Unit 17. Millbrook Business Park, Sybron Way • Crowborough, East Sussex TN6 3JZ United Kingdom

Phone: 00 44 (0) 1892-665313, Fax: 00 44 (0) 1892-668838 • E-mail: info@charleswater.co.uk, Internet: Charleswater.co.uk

PPE-5084.E Page 3 of 4 © 2007 CHARLESWATER LTD.

POLARITY SELECTION

The top of the rocker switch is labeled

“+”, and the bottom is labeled “-”. To

provide a POSITIVE voltage output,

touch the plate located underneath the

charger, and press the switch forward at

the same time. To provide a NEGATIVE

voltage output, touch the plate located

underneath the charger, and press the

switch downward at the same time.

GROUNDING - IMPORTANT!

For the charger to work correctly, the

operator and the field meter must be

properly grounded. A ground path to

the touch plate must exist.

IONIZER DISCHARGE TIME

MEASUREMENTS

Use the field meter with the conductive

plate in the appropriate location for

measurements.

POSITIVE DISCHARGE TIME

MEASUREMENT

To provide a POSITIVE voltage output,

touch the plate located underneath the

charger, and press the switch forward at

the same time. Momentarily touch the

charger’s output terminal to the

conductive plate attached to the field

meter. The meter reads approximately

+1.10kV. By using a stop watch or

other timing device, determine the time

needed for the voltages to decrease

from +1.10kV to +0.10kV. This is the

positive discharge time.

NEGATIVE DISCHARGE TIME

MEASUREMENTS

To provide a NEGATIVE voltage output,

touch the plate located underneath the

charger, and press the switch downward

at the same time. Momentarily touch

the charger’s output terminal to the

conductive plate attached to the field

meter. The meter reads approximately -

1.10kV. By using a stop watch or other

timing device, determine the time

needed for the voltages to decrease

from -1.10kV to -0.10kV. This is the

negative discharge time.

IMPORTANT: A ground path must be

provided between the touch plate of the

Charger and the ground reference of

the Field Meter and Conductive Plate.

This is normally provided by holding the

Charger in one hand and the Field

Meter with Conductive Plate in the

other.

Calibration

The overall accuracy of the Ionisation

Test Kit and the Digital Static Field

Meter is ±5% nominal. The Digital

Static Field Meter is factory calibrated.

If for any reason you believe the meter

is not working correctly, please contact

Charleswater Customer Service

.

CAUTION - There are no user

serviceable parts. Any unauthorized

service will void the warranty and

result in additional repair charges.

Maintenance

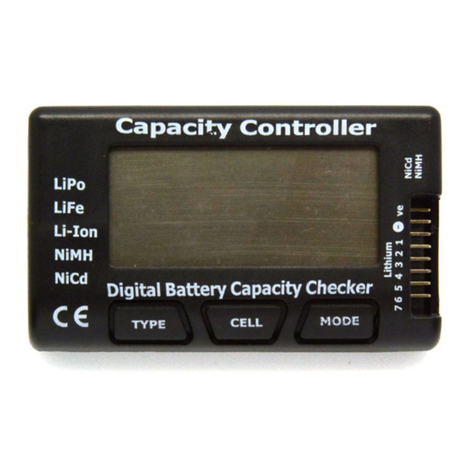

BATTERY REPLACEMENT

The Digital Static Field Meter and

operates from a standard 9 VDC

alkaline battery. Battery life is in excess

of 30 hours under normal use. When

the battery voltage drops below 6.7

volts, a battery symbol will appear in the

display. To change the battery, slide the

battery cover down at the back of the

meter and remove the battery from the

battery clip. Replace the battery with a

fresh one and reinstall the battery cover.

The battery should be removed from the

meter if its is to be stored for an

extended period of time.

The battery in the Charger should be

replaced annually and whenever you

plan an extended period of unattended

monitoring.

CLEANING

It is important to keep the insulators on

the adapter plate clean and free of

contaminates that may cause surface

leakage. To test the performance of the

adapter plate, charge the plate and note

the discharge rate in a non-ionized

area. The self discharge rate to 10% of

original voltage should not be less than

five minutes.

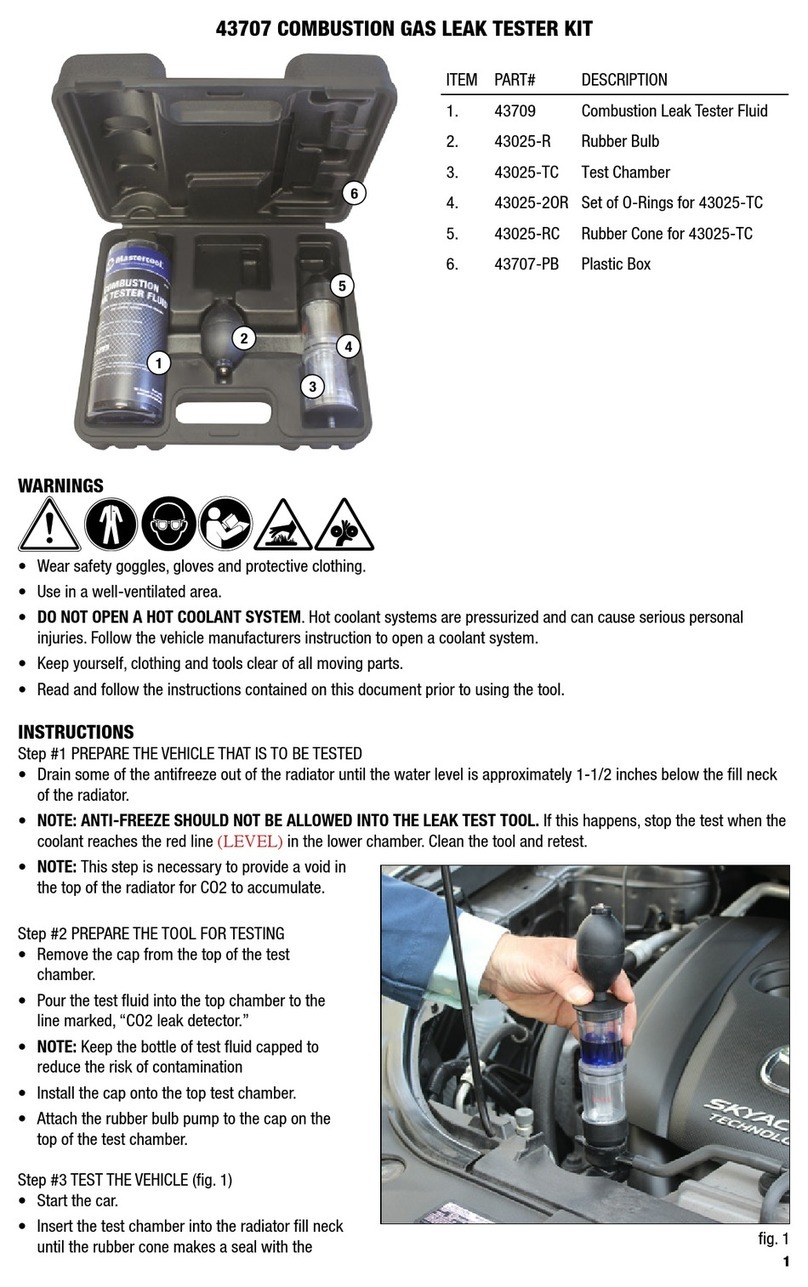

Figure 6. Taking decay measurements

The area around the aperture of the

Digital Static Field Meter must be kept

clean to ensure accurate, drift-free

readings. Never touch the aperture with

anything. To remove dust or other

particulate matter, use low-pressure

instrument-grade air. To remove more

severe contamination, spray or flush

with the smallest practical amount of

clean technical-grade of isopropyl

alcohol. Then allow the instrument to

air dry for several hours.

Specifications

Digital Static Field Meter

Display:

3.5 digits, 9.5mm digit height LCD

Response:

<1 sec., 10% to 90% equivalent to 5Hz

output

Range:

±0.00 to ±19.99 kV/25mm (kV/inch)

Accuracy:

±5% of displayed value

Environment:

0 - 50°C at 85% RH (non-condensing)

Analog Output:

2.5mm phone jack/plug

±10 mV corresponds to ±1 kV

Power:

9 VDC alkaline battery

Battery life in excess of 30 hours

Size:

6.1 cm x 10.7 cm x 3.3 cm

Weight:

0.14 kg (with battery)

Conductive Plate

Plate Capacitance:

13 picofards ± 2 picofards

Range:

0 to ± 2kV, higher voltages may be

measured

Grounding:

Connection through conductive case

of Digital Static Field Meter

Weight:

0.04 kg

Charger

Output:

1100VDC monimal, <1:A Max.

Output Terminals:

Banana / acorn assembly