Unit 17. Millbrook Business Park, Sybron Way • Crowborough, East Sussex TN6 3JZ United Kingdom

Phone: 00

44 (0)

1892-665313, Fax:

00 44

(0) 1892-668838

• E-mail:

[email protected], Internet:

Charleswater.co.ukPPE-5034.E November 2009 Page 1 of 2

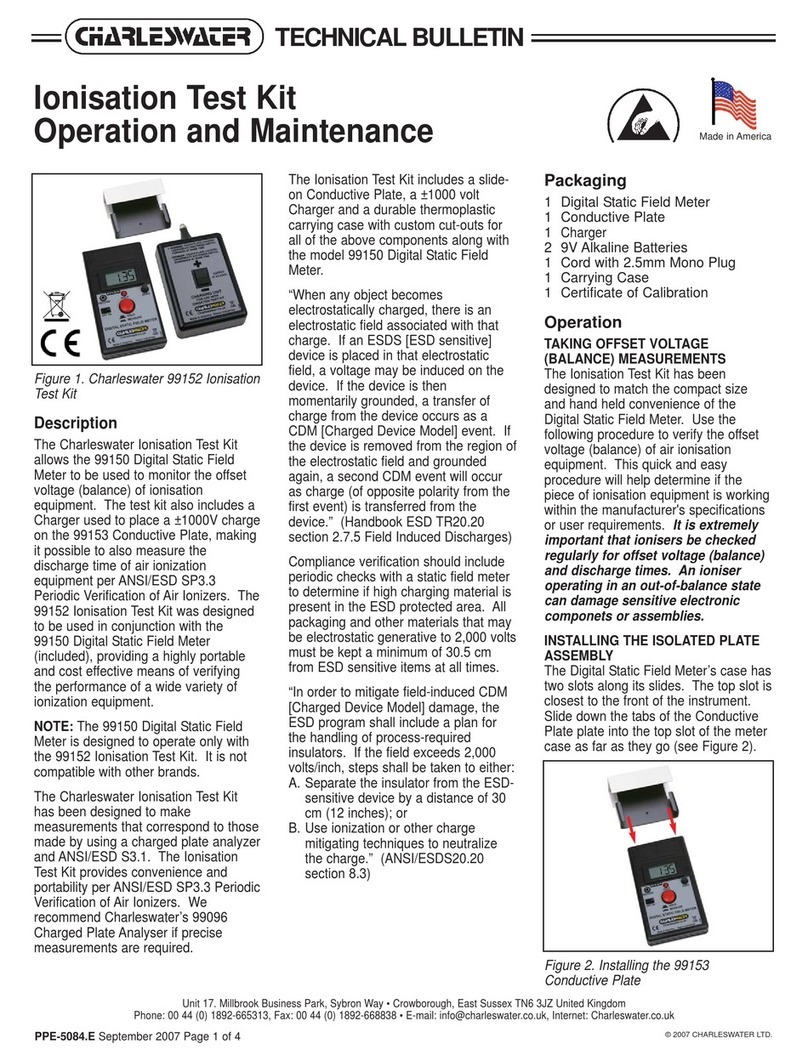

Figure 1. Charleswater 99090 Tester

Calibration Unit

Description

The Charleswater 99090 Tester

Calibration Unit is designed to

simplify the process of calibrating

the Charleswater 99000 and 99004

Combo Wrist Strap / Footwear

Tester. The calibration unit allows

the user to quickly and easily verify

whether the tester is operating within

specifications. The Calibration Unit

is a passive device, and requires no

power source. It is manufactured

with industry accepted test ranges

for both wrist straps and foot

grounders. The wrist strap pass

range is set at 825k- 35M, and the

foot ground test range is set at

825k - 35M. The Calibration Unit is

supplied calibrated to NIST traceable

standards.

Packaging

1 Tester Calibration Unit

2 Test Leads

1 Certificate of Calibration

Operation

WRIST STRAP TEST CIRCUIT

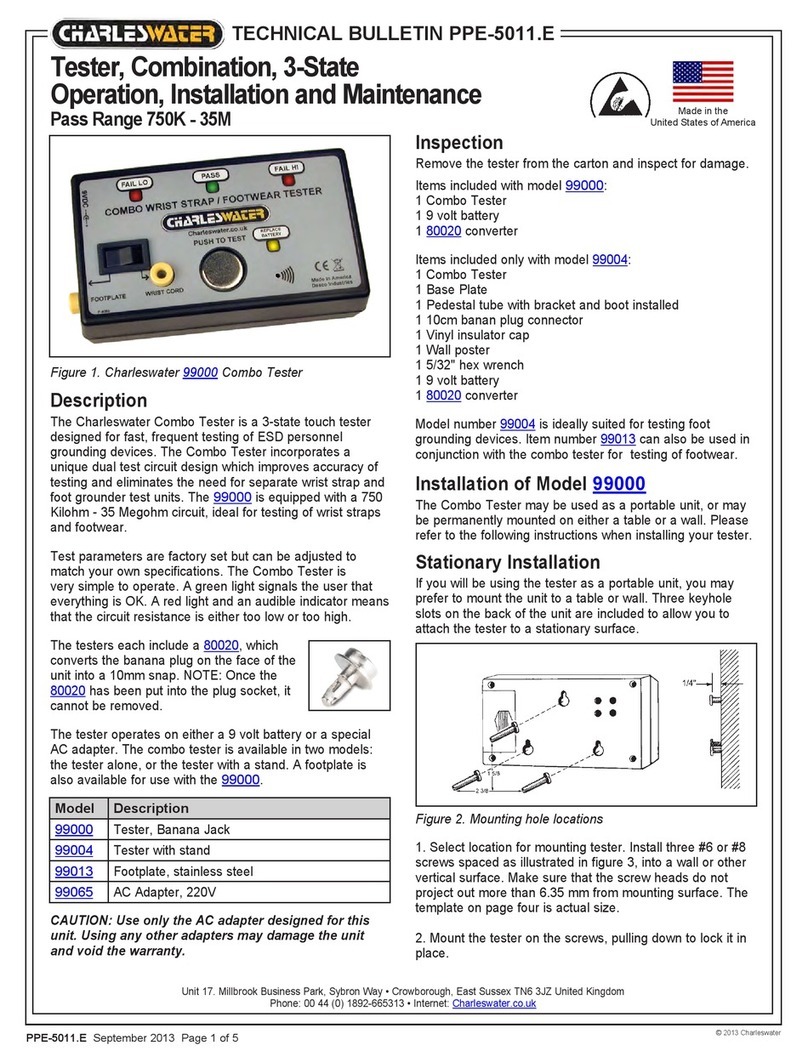

Step 1: Connect one of the test

leads to common point banana jack

“E” on the Calibration Unit. Connect

the opposite end of test lead to the

banana jack labeled “WRIST CORD”

located on the face of the Combo

Wrist Strap / Footwear Tester.

Ensure that the rocker switch on the

tester is set to WRIST CORD.

Step 2: Connect the second test

lead to the 675k jack labeled “A” on

Calibration Unit. Touch the opposite

end of test lead to tester’s test

plate and press down with enough

pressure to activate the test circuit.

Observe the LED’s for the proper

response as indicated below. Be

sure to hold the cord at an insulated

point, so that the resistance value is

not affected by the body.

Resistance Value Test Output - LED

Red jack “A” - 675k: Red (FAIL LO)

Green jack “B” - 825k: Green (PASS)

Green jack “C” - 35M: Green (PASS)

Yellow jack “D” - 40M: Red (FAIL HI)

Step 3: Repeat the procedure

testing across jacks B, C, and D on

the Calibration Unit. The different

resistance ranges should give

the display shown above. If the

tester does not meet calibration

specifications, contact Charleswater

for calibration.

Tester Calibration Unit

Operation and Maintenance

TECHNICAL BULLETIN

© 2009 CHARLESWATER LTD.

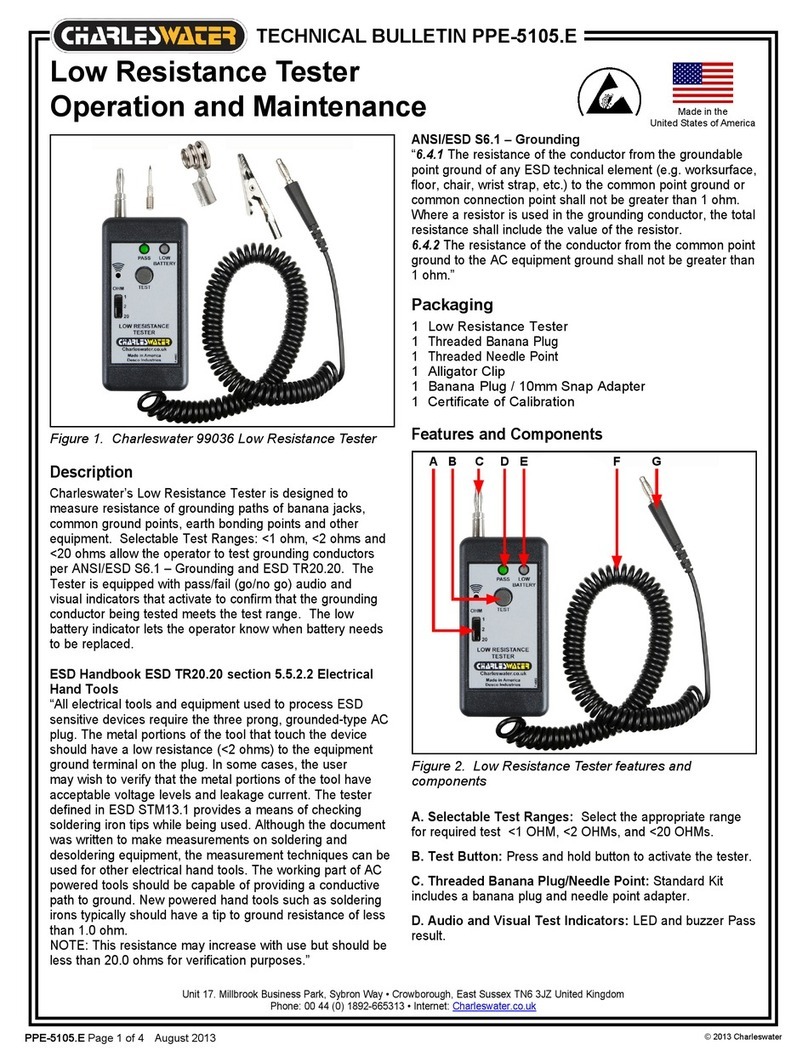

Ensure that the rocker switch on the

tester is set to FOOTPLATE.

Step 2: Connect the second test

lead to the 675k jack labeled “A” on

Calibration Unit. Touch the opposite

end of test lead to tester’s test

plate and press down with enough

pressure to activate the test circuit.

Observe the LED’s for the proper

response as indicated below. Be

sure to hold the cord at an insulated

point, so that the resistance value is

not affected by the body.

Resistance Value Test Output - LED

Red jack “A” - 675k: Red (FAIL LO)

Green jack “B” - 825k: Green (PASS)

Green jack “C” - 35M: Green (PASS)

Yellow jack “D” - 40M: Red (FAIL HI)

Step 3: Repeat the procedure

testing across jacks B, C, and D on

the Calibration Unit. The different

resistance ranges should give

the display shown above. If the

tester does not meet calibration

specifications, contact Charleswater

for calibration.

Made in America

Figure 2. Testing the Combo Tester’s

Wrist Strap Circuit

FOOTWEAR TEST CIRCUIT

Step 1: Connect one of the test

leads to common point banana jack

“E” on the Calibration Unit. Connect

the opposite end of test lead to the

banana jack labeled “FOOTPLATE”

located on the side of the Combo

Wrist Strap / Footwear Tester.

Figure 3. Testing the Combo Tester’s

Footwear Circuit