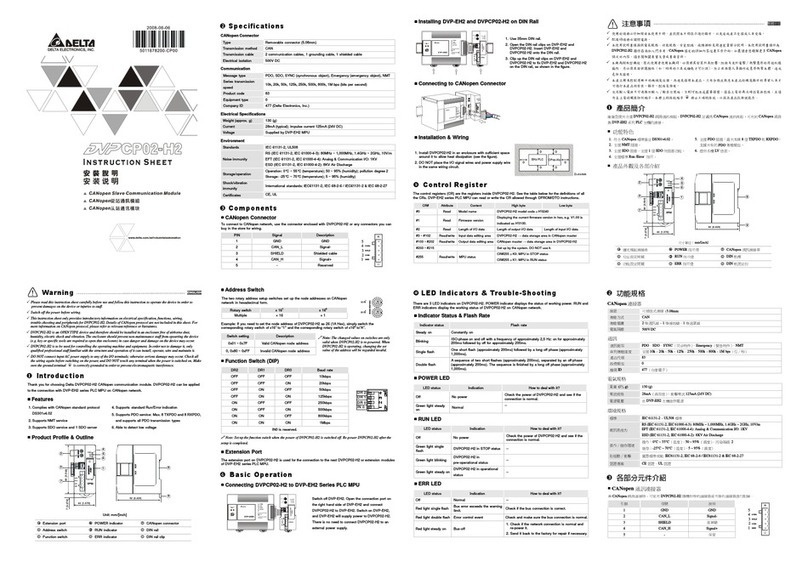

Delta Electronics CANopen Communication Module DVPCP02-H2 instruction manual

Sony

Sony BKMW-E3000 Operation manual

Zonet

Zonet ZEW1505 Quick installation guide

National Instruments

National Instruments DAQCard-1200 user manual