CHERNE HI-FLOW AIR-LOC LINE ACCEPTANCE User manual

Line Acceptance

Kit

2

TABLE OF CONTENTS

Introduction

Page 2

Warranty

Page 3

Safety

Page 4

Manhole Safety Procedures

Page 5

Packing List

Page 6

Individual Component

s

Page 7

Li

ne Acceptance Testing

Page 8

Ground Water

Pressure Calculation

Page 11

Trouble Shooting Guide

Page 12

-13

Time Charts

Page 14

Introduction

The Cherne Air

-

Loc Lin

e Acceptance

has been specifically designed for low pr

essure air testing of

sewer lines. Line acceptance testing is done on complete sections of pipe.

LIMITED WARRANTY

Line Acceptance

Kit

3

Manufacturer warrants all products manufactured by it will be free from defects in material and workmanship for one

(1) year following the date of manufacture. If any of the goods are found to be defective, such goods will, at

manufacturer's option be replaced or repaired at manufacturer's cost. The parties hereto expressly agree that buyer's sole

and exclusive remedy

against the manufacturer shall be for repair or replacement of defective goods as provided herein.

(The sole purpose of the stipulated exclusive remedy shall be to provide the buyer with free repair and replacement of

defective goods in the manner provid

ed herein. The exclusive remedy shall not be deemed to have failed of its essential

purpose so long as the manufacturer is willing and able to repair or replace defective goods in the prescribed manner.)

Goods which may be sold by manufacturer but are not manufactured by it are not warranted by manufacturer, but are

sold only with the warranties, if any, of the original manufacturers thereof. (This warranty does not cover labor or other

costs or expenses to remove or install any defective, repaired or re

placed goods.) Manufacturer's warranty does not

apply to any goods which have been subjected to misuse, mishandling, misapplication, neglect (including but not limited

to use of unauthorized parts or attachments), or adjustment or repair performed by anyo

ne other than manufacturer or

one of manufacturer's authorized agents.

Any claim by buyer with reference to the goods sold hereunder shall be deemed waived by the buyer unless submitted in

writing to manufacturer within the earlier of (1) thirty days (30)

days following the date buyer discovered or by

reasonable inspection should have discovered, any claimed breach of the foregoing warranty, or (2) thirteen (13) months

following the date of manufacture. Any cause of action for breach of the foregoing warr

anty shall be brought within one

year from the date the alleged breach was discovered or should have been discovered, whichever comes first.

LIMITATION OF LIABILITY.

Manufacturer's liability (whether under the theories of breach of contract or

warranty,

negligence, or strict liability) for its goods shall be limited to repairing or replacing parts found by the

manufacturer to be defective, or at manufacturer's option, to refunding the purchase price of such goods or parts thereof.

DISCLAIMER OF CONSEQUEN

TIAL DAMAGES.

In no event shall manufacturer be liable for consequential

damages arising out of or in connection with this agreement, including without limitation breach of any obligation

imposed on manufacturer hereunder or in connection herewith. Conse

quential damages for purposes hereof shall

include, without limitation (including death) to any person, or loss of or damage to property (including without

limitation property handled or processed by the use of goods). Buyer shall indemnify manufacturer a

gainst all liability,

cost or expense which may be sustained by manufacturer on account of any such loss, damage or injury.

DEFECTIVE PRODUCTS POLICY. To obtain performance under this warranty, any product suspected of having a

manufacturing defect in ma

terials or workmanship at manufacturers request must be returned to CHERNE

INDUSTRIES INCORPORATED, freight prepaid, for inspection. A returned goods authorization must be obtained

before shipping any product back to CHERNE. Call 1

-800-843-

7584 and ask f

or customer service.

CUSTOMER TRANSPORTATION REIMBURSEMENT.

Whenever CHERNE repairs or replaces a product at

CHERNE'S expense CHERNE will reimburse the distributor by credit memo, the surface freight amount it cost

CHERNE to return the warranty items.

T

he foregoing warranty is in lieu of all other warranties express or implied, including those of merchantability or fitness

for any purpose not expressly set forth herein. No affirmation of manufacturer, by words or action, other than as set

forth in this

language shall constitute a warranty.

Line Acceptance

Kit

4

SAFETY

1. Prior to using your Air

-

Loc testing equipment, the

PIPE PLUG SAFETY INSTRUCTION

AND DATA BOOKLET

should be read. Additional copies can be obtained from Cherne

Industries Incorporated

by requesting form 103

-586.

2. Always make sure that the TEST valve and the BALL valve on the Air

-

Loc control panel

are in their OFF position.

3. During testing,

do not

allow anyone in or near the danger zones (sewer line, manhole) unti

l

the test area has been vacated and the plugs are completely deflated.

4.

Do not

operate at an air inlet pressure greater than 120 PSIG ( 8.2 Bar ).

5.

Do not

deflate the plugs before the test area has been completely exhausted. Air pre

ssure

within the test area may cause the balls to blow out of the sewer causing damage, serious

bodily injury or death.

6

. Never

inflate a plug outside of pipe or inside of an unsupported (above ground) pipe; the

pipe may burst, resulting in

serious bodily injury or death.

7. Disconnect the air supply hose to the Air

-

Loc control panel and relieve all test pressure

before servicing.

8. Do not over inflate the plugs. Refer to the

PIPE PLUG

SAFETY INSTRUCTION AND

DATA

BOOKLET

for the proper inflat

ion and back pressure ratings.

Line Acceptance

Kit

5

MANHOLE SAFETY PROCEDURE

RECOMMENDED SAFETY PROCEDURE FOR ENTRANCE INTO MANHOLES OR CONFINED SPACES

WARNING:

THESE RECOMMEMDATIONS ARE TO

BE USED AS A GENERAL GUIDELINE ONLY:

ALTHOUGH CHERNE RECOMMENDS THESE FOLLOWING GUIDELINES, IT DOES NOT WARRANT,

REPRESENT OR ASSUME ANY RESPONSIBILITY THAT THESE RECOMMENDATIONS WILL FULFILL ALL

APPLICABLE FEDERAL, STATE OR LOCAL REQUIREMENTS. CHERNE AS

SUMES NO LIABILITY FOR

EITHER PERSONAL INJURY OR CONSEQUENTIAL DAMAGES THAT RESULT FROM THE RELIANCE ON

THESE RECOMMENDATIONS.

WARNING:

IT IS THE PRODUCT USER'S RESPONSIBILITY TO READ AND COMPLY WITH ALL

APPLICABLE REGULATIONS. REFER TO THE

CODE OF FED

ERAL REGULATIONS, "CFR" PART 1926

AND

ALL OTHER PERTINENT FEDERAL, STATE, AND LOCAL REGULATIONS.

ALWAYS OUTFIT YOURSELF WITH THE NECESSARY SAFETY EQUIPMENT FOR ENTRANCE INTO A

MANHOLE OR CONFINED SPACE. THIS MAY INCLUDE, BUT NOT BE LIMITED TO, THE FOLLOW

ING

ITEMS (REFER TO WARNING STATED IMMEDIATELY ABOVE):

Recommended equipment is as follows:

A. Safety Hat

G. Ear Protection

B. Safety Glasses

H. Hazardous Gas Detector and Oxygen Monitor

C. Respirator or self

-

contained Air Source

I. Manho

le or Confined Space Ventilation

D. Safety Harness, Ropes, and Winch System

J. Protective Clothing

E. Safety Shoes or Boots

K. Safety Ladders

F. Protective Gloves

L. Any Other Recommended or Required Equipment

ALWAYS ENSURE THAT ALL EQUIPMENT

MEETS OR EXCEEDS THE MINIMUM REQUIREMENTS OF ALL

APPLICABLE REGULATORY GUIDELINES. ALL EQUIPMENT SHOULD BE PROPERLY MAINTAINED, STORED,

CALIBRATED IF NECESSARY, AND INSPECTED PRIOR TO EACH USE, IN COMPLIANCE WITH APPLICABLE

REGULATIONS AND EQUIPMENT MANU

FACTURER RECOMMENDATIONS.

ALWAYS PROPERLY VENTILATE MANHOLE OR CONFINED SPACE BEFORE ENTERING AND MAINTAIN

VENTILATION WHILE IN MANHOLE OR CONFINED SPACE.

ALWAYS THOROUGHLY CHECK AT ALL LEVELS FOR HAZARDOUS GASES AND PROPER OXYGEN LEVELS

(20% MINIMUM).

CONTINUOUSLY MONITOR THESE LEVELS WHEN WORKERS ARE IN THE MANHOLE.

NEVER ENTER A MANHOLE OR CONFINED SPACE WITHOUT CO

-

WORKER ASSISTANCE. CO

-

WORKERS

MUST BE PROPERLY TRAINED IN SAFETY REQUIREMENTS FOR ACCESS TO MANHOLES OR CONFINED

SPACES.

IF YOU ENCOUNT

ER OR OBSERVE ANY CONDITIONS THAT ARE NOT EXPLAINED HERE OR NOT FULLY

UNDERSTOOD BY YOU, NOTIFY YOUR SUPERVISOR OR SAFETY DIRECTOR BEFORE PROCEEDING.

!!DANGER!!

ALWAYS CONSULT WITH PROPER STATE, LOCAL, AND FEDERAL AGENCIES TO INSURE THAT ALL

REQUIRED REGUL

ATIONS ARE BEING FULFILLED.

FAILURE TO COMPLY WITH PROPER SAFETY REGULATIONS MAY RESULT IN SERIOUS BODILY

INJURY OR DEATH!!

Line Acceptance

Kit

6

PACKING LIST

Inspect your kit for damage as soon as it is received. If damage is found, the delivering carrier must be n

otified

immediately to file a claim. If the carrier is not notified immediately, they are within their rights to refuse any

claims of damage. When unpacking, make sure all items are accounted for and that none are discarded with the

packaging.

ITEM

QT

Y

PART NUMBER

DESCRIPTION

1

1 304-708

A/L Control Panel

2

1 261-106

30 Foot Poly Lift/Inflation Line

3

1 273-968

Deluxe Tire Pump w/gauge

4

1 257-098 50 Foot Triple Hose Assembly (w/QD s)

5

1 103-586

Safety Instructions and Dat

a Booklet

Line Acceptance

Kit

7

INDIVIDUAL COMPONENTS

Item 1:

Air

-

Loc Control Panel (Part No. 304

-

708).

The Control Panel allows the operator to monitor and regulate line acceptance and leak location

testing from various locations. A handle located at

the top of the panel makes it easy to carry and

transport to each test area.

The Control Panel is equipped with:

-

Two air control regulators and three mechanical valves. These are provided to control the air flow

throughout the system.

-

Three air press

ure gauges to monitor the pressures of the air compressor, test chamber and the

pneumatic plugs.

Compressor Gauge

-

0 to 160 PSIG

Test Gauge

-0 to 15 PSIG

Pneumatic Plug

-0 to 60 PSIG

-

Leak location / Line acceptance ball valve allows us

er to switch (blue) test pressure port

from 3/4

to 3/8 .

Item 2

:

30 Foot Poly Lift/Inflation Line (Part No. 261

-

106).

A combination rubber inflation hose and braided poly line, the 30 foot Poly Lift/Inflation Line

allows you to lower, inflate and re

move a plug from the sewer line without putting tension on the

inflation hose.

Item 3

:

Deluxe Tire Pump (Part No. 273

-

968).

Deluxe Tire Pump is used in inflate the plug that is used for blocking in line acceptance testing.

The test pump has a large c

apacity air chamber, long lasting pressure gauge, corrosion resistant

brass fittings, and a handy quick disconnect valve.

Item 4

:

50 Foot Triple Hose Assembly (Part No. 257

-

098).

The 50 Foot Triple Hose is used in conjunction with the portable Air

-

Loc

Panel for line acceptance

testing.

Three different colored hoses simplify identification and connection to the panel and plugs. A cable

restraint is attached to the ball end of the hose assembly to eliminate the need for a separate tow

cable.

Line Acceptance

Kit

8

L

INE ACCEPTANCE TESTING

CAUTION:

PRIOR TO BEGINNING LINE ACCEPTANCE TESTING, THE

PIPE PLUG

SAFETY INSTRUCTION AND DATA BOOKLET

MUST BE READ. A BOOKLET IS

INCLUDED WITH EACH CHERNE PLUG. ADDITIONAL COPIES CAN BE OBTAINED

FROM CHERNE INDUSTRIES BY REQUEST

ING PART NO. 103

-586.

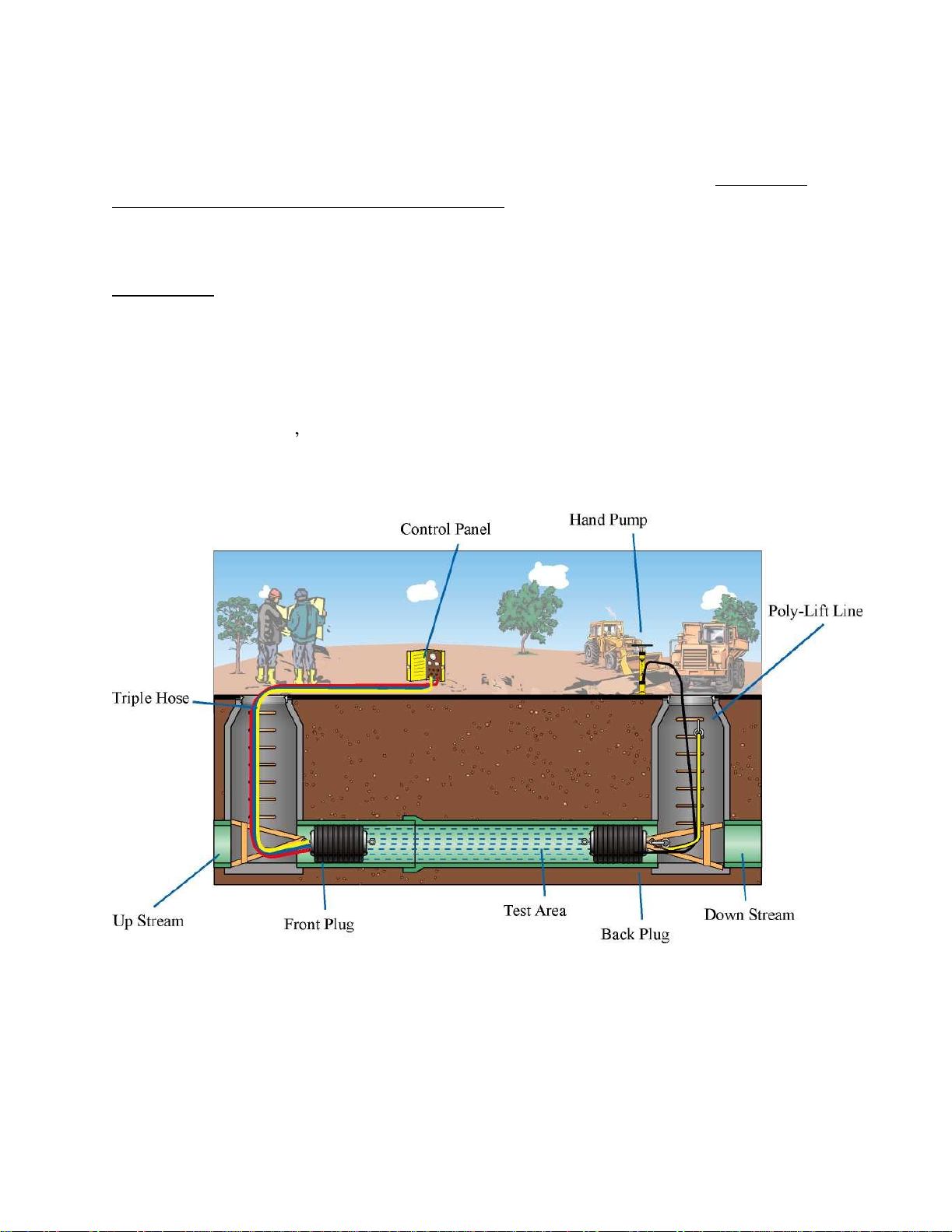

Introduction

Refer to FIGURE 1

Line Acceptance Testing consists of low air pressure testing of sewer lines using two pipe plugs. One

plug is placed in each end of a section of sewer line. The plugs are inflated to create an airti

ght seal

and the pipe (test chamber) between the two plugs is pressurized with air. A drop in air pressure

beyond the municipality s specifications indicates a leak (refer to test engineers specs). Otherwise, the

section passes. When the test is complet

ed, the test chamber is depressurized; the plugs are deflated,

and then moved to the next section of pipe to be tested.

FIGURE 1

Line Acceptance

Kit

9

PRESET TEST

PRESSURE AND BALL PRESSURE FOR

LINE ACCEPTANCE & LEAK

LOCATION

NOTE: Before the triple hose can be a

ttached to the front ball, the Air

-

Loc control panel test and

ball regulators must be adjusted.

1.

Unlatch and open the Air

-

Loc control panel (Item 1). Connect each 50 or 500 foot triple hose

quick disconnect to the fittings on the front of the control

panel according to color code.

NOTE: Leak Location Procedures use the 500 foot triple hose. Line Acceptance Procedures use

the 50 foot triple hose. This allows for faster inflation and deflation times, therefore, speeding up

the testing procedure.

2.

At the other end of the triple hose, connect the yellow and blue hoses together using two quick

disconnect nipples and a hex coupling, if available. If these types of fittings are not available,

you ll need to determine the best way to connect these two

hoses.

NOTE: Use teflon tape on all pipe thread fittings.

3.

Place the TEST VALVE in the EXHAUST position. Make sure the TEST REGULATOR and

BALL REGULATOR control knobs are turned fully COUNTERCLOCKWISE.

NOTE: The Test Regulator as well as the Ball

Regulator have spring loaded control knobs. Pull

the control knob out, turn to adjust, then release to lock.

4.

Connect the air compressor hose to the INLET AIR fitting on the control panel and place the TEST

VALVE in the OFF position.

5.

On the air compr

essor, relieve all residual backpressure. Start the compressor. Let it build to

full pressure (approx. 110 PSIG) before adjusting the TEST REGULATOR.

CAUTION: DO NOT OPERATE AT AN AIR INLET PRESSURE GREATER THAN 120

PSIG (8.2 BAR).

6.

Place the TEST VALV

E in the INFLATE position and adjust the TEST REGULATOR control

knob by turning it in a CLOCKWISE direction. Adjust the TEST REGULATOR to the correct

TEST PRESSURE" . Refer to your city/state municipal test requirements.

7.

Return the TEST VALVE to th

e EXHAUST position.

8.

Disconnect the blue and yellow hoses.

9.

Place the BALL VALVE in the EXHAUST position. Make sure the BALL REGULATOR

control knob is turned fully COUNTERCLOCKWISE.

Line Acceptance

Kit

10

10.

Place the BALL VALVE in the INFLATE position and adjust

the BALL REGULATOR

control knob by turning it in a CLOCKWISE direction. Adjust the BALL REGULATOR to

the correct Ball Inflation Pressure as indicated on the plug and/or in the

SAFETY

INSTRUCTION AND DATA BOOKLET.

NOTE: The quick disconnect coupler on th

e red hose does not need to be plugged to set the ball

pressure.

11.

Return the BALL VALVE to the EXHAUST position.

12.

Attach the 50 or 500 foot triple hose with cable restraint to the Air

-

Loc plug according to the color

coding of the hoses.

Triple hose color codes:

Red

-

Ball Inflation

Blue

-

Pressurizes the test area

Yellow

-

Monitors test pressure (on large gauge)

13.

Attach the cable from the strain relief on the triple hose to the eye bolt using the snap hook.

When line acceptance testing is completed, this cable assists in the removal of the ball from the

manhole.

14.

Lower the converted ball into the upstream manhole and insert fully into the pipe. Make

sure that the area within the pipe where the ball will be seated is cleaned of all debris or

matter that may cause an improper seal.

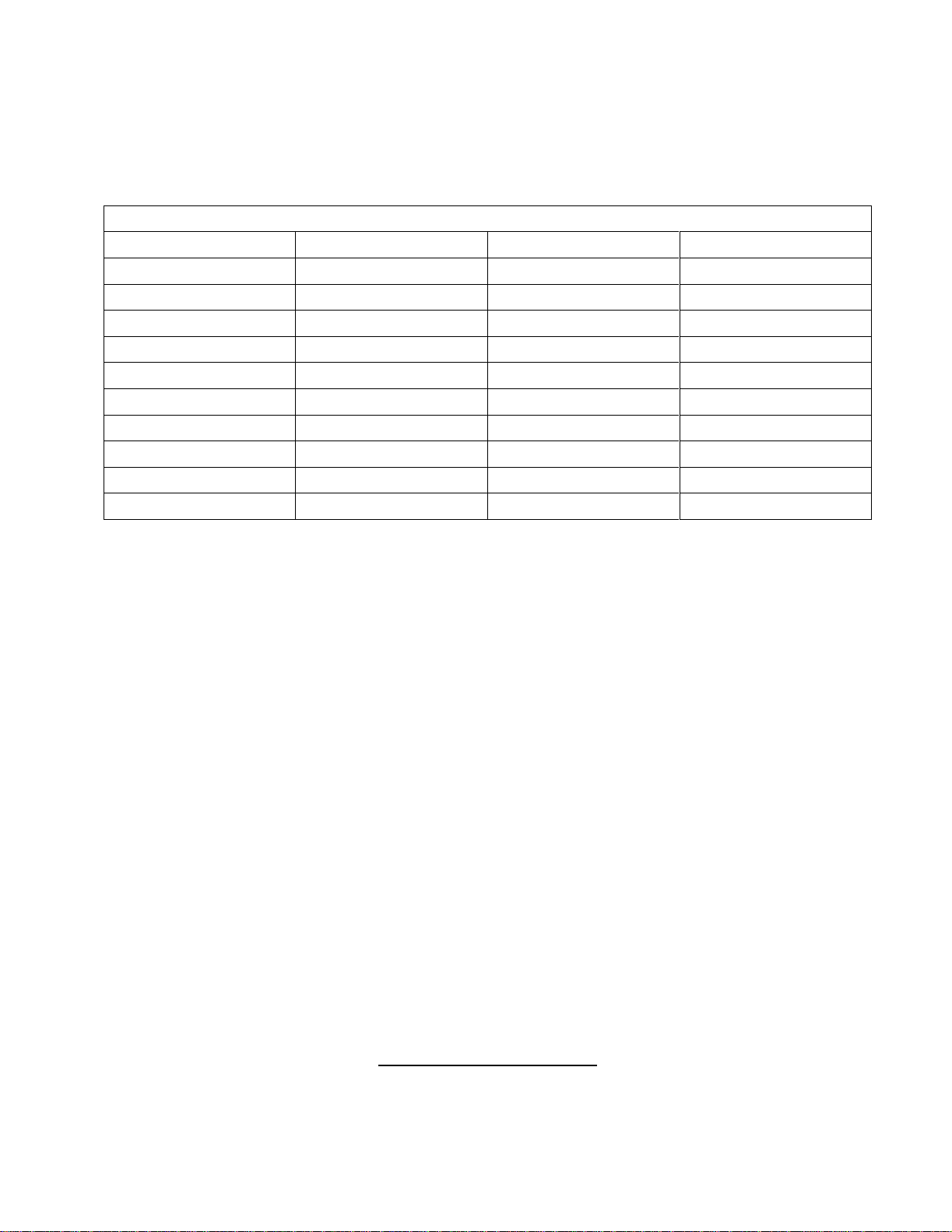

Ground Water Pressure Calculation

Where ground water is present in the area to be air tested, the pressure of the water

must be

Line Acceptance

Kit

11

calculated and added to the test pressure specified.

Water exerts a pressure of 0.433 PSI for each foot in height. The calculated water pressure should

be added to the pressures in the engineers specifications for a total pressure required in

air testing.

GROUND WATER CHART

FEET

PSI

METERS

Kg/CM

2

1

.43

.3

0.03

2

.86

.6

0.06

3

1.2

.9

0.09

4

1.7

1.2

0.12

5

2.1

1.5

0.15

6

2.6

1.8

0.18

7

3.0

2.1

0.21

8

3.4

2.4

0.24

9

3.9

2.7

0.27

10

4.3

3.0

0.30

TROUBLE SHO

OTING GUIDE

PROBLEM: AIR

-

LOC PLUGS WILL NOT INFLATE

Symptom:

Ball pressure gauge registers too low.

Line Acceptance

Kit

12

Cause . . . . Regulator set too low.

Solution . . Reset as required.

Cause. . . . Compressor off.

Solution . . Start compressor.

Symptom:

Ball press

ure gauge will not register.

Cause . . . . Leak in Air

-

Loc plug.

Solution . . See Air

-

Loc plug sleeve/body replacement.

Cause . . . . Leak in air hose system.

Solution . . See "Air Line System Leaks on page 14.

Cause . . . . Broken pressure gauge.

Solu

tion . . Replace gauge.

PROBLEM: AIR

-

LOC PLUGS LOSE PRESSURE

Symptom:

Reading on ball pressure gauge drops; leak is heard at the control panel.

Cause . . . . Leak in air hose system.

Solution . . See "Air Line System leaks" on page 14.

Symptom: Readi

ng on ball pressure gauge drops; no leak is heard.

Cause . . . . Leak in air hose system.

Solution . . See "Air Line System leaks" on page 14.

Cause . . . . Hose between plugs leaking or fittings are loose.

Solution . . Repair or replace hose, tighten fi

ttings.

Cause . . . . Leak in Air

-

Loc ball.

Solution . . Repair or replace.

PROBLEM: TEST PRESSURE WILL NOT BUILD

Symptom:

Test Pressure gauge registers too low.

Cause . . . . Compressor off.

Solution . . Restart compressor.

Cause . . . . Water in te

st monitor line.

Solution . . Temporarily reverse the yellow and blue hoses at the Air

-

Loc control panel to flush the

test line.

-

Trouble Shooting Guide continued on next page

-

TROUBLE SHOOTING GUIDE

(Continued)

Cause . . . . Regulator set

too low.

Solution . . Reset as required.

Line Acceptance

Kit

13

Cause . . . . Leak in pipe.

Solution . . Replace or repair pipe.

Cause . . . . Air by

-

passing balls.

Solution . . Clean line, remove debris.

Symptom:

Test pressure gauge will not register.

Cause . . . . Yellow

hose plugged.

Solution . . Disconnect the yellow hose from the Air

-

Loc reel rotary union and induce air into the

test line. This will remove any debris blocking the test line air passage.

Cause . . . . Bad leak in

pipe.

Solution . . Leak location procedure.

PROBLEM: TEST PRESSURE DROPS

Symptom:

Reading on test pressure gauge drops, leak is heard at control panel.

Cause . . . . Leak in hose system.

Solution . . See "Air Line System Leaks" on page 14.

Symptom:

R

eading on test pressure gauge drops, no leak is heard at control panel.

Cause . . . . Leak in hose system.

Solution . . See "Air Line System Leaks" on page 14.

Cause . . . . Air by

-

passing Air

-

Loc balls.

Solution . . Clean line, remove debris. See probl

em called "Air

-

Loc balls will not inflate".

Cause . . . . Leak in sewer line.

Solution . . Leak location procedures.

PROBLEM: TEST PRESSURE INCREASES

Symptom:

Reading on test pressure gauge rises.

Cause . . . . Sewer line is warmer than test air intro

duced.

Solution . . Read air testing procedures.

Cause . . . . Infiltrating water between balls.

Solution . . See "Ground Water Pressure Calculation", page 16.

Cause . . . . Air by

-

passing to test chamber.

Solution . . Check all air connections, check fi

ttings on ball.

Time Charts

APPROXIMATE TIME REQUIRED TO PRESSURIZE TO 4 PSIG (0.28 Kg/cm2)

THROUGH 50 FOOT (15.2 METERS) INFLATION HOSE

(IN MINUTES, UNLESS OTHERWISE NOTED)

Line Acceptance

Kit

14

Pipe Size

20' Reach

100' Reach

200' Reach

300' Reach

400' Reach

500' Reac

h

600' Reach

Inches

Millimeters

(6.09 M)

(30.4 M)

(60.9 M)

(91.4 M)

(121.9 M)

(152.4 M)

(182.8 M)

4

101

1 sec.

7 sec.

14 sec.

21 sec.

28 sec.

34 sec.

42 sec.

6

152

3 sec.

14 sec.

31 sec.

44 sec.

1.02 min.

1.37 min.

1.51 min.

8

203

5 sec.

28 Sec.

52 sec

.

1.4 min.

1.79 min.

2.24 min.

2.7 min.

10

254

8 sec.

39 sec.

1.37 min.

2.1 min.

2.7 min.

3.4 min.

4.1 min.

12

304

12 sec.

58 sec.

1.96 min.

2.94 min.

3.92min.

4.94 min.

5.99 min.

15

381

18 sec.

1.54 min.

3.1 min.

4.62 min.

6.16 min.

8.2 min.

9.24 min.

18

457

28 sec.

2.21 min.

4.4 min.

6.6 min.

8.8 min.

11 min.

13.2 min.

21

533

36 sec.

2.5 min.

5.9 min.

8.82 min.

11.8 min.

15 min.

17.6 min.

24

609

48 sec.

4 min.

7.9 min.

12 min.

15.9 min.

24 min.

32 min.

* The above times are approximate only. The

y re applicable to a compressor with capacity of 17.9 CFM at 100 PSI.

SAMPLE PIPE TESTING TIMES

PIPE DIAMETER/INCHES

PIPE DIAMETER/MM

MINUTES PER 100 FEET

4 101 .11

6 152 .23

8 203 .42

10 254 .53

12 304 .63

15 381 .74

18 457 .84

21 533 1.1

24 609 1.3

Form 044

-

948, Rev. C

-

ECN 06

-7552

©2006

Cherne Industries Incorporated

All Rights Reserved

TJB 6/14/06

Table of contents

Other CHERNE Test Equipment manuals

Popular Test Equipment manuals by other brands

Galaxy Audio

Galaxy Audio CHECK MATE CM-C200 instruction manual

Fortinet

Fortinet FortiTester 2500E quick start guide

Megger

Megger MET1000 user guide

Ibiza

Ibiza STROBE132LED instruction manual

Alcohol Countermeasure Systems

Alcohol Countermeasure Systems Alcolock V3 B-2 Series instruction manual

Chauvin Arnoux

Chauvin Arnoux AEMC Instruments 6470-B user manual

Dräger

Dräger Alcotest 6810 GB Operator's instruction manual

iBACheck

iBACheck i1 AA1698 Operation manual

Time Electronics

Time Electronics 8030 user manual

Fluke

Fluke NetTool Quick reference guide

Pacific Data Systems

Pacific Data Systems AlcoVUE DDS-ALV-100 User handbook

Tektronix

Tektronix MDO4104 Technical reference