Charles Wescom DuaLine Plus DDL201 Operating and installation instructions

L

SOUTHWESTERN BELL TELEPHONE COMPANY

SWBT Standard section WSCM 363-400-801SW

ksue~ July 1993

WESCOM DUALINE PLUS

DIGITAL SINGLE SUBSCRIBER CARRIER SYSTEM

DDL 201 CENTRAL OFFICE

TERMINAL SHELF (23 INCHES)

L

1.01

1.02

1.03

1.04

1.05

1.08

2

201

202

GENE~

This section is acover sheet for the Wescom DuaUne Plus DDL 201 Central Oflke

Terminal Shelf for use at the subscriber location. This section is copyrighted and

reproduced with the permission of Charles Industries.

Whenever this section is reissued the reason(s) for reissue will be listed in this

paragraph.

The Wescom DuaLine Plus System is a general purpose digital single subscriber carrier

(DSSC) system that provides pair gain capability over anon-loaded, two wire, copper

facility.

The DuaLine Plus requires installation of acentral oflke terminal and afield module,

located at or near the subscriber premise.

Associated practices for installation and maintenance of the system are:

Section

363-400-800SW

502-204-800SW

502-204-801SW

502-204-802SW

363-400-802SW

363-400-803SW

363-400-804SW

363-400-805SW

502-204-803SW

502-204-804SW

n~

System Ovemiew

DDL 102 DuaLine Plus Remote

Terminal

DDL 104 DuaLine Plus Remote

Terminal

DDL 112 DuaL#nePlus Remote

Terminal

DDL 210 DuaLine Plus Central

O!lke Terminal (CO’Tl Power Unit

DDL 221 DuaLine Plus Central

Office Terminal (COTj Common

unit

DDL 230 DuaLine Plus Central

Offiice Terminal (CO”ll Line Unit

DDL 391 DuaLine Plus Une Unit

DDL 190 DuaLine Plus Remote

Terminal Simulator

Digital Signal lYak-A-Tone

Model 92-5

If corrections are required in the attached document use Form-3973 as described in

Section 000-010-015.

If manufacturing and/or design problems are encountered, refer to Section

SW 010-522-906 for procedures on filing an Engineering Complaint.

ORDERING PROCEDURES

Components of the DuaLine Plus System maybe ordered via the southwestern Inventoxy

Management System (SWIMS).

To order additional copies of this practice, use WSCM 363-400-801 SW.

PROPRIETARY

Not for use or disclosure outside Soutwestem Bell

Telephone Company except under written agreement.

mWescom

~ACharles industries Company

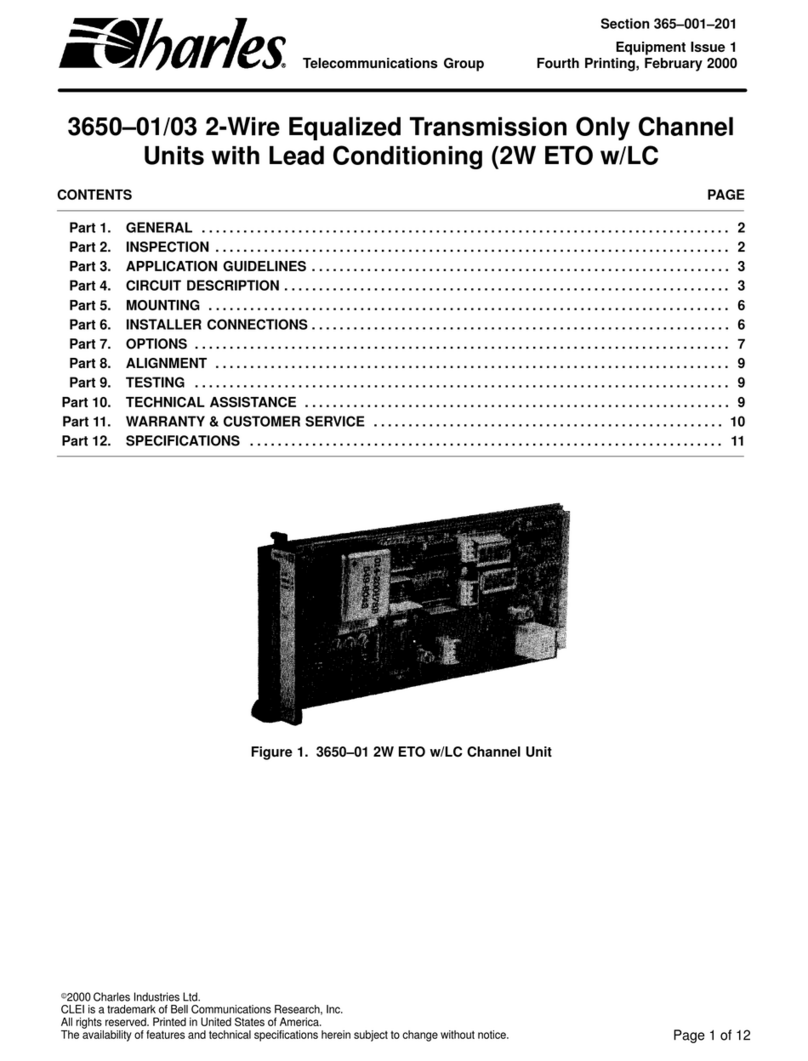

Section DDL-201-301

Eauioment Issue 1

Second Printing,” December 1992

Wescom@DDL201 DuaLine Plusm

Central Office Terminal Shelf (23-inch)

General Description, InstallationAnd Turn-Up Procedures

clXl~Code: SIMCWU091?A

CONTENTS PAGE

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . ,. . . . . 1

FCC PART 15 SUBPART B, CLASS A

REQUIREMENTS .........................1

SITE REQUIREMENTS . . . . . . . . . . . . . . . . . ...1

INSPECTION .....!... ...................2

COT SHELF INSTALLATION ...............2

POWER CONNECTIONS ...................5

SIGNAL CABLING ........................5

COT MODULE INSTALLATION

AND POWER UP . . . . . . . . . . . . . . . . . . . . . . 6

PRE-PROVISIONING .....................8

GENERAL

The Central Office Terminal (COT) is arack mount

shelf unit and is located in the CO or CEV. One fully

equipped shelf is capable of supporting 12 DDL1XX

RT units. The COT is comprised of the following

units:

●DDL201 COT (23-inch) Shelf; the rack

mountable shelf is installed in aCentral Office

(CO) or Controlled Environment Vault (CEV)

which contains the COT units.

●DDL21 OCOT Power Unit; the plug-in power

supply in the COT shelf (one per shelf).

●DDL221 COT Common Unit; the plug-in unit

which performs common functions, such as

alarms, for the COT shelf (one per shelf).

cDDL230 or DDL235 COT Line Unit; the plug-in

unit which connects two lines from a

co-located CO or Digital Loop Carrier Remote

Terminal (DLC RT) to the local loop which is

being used as a 2-wire Digital Subscriber Line

(1 to 12 per shelf).

This practice is reprinted to make reference to the

DDL235 COT Line Unit. An editorial update is also

included.

FCC PART 15 SUBPART B, CLASS A

REQUIREMENTS

The A92-DDL201 COT Shelf, when configured with

the C91 -DDL21 O Power Supply Unit, the A91 -DDL221

Common Control Unit, and C91 -DDL230 Line Units,

(or their later issues), complies with the limits for a

Class Adigital device pursuant to SubpaR 15 of FCC

Rules. These requirements are designed to provide

reasonable protection against interference when

operated in acommercial environment, This

equipment generates and uses radio frequency

energy, and if not installed and used properly in

accordance with this user’s manual, may cause

interference to radio communications. Operation of

this equipment in aresidential area is likely to cause

interference; in which case, the user, at his own

expense, will be required to take whatever measures

may be required to correct the interference.

SITE REQUIREMENTS

The COT (23-inch) Shelf mounts in astandard

23-inch relay rack and occupies 7inches of vertical

rack space (four 1.75 inch rack mounting spaces).

One shelf has positions for one DDL221 COT

Common Unit, one DDL21 OCOT Power Unit and up

to 12 DDL230 or DDL235 COT Line Units, 25-Pair

Amphenol type connectors are used for CO line and

DSL (Digital Subscriber Line) connections.

The shelf is locally powered with -48Vdc Battery and

ground connections.

Tool Requirements

The following tools are required for mounting the

Shelf:

●Aflat blade screwdriver for Number 6screws

used on the COT mounting bracket.

●Afastening tool for whatever rack fasteners

are used.

●Wire cutting and stripping tools for power

wiring.

●TooIs for fabricating 25-pair cables with

Amphenol-type connectors.

●Test gear for checking COT voltages.

@1992Charles IndustriesLtd.

All rightsreserved

Wescom is aregisteredtrademarkof Charles IndustriesLtd.

Dual-ins Plus Is atrademarkof Charles IndustriesLtd. Page 1of 9

printed in UnitedStates of Amerioa.

The availabilityof features and technicalapeoificationshereinsubjectto change withoutnotice,

Section DDL-201-301

+AIR FLOW fylUST NO-

BE RESTRICTED

‘} MAXIMUM OF 5COT

SHELVES IN AGROUP.

MAxWJJy &I;OUPS

iMINIMUM OF 3.5 INCHES

(2u) BETWEEN THE 2

GROUPS OF SHELVES. NC

EQUIPMENT SHOULD BE

MOUNTED IN THIS SPACE

MAXIMUM OF 5COT

SHELVES IN AGROUP.

igure 1. COT Shelf

J

—AIR FLOW MUST NOT

BE RESTRICTED

Orientation For ProDer

Heat Dissipation –r-

Rack Requirements

●Astandard 23-inch relay rack (channel or

unequal flange) for COT mounting.

●Maximum of 10 shelves per rack for proper

heat dissipation. See Figure 1.

●Primary surge protection should be provided

for any exposed lines.

●Power from afused battery distribution panel.

Environmen@l Requirements

●Asheltered temperature-controlled

environment.

●An ambient temperature within the range of

32° to 122° F(0° to 50° C).

●Sufficient space should be provided both in

front of and behind the shelf to allow free

access to the equipment.

INSPECTION

Inspect the equipment thoroughly upon delivery. If

the equipment has been damaged in transit,

2

immediately report the extent of damage to the

transportation company.

Wescom equipment is identified by amodel and

issue number imprinted on the front panel or located

elsewhere on the equipment. Each time amajor

engineering design change is made on the

equipment, the issue number is advanced by one

number on any following models that are

manufactured. Therefore, be sure to include both

the model number and its issue number when

making inquiries about the equipment.

Each COT module is shipped in astatic-protective

package to prevent electrostatic charges from

damaging CMOS devices. Aunit intended for future

use should be tested as soon as possible and

returned to its protective package for storage.

~< STATIC-SENSITIVE ~<

COT SHELF INSTALLATION

After the site requirements have been verified, the

COT shelf may be installed at the specified location.

(a) Locate the COT shelf and obtain the appro-

priate shelf mounting hardware.

(b) Determine and obtain the tools required for

the shelf mounting hardware.

NOTE

~

The COT shelf should be empty during the shelf

mounting procedures. If any modules are in the

COT, remove and store them maccordance with

static sensitive device storage procedures.

d‘

Section DDL-201-301

COT Shelf Mounting Brackets If the COT shelf mounting brackets are shipped

The position and orientation of the shelf mounting loose or need to be reinstalled, use the following

brackets is dependent on the type of rack used for mocedures.

COT mounting ~The shelf may be front mounted in a“

Front Mount Bracket Position

standard channel rack (5 inch projection) or rear For astandard front mount rack, the mounting

mounted in an unequal flange duct type rack. The bracket must be fastened to the two mounting holes

shelf may be shipped with the mounting brackets closest to the front of the shelf.

installed in one of two mounting positions or shipped (a) Position one of the mounting brackets at the

loose (see Figure 2).

BRACK~ BRACKHG

MOUNTING MOUNTING

BRACK~ BRACK~

/FRONT

UNEVEN

FLANGE

first set of holes (Figure 3). The flange of

the bracket is toward the rear of the shelf.

(b) Screw the bracket in place from inside the

shelf using the two #6 mounting screws for

the bracket.

(c) Fasten two #6 nuts to mounting bracket

screws.

(d) Repeat for the other side of the shelf.

Rear Mount Bracket Position

The shelf is mounted from the rear of the rack and

the second set of shelf mounting holes (second

position from front) is used for the two shelf

mounting brackets.

(a) Position one of the mounting brackets at the

second set of holes (Figure 4). The flange of

the bracket is toward the front of the shelf.

(b) Screw the bracket in place from inside the

shelf using the two #6 mounting screws for

the bracket.

(c) Fasten two #6 nuts to mounting bracket

Figure 2. Mounting Bracket Orientation (Top View) screws,

(d) Repeat for the other side of the shelf,

.........

MO[

BRACK~ /~&&~z

FRONT C&

e?” MOUNTING

BRACKET

K

3“

NUT

Figure 3. Shelf Mounting Bracket Position for Standard Front Mount

3

Section DDL-201-301

Rack Mounting, Front mount Rack Mounting, Rear Mount

(a) From the front of the relay rack, position the (a) From the rear of the relay rack, position the

COT shelf in its relay rack mounting location COT shelf in its relay rack mounting location

(Figure 5). (Figure 6),

(b) Secure the COT shelf in its relay rack loca- (b) Secure the COT shelf in its relay rack loca-

tion using the appropriate rack mounting tion using the appropriate rack mounting

hardware in the left and right mounting hardware in the left and right mounting

bracket. bracket.

/

MOUNTING””?

\

BRACKET i..,.<,z:,:,:,:,:

SCREWS .,,,:~

..:::::.:,.,.,

FRONT S

o

{

Q

REAR OF SHELF

IMOUNTING

BRA\C~ /&

/

-- -. a?

/

,

MOUNTING

BRACK~

NUT

..

IUNEQUAL

IFLANGE

DUCT k

Figure 4. Shelf Mounting Bracket Positions for Uneven Flange Rack, Rear Mount

F387(b)

Figure 5. Front Rack Mount

-,.

P3S7(b)

Figure 6. Rear Rack Mount

4

b

.

u

,, ‘w

‘b

Section DDL-201 -301

POWER (a)

(b)

(c)

Obtain the appropriate gauge and length

wire for the frame ground (#1 4AWG is rec-

ommended). Connect one end to one of the

FRAME GND terminals of the COT shelf TB-1

terminal block (see Figure 7). Connect the

other end to office frame ground.

The COT is powered from the CO battery. It is rec-

ommended that the shelf be powered from afused

power distribution panel. Locate the (Y3T shelf

power terminal strip and connect the shelf power

wiring as shown in Figure 7. It is recommended that

14 or 16 AWG stranded wire be used for -48V and

ground. DO NOT exceed 14 feet of 16 AWG.

CAUTION Obtain the appropriate gauge and length

wire for the power ground. Connect one end

to one of the BATT GND terminals of the COT

shelf TB-1 terminal block (see Figure 7).

Connect the other end to the power ground

source (power distribution panel).

TB-1 5A (Recommended) Obtain the appropriate gauge and length

~;

THESE TERMINALS

1ARE COMMON

e= ‘~f-~D —

—

THESE TERMINALS

1ARE COMMON

s

THESE TERMINALS

@ARE COMMON

BATT

-48V wire for the -48Vdc battery. Connect one

end to one of the BATT-48V terminals of the

COT shelf TB-1 terminal block (see Figure

7). Connect the other end to the CO -48Vdc

battery source (power distribution panel).

BATT

-48V

BATT

GND

BATT

GND

FRAME

GND SIGNAL CABLING

Central Office line terminations and Digital

Subscriber Loop terminations are accessed through

connectors J15 and J16 respectively (Figure 8).

8KHZ EXT

INPUT

8KHZ

OUTPUT

CAUTION

A

B

Figure 7. COT Shelf Power Terminal Strip

TB-1

J14.

66: :66 J12 .

. . 56::65

. . J1l. J1O.

56: :55 56: :555?

:: ’130 ::

. . 56: :66 . .

. . . .

. . . . . . . .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. .

. . w+’ . .

. .

. .

. .

. .

. .

. .

. .

. .

. . . .

,.

. .

. . . .

. . . . . .

. . . .

. . . . . . . .

. . . .

. .

. . . . . . . . . .

. . . . . .

. .

:: TB2::T63:: . .

. .

. .

. . . .

. . . . . . . .

. .

. . . .

. . . . . .

. . 25 PAIR AMPHENOL (FEMALE)

/

,. . . . . . .

. . . . . .

. . . . . .

. . . . . . . .

. . . . . . . .

. . . . . . . .

. . . . .,

. . . . . .

. . . . . . . .

. .

. . . . . . . .

. . . .

. .

. . . .

. . . .

. . . .

. . ,.

. . . .

. . . .

. . . .

. . . .

. . . .

. .

. . . .

. . . .

. . . .

.,

.,

. .

. .

. . . . ,. . .

. .

. .

. . . .

. . ,.

. . . .

. .

. . . . . .

. .

. .

. . . .

. . . .

. . . .

. . . .

. .

. . . . . .

. . . . ,.

. . . .

2.1::;{

. . . . 2..1

. . .

. . . . . .

. . . .

. . . . . .

/

. . . . .. . . . . . . . . . .

. . . . . . .. . . . . . . . . . .

::1 2::1 2:”1 2;:1 2;:1 2:;1 2;:1 2L:1 2::1

2::1 2;:1 2

. .

%-~DCHANNEL DATA

. .

I

P3B6 Figure 8. COT Shelf Backplane Connectors

8

-#

5::

:/

Section DDL-201 -301

CO Line Terminations

The CO line terminations are made via a25-pair Am-

phenol connector (JI5) on the COT shelf backplane

(Figure 8).

Table 1. COT Shelf CO Line and 2W Diaital

Subscriber Loop Terminations

(a) Obtain the appropriate type 25-pair cable for

the CO lines between the COT shelf and the

frame. Connect the cable to an appropriate

25-pair Amphenol-type male connector.

Refer Table 1for wiring information.

(b) Secure the connector to the J15 female

connector of the COT backplane.

(c) Terminate the other end of the cable at the

distribution frame.

Digital Subscriber Loop Terminations

The 2-Wire Digital Subscriber Loop terminations are

made via a25-pair Amphenol connector (JI 6) on

the COT shelf backplane (Figure 8).

(a) Obtain the appropriate type 25-pair cable for

the DSL lines between the COT shelf and the

frame. Connect the cable to an appropriate

25-pair Amphenol-type male connector.

Refer Table 1for wiring information.

(b) Secure the connector to the J16 female

connector of the COT backplane.

(c) Terminate the other end of the cable at the

frame.

Alarm Connections

The COT MAJOR/MINOR AUDIBLE COAS (Central Of-

fice Alarm System), MAJOR/MINOR VISUAL COAS,

ACO (Alarm Cut-Off), MAJOR/MINOR E2A, and SYS-

TEM ID alarm points are accessible at the COT shelf

backplane. Open relay contacts indicate non-alarm

condition. Wire-wrap to the backplane pins of TB2

2W DIGITAL

SUB~OC~~BER

1

2

COT

J16

=

1;;6

2T27

R2

3;;8

4T29

R4

5T30

R5

T26

RI

3

“J

T29

R4

4

5

++

6

7T32

R7

t

+

15 T40

R15

16 T41

R16

17 T42

R17

and TB3. It is recommended that 22 AWG wire be

used. Refer to Figure 9.

COT MODULE INSTALLATION AND

POWER UP

There are three types of DuaLine Plus modules used

in the COT shelf; DDL21 OCOT Power Unit, DDL221

COT Common Unit, and DDL23X (DDL230 or

DDL235) COT Line Unit (depicted in Figure 10). One

COT Common Unit and one COT Power Unit are nec-

essary for each shelf. They can power and control

from one to twelve COT Line Units and their respec-

tive DDL1 XX Remote Terminals (RT) at the sub-

scriber sites. Each COT Line Unit provides the inter-

face between two POTS lines and the DDL1XX RT,

6

T33

R8

8

9

18 IT43

R18

T35

R10

10

1

+-HE 11

wT37

R12

12 d

ti

;

Section DDL-201-301

..— —. ————— —————

BACKPLANE AIARM

PIN CONNECTIONS

u

rB2 TB3

e13 *10

0eMAJOR

evlsuAL

oALARM

o e

e @ MAJOR

*$LILI~E

@Q: ACO

e(NOTE) :W:l

e

e=*SY~:EM

ee~

*

———— ——_ 1

I

I

I

I

I

I

/

I

I

I

I

4

eI

eNOTE: ALL ALARM CONTACTS AREl

SHOWN IN THE OPERATED

I1f$?N%?%! NON-AIARM I

P3.W— ——— ——— ——— ——— ——— ——— ——— I

/

I

IBACKPIANE AIARM

PIN CONNECTIONS

::~+k$ii~. fiJiE!By

—————— —— CUSTOMER)

REMOTE ALARM CLEAR CONFIGURATION

NOTE: THE REMOTE ALARM CLEAR GROUND AND SENSORIS

SUPPLIEDBY THE DDU21 COT COMMON UNIT.

---

Figure 9. COT Common Unit Backplane External Alarm Pinout

Power-Up COT Shelf

Apply power to the fused power distribution panel

feeding the COT shelf. Using aDC voltmeter, check

for proper voltage across terminals 1(BATT-48V)

and 3(BATT GND) of the Shelf Power Terminal Strip

(TB-1 ). Verify avoltage between -42 and -56Vdc.

Install/Test COT Modules

After verification of proper voltage at the power ter-

minal strip (TB-1 ), COT module installation/test can

occur:

(a) Raise the locking bar at the top of the shelf.

(b) Insert and seat the COT Power Unit into its

slot (see Figures 10 and 11). The POWER

LED lights steady. If it does not light, there is

aproblem with the module or shelf power.

Check the COT Power Unit fuse and shelf

power at the shelf power terminal strip.

(c) Insert and seat the COT Common Unit in its

., slot next to the Power Unit (see Figures 10

and 11).

(d) Insert and seat the COT Line Units in their

assigned slots per facility plan (see Figures

10 and 11). The POWER/SELF TEST LED of

each module lights steady. If the POWER/

SELF TEST LED blinks continuously (self test

fail) or does not light for any COT Line Unit,

replace that module.

NOTE

If no corresponding DDLIXX RT unit is installed

and connected to the Digital Subscriber Loop, the

COT Common Unit Audible and Visual Alarms will

activate unless the COT Common Unit has been

placed in the ‘Pre-provision’ mode. Press the

ACO (AL4RM CUT OFF) pushbutton on the COT

Common Unit to cancel the alarms.

(e) After all equipped COT modules are in-

stalled, press the LED TEST pushbutton on

the Common Unit. All module LEDs should

light. If all LEDs do not light, replace module.

NOTE: The DDL23X COT Line Unit’s POWER/

SELF TEST LED will flash to indicate that full

idle power is being applied to the Digital Sub-

scriber Loop.

(f) Swing the locking bar (located at the top

front of the shelf) down into the latched

position.

Section DDL-201 -301

9

,!

PRE-PROVISIONING

The Pre-provisioning feature allows the user to install

COT Line Units in the COT Shelf without generating

alarms prior to the Line Units being synchronized

with the associated Remote Terminal (RT). This

allows the installation of the Line Units and the RTs at

different times. When aLine Unit synchronizes with

an RT, the Pre-provisioning feature for that line is

canceled and normal alarm reporting resumes. To

activate this feature, the following three-step

procedure must be performed.

(a)

(b)

(c)

(d)

(e)

(f)

(a)

Step 1

PreDare the DDL221 COT Common Unit for

Pre-rxovisionin~

Depress and hold the front panel LED TEST

push-button switch (DO NOT release).

Depress and hold the front panel ACO push-

button switch (DO NOT release),

Observe that the MAJOR AND MINOR LEDs

flash three times at afast rate and then ex-

tinguish.

Release the LED TEST and ACO push-but-

tons.

Observe that the Common Unit MAJOR AND

MINOR LEDs flash at aslow rate.

The DDL221 COT Common Unit is now

“Ready” for pre-provisioning.

Step 2

Install COT Line Uni@

Install the DDL Line Units in the shelf that are

to be pre-provisioned.

NOTE

IAny Line Units that were previously installed will I

not be pre-provisioned unless they ‘are unplugged

at this time (for at least five seconds) and then

[re-insta//ed.

(a)

(b)

(c)

(d)

(e)

Step 3

Activate Pre-movisionin~

Observe that the Common Unit MAJOR AND

MINOR LEDs are flashing at aslow rate.

Depress and hold the front panel LED TEST

push-button switch (DO NOT release).

Depress and hold the front panel ACO push-

button switch (DO NOT release).

Obsewe that the Common Unit MAJOR AND

MINOR LEDs flashes three times at afast

rate and then extinguish.

Release the LED TEST and ACO

push-buttons.

NOTE

If the “Ready” period of the COT Common Unit is

allowed to time out before the pre-provisioning is

Activated, all Line Units installed in the shelf (in

Step 2) will not be pre-provisioned and will repoti

alarm conditions. The “Ready” period of the

DDL221 COT Common Unit times out in twenty

minutes.

NOTE

I If power to the shelf is interrupted, anv Line Unit I

Iinstalled in the shelf will not” be pre-provisioned

and will reDort alarm conditions.

Alarm LEDs on pre-provisioned COT Line Units will

be lit. However the COT Common Unit will not report

alarms from these COT Line Units (LEDs or Relays).

The COT Common Unit will report alarms from in-

service COT Line Units.

Technical Assistance

If difficulty is encountered

mounting assemblies or

assistance is required,

with the installation of the

modules, and technical

contact the Technical

Services Department of Charles industries-Wescom,

by calling:

1-708-806-8500

FAX 1-708-806-6231

u

Wescom

DDIJ?1O

COT POWER UN~

@POWER

1

FUSE

7.5A

.. ~

STATIC-SENSITIVE

rl

LLJ

91-DDL21O 1SS

DDI21O

COT POWER UNIT

Pos 1

=

p:

UNIT

@

@

:

@

L

............

~

Pos 3

.......................

=

COT

LINE

UNIT

@

@

e

@

@

L

,,,,.:.:.:.:.:.:.:.,,

Wescom

DDL221

COT COMMON UNI1

lhRlylJ3

@+%T

@AGO

~

STATIC-SENSITIVE

LI-J

91-DD1221 1SS

DDL221

POS4 Pos 5

. ,,

-:,0;

[

p:

UNIT UNIT

J

6363

:+=.:.:.:+:!.. :.:.:.2:.:.:.:.:..

COT COMMON UNIT

Figure 10, DuaLine Plus COT Modules

Pos 8

?=

:,0:

UNIT

@

@

@

@

@

1- ..,.,.,.,.,.,.,,,.,.,,

Pos 9

..........

?=

flog

UNIT

@

@

@

e

@

1- ,.,,,.,.,.,.,.,.,.:.,.

Figure 11. Fully Equipped COT Shelf Module Positions

Section DDL-201-301

‘RE1

Wescom

DDL23X

COTLINE UNIT

@SIGNAL

@ALM ON ON ON

@B;Y ON OFF ON

@‘3:Yor o/J Op

ALMALMALM

COT RT CBL

~

STATIC-SENSITIVE

rl

l!-

L-d

91-DD123X ISS

DDK30 OR

DDL235

COT LINE UNIT

Pos 1:

.................

,:,:,:,:,.:<.:.....,.:.,

1

DD1221

COT

COM

UNIT

@

@

@

@

L

Au&i

Pos 14

.:,:,:.:.:.:.+:::y::fi>~:~:;

..............

JDD1210

COT

POW&R

@

1

1- .....................

,,,,,,:,:,:,:.:.:.:........,..,,,.,,,.,,

Table of contents

Other Charles Network Hardware manuals

Popular Network Hardware manuals by other brands

Seagate

Seagate Exos AP 4U100 Installation and maintenance guide

QNAP

QNAP NVR-101 user manual

IBASE Technology

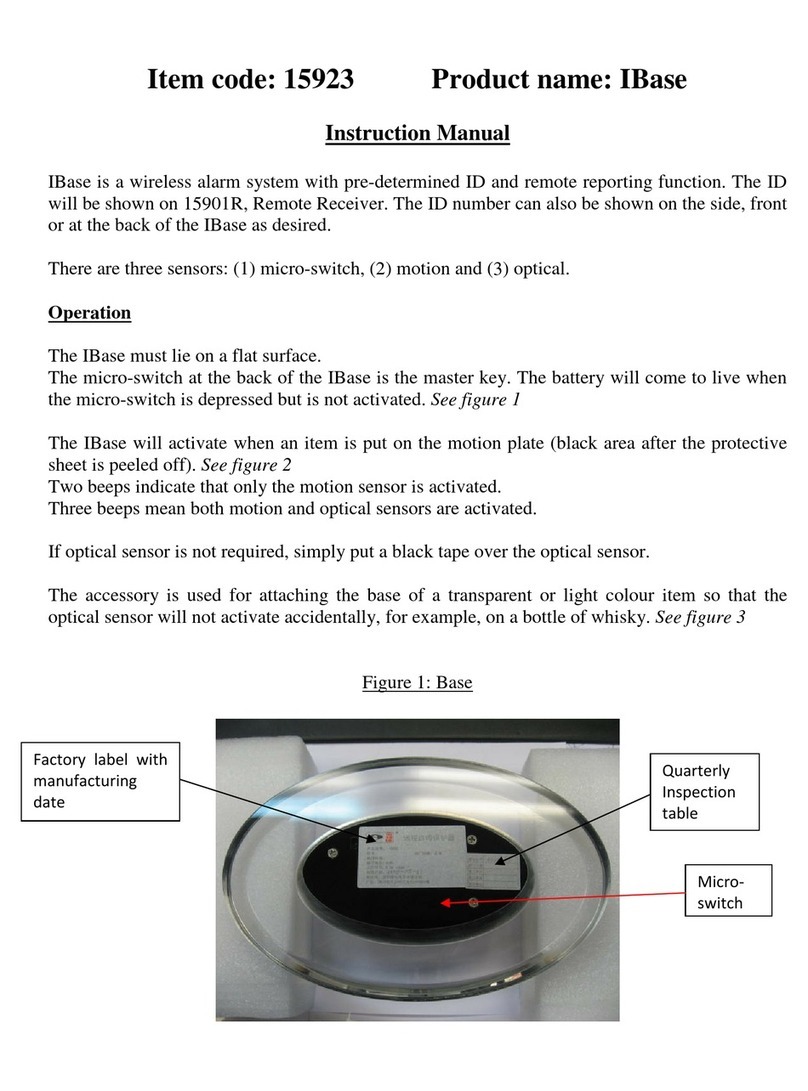

IBASE Technology 15923 instruction manual

HMS Networks

HMS Networks Anybus Wireless Bolt LTE Startup guide

Watchguard

Watchguard Firebox T85-PoE Hardware guide

Tosibox

Tosibox Central Lock instruction manual

Westlock Controls Corporation

Westlock Controls Corporation Intellis 7604 Installation and operation manual

Flexwatch

Flexwatch FW 3850 user manual

Apposite

Apposite Netropy N91 Hardware guide

MikroTik

MikroTik RBLDF-5nD quick guide

MikroTik

MikroTik CRS504-4XQ-OUT quick start guide

Nokia

Nokia G-240W-J Quick reference guide