Cheonsei KEMPION SP-A Series User manual

Thank you very much for purchasing CHEONSEI SP-A Series.

Before beginning operation, please read this instruction manual carefully. Correct

handling, repair, & maintenance are described easily.

Please use this pumps safely to be guaranteed performance & long life of the

pump after reading this instruction manual.

Please keep this instruction manual at the place where you can find it easily.

1. Notice for Safety 4

2. Confirmation of Product 5

3. General 6

4. Model Code 6

5. Specifications 7

6. Standard Liquid End Materials 7

7. Performance Curves 8

8. Principle of Operation & Structure 10

9. Installation 13

10. Operation 19

11. Repair and Maintenance 20

12. Cause of Trouble and Troubleshooting 21

13. Replacement of Parts 22

14. Consumable Parts and Spare Parts 23

15. Warranty 24

16. Repair Service 24

17. Structure and Name of Each Parts 25

To use the products safely, the signs are showed on the manual as below.

As it is a matter of safety, please be sure to keep the directions in manual.

The sign and indications are as follows.

Person death or serious injury will be occurred, if warning is not kept by wrong handling.

Person injury or property damage will be occurred, if cautions is not kept by wrong handling.

Do not use this pump for other purposes except liquid injection.

Otherwise it may cause trouble.

Please keep the followings, otherwise it may cause trouble.

Ambient temperature : 0~40

Temperature of the handling liquid : Head material of PP & PVDF 0~50

Piping pressure : Below the max. discharge pressure indicated on the Specifications.

Do not use this pump to transfer the liquids containing slurry.

Install this pump beyond the reach of children and/or unauthorized person.

Turn off the power and stop the pump & other equipments when repairing or disassembling pumps.

If power is on during work, it may cause electric shock.

Do not operate when the discharge valve is closed or do not close the valve during operation.

Pump and piping may be damaged with excessive pressure rising and liquid may spout when operation

under valve closing.

Do not touch with wetted hand. Electric shock may be occurred.

Use only designated parts. If undesignated parts are used to the pump, it may cause accident & trouble.

Do not arbitrarily reconstruct the pump. If the pump is arbitrarily reconstructed, it may cause accident &

trouble.

Do not use damaged pump. It may cause accident.

Do not install pump in the heavy moist or dusty place. It may cause electric shock and trouble.

Wear suitable protective clothing(gloves, mask, goggles, working clothes, & etc.) during

assemble and disassemble work when pumping hazardous liquids or uncertain liquids.

Do not use power other than that specified in the motor nameplate. Otherwise, it may cause

malfunction or fire.

Please check following points immediately after receiving the pump.

If the defect is found from pump, please request it to local agent or CHEONSEI.

Is specification correct as ordered?

Is there any missing parts?

Is there any visible damage caused by vibration or shock during transport?

Is there any loosened bolt or nut?

Pump should be properly grounded. If pump is not grounded, it may cause electric shock.

Work after releasing pressure from discharge piping and remove liquid from Liquid End Part prior to

repair or maintenance of pump.

Pump may be damaged when ambient temperature go down below freezing point of liquid.

Be sure to remove the liquid in the pump and piping after operation stop.

Make proper protection in consideration of indeliberate leakage from damage of pump & Piping.

Dispose of waste pump in accordance with related national law.

Anti-siphon Check Valve 1 Set Strainer Foot Valve 1 Set

Mounting Bolt & Nut 2 Sets

Discharge Hose 2m

Suction Hose 1m

Air Vent Hose 1m

----

-a -b -c

011S

W

1CFP20ASP

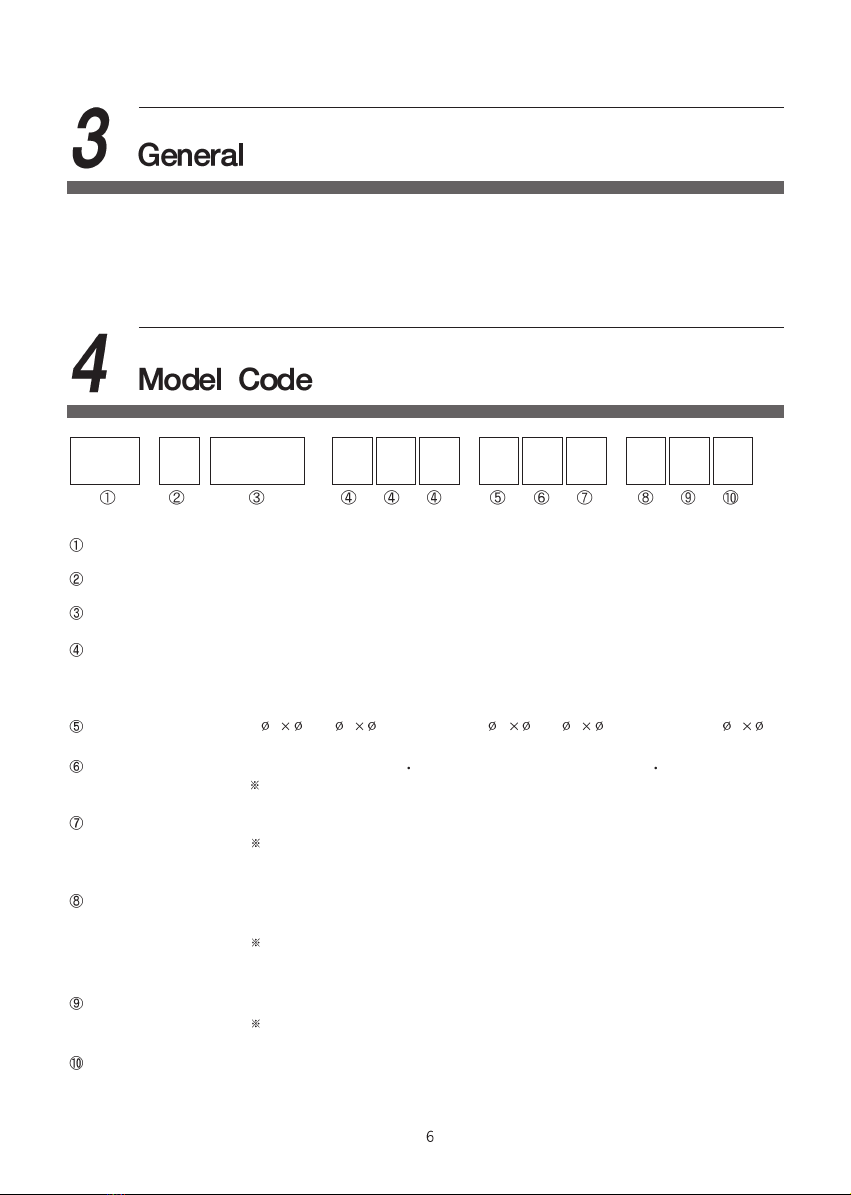

Series Name SP: SP Series

Control Panel Type A: Automatic or Advanced

Nominal Capacity 20 : 20 mL/min

Liquid End Material (a) Head P:PP F:PVDF

(b) Ball Seat F:FKM E:EPDM V:FKM(ETP)

(c) Check Ball C:CERAMIC S:SS316

Hose Standard

1: 46 2: 49(Braided PVC) 3: 68 4: 611(Braided PVC) 5: 58

Valve Structure W:Standard(0~100mPa s) V:High Viscosity(100~1000mPa s)

In case of high viscosity, spring is installed in the valve.

General Specification S:Standard B:Boiler F:Relief Valve G:Boiler + Relief Valve

In case of Boiler type, discharge hose is nylon and the body of Anti-siphon

Check Valve is PPS.

Control Specification 1:Manual 2:Manual +Add. Func. 3:PULSE(1:1) 4:PULSE(1:1)+Add. Func.

5:4~20mA 6:4~20mA+Add. Func. 7:PULSE(DIV/MUL)+4~20mA+Add. Func.

Additional Function is Input of Level Switch, Output of Alarm, & Remote

RUN/STOP.

Power Supply 1:AC220V(198~242V) 2:AC240V(216~264V) 3:AC115V(104~127V)

Common:1 Phase 50/60Hz

Power Cord 0:2m of Power Cord without Plug 1:2m of Power Cord & Plug

Solenoid Metering Pump SP-A Series is reciprocating diaphragm metering pump which have a solid &

compact structure and liquid end part of strong chemical resistance.

It can be used for injection of Boiler Chemical, Chlorine Disinfectants, & Food Additives, and used for dosing

chemicals in various industrial fields including physico-chemical fields, semiconductor device, water

treatment, waste water treatment filed, & etc.

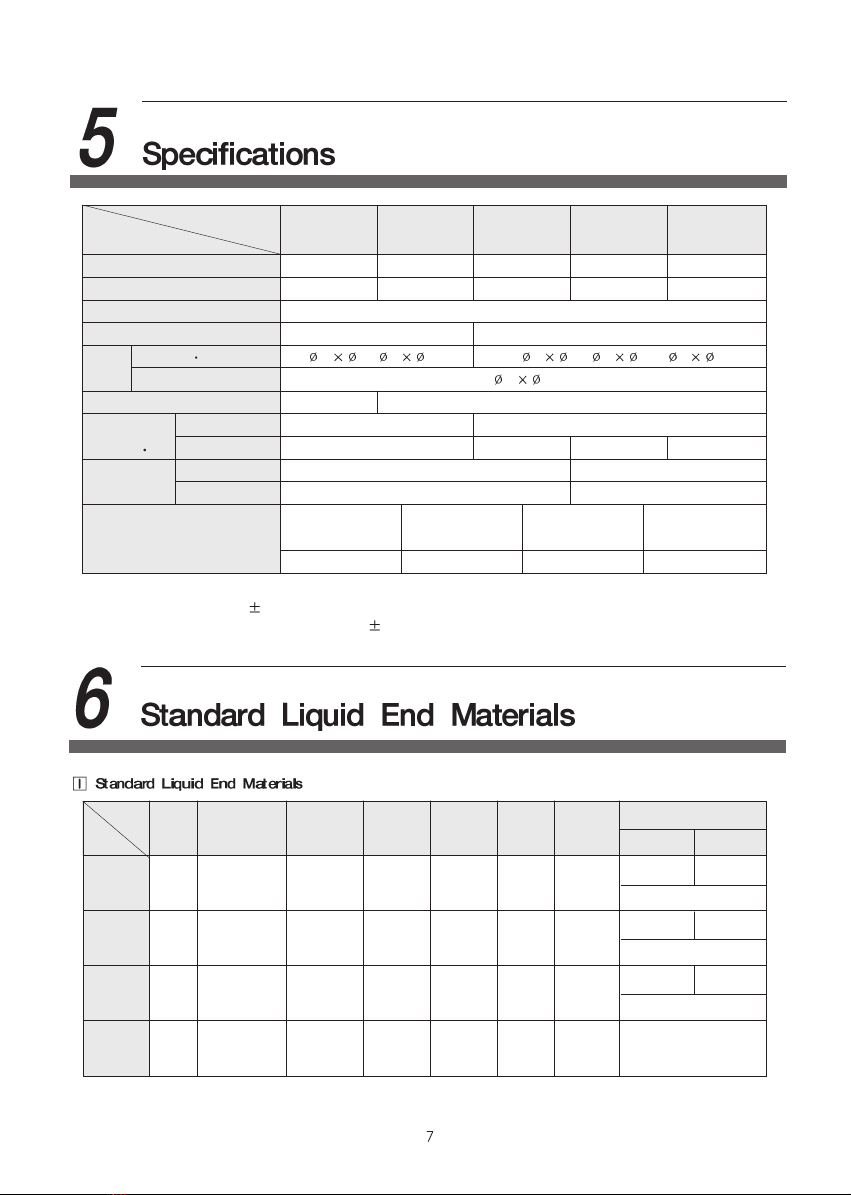

Model

Spec. SP-A20 SP-A40 SP-A60 SP-A100 SP-A200

Max. Capacity (mL/min) 17 35 60 110 200

Max. Discharge Pressure (bar)

16 12 8 5 3

Stroke Number (SPM) 150

Stroke Length (mm) 1.0 (40~100%) 1.25 (30~100%)

Hose Suction Discharge 46, 4 9 6 8, 611, 5 8

Air Vent 4 6

Self-priming (m) 1.5 2

Viscosity Limit

Standard 50 100

(mPa s) High Viscosity 500 1000 800 500

Weight (kg) PP Material 2.4 2.5

PVDF Material 2.5 2.6

Average Power Rated Current(A) Protection Class Insulation Class

Electrical Data Consumption(W)

17 0.5/0.8(115V) IP65 F

Note) 1. Max. capacity is the volume at max. discharge pressure.

2. Repeatability is 2%F.S.(Full Scale) and noise is within 70dB.

3. Setting pressure of Relief Valve is 10% of max. discharge pressure.

4. Specification can be changed for improvement without prior notice.

Note) In case of Boiler type, discharge hose is nylon.

Head Diaphragm

Check Ball

Ball Seat

Ball Guide

Joint O-ring

PFC PP PTFE

CERAMIC

FKM PP PP FKM

PFS PP PTFE SS316 FKM PP PP FKM

PEC PP PTFE

CERAMIC

EPDM PP PP EPDM

FVC PVDF PTFE

CERAMIC

FKM(ETP)

PVDF PVDF

FKM(ETP)

PTFE

Part

Type

Hose

Discharge

Suction

PE PVC

Braided PVC

PE PVC

Braided PVC

PE PVC

Braided PVC

Part Body Joint Check Ball Ball Seat Ball Guide O-ring

Type

PFC,PFS PP PP CERAMIC FKM PP FKM

PEC PP PP CERAMIC EPDM PP EPDM

FVC PVDF PVDF CERAMIC FKM(ETP) PVDF FKM(ETP)

Part Body Joint Plug Head Spring O-ring

Type

PFC,PFS PP PP FKM HC-276 FKM

PEC PP PP EPDM HC-276 EPDM

FVC PVDF PVDF FKM(ETP) HC-276 FKM(ETP)

Boiler PPS PPS EPDM HC-276 EPDM

Condition : Clean water, Room temperature, Suction head - 1m

Stroke Length(%)

Capacity Rate(mL/min)

020 40

25

60 80 100

5

10

15

20

Correction Factor

Pressure (bar)

0.8

1.0

1.2

1.4

1.6

1.8

161412108642

0

150spm

120spm

90spm

60spm

30spm

020 40

50

60 80 10

0

20

30

40

0.8

1.0

1.2

1.4

1.6

1

2

10.57.5630

150spm

120spm

90spm

60spm

30spm

10

94.51.5

45

35

25

15

5

Stroke Length(%)

Capacity Rate(mL/min)Correction Factor

Pressure (bar)

Note) 1. Above performance curves were tested

at our testing equipment under the

fixed condition(Clean water, Room

temperature, Suction head - 1m).

Therefore, performance curves can be

somewhat different in accordance with

condition of job site.

2. Way to understand performance curves

Ex.) In case of SP-A200,

Capacity Rate is 150mL/min at 80% of

Stroke Length & 120SPM of Stroke

Number. If discharge pressure is 1bar,

correction factor will be 1.1 and

expected capacity rate will be 165mL/min

(1.1 150mL/min = 165mL/min)

3. Capacity rate can be changed according to

piping condition of suction & discharge. For

effective use, measure the discharge

rate(make out performance curve) when trial

operation, after installation.

4. if test of capacity rate is regularly operated,

operator can know exchange cycle for the

consumable parts in Liquid End part.

Stroke Length(%)

Capacity Rate(mL/min)Correction Factor

Pressure (bar)

Stroke Length(%)

Capacity Rate(mL/min)Correction Factor

Pressure (bar)

020 40 60 80 10

0

0.8

0.9

1.0

1.1

0

150spm

120spm

90spm

60spm

30spm

3

250

1.51

1.2

225

200

175

150

125

100

75

50

25

2 2.5

Stroke Length(%)

Capacity Rate(mL/min)Correction Factor

Pressure (bar)

If electric power is supplied to the Solenoid Coil, magnetic field is generated in the Solenoid and Plunger

moves forward by magnetic force, and, if electric power is shout down, magnetic field disappears in the

Solenoid and Plunger moves backward by spring force.

Reciprocating motion of Solenoid Plunger is transferred to the Diaphragm connected with the end of

Slider Shaft and Diaphragm can be reciprocated. Volumetric change occurs in the pump head by this

reciprocating motor of Diaphragm.

When diaphragm moves backward, minus(-) pressure is generated in pump head. At this time, check ball

of discharge side is closed in order to prevent flowing backward of liquid from piping of discharge side to

pump head. On the contrary, check ball of suction side is opened so that liquid can be flowed into the

pump head.

When diaphragm moves forward, plus(+) pressure is generated in pump head. At this time check ball of

suction side is closed and check ball of discharge side is opened so that liquid can be discharged.

Capacity rate can be accurately controlled by adjustment of stroke length or stroke number.

The pump consists of Liquid End Part, Driving Part, Control Part as follows.

Liquid End Part Driving Part Control Part

1 Head 9 Pump Housing 13 Stroke Shaft

2 Diaphragm 10 Solenoid Coil 14 Circuit Board

3

Check Valve of suction side

11 Solenoid Plunger 15 Control Panel

4

Check Valve of discharge side

12 Spring 16

Control Knob for Stroke Length

5 Joint 17

Control Knob for Stroke Number

6 Air Vent 18 Cable Socket

7 Hose Nut

8 Support Ring

9

4

2

1

3

7

5

7

6

12 11

1

6

1

7

1

8

810 13 14 15

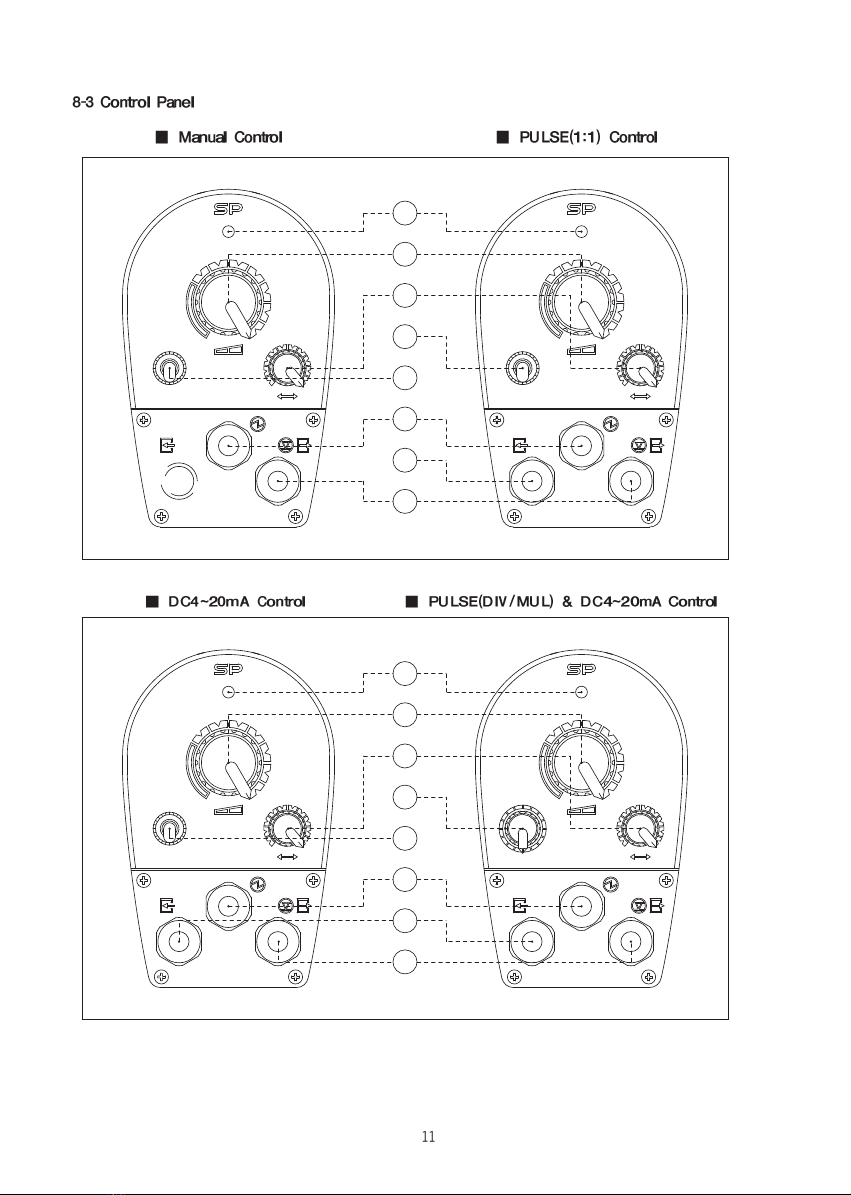

1: Status Lamp(LED) 2: Control Knob for Stroke Length 3: Control Knob for Stroke Number

4: Toggle Switch of 2 Stages 5: Toggle Switch of 3 Stages 6: Rotary Switch

7: Cable Socket for Power 8: Cable Socket for Input Signal 9: Cable Socket for Level Switch &

Output Signal

70

30

0

10

20 80

100

90

Solenoid metering Pumps

50

0

40

30

80

90

40

100

50 60

70

60

STOP

RUN

100

10

20

0

90

0

100

60

40 50

30

80

70

30

40 60

50

70

90

80

Solenoid metering Pumps

MANU

STOP

PULSE

1

2

3

4

7

9

8

5

Solenoid metering Pumps

70

30

40 50 60

80

90

100

0

1

STOP

/4

MANU

/64

/8

/32

/16

/2 X4

4~20mA

X8

X16

X32

X64

X2 30

0

10

20 80

100

70

90

50

40 60

MANU

STOP

0

90

10 0

100

30 40

20

100

70

80

50 60

Solenoid metering Pumps

30

40 50

70

80

90

60

4~20mA

9

8

7

5

6

3

2

1

Status Lamp(LED)

Stand by : Green Lamp is lighted

Operation : Green Lamp is flickered

Faulty Input Signal of DC 4~20mA : Yellow Lamp is lighted and Pump is stopped

Low level of Tank : Red Lamp is lighted and Pump is stopped

Operation by manual control according to Stroke Length and Stroke Number

Operation by automatic control according to external Input Signal

Proportionally Automatic control of Stroke Number according to Analog Input Signal(DC4~20mA)

PULSE : 1/2, 1/4, 1/8, 1/16, 1/32, 1/64 Division selection

1:1 selection

12, 1 4, 1 8, 1 16, 1 32, 1 64 Multiplication selection

Pump perform the calculated stroke number(SPM) according to the selection

Ex.1) When Rotary Switch is located at "1/4"

PULSE

PUMP STROKE

Ex.2) When Toggle Switch of 3 Stages is located at "PULSE" or Rotary Switch is located at "1"

PULSE

PUMP STROKE

Ex.3) When Rotary switch is located at "x4"

PULSE

PUMP STROKE

Note) Even if a lot of PULSE is inputted, pump's Stroke Number can't exceed 150SPM.

When Tank is LOW Level according to Input Signal of Level Switch or Analog Input Signal is ERROR,

Pump is stopped and Alarm Signal is outputted.

Pump can be remotely stopped or operated during Manual operation or Automatic operation by Input

Signal.

42

0

16.813.610.47.2

0

20

40

60

80

100

Stroke Number(%)

Analog Signal(mA)

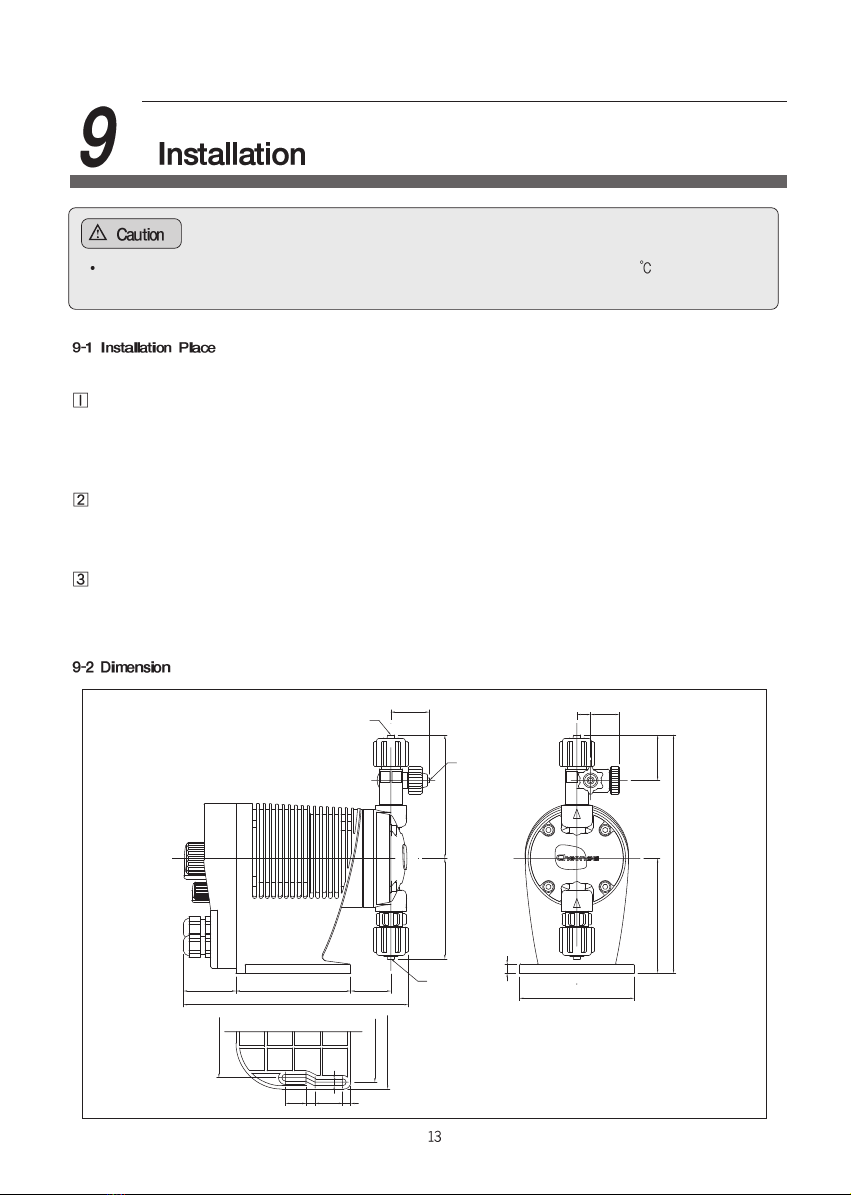

Please take into consideration of those conditions listed below.

Place where is out of the direct rays of light, rain, & wind.

Temperature rise of metal part, Heat deterioration of plastic part by direct rays of light and Damage &

rust by sand, dust and rain may occur.

If the pump should be installed at outdoor, the pump should be protected by roof or cover in order to

prolong the life time.

Place where is well ventilated in summer and not frozen in winter.

If pump is used in the closed room where is high temperature & humidity, solenoid will be overheated

and rust of metal part will be accelerated.

If pump is used for the liquid which may freeze in winter, install warming or heating device.

Take sufficient space around the pump to facilitate maintenance or repair.

Several tools are used for disassembly of pump, therefore, fully consider enough space for using tools

and work space when installing pump.

Do not install pump at the place where ambient temperature is higher than 40 or lower than

freezing point. If the pump is installed at the place, internals of the pump may be damaged.

12

100

100

8

E

C10046 D

B A

39.5

33.5

25

F

F

G

100

88

80

7

24

8

18

6

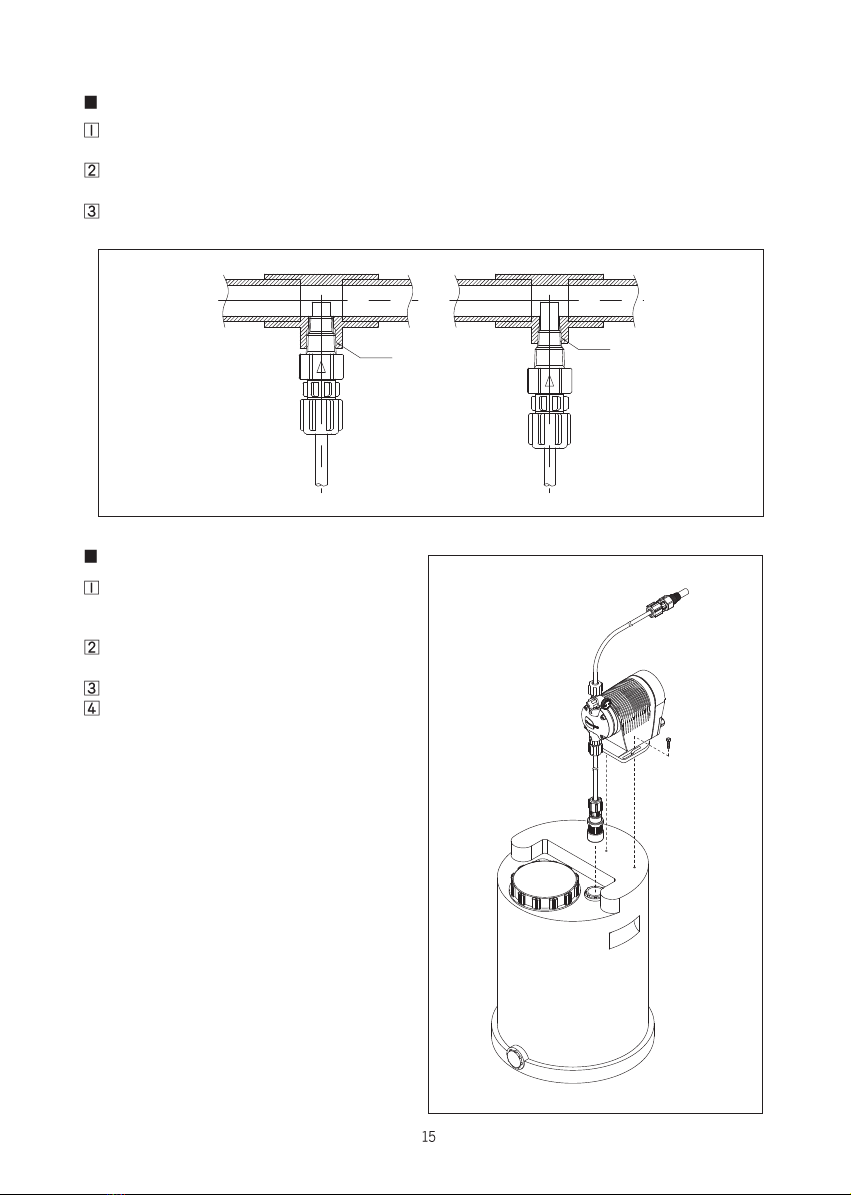

Pulsation which is the characteristic of metering pump occurs since the pump is reciprocating type.

Can reduce pulsation by using Air Chamber.

Note) Possible piping length is changed according to Liquid Viscosity or piping diameter.

When changing piping diameter, be fully careful.

When bending the hose, be careful not to be folded.

Before inserting Hose to Hose Adaptor, insert Hose

Nut & Clamp Ring, then be careful that Hose is not

twisted, and connect Joint & Hose Nut.

Hose is vibrated because reciprocating metering

pump makes pulsation.

Support Hose in order not to be vibrated.

(It is enough to support hose with string)

Install Hose in consideration of temperature condition.

Specially, keep out of the direct rays of light in summer,

consider freeze protection in winter.

(Roof, cover, winterization, & etc.)

When re-connecting Hose after maintenance,

re-connect after cut the end of Hose about min. 10mm.

Anti-siphon Check Valve

In case that injection port is open to atmosphere and its location is lower than liquid level in the tank.

Siphon Phenomenon: although pump is stopped, liquid may continuously flow because location of

discharge port is lower than liquid level in suction tank

If there is constant pressure at injection port, it may be used as Check Valve.

When injecting to suction piping of centrifugal pump

When flow is much larger than rated capacity

(In spite of upward piping, if piping length is too long, Overfeeding can be generated.)

Overfeeding : Overfeeding stands for the excessive discharge flow due to abnormal function of the

Check Valve caused by pulsation of the liquid in piping.

Check carefully differential pressure if the differential pressure between suction side and

discharge side is lower than 0.5~1 bar and discharge piping is too long.

Model SP-A20 SP-A40 SP-A60 SP-A100 SP-A200

Dimension

A 96.5 99 101 102.5 107.5

B 76.5 79 81 82.5 87.5

C 33.5 33.5 33.5 35 35

D 194.5 194.5 194.5 196 196

E 196.5 199 201 202.5 207.5

F 4 6, 4 9 6 8, 611, 58

G 46

Hose Nut

Hose

Clamp Ring

Hose Adaptor

O-ring

Joint

Mounting of Anti-siphon Check Valve

Install Rc3/8 or Rc1/2 of Female Thread at the injection point.

Fits both sizes because Anti-siphon Check Valve has both R3/8 and R1/2 of Male Thread.

Anti-siphon Check Valve is fragile against impacts since it is made by plastics such as PP, PVDF, &

PPS, therefore, install it in a place sheltered from impacts and free from obstacles.

Cut off the end of the injection nozzle properly. It is suitable that the end of injection nozzle is

positioned in the middle of water pipe.

Installation on Liquid Tank

Fix the pump to the bracket on the tank, by

using the Mounting Bolts supplied as

standard accessories.

Pass the Hose Nut into the suction side

hose and connect it to the Strainer Foot Valve.

Place the Strainer Foot Valve into the tank.

Pass the Hose Nut into the discharge side

hose and connect it to discharge side Joint of

pump.

Drive the Anti-siphon Check Valve into the

injection point and connect the hose.

R

R1/2 R3/8

Solenoid Metering Pump

Anti-siphon Check Valve

Mounting Bolt

Strainer Foot Valve

Liquid Tank

Do not touch with wetted hand. Electric shock may be occurred.

Before wiring, check voltage, phase, & frequency and connect the pump with correct power.

It may cause trouble and fire, if connecting with incorrect power.

Pump should be properly grounded in order to prevent electric shock.

Entrust the wiring to electrical engineer.

Install regulated Magnet Switch and Thermal Relay for the adjustment and maintenance of the pump.

Use standardized parts in wiring and fully pay attention to safety in accordance with the technical

standard & wiring regulation of the electrical equipment.

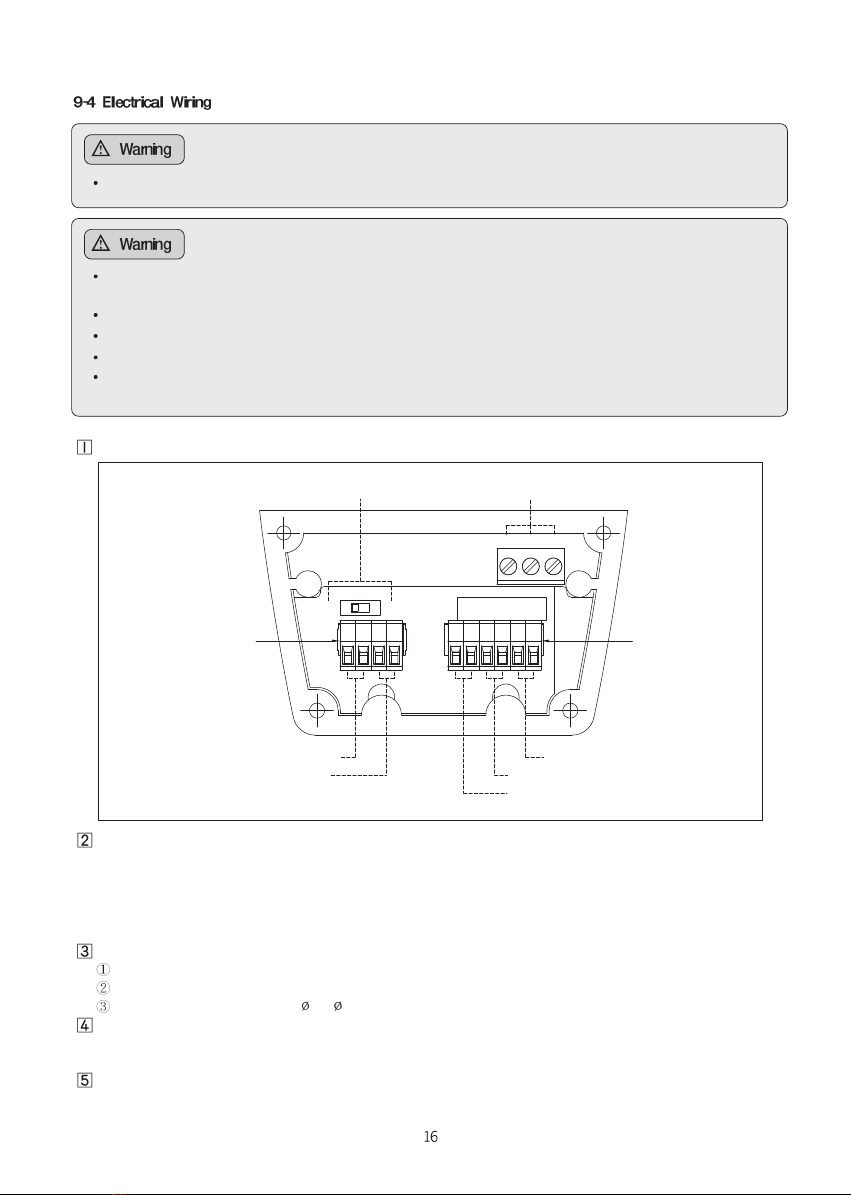

Disassemble Terminal Cover after loosening tapping screw from Control Panel by (+) screwdriver.

Connector inserted to Terminal Block

Separate the Terminal Connector connected to Terminal Block by Long Nose Plier and after passing the

wire into the Cable Socket and inserting the wire to the Terminal Connector.

Fix it by (-) screwdriver.

Terminal Block for external contacts such as Level Switch is connected with jumper wire.

Before wiring, remove it.

Allowable wire standard for Terminal Block & Cable Socket is as follows.

Terminal Block for Flow Control & Additional Function : AWG16~30

Terminal Block for Power : AWG18~26

Cable Socket: External dia. 4~ 8

Put the Terminal Connector connected with wire into the Socket of Terminal Block and assemble the

Terminal Cover.

Tighten the Cable Socket so that wire don't be fall out, after adjusting wire length.

Power wires are 3 wires including ground. be careful not to confuse since Green & Yellow color are

used for ground wire.

DI1 DI2

A+A-P+P- L1 L2 R1 R2 A1 A2

AC-L AC-N F.G

Power Cable

Alarm Output4~20mA Input

RUN/STOP Input

PULSE Input

Level Switch Input

Selection Switch for PULSE

Terminal Block

Function for Flow Control Terminal Block

Additional Function

Terminal Cover

Power Terminal Block

Terminal Connector

Terminal Socket

Cable Socket

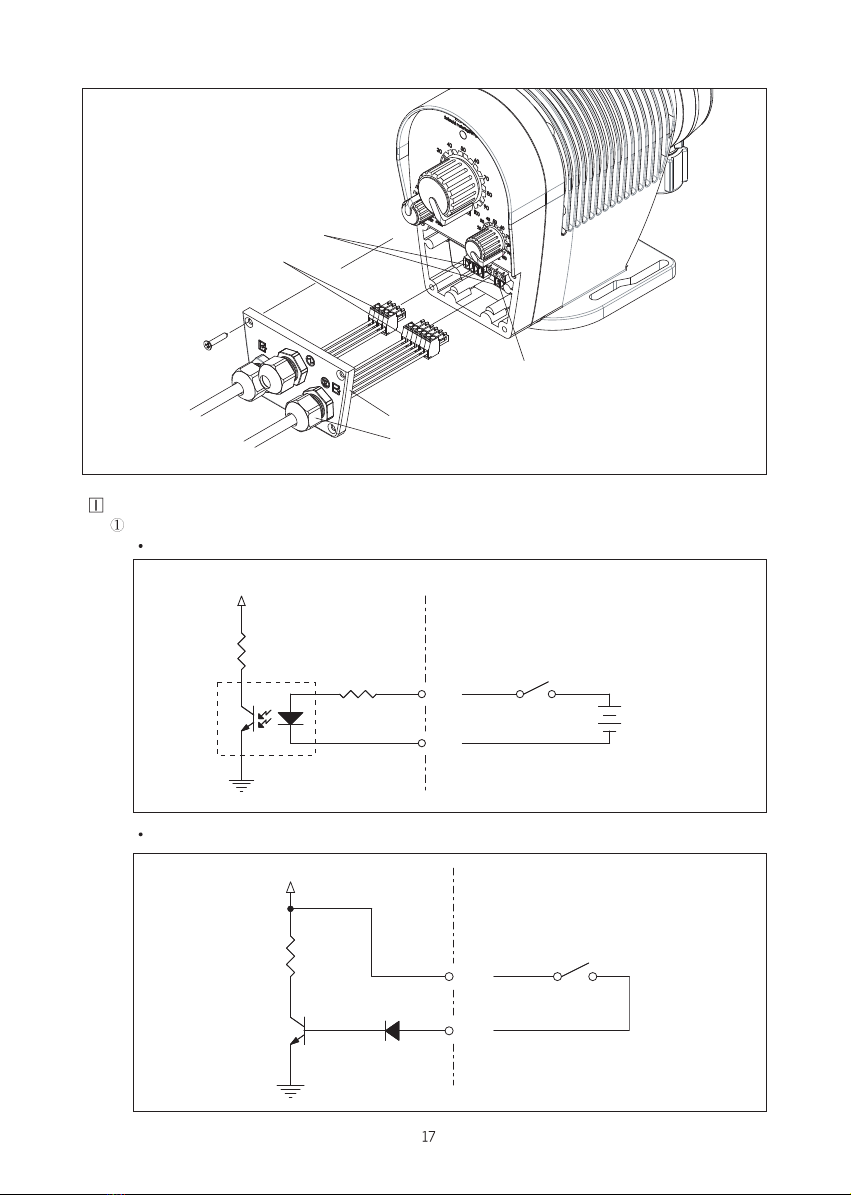

Diagram of Electric Circuit (Example)

PULSE Input Signal: Min. PULSE Duration Time is 4ms

DI1 Selection: VOLTAGE WITH OPEN CONTACT

DI2 Selection: NO VOLTAGE WITH OPEN CONTACT

PUMP USER

R

P+

PULSE

VDC

NPN

D

P -

PUMP USER

OPTO-COUPLER

R

R

P+

PULSE

DC12~24V

VDC

1

2

34

P -

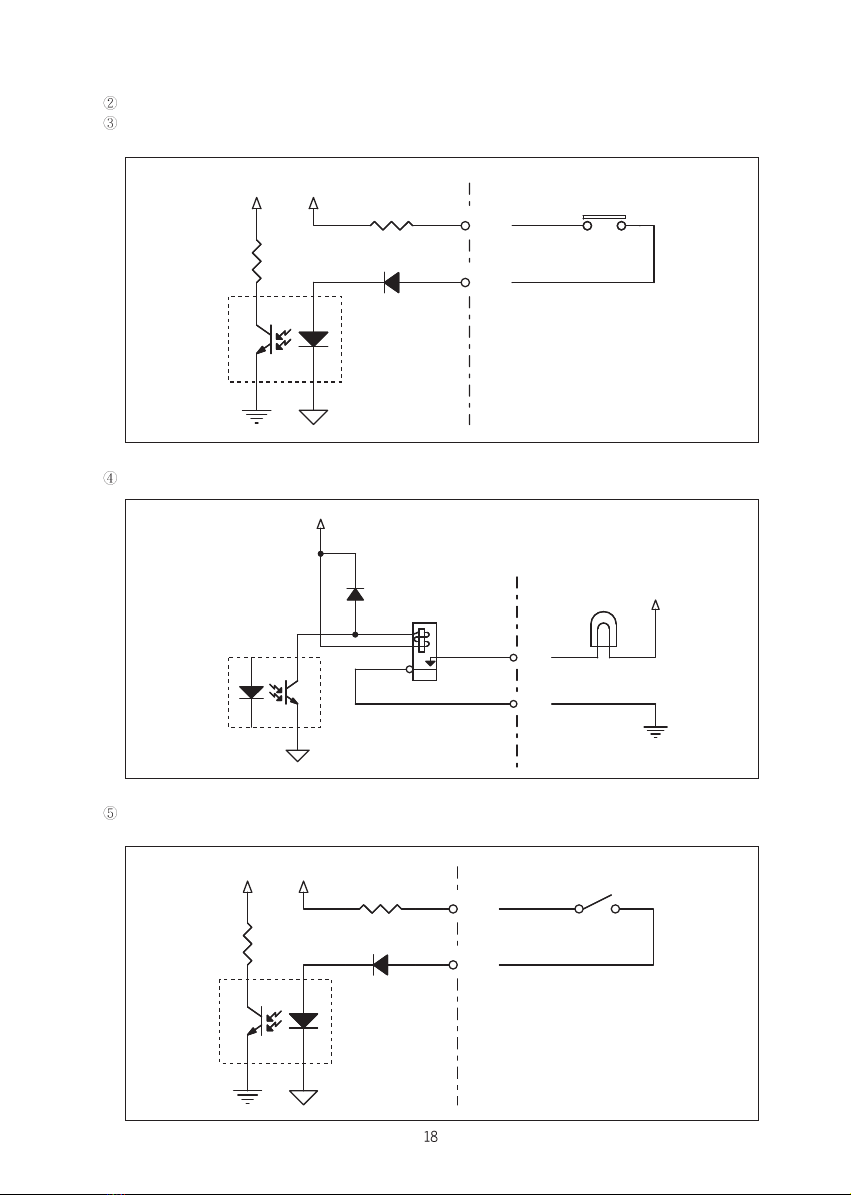

DC4~20mA Input Signal

LEVEL SWITCH Input Signal : NO VOLTAGE WITH OPEN CONTACT

OPEN : LOW LEVEL CLOSE: NORMAL LEVEL

ALARM Output: DRY CONTACT (SPST) Contact Capacity: 3A 250VAC (5A 30VDC)

REMOTE RUN/STOP Input Signal : NO VOLTAGE WITH OPEN CONTACT

OPEN : PUMP STOP CLOSE: PUMP RUN

PUMP USER

34

12

OPTO-COUPLER

+12VVDC

D9

R

R

LEVEL SWITCH

L1

L2

USERP

34

12

3

4

1

2

OPTO-COUPLER

+12V

D

ALAM LAMP

POWER

A1

A2

RELAY SPST(NO)

UMP

PUMP USER

34

12

OPTO-COUPLER

+12VVDC

D9

R1

RUN SWITCH

R2

R

Do not operate when the discharge valve is closed or do not close the valve during operation.

Pump and piping may be damaged with excessive pressure rising and liquid may spout when operation

under valve closing.

Do not turn the Control Knob of Stroke Length & Stroke Number below 0% or over 100%.

When discharge valve of pump is clogged with foreign substance, pressure is raised and liquid is

spouted and it cause damage of piping.

Wear suitable protective clothing(gloves, mask, goggles, working clothes, & etc.) when pumping

hazardous liquids.

Some water may be remained in the pump after final performance test.

In case of use for some liquids reacted to water, remove water in the pump and dry the pump necessarily.

Check if suction side and discharge side hose is tightly connected, and Hose of Air Vent is connected with

Liquid Tank or other container.

Set each Control Knob to 100% and operate the pump after turning the Air Vent Cock counterclockwise

about 1~ 1 revolutions.

Confirm that liquid is flowed through Air Vent and start normal operation after closing the Air Vent Cock by

turning it clockwise.

In case of the pump attaching Relief Valve, if the Knob of Relief Valve is clockwise turned about 90°, Air

Vent Valve is opened. On the other hand, if the Knob of Relief Valve is clockwise turned about 90° again,

Air Vent Valve is automatically closed by spring force.

Since capacity Rate is controlled by both the Control Knob of Stroke Length and the Control Knob of Stroke

Number, fine control of capacity rate is possible.

Tan k

Discharge Piping

Relief Valve

Air Vent Cock

Knob(Relief)

Turn off the power and stop pump & other equipments before repair & maintenance, otherwise it may

cause electric shock.

Wear suitable protective clothing during assemble and disassemble work.

Work after releasing pressure from discharge piping and remove liquid from Liquid End Part prior to

repair or maintenance of pump..

Check the level of liquid tank and, if it is insufficient, supplement the liquid.

Check if the valves on the suction & discharge piping are opened.

Check if piping is loosened or damaged.

Check electrical wiring if there are no electrical short & disconnection.

Check the level of liquid tank and, if it is insufficient, supplement the liquid. Specially, be areful for the

process or chemical influenced by Air.

Check if liquid is leaked out the Joint or other parts. If necessary, fasten it again.

If leakage doesn’t stop, check O-ring and/or Packing of each parts and replace the damaged O-ring

and/or Packing with new one.

Check if noise sounds from the pump.

Check if the needle of pressure gauge is located at normal range.

Wash inside Pump Head by drawing & discharging clean water for 30 minutes.

Put the cover on the pump to protect it from dust and/or corrosion.

Set the Control Knob of Stroke Length at 100% in order to prevent the deformation of diaphragm.

Check foreign substances lay on the Check Ball and/or Ball Seat before restarting the pump.

When diluted liquid or high viscosity liquid is used at freezing place in the winter, install HEAT TRACING

to prevent the pump from freezing because it causes the damage of the pump & other devices with

freezing on the liquid end part of pump and inside piping.

Clean the inside of Tank and Joint every 3 months at least.

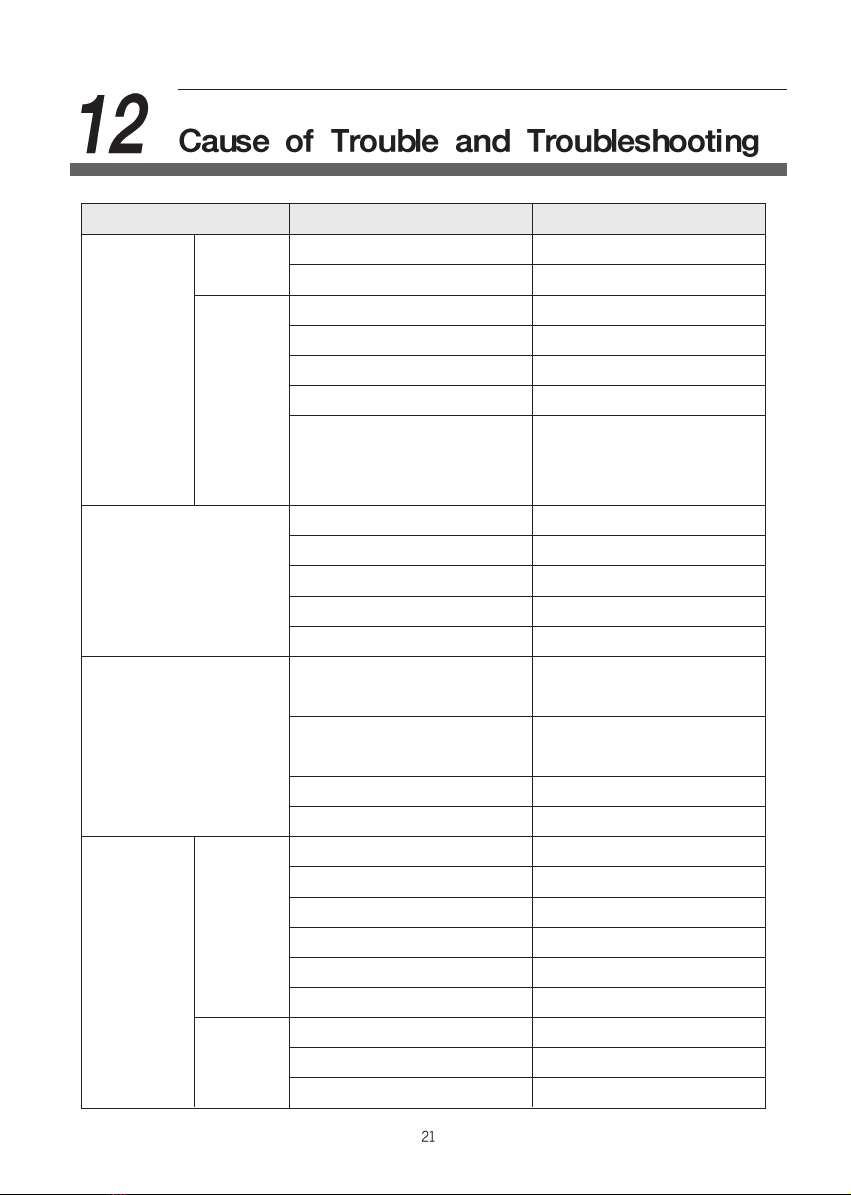

Trouble Cause Troubleshooting

Leaks from joint or sealing part Check o-ring & tighten

Empty tank Fill up and expel air

Strainer is clogged Clean strainer & tank

Pump head is filled with gas Purge the gas by air vent cock

Assembly direction of valve is wrong Re-assemble the valve

Ball Seat is worn out Replace

Set stroke length at 100% and

Short stroke length control discharge capacity by

stroke number

Check ball & ball seat are damaged Replace

Spring is broken Replace

Diaphragm is aged or broken Replace

Setting of knob is wrong Readjust

Liquid being treated is changed Recheck the pump specifications

Pressure is increased by foreign Disassemble and clean

substance or clogging

Hose or diaphragm broken due Replace

to fatigue

Head and joint are loosened Tighten

There is no o-ring Insert o-ring

Wrong voltage Check voltage & correct

Wrong wiring Check the wiring & correct

Disconnection of cable Modify or replace

Switch is cut off Turn on switch

Fuse is burnt out Check the cause and replace fuse

Defective magnetic switch Replace

Unsuitable voltage Connect suitable voltage

Spring is broken Replace

Defective solenoid Check the resistance & insulation

Pump is

running but

liquid is not

discharged.

Air is drawn

Suction is

not

sufficient.

Insufficient discharge rate

Leakage of liquid

Pump dose

not run

Status

Lamp(LED)

is off

Solenoid

does not run

Other Cheonsei Water Pump manuals

Popular Water Pump manuals by other brands

Xylem

Xylem GOULDS NPO instruction manual

Teral

Teral LPWE-GS instruction manual

Grundfos

Grundfos Hydro Multi-B instructions

Zwilling

Zwilling Fresh & Save Vacuum Storage System operating instructions

T.I.P.

T.I.P. GP 4500 INOX operating instructions

Markes International

Markes International ACTI-VOC Operator's manual