9000 SERIES OPERATION MANUAL

TRANSMILLE LTD. Page 4

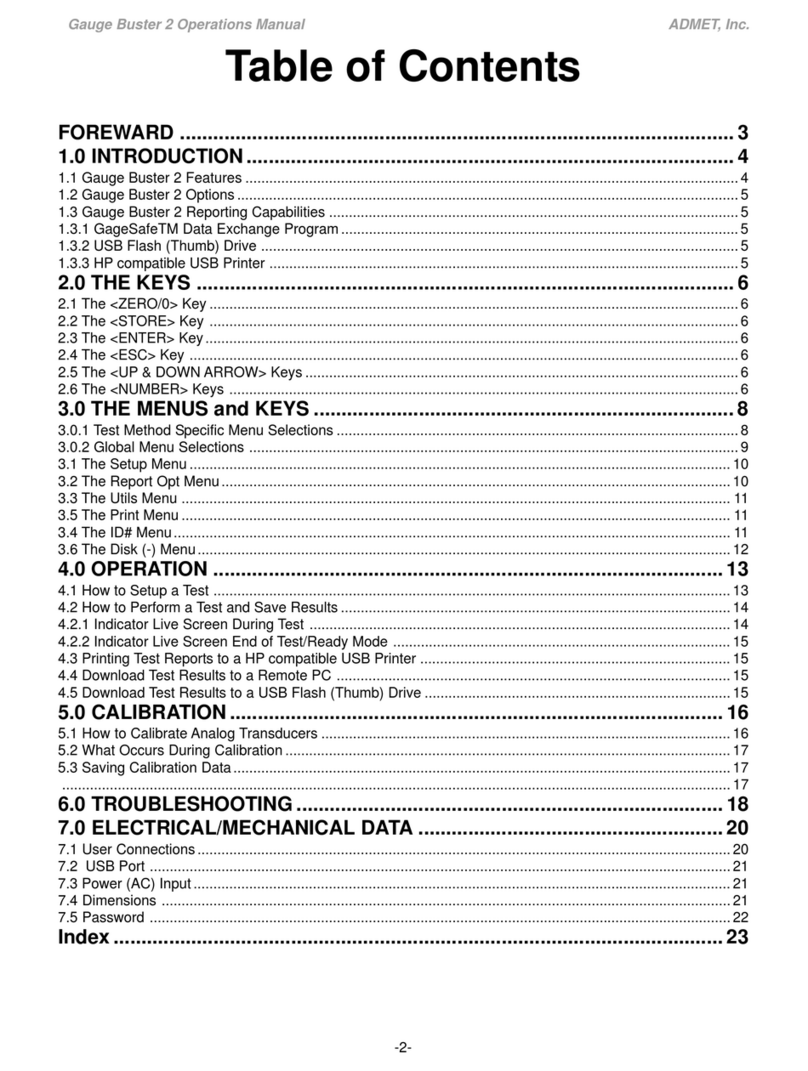

TABLE OF CONTENTS

9000 SERIES CALIBRATOR INTRODUCTION....................................................................................6

MAIN FEATURES..................................................................................................................................6

ACCURACY AND FUNCTIONALITY....................................................................................................7

TRUE MULTIPRODUCT CALIBRATION FROM ONE INSTRUMENT................................................7

PREPARING THE CALIBRATOR FOR USE........................................................................................9

INITIAL INSPECTION...............................................................................................................................9

TRANSPORTING THE CALIBRATOR .........................................................................................................9

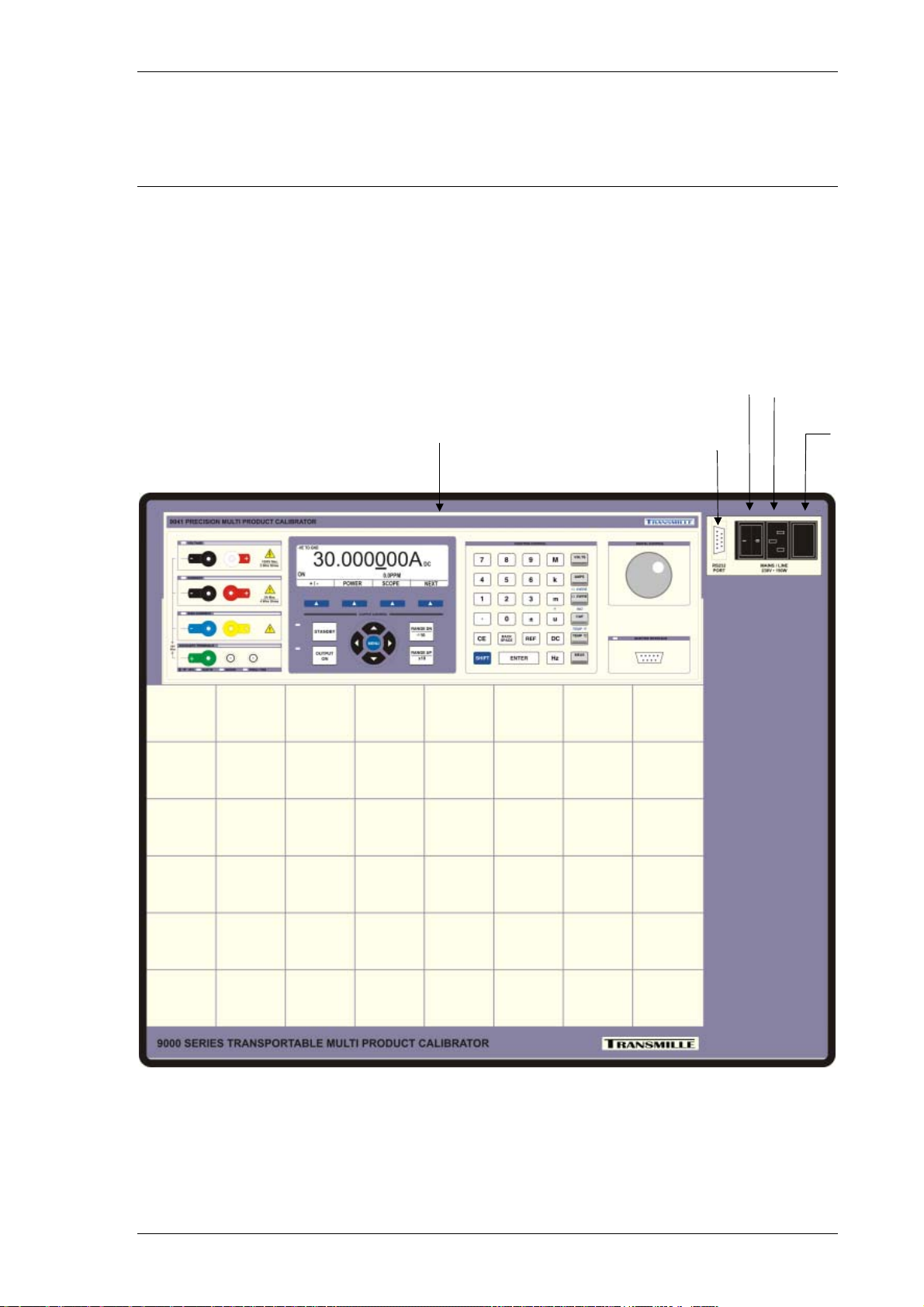

POWER / INTERFACE CONNECTIONS AND CONTROLS............................................................................10

SETTING AND CHECKING THE LINE VOLTAGE........................................................................................11

POWER LINE INLET FUSE AND RATING .................................................................................................11

CONNECTING TO A COMPUTER.............................................................................................................12

POWERING UP THE CALIBRATOR..........................................................................................................12

OUTPUT CONNECTIONS ......................................................................................................................13

OUTPUT OVERLOADS..........................................................................................................................14

OPERATION ........................................................................................................................................15

SAFETY WARNINGS ............................................................................................................................15

INTRODUCTION TO OPERATION............................................................................................................15

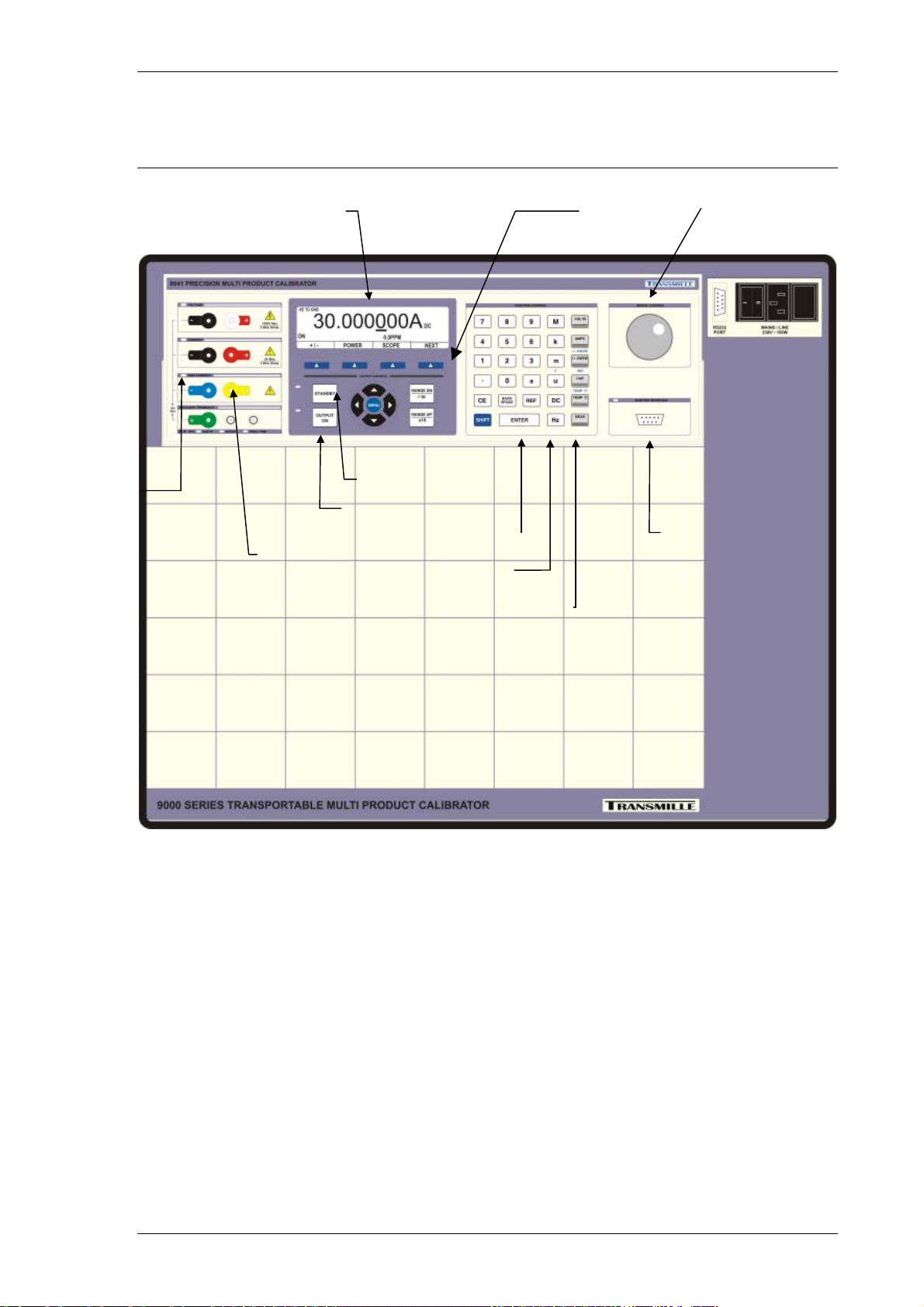

FRONT PANEL CONTROLS AND INDICATORS.........................................................................................16

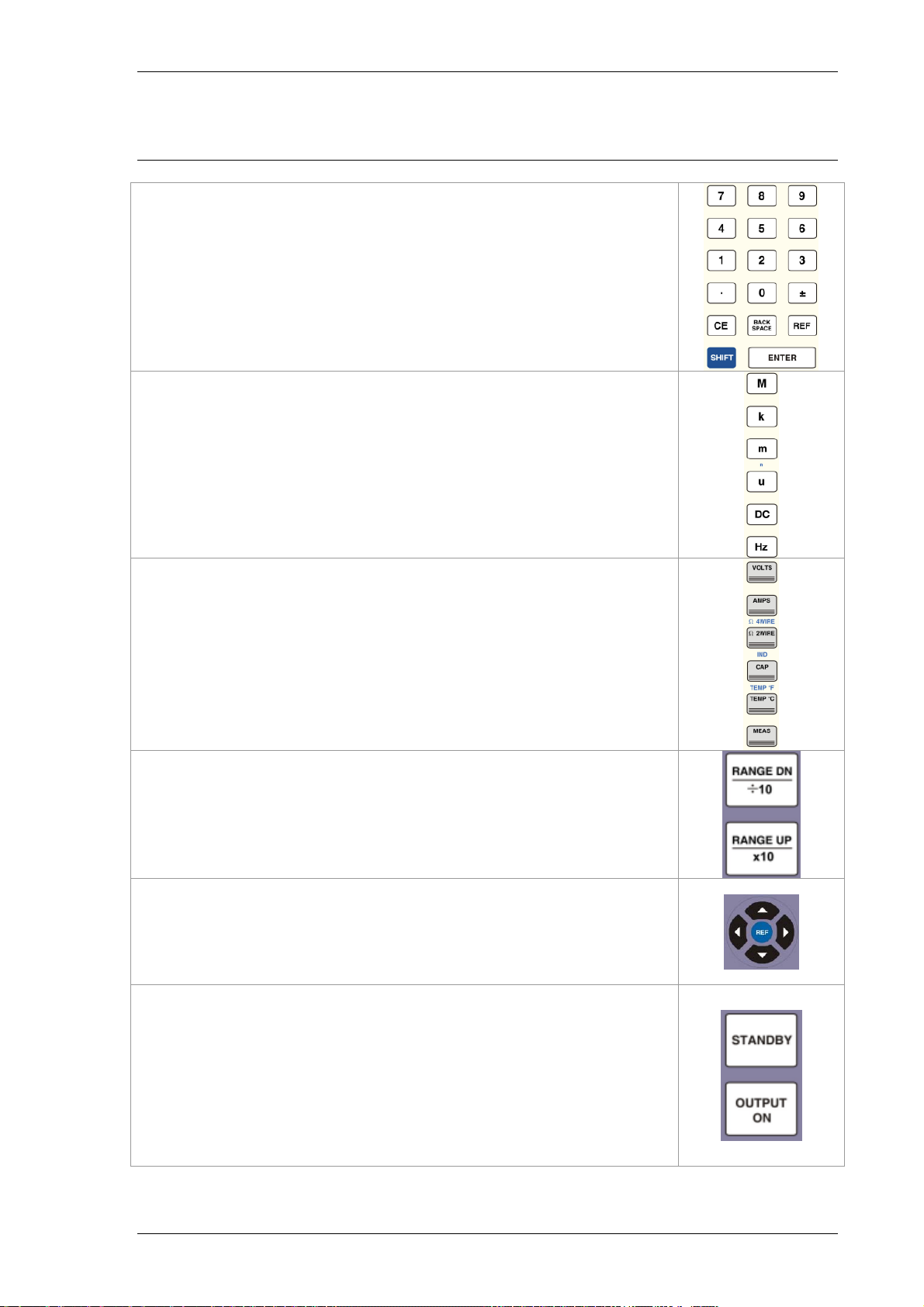

FRONT PANEL KEYBOARD ..................................................................................................................17

FRONT PANEL KEYBOARD – CONTROL SECTIONS................................................................................18

GRAPHIC LCD DISPLAY .....................................................................................................................19

DIGITAL CONTROL..............................................................................................................................20

TERMINAL STATUS LED’S...................................................................................................................21

9 PIN ADAPTER INTERFACE CONNECTOR.............................................................................................23

SETTING A VOLTAGE OR CURRENT OUTPUT.........................................................................................24

ADJUSTING THE SET OUTPUT USING THE DIGITAL CONTROL...................................................................24

AUTOMATIC DISPLAY OF % OR PPM ERROR AND REF. KEY...................................................................25

SELECTING AC AND SETTING A FREQUENCY. ......................................................................................26

RETURNING THE CALIBRATOR TO DC...................................................................................................27

SETTING 2 WIRE RESISTANCE OUTPUT. ..............................................................................................28

SETTING 4 WIRE RESISTANCE OUTPUT. ..............................................................................................30

SETTING CAPACITANCE OUTPUT.........................................................................................................32

SETTING INDUCTANCE OUTPUT (OPTION) ............................................................................................33

THERMOCOUPLE SIMULATION (OPTION)...............................................................................................34

SPECIAL FUNCTIONS AVAILABLE USING THE ‘SOFT’ KEYS.....................................................................38

CONNECTING OUTPUT NEGATIVE TO LINE EARTH OR FLOATING.............................................................38

SELECTING FRONT PANEL CONTROL ....................................................................................................39

SETTING TTL LOGIC FREQUENCY OUTPUT..........................................................................................39

SETTING PWM (MARK SPACE RATIO).................................................................................................40

SELECTING PRT (PT100) RESISTANCE OUTPUT (OPTION)..................................................................41

SELECTING AC POWER CALIBRATION OUTPUT (OPTION).....................................................................42

SELECTING DC POWER CALIBRATION OUTPUT (OPTION).....................................................................44

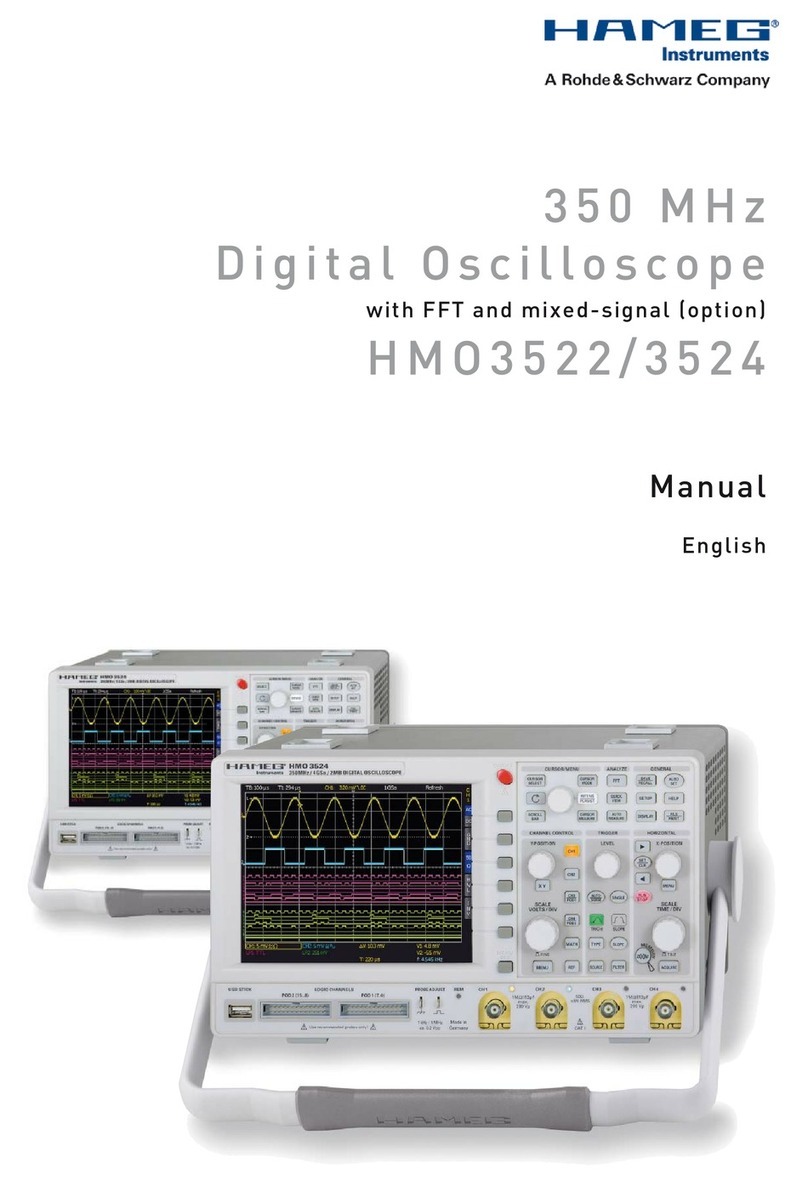

SELECTING OSCILLOSCOPE CALIBRATION OUTPUT (OPTION)...............................................................45

WARNING AND OUTPUT OVERLOAD INDICATIONS...................................................................................47

HIGH VOLTAGE TIMEOUT. ...................................................................................................................47

30 AMP TEMPERATURE CUT-OUT........................................................................................................47

DRY BLOCK TEMPERATURE CALIBRATION MODULE .............................................................................48