Charles 3650-01 User manual

Section 365–001–201

Equipment Issue 1

Fourth Printing, February 2000Telecommunications Group

2000Charles Industries Ltd.

CLEI is a trademark of Bell Communications Research, Inc.

All rights reserved. Printed in United States of America.

The availability of features and technical specifications herein subject to change without notice. Page 1 of 12

3650–01/03 2-Wire Equalized Transmission Only Channel

Units with Lead Conditioning (2W ETO w/LC

CONTENTS PAGE

Part 1. GENERAL 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 2. INSPECTION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 3. APPLICATION GUIDELINES 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 4. CIRCUIT DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 5. MOUNTING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 6. INSTALLER CONNECTIONS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 7. OPTIONS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 8. ALIGNMENT 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 9. TESTING 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 10. TECHNICAL ASSISTANCE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 11. WARRANTY & CUSTOMER SERVICE 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 12. SPECIFICATIONS 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

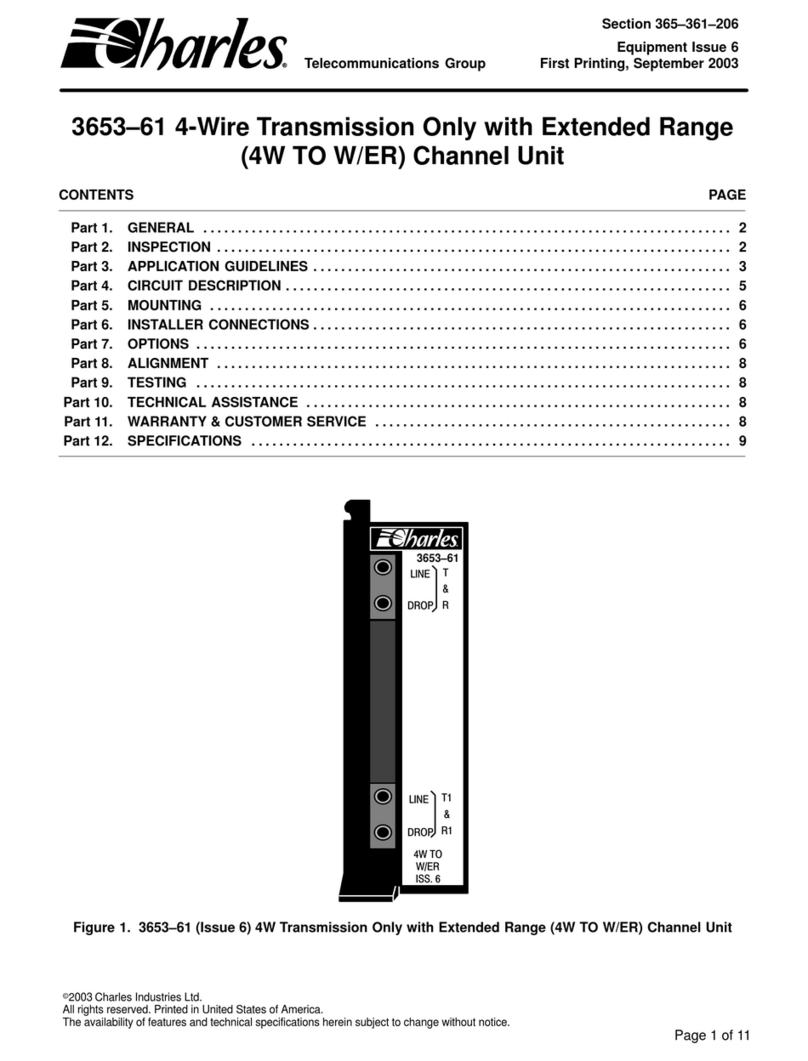

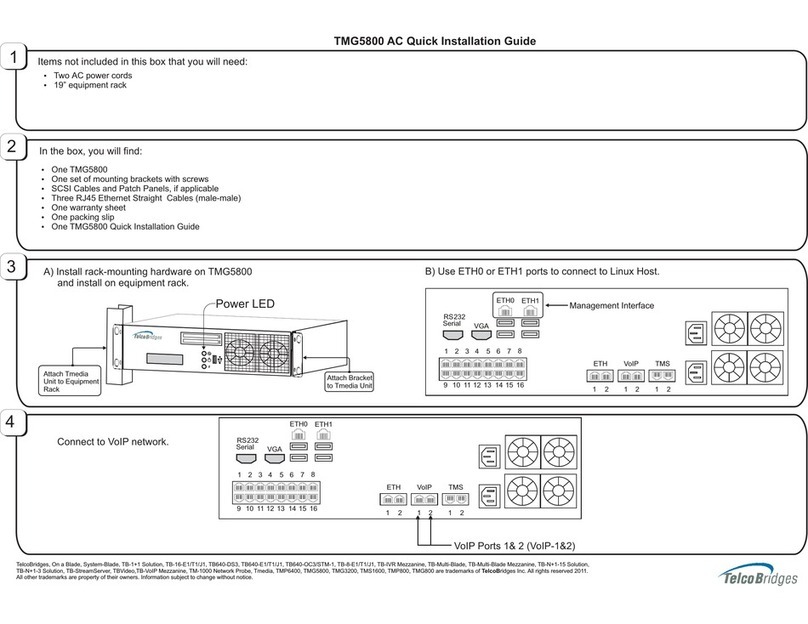

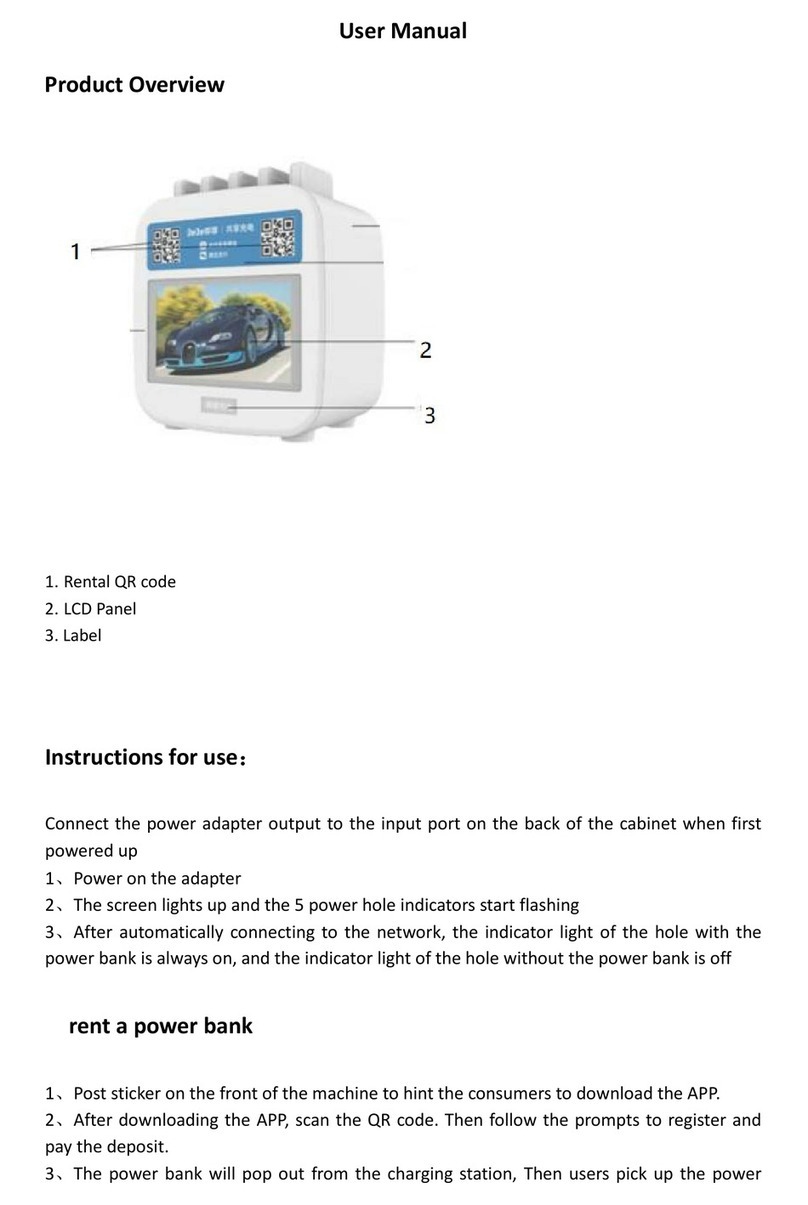

Figure 1. 3650–01 2W ETO w/LC Channel Unit

Section 365–001–201

2

1. GENERAL

1.1 Document Purpose

This document provides a general, circuit, installation and testing information for the Charles Industries

3650–01/03 2-Wire ETO w/LC Channel Units

1.2 Document Status

This document is reprinted to provide a general editorial update.

1.3 Equipment Function

The Charles Industries 3650-01/03 2-Wire ETO w/LC Channel Units are used in the CHarles Industries 360/363

D4 Digital Carrier Terminal to provide an interface to in-band (with no DC) signaling or no signaling special service

units such as 2-wire voice frequency extensions, data sets, or modems on a private line. The 3650–01 provides a

900-ohm balanced interface, while the 3650–03 provides a 600-ohm balanced interface. The 3650–01 is shown in

Figure 1.

1.4 Equipment Location/Mounting

This unit occupies one channel unit slot of a Charles Industries 360/363 D4 Digital Carrier Terminal Channel Bank

assembly.

1.5 Equipment Features

The 3650–01/03 2-Wire ETO w/LC Channel Units include the following features:

Termination impedance of 2.15 uF in series with 900 ohms (3650–01) or 600 ohms (3650–03) for

matching the impedance of the 2-wire port interface.

Built-in selectable hybrid-balancing compromise network of 2.15 uF in series with 900 ohms

(3650–01) or 600 ohms (3650–03)

Built-in jack (J3) to mount an optional 3690–00/10 compromise network subassembly or an optional

3690–01/11, 02/12, or 03/13 precision balance network (PBN) subassembly, and provisions (pins 41

and 46) to connect an external PBN.

Built in jacks (J2 and J4) to mount optional 3691–00 nonloaded cable equalizer and/or 3691–01 H88

loaded cable equalizer subassemblies for post- and/or pre-equalization.

Transmit and receive prescription attenuation of 16.5 dB in 0.1 dB increments.

Sealing current for internal, external or looped feed.

Carrier group alarm, ground or shorting contact, with wink for lead conditioning.

68 dB of gain transfer, eliminating the need for external VF amplifiers.

Selectable full 8-bit coding for optimum signal-to-distortion ratio.

Front-panel-accessible bantam-breaking jacks for accessing the distant (line) or local (drop) end.

2. INSPECTION

2.1 Inspect for Damages

Inspect the equipment thoroughly upon delivery. If the equipment has been damaged in transit, immediately re-

port the extent of damage to the transportation company.

2.2 Equipment Identification

Charles Industries’ equipment is identified by a model and issue number imprinted on the front panel or located

elsewhere on the equipment. Each time a major engineering design change is made on the equipment, the issue

Section 365-001-201

3

number is advanced by 1 and imprinted on subsequent units manufactured. Therefore, be sure to include both

the model number and its issue number when making inquiries about the equipment.

2.3 Static Concerns

Each module is shipped in static-protective packaging to prevent electrostatic charges from damaging static-sen-

sitive devices. Use approved static-preventive measures, such as static-conductive wrist straps and a static-dissi-

pative mat, when handling modules outside of their protective packaging. A module intended for future use should

be tested as soon as possible and returned to its original protective packaging for storage.

Do not ship or store modules near strong electrostatic, electromagnetic, or magnetic fields. Use the

original static-protective packaging for shipping or storage.

CAUTION

3. APPLICATION GUIDELINES

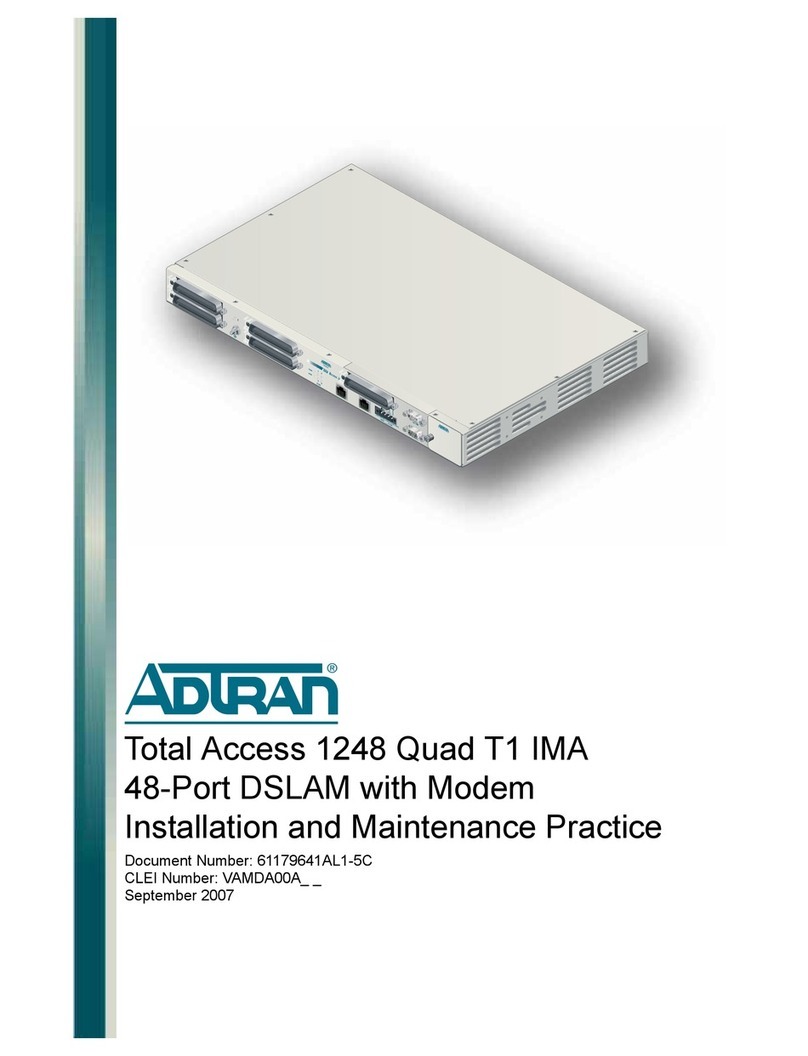

The 3650-01/03 channel units provide a voice path without signaling. Typical applications are for private line data

services requiring a metallic facility extension, tandem circuits employing inband signaling such as SF circuits,

and other applications where voice transmission without signaling is required. See Figure 2 for a typical applica-

tion.

360/363

D4

T

E

R

M

I

N

A

L

2W ETO

3650-

01/03

STATION

EQUIP-

MENT

TCXR Facility

+6 to –10.5 dBm

METALLIC FACILITY

–9.5 to +7 dBm

Figure 2. 3650–01/03 2W ETO w/LC Channel Unit Typical Application

4. CIRCUIT DESCRIPTION

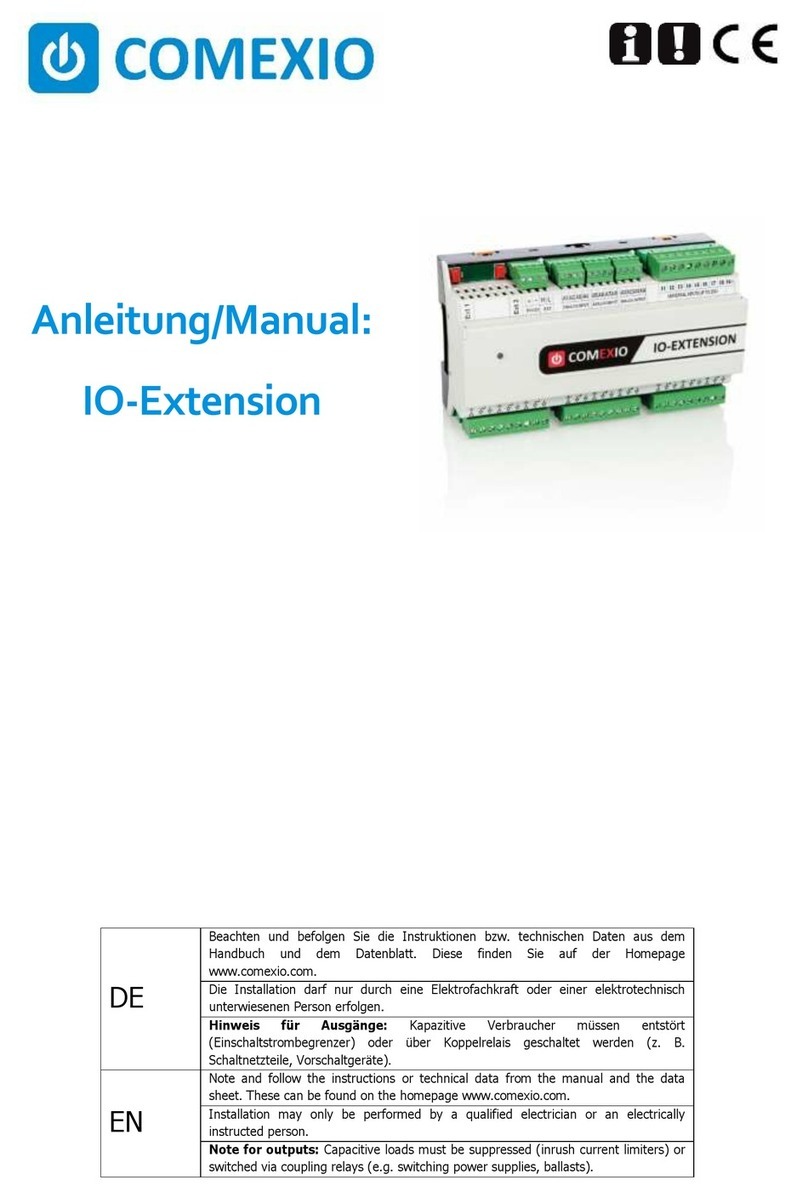

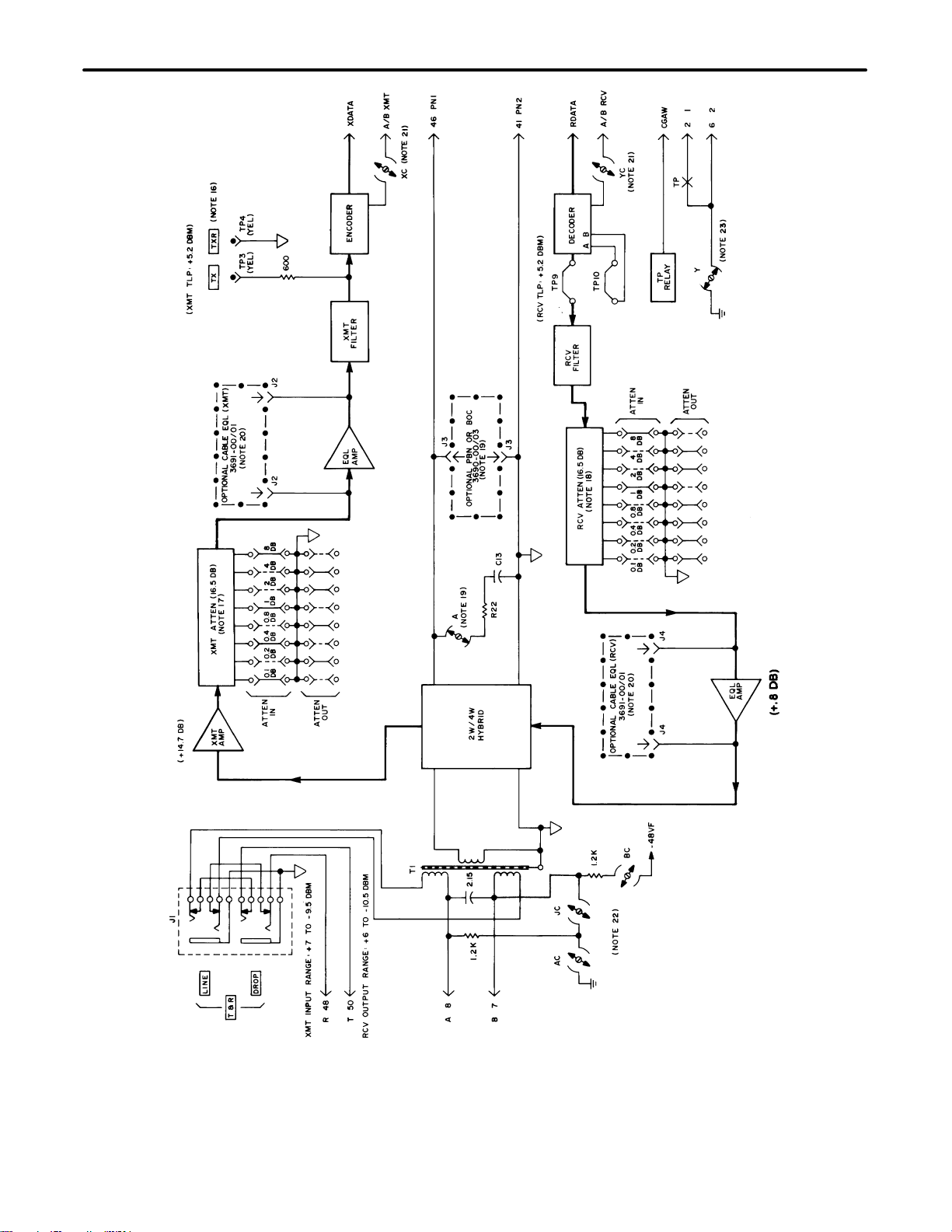

Refer to the block diagram in Figure 3 while reading the following circuit description.

4.1 Transmit VF Path

VF signals applied to the input tip and ring leads (pins 50 and 48) are routed through the DROP and LINE break-

ing jacks to transformer T1. In turn, transformer T1 provides DC isolation from the metallic facility and accepts

input signals from –9.5 to +7 dBm. After passing through the 2W/4W hybrid, the VF signals are routed to the XMT

AMP. This circuit amplifies the signal to compensate for losses in the transformer and filters.

From the XMT AMP, signals pass to the XMT ATTEN circuit, which is adjusted to provide the proper signal level

to the encoder. Adjustment is accomplished via push-on jumpers which provide up to 16.5 dB attenuation in 0.1

dB increments. The output of the XMT ATTEN is forwarded to the EQL AMP. The EQL AMP, in conjunction with

an optional equalizer subassembly, provides amplitude post-equalization for non-loaded or loaded cable.

The adjusted VF signal is then applied to the XMT filter, which suppresses frequencies outside the bandwidth of

the standard voice frequency and prevents them from entering the encoder.

The filtered VF signal is then applied to the encoder. Access to the signals at the encoder input is provided by

jacks TX and TXR. The nominal level at this point it +5.2 +/–0.1 dBm (measured with a 600-ohm bridged meter).

During the encode command pulse on the ECM lead, analog signals present at the input of the encoder are con-

verted to digital signals. The digital data stored in the encoder is transmitted on the XDATA lead.

Section 365–001–201

4

Figure 3. Block Diagram

Section 365-001-201

5

Table 1. Notes for Figure 3

# Note # Note

1. Connector 13. XMT input range at tip and ring: +7 dBm to –7.5 dBm. The unit is

factory adjusted for 0 dBm input. The XMT ATTEN is set for 9.5

dB attenuation.

2. Primary transmission path 14. RCV output range at tip and ring: +6 dBm to –10.5 dBm. The

unit is factory adjusted for –3 dBm output. The RCV ATTEN is

set for 9.0 dB attenuation.

3. PC mount test point 15. Models: 3650–01 900 ohm w/LC

3650–03 600 ohm w/LC

4. Signal flow direction 16. The level at the transmit unbalanced monitor points TX–TXR.

Measured with a bridged meter, should be +5.2 dBm +/–0.1 dB.

5. N.O., N.C. relay contacts 17. The XMT ATTEN provides 16.5 dB attenuation in 0.1 dB steps

to accommodate input range of from +7 dBm to –9.5 dBm. With

–9.5 dBm input, no attenuation is needed. When input goes up,

an appropriate amount of attenuation is added so that the level

at TX–TXR is maintained at +/–5.2 dBm to +0.1 dB.

6. Front panel marking 18. The RCV ATTEN provides 16.5 dB attenuation in 0.1 dB steps to

accommodate output range of from +6 dBm to –10.5 dBm. With 6

dBm output, no attenuation is needed. An appropriate amount of

attenuation is added when a lower output level is required.

7. Optional circuit enclosure 19. A91–369000/03PBN/BOC are ordered separately and used when

inserted into connector J3. Open option A when PBN/BOC is used.

8. Receptacletype, optional strap

Alternate position 20. A91–369100nonloaded cable equalizer or a A91–369101 loaded

cable equalizer is ordered separately to provide post-equalization

when inserted into connector J2, and pre-equalization when in-

serted into connector J4.

9. Open, closed screw option 21. For full 8-bit conversion, open screw options XC (encoding) and

YC (decoding). For 7 5/6 bit encoding and to send a busy to the

far end on both signaling highways close option XC. Similarly,

for 7 5/6 bit decoding, close option YC.

10. Coil type test point 22. Screw options AC, BC and JC are used to provide sealing cur-

rent.

Close Option Open Option Function

AC, BC JC Supply sealing current to the

loop.

JC AC, BC Complete the path when seal-

ing current is supplied from the

far end of the loop.

11. Ganged switches are indicated by dashed connection line or

suffixed reference designation. 23. The trunk processing relay (TP) is activated immediately upon

an alarm condition in the channel bank. Approximately 2 sec-

onds later it is deactivated for 70 milliseconds During the acti

12. PC mount test jacks: onds later it is deactivated for 70 milliseconds. During the acti-

vated mode, leads designated as 1 and 2 are shorted. Lead 2

Marking Function

vated

mode

,

leads

designated

as

1

and

2

are

shorted

.

Lead

2

can be grounded by screw option Y. When the channel unit is

removed from the mounting slot, the

“

1

”

lead (

p

in 2) is con

-

T&R Line (J1–A) Access towards channel unit

removed

from

the

mounting

slot

,

the

“1”

lead

(pin

2)

is

con

-

nected to ground through a shorting contact in the backplane

card connector

T&R drop (J1–B) Access towards office equip-

ment

ggg

card connector.

TX&TXR (TP3 & TP4) 4-wire XMT monitor

4.2 Receive VF Path

Digital data on the RDATA lead is read into the decoder, which provides digital-to-analog conversion.

The output of the decoder is applied to the RCV filter. The RCV filter reconstructs the transmitted waveform from

the stair-step output of the decoder and suppresses frequencies above 4kHz.

From the RCV filter, signals pass to the RCV ATTEN circuit, which is adjusted to provide the required output level

at the 2-wire pair. Adjustment is accomplished via push-on jumpers which provide up to 16.5 dB attenuation in 0.1

dB increments. The output of the RCV ATTEN is forwarded to the EQL AMP. The EQL AMP, in conjunction with

an optional equalizer subassembly, provides amplitude pre-equalization for nonloaded or loaded cable.

The output of the EQL AMP is applied through the 2W/4W hybrid to transformer T1 and to tip and ring (pins 48

and 50).

Section 365–001–201

6

4.3 Trunk Processing During a Carrier Group Alarm (CGA)

Upon carrier failure, the CGAW bus goes to ground immediately; it then winks open for 70 milliseconds approxi-

mately 2.5 seconds later. The CGAW bus controls the TP relay which controls the status of the 1 (pin 2) and 2

(pin 6) lead pins. The TP relay operates when CGAW goes to ground and releases for for 70 milliseconds when

CGAW winks open; it then remains operated for the duration of trunk processing. When the TP relay operates, it

shorts the 1 and 2 leads together. The 2 lead can be tied to ground by setting screw option Y closed. When the

channel unit is removed from its mounting slot, the 1 lead is connected to ground through a shorting contact in the

backplane connector.

5. MOUNTING

The 3650–01/03 mounts in one channel unit slot of a 360/363 D4 terminal. The hinged front panel serves as an

insert lever to ensure a positive connection of the channel unit’s card-edge connector to the backplane connector

when the unit is installed and as an eject lever when the module is taken out of service.

Never handle or carry the channel unit by using the front panel in its open (upward) position.

CAUTION

Install and remove the module with care. Do not force it into place. If excessive resistance is

encountered while installing the module, remove it and check the card guides and connector to

verify proper alignment and the absence of foreign material.

CAUTION

Use the following steps to mount the unit:

Step Action

1. Align the channel unit with the appropriate card-guided slot of the terminal.

2. Slide the unit into the slot with the front panel in the horizontal (up)position.

3. When the top portion of the hinged front panel is under the front lip of the terminal, push down on the

front panel until it is in the vertical position. The channel unit’s card-edge connector will begin to make

contact with the backplane connector.

4. Continue to apply light pressure to the bottom edge of the front panel until the unit snaps into place.

6. INSTALLER CONNECTIONS

6.1 Non-Connectorized Terminal

Installer connections are made to the 3650–01/03 channel unit by wire-wrapping to the T and R leads (pins 50

and 48), the make-busy leads 1 and 2 (pins 2 and 6) and, as required, the sealing current A and B (pins 8 and 7)

leads and/or the PN1 and PN2 (pins 46 and 41) leads of the associated 50-pin connectors on the backplane as-

sembly of a non-connectorized 360/363 D4 terminal.

6.2 Connectorized Terminal

On connectorized 360/363 D4 terminals, (360–10, –11, etc.) connections are made via 25-pair female connectors

(CINCH 222–22–50–023 or equivalent) to the appropriate 25-pair male connectors of the 360/363 D4 terminal.

Refer to section 360–000–200 for the wiring diagrams of the female connectors with respect to the 360/363 D4

terminal being used. Electrical connections are made when the unit is installed; PN1 and PN2 are not connecto-

rized.

Section 365-001-201

7

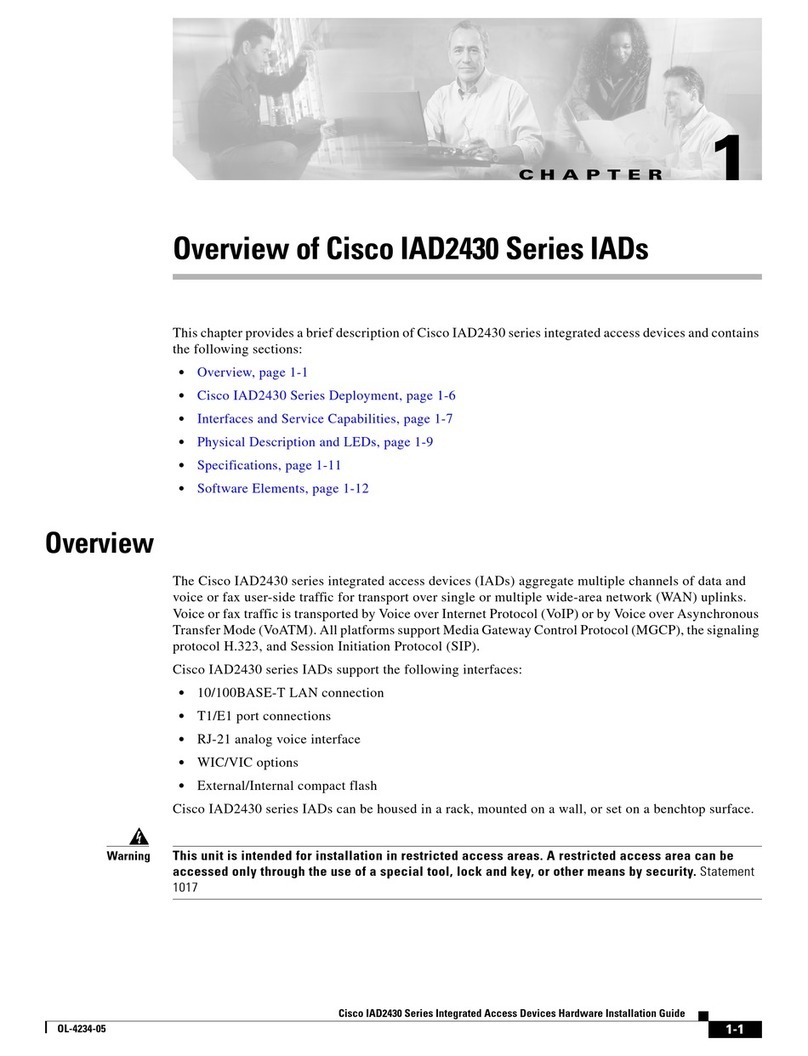

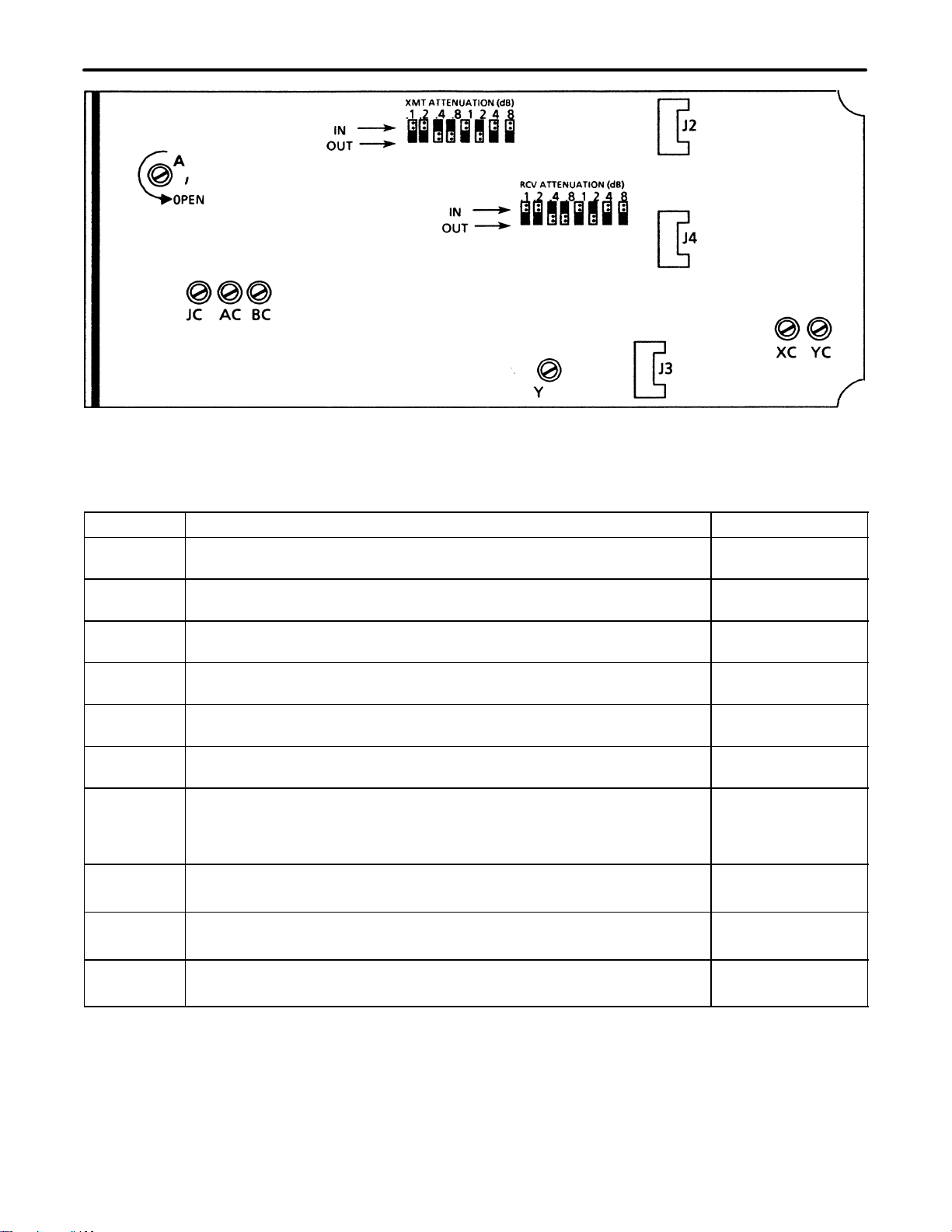

7. OPTIONS

The following paragraphs describe the connecting jacks, push-on jumper options, and screw options that are

used to condition the 3650–01/03 for proper application and operation. Also refer to Figure 4 for an illustration of

the connecting jack and option locations and to Table 2 for a brief summary of the option conditioning require-

ments.

Note: When opening a screw option, rotate the screw counterclockwise two full turns to ensure that the connec-

tion is open. When closing a screw option, rotate the screw clockwise until it seats. When selecting the

push-on jumper options, push the jumper over the appropriate pins with that option grouping to obtain the

desired operation.

7.1 Post-Equalization (J2)

A Charles Industries 3691–00 Nonloaded Cable Equalizer Subassembly or 3691–01 H88 Loaded Cable Equalizer

Subassembly can be ordered separately to provide post-equalization (transmit path) when inserted into jack J2.

Additional information about the equalizer is available in the 3691–XX documentation.

7.2 Comp Net/PBN—Hybrid Balancing (J3)

A Charles Industries 3690–00/10, –01/11, –02/12, or –03/13 BPN Subassembly can be ordered separately and

inserted into jack J3 to provide hybrid balancing. Refer to the 3690–XX documentation for more information.

7.3 Pre-Equalization (J4)

A Charles Industries 3691–00 Nonloaded Cable Equalizer subassembly or 3691–01 H88 Loaded Cable Equalizer

subassembly can be ordered separately to provide pre-equalization (received path) when inserted into jack J4.

Refer to the 3691–00/01 document for additional information.

7.4 XMT Attenuation (push-on jumpers)

Eight push-on jumpers select up to 16.5 dB attenuation in 0.1 dB increments for adjusting the transmit path to the

proper operating level. By placing each jumper (0.1, 0.2, 0.4, 0.8, 1, 2, 4, 8 dB) to the IN position, as required, a

level of +5.2 dBm at the TX and TXR test points can be achieved. Placing all of the jumpers in the OUT position

results in 0 dB attenuation.

7.5 RCV Attenuation (push-on jumpers)

Eight push-on jumpers select up to 16.5 dB attenuation in 0.1 dB increments for adjusting the receive path to the

proper operating level. By placing each jumper (0.1, 0.2, 0.4, 0.8, 1, 2, 4, 8 dB) to the IN position, as required, the

desired output level can be achieved. Placing all of the jumpers in the OUT position results in 0 dB attenuation.

7.6 Hybrid Balance (Screw Option A)

The 3650–01/03 can accept an internal PBN or BOC via connector J3 or an external PBN or BOC via pins 46 and

41 (PN1 and PN2 respectively). Open option A to condition the unit to use an optional PBN or OBC. Closing op-

tion A when an optional PBN or BOC is not being used selects the on-board compromise network of 900/600

ohms in series with 2.15 uF.

7.7 Sealing Current (screw options AC, BC, JC)

Sealing current is a direct current that prevents contact deterioration, reducing poor-contact noise in non-soldered

cable splices. It is used on metallic lines carrying data, carrier, or other services employing low-level AC signals

not superimposed on a direct current. Sealing currents can be provided externally or internally (from the channel

unit); it can also be looped back when the distant end provides the sealing current source.

Sealing current is provided externally (customer supplied Charles Industries 8491–00 or equivalent connected to

pins 7 and 8) on the A and B leads by opening screws JC, AC, and BC. Use these settings also if sealing current

is NOT used on the metallic facility. When sealing current is provided from the far end of the 2W metallic facility,

close screw JC (to complete the loop) and open screws AC and BC. To use the on-board source of –48VDC seal-

ing current, open screw JC and close screws AC and BC.

7.8 Lead-Conditioning (screw option Y)

During an alarm, trunk processing is implemented on the 1 and 2 leads (pins 2 and 6, respectively) to the interfac-

ing trunk or switching system as follows: busy condition immediately upon an alarm, with a 70-millisecond wink

idle occurring 2.5 seconds after the alarm.

Section 365–001–201

8

Figure 4. 3650–01/03 ETO w/LC Options

Table 2. 3650–01/03 ETO w/LC Option Description

Option Function/Remarks Position

J2 Jack for mounting an optional transmit post-equalizer (3691–00/01). See documentation

for 3691–00/01

J3 Jack for mounting optional compensation network/PBN 3690–00/10,

–01/11, –02/12, or –03/13. See documentation

for 3690–XX

J4 Jack for mounting an optional receive pre-equalizer 3691–00/01 See documentation

for 3691–00/01

XMT ATTEN Eight push-on jumpers (0.1, 0.2, 0.4, 0.8, 1, 2, 4, 8) total 16.5 dB of trans-

mit attenuation when all jumpers are in the IN position. See part 7.4

RCV ATTEN Eight push-on jumpers (0.1, 0.2, 0.4, 0.8, 1, 2, 4, 8) total 16.5 dB of re-

ceive attenuation when all jumpers are in the IN position. See part 7.5

A Set to the OPEN position if jack J3 is equipped or if an external PBN/BOC

is used. Open/Closed

AC, BC, JC For external sealing current at pins 7 and 8 (or no SC) open JC, AC, and

BC. For looping sealing current from the 2W line, close JC and open AC

and BC. For supplying –48 VDC sealing current to the 2W line, open JC

and close AC and BC.

Open/Closed

Y1 lead/2 lead floating dry contact closure during trunk processing.

Ground on 1 lead during trunk processing. Open

Closed

XC Full 8-bit encoding.

7 5/6 bit encoding. Open

Closed

YC Full 8-bit encoding.

7 5/6 bit encoding. Open

Closed

Screw option Y conditions the 1 and 2 leads for the proper trunk or switching system interface. For a dry-contact

closure of the 1 and 2 leads during trunk processing, open screw Y. For a ground on the 1 lead (pin 2) during

trunk processing, close option Y.

Section 365-001-201

9

7.9 Full Bit Encoding/Decoding (screw options XC, YC)

Screw options XC and YC condition the channel unit for either full 8-bit encoding/decoding (no signaling) or 7 5/6

bit encoding/decoding (busy condition transmitted to far end). For full 8-bit decoding, open screw YC. For 7 5/6 bit

decoding, close screw YC. The 8-bit encoding and decoding provides a better signal-to-noise ratio than the 7 5/6

bit encoding and decoding.

8. ALIGNMENT

8.1 Transmit Alignment

The XMT attenuation push-on jumpers provide attenuation from 0 to 16.5 dB in increments of 0.1 dB to accom-

modate an input TLP range from –9.5 to +7 dBm. To adjust the transmit path to the proper operating level, the

difference between –9.5 and the transmit TLP and tip and ing must be calculated.

[XMT ATTN = TLP–(–9.5)]

For an input TLP of 7 dBm, the XMT ATTN = 7–(–9.5) = 16.5 dB. Se the sum of the push-on jumpers to 16.5 (all

to the IN position).

8.2 Receive Alignment

The RCV attenuation push-on jumpers provide attenuation from 0 to 16.5 dB in increments of 0.1 dB to accom-

modate an output TLP range from +6 to –10.5 dBm. To adjust the receive path to the proper operating level, the

difference between +6 and the receive TLP at T1 and R1 must be obtained.

[RCV ATTN = +6–TLP]

For an output TLP of –12.5 dBm, the RCV ATTN=+6–(–10.5) = 16.5 dB. Set the sum of the push-on jumpers to

16.5 (all to the IN position).

9. TESTING

After mounting, installation, optioning and alignment, use the following steps to test the unit.

Step Action

1. Place a call end-to-end through the facility to verify proper operation.

2. If trouble is encountered, re-check all installer connections, options and alignment settings and verify

that the channel unit is making positive connections to the backplane connector. Then re-test.

3. If trouble persists, replace unit with a similar unit known to be in operating order and retest the facility.

Channel unit testing for fault diagnosis or verification of circuit operation is provided in section

360–001–20X.

10. TECHNICAL ASSISTANCE

10.1 Technical Assistance — U.S.

If technical assistance is required, contact Charles Industries’ Technical Services Center at:

847–806–8500

847–806–8556 (FAX)

800–607–8500

[email protected] (e-mail)

10.2 Technical Assistance — Canada

Canadian customers contact:

905–821–7673 (Main Office)

905–821–3280 (FAX)

Section 365–001–201

10

11. WARRANTY & CUSTOMER SERVICE

11.1 Warranty

Charles Industries, Ltd. offers an industry-leading, 5-year warranty on products manufactured by Charles Indus-

tries. Contact your local Sales Representative at the address or telephone numbers below for warranty details.

The warranty provisions are subject to change without notice. The terms and conditions applicable to any specific

sale of product shall be defined in the resulting sales contract.

Charles Industries, Ltd.

5600 Apollo Drive

Rolling Meadows, Illinois 60008–4049

847–806–6300 (Main Office)

847–806–6231 (FAX)

11.2 Field Repairs (In-Warranty Units)

Field repairs involving the replacement of components within a unit are not recommended and may void the war-

ranty and compatibility with any applicable regulatory or agency requirements. If a unit needs repair, contact

Charles Industries, Ltd. for replacement or repair instructions, or follow the

Repair Service Procedure

below.

11.3 Advanced Replacement Service (In-Warranty Units)

Charles Industries, Ltd. offers an “advanced replacement” service if a replacement unit is required as soon as

possible. With this service, the unit will be shipped in the fastest manner consistent with the urgency of the situa-

tion. In most cases, there are no charges for in-warranty repairs, except for the transportation charges of the unit

and for a testing and handling charge for units returned with no trouble found. Upon receipt of the advanced re-

placement unit, return the out-of-service unit in the carton in which the replacement was shipped, using the pre-

addressed shipping label provided. Call your customer service representative at the telephone number above for

more details.

11.4 Standard Repair and Replacement Service (Both In-Warranty and Out-Of-Warranty Units)

Charles Industries, Ltd. offers a standard repair or exchange service for units either in- or out-of-warranty. With

this service, units may be shipped to Charles Industries for either repair and quality testing or exchanged for a

replacement unit, as determined by Charles Industries. Follow the

Repair Service Procedure

below to return units

and to secure a repair or replacement. A handling charge applies for equipment returned with no trouble found. To

obtain more details of this service and a schedule of prices, contact the CI Service Center at 217–932–5288 (FAX

217–932–2943).

Repair Service Procedure

1. Prepare, complete, and enclose a purchase order in the box with the equipment to be returned.

2. Include the following information:

– Company name and address

– Contact name and phone number

– Inventory of equipment being shipped

– Particulars as to the nature of the failure

– Return shipping address

3. Ship the equipment, purchase order, and above-listed information, transportation prepaid, to the ser-

vice center address shown below.

CI Service Center

Route 40 East

Casey, IL 62420–2054

4. Most repaired or replaced units will be returned within 30 or 45 days, depending on the product type

and availability of repair parts. Repaired units are warranted for either 90 days from the date of repair

or for the remaining unexpired portion of the original warranty, whichever is longer.

Section 365-001-201

11

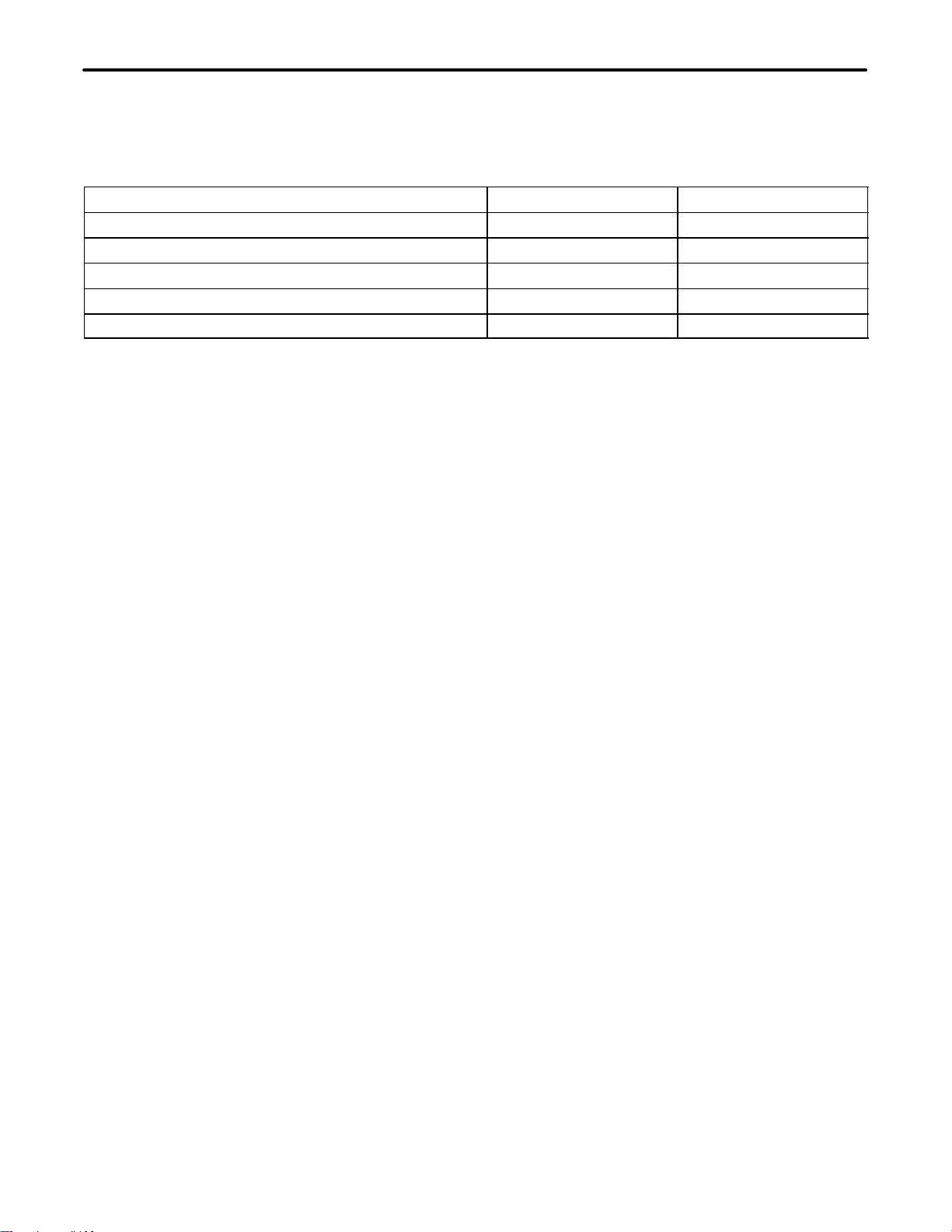

12. SPECIFICATIONS

12.1 Electrical (Single-Ended)

(a) Transmit input TLP range: –9.5 to +7 dBm

(b) Receive output TLP range: –10.5 to +6 dBm

(c) Transmit prescription attenuation: 0 to 16.5 dB in increments of 0.1 dB

(d) Receive prescription attenuation: 0 to 16.5 dB in increments of 0.1 dB

(e) Transmit and receive port impedance: 3650–01, 900 ohms + 2.15 uF; 3650–02, 600 ohms + 2.15 uF

(f) Transmit and receive path frequency response (referenced at 1kHz):

Frequency (Hz) XMT (dB) RCV (dB)

60 –20 minimum –

200 –2.5 to 0 –1.5 to 0

300 –0.49 to +0.24 –0.49 to +0.24

1000 0 (ref) 0 (ref)

3000 –0.49 to +0.24 –0.49 to +0.24

3400 0 to –1.2 0 to –1.2

4000 –14 minimum –14 minimum

5100 –32 minimum –32 minimum

(g) Longitudinal balance: –62 dB or less at 200 Hz to 1 kHz; –60 dB or less at 3 kHz

(h) Signal to distortion ratio: 35 dB minimum at 0 to –30 dBm0; 29 dB minimum at –40 dBm0; 25 dB

minimum at –45 dBm0

(i) Trans-hybrid loss: Echo return loss, 36 dB minimum; singing return loss, 25 dB minimum; singing re-

turn loss high, 32 dB minimum

(j) Return loss: Echo return loss, 35 dB minimum; singing return loss, 23 dB minimum; singing return

loss high, 32 dB minimum

(k) Transmit/receive idle channel noise: 20 dBrnC0 maximum

(l) Crosstalk: 61 dBm0 minimum at 400 Hz, 71 dBm0 minimum at 700 Hz to 1 kHz, 70 dBm0 minimum

at 3 kHz

(m) Level tracking (measured single-ended at 1010 Hz): +/–0.25 dB from +3 to –37 dBm0, +/–0.5 dB

from –38 to –50 dBm0

Section 365–001–201

12

12.2 Physical

Physical specifications are shown in Table 3.

Table 3. Physical Specifications

Feature U.S. Metric

Height 4.2 inches 10.6 centimeters

Width 1.35 inches 3.4 centimeters

Depth 10.3 inches 26.7 centimeters

Weight 16 ounces 455 grams

Temperature 32to 122F 0to 50C

This manual suits for next models

1

Table of contents

Other Charles Network Hardware manuals