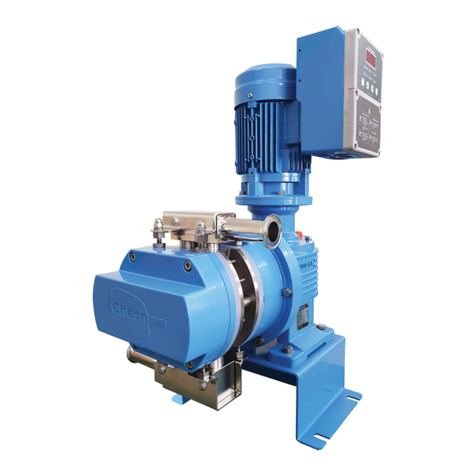

Cheonsei Kempion PKD Series User manual

This manual suits for next models

16

Table of contents

Other Cheonsei Water Pump manuals

Popular Water Pump manuals by other brands

ekwb

ekwb EK Series installation manual

Olympus

Olympus KV-5 instructions

Brooks Automation

Brooks Automation PFC-552HC Operation manual

SKF

SKF LINCOLN P203 Assembly instructions

ClimateMaster

ClimateMaster Tranquility Low-Profile Series Installation operation & maintenance

SOLIDSVAC

SOLIDSVAC SV800-CAROUSEL Operation manual

Trebor

Trebor MAGNUM 610R Operation & maintenance manual

ITT

ITT FLOJET R3521 Series INSTALLATION & SERVICE INFORMATION

GNC

GNC P550 Operation and parts manual

VERDER

VERDER JEC JRZLF Series Operation and maintenance manual

EINHELL

EINHELL GE-SP 18 Li Original operating instructions

Glentronics

Glentronics Basement Watchdog SIT-33D Instruction manual & safety warnings

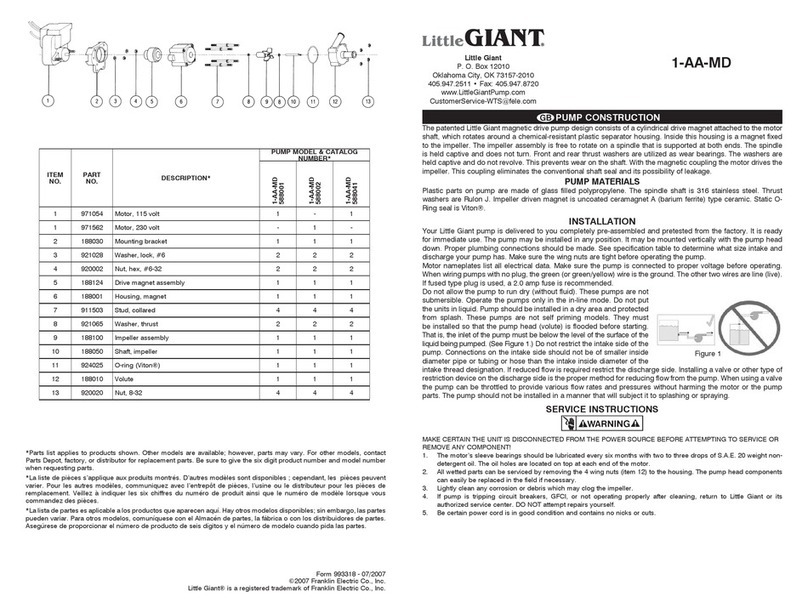

Little Giant

Little Giant 1-AA-MD installation manual

EHEIM

EHEIM compactON 2100 operating instructions

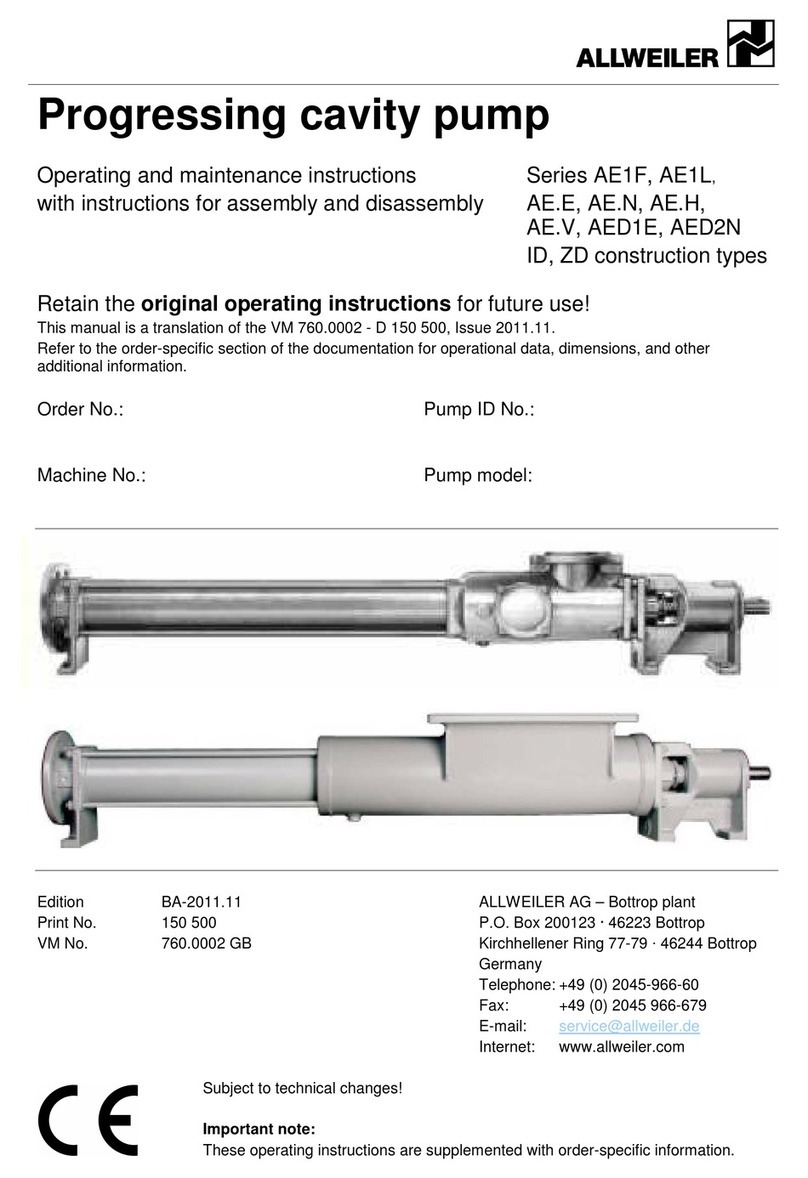

Allweiler

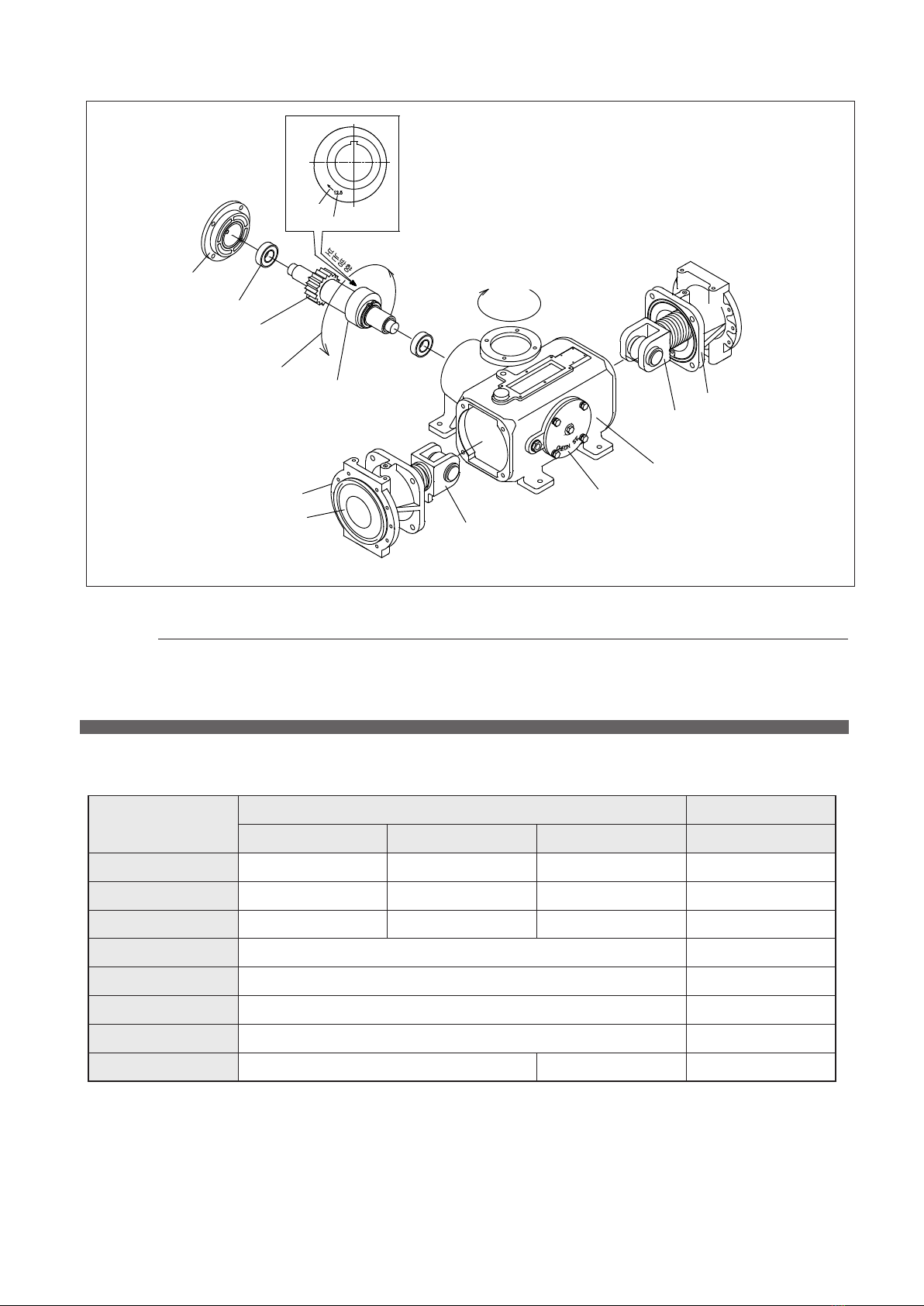

Allweiler AE1F Series Operating and maintenance instructions with instructions for assembly and disassembly

red lion

red lion 2RLAG-1L owner's manual

Little Giant

Little Giant 5-ASP-FS manual

aqua technix

aqua technix AQUA Mini 3 Installation and operation manual