Instructions

for Adjusting

the

Pfaff 481

and

Illustrated Guide for

Tape-Recorded

Instructions

Important

note

Never

use a

C-clamp

on the needle bar of

Pfaff

480 series

machines

because this

would

damage

Its

special

coating.

Furthermore,

all adjustments

which

are to be made at a

stitch

length

of "0" on

Model

Nmachines have to be carried out at a stitch length of 1.5

mm

and

with the reverse-feed control depressed, that means with the machine

set

for sewing back

wards

at

a

stitch

length

of

1.5

mm.

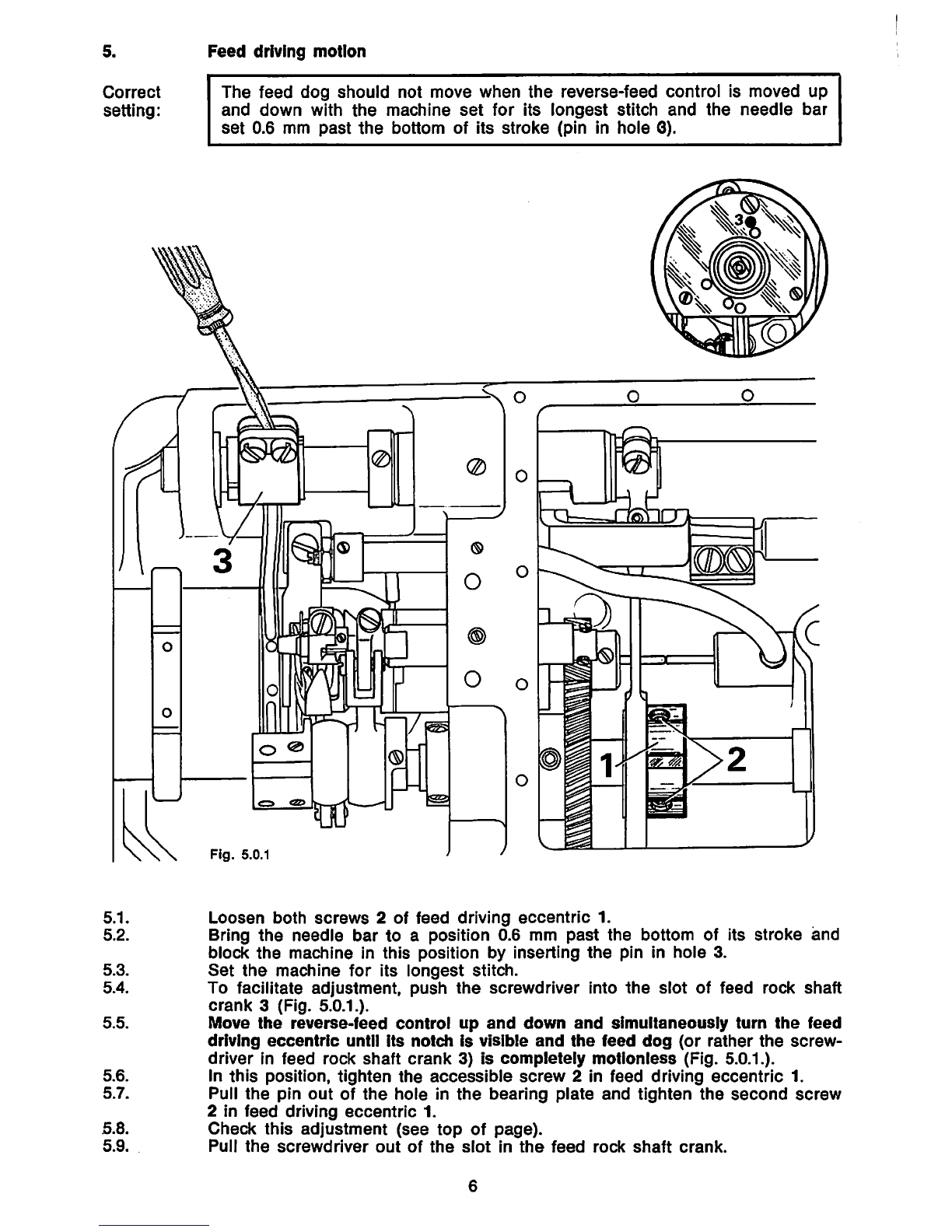

The machine can be blocked at certain positions by Inserting a 5-mm-thlck pin In one of

the holes In the bearing plate

which

Is located underneath the face cover.

When

Inserting

the

pin,

be sure to push It

In

until

Itenters the slot

In

the disc

behind

the bearing plate. For

easy Identification, the Individual holes are marked by the numbers 1 to 5 or by the appro

priate adjustment data. The abbreviations used In this connection stand for the

following:

n. o. T. =

past

the

top

of

the

needle

bar

stroke

n. u. T. =

past

the

bottom of

the

needle

bar

stroke

o. T. N. =

top

of

needle

bar

stroke

o. T. F. =

top

of

take-up

lever

stroke

Schl.-H. = 1.8 mm

past the

bottom of

the

needle

bar

stroke

The following tools, gauges and accessories are required for adjusting the Pfaff 481;

1

set

of

screwdrivers

with

blades

from

2 —

10

mm

wide

1

set

of

alien

keys

ranging

from

1.5

to 6 mm

1

set

of

spanners

from

7 to 14 mm

wide

1

22-mm

spanner

1

metal

rule

1cylindrical pin, 5 mm dia..

Order

No. 13-030341-05

1

universal

gauge.

Order

Nr.

61-111642-19

1

wrapper

with

System

134

needles

1

strip

of

white

paper,

sewing

thread

and

material

for

testing

purposes.