Chery SQR372 User manual

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

1

SQR372 Engine

ServiceManual

CheryAutomobileCo., Ltd.

Forewords

Inordertohelpthetechnicalservicingpersonneltohavecorrectunderstanding andgoodcommandofthe

cute Chery ModelSQR7080 vehicle,andtomastertheskillsforfastrepairsandrationalmaintenance,a

specialeditionofthe Chery QQ TechnicalServiceManual—372EngineMechanicsDivision”is

compiledandpublished.

ThisManualgivesadetaileddescriptiononthedismounting, installation,checksandtests,adjustments

anddiagnoses,technicalstandardsandspecificationsforadjustmentsanddiagnosesofvariouspartsand

componentsaswellassubsystemsof Chery QQ372engines.ThisManualispublishedby Chery

AutomobileCo.,Ltd.

AnypartsorsectionsofthisManualshallnotbecopiedorduplicatedinwhateverformorbywhatever

approachwithoutthewrittenauthorizationofthepublisher.

Therightofinterpreting theManualbelongstotheServiceDepartmentof CheryAutomobileCo. Ltd

Editors

Marchof2004

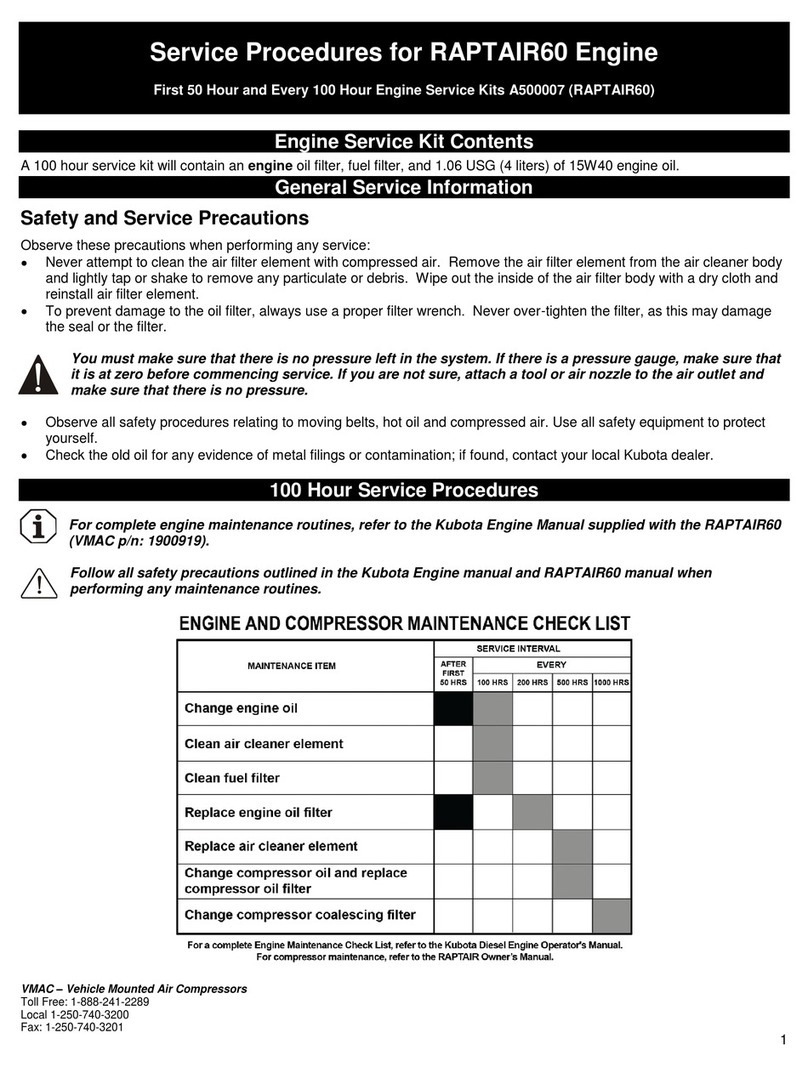

3Specialtoolsformaintenance:

Outer appearance CodeandName Purpose

Auxiliarydevicesforengine

dismountingandchecks

Mounting ontoengine

dismountingandcheck

stand

Enginedismounting andcheckstand

Dismounting and

installing engine

Clockwisebeltwheelwrench Camshaftclockwise

belt wheeldismounting

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

2

Springbushpulling andremoving

device

Installingcrankshaft

oil seal

Valve locking blockremovaldevice

Auxiliarytools

Dismounting and

installationof valve

spring locks

Flyingwheelfixture Dismounting and

installationof

crankshaft

Valve guidingpipepunch Removingand

installationof valve

guiding pipe

Shaftoilsealreplacer

T

Oilsealstandscrewdriver

Outer appearance Codeand Name Purpose

Crankshaftbeltwheelfixture Removeandinstall

crankshaftbelt wheel

Wrench Removeandinstall

camshaft slavegear

wheel

Replace valvespacing

adjustwasher

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

3

Waterpumppulleyassembly

wrench waterpumpAssembly

Measuring

tools Clearancegauge,calipers,Micrometer,ruler,centesimalmeter,cylindergauge,

pressuremeter, torquewrench

Tool Pistonring dismountingdevice

Oils Engine lubricating oil, bond

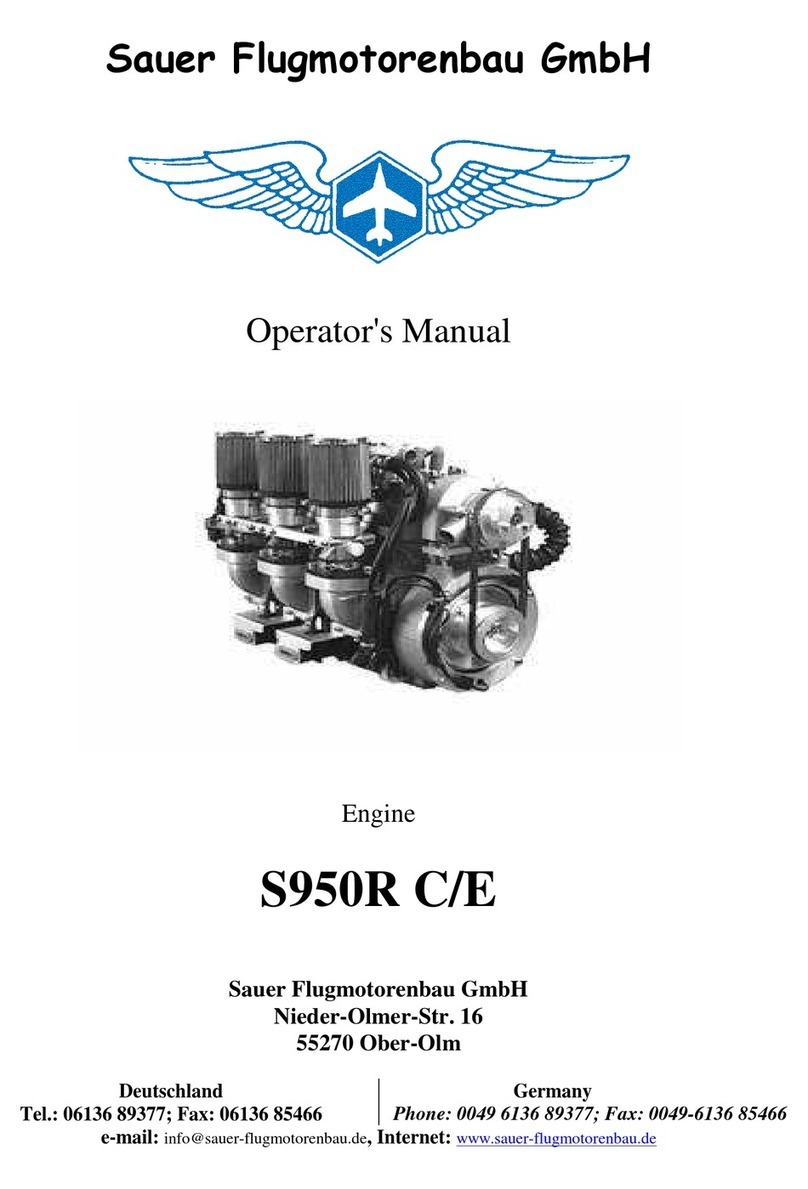

Chapter2Timing Belt Service

1. Configurationdiagram

1Waterpumppulley

2Timingbeltcover

3Timingbelt

4Torsionshockabsorber

5Timingpulleydamper

6Tensioner

7Crankshafttimingpulley

※:Non-reusable part

Unit:N·m(kg·cm)

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

4

Removetorsional vibration damper.

Removewaterpumppulley.

Removethewaterpumppulleyaccording tothe

illustration.

Removeitwithscrewdriverandwrenchaccordingto

theillustration.

SST

Removetorsional vibration damper

(1)Fixtheflywheelandpreventthegearring from

rotating.

(2)Removeboltoftorsional vibration damper.

图29

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

5

Removetimingcovercap

Torque:6±1N.m

Removetimingpulleydamper

Removethetensioner

(1)Carryouttheoperationattheupperthrustpoint

ofcompressionofthefirstcylinderpiston

(2)Afterremoving thetimingcovercap,turnthebolt

androtatethetiminggearclockwisewithwrench,

aligntiming markofcamshafttiminggearwiththe

cammarkofcamshaftcovercap;

Attention:You canrotatetheengineclockwiseonly,

afterinstalling thepulley;

Beforeremoval,makeaarrowmarkonthepositionof

timingmark,assembleaccordingtooriginalstate.

(3)Makesurethatthecrankshafttimingpulleywheel

markisalignedwiththemarkoftheoilpump.

(4)Removethetensionerbolt,andtakeoffthe

tensioner

Timing mark

Timing mark

Clockwise

Do“mark”

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

6

Removethetimingbelt.

[Caution] Itisabsolutelynotallowedtousescrew

driverorsomeothersharp-edgedtoolstoremovethe

belt.

Attention:Pay attention tothefollowing pointswhile

using timing belt:

-Don’tbendthebelt evenatasmallangle,

otherwiseitwillresultinropefractureinsidethe

belt.

--Service lifeofbelt isshort,don’tpollutethebelt

withgreaseandwater.

-You havenochoice butrotatetheengine

clockwiseafterinstallingthebelt.

2.7Removethecrankshafttiminggear

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

7

3 Makecarefulanddetailedchecksonthetiming belt.Replacewithnewpartsifanyofthe

conditionsshowninthefigureoccurs.

3.1Cracksonthebacksiderubber;

3.2Cracksofteethroots,cracksclearing off thefabriclining layer;

3.3Tearsandwearsoffabriclininglayer, missing rearteeth, brokenteeth,etc.

3.4 Abnormaltearsandwearsonbeltsides

Chap

Chap

Tearsand

wears

Abnormal

tearsand wears

MIS

Drop-off

ofbeltcore

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

8

3.5 Evenifthedamagesontheouterappearance cannotbeconfirmed,thebelt shouldbereplaced

underanyofthefollowingcircumstances:

3.5.1If thewaterinthewaterpump isleaked,whichmakesitnecessarytorefillthewater

continuously;

3.5.2 Therearemuchoil stainsonthebelt,thebeltshouldbereplacedfortherubberwillbedamaged

whenitisexpanded;

3.6 Specificationsandmodelofthetiming belt

Partnumber 372-1007081

Beltwide 25.3mm

3.7 Timingbelttensioner

Turnthebelttensionersupporting stand bolts toseeifthereareanyabnormal sound.Checktoseeif

thereareanydamagesonthecontacting surface ofthebelt.

Specificationsandmodelofthetimingbelttensioner

Partnumber 372-1007030

Wide 27.0mm

Outsidediameter φ50mm

3.8 Checktosee ifthereareanydamagesontheouter appearance

Specificationsandmodelofclockwisepulley

EFModel

Item GL、ZL、G 、Z

Diameterofcamshafttiming

gear (mm)φ110.7+0.1-0.2

Diameterofcrankshafttiming

gear (mm)φ54.65+0.7-0.13

3.9 Baffleofcrankshafttiminggear

Checktosee ifthereisanydeformation

Standardsizeofcrankshaft timing gear:

Wide 28.6mm

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

9

4. Installation

4.1 Installationofcrankshafttiming gear

4.2 Installationoftiming belt

4.2.1 Ontheupperthrustpointofthefirstcylinder

compression

Place thecamshafttiming geararound thefrontendof

theairexhaustcamshaftsoastomakethepositioning

grooveonthegearbealignedwiththepositioningpin

ontheendsurfaceofthecamshaft.Thenusescrewsto

fixtheclockwisegear, withthetorqueof100 ±5N.m.

4.2.2 Makesurethatthepunchedmarkonthe

crankshaftclockwisepulleyisalignedwiththemark

oftheoil pump.

4.2.3 Installtimingpulleyaccordingly.

Timingmark

Timing mark

Clockwise

Timingmark

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

10

4.3 Installthetensioner

4.3.1 Adjustthetensionofthetimingbelt

Asshowninthefigure,makethespacebetweenthe

edgeofthestretchingwheelandthewaterpumpcase

arctobeabout8mm;

Tightentheboltofthestretching wheelwitha②

torqueof25 ±3N.m.Useascrewdrivertoswingthe

stretchertowardtheright..

③Turnthecrankshaftfortwocirclestowardsthe

enginerotating direction,sothatthecamshaftpulley

andthecrankshaftpulleymatchestheclockwisemarks

respectively.

④Usehandstopressdownforabout5mm.Theforce

forpressing theclockwisebeltisabout: [Reference]

20~30 N

Notice:Whenthedeflectionofthetiming beltfailsto

meetthespecifications,thekeyistoadjustthe

above-mentionedstretcherfastening boltbywidening

thespacing.

TightentheS/Afixing boltofthestretcherwiththe

specifiedtorqueof25 ±3N.m

4Install thebaffleofthe crankshaft timing pulley

[Attention]Installthebaffle towards thedirection

shownintherightfigure.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

11

5Install thetimingcovercap

torque:6±1N.m

6Install thetorsional vibration damper(useSST)

1)、 Whenthereis not aflyingwheel,

Fixapartofthecrankshaftpulley.

②Payattentionnottomakethegearbeltmoving,

tightenthebolt accordingtothespecifiedtorque:

torque98.0±10N.m{10±1kgm}

2 )、 Whenthereisaflyingwheel,

Fixtheflywheeltopreventthe tooth ringfrom

turning

②Thentightenbolt oftorsional vibration damper.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

12

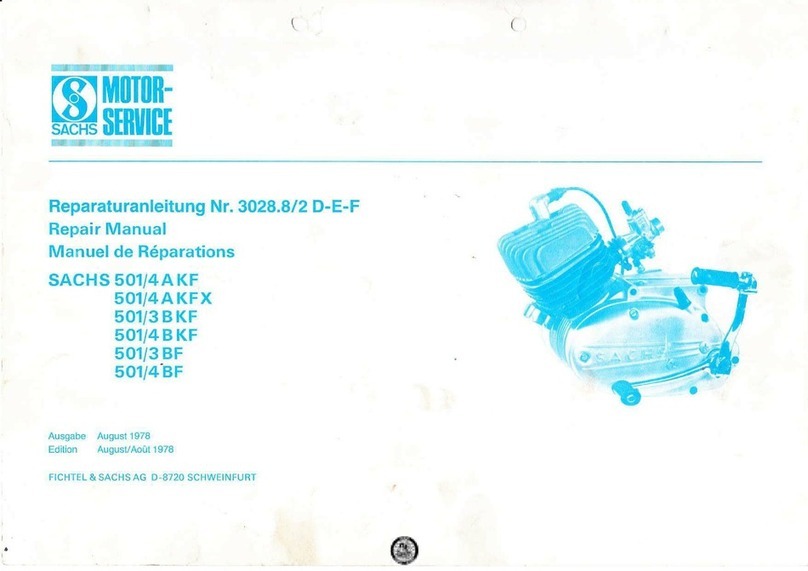

Chapter3CamshaftService

3-1.Diagram(Removalandinstallationorder fortimingbelt)

3-2Removal

Removecylinder

headcoverassembly

Removethevalvechambercovercapbolt

fromtwosidestothecentresymmetrically.

Remove②valvechambercovergasket

2Routinecheckofvalve

valveclearancestandard:

IN 0.18±0.05

Valve

clearance EX

0.25±0.05

3 Dismountthecamshaftclockwisegear

Attention·Youmustpreventthecamshaftfrom rotating.

(1) Valvecagecover

(2) Valvecagecover

gasket

(3) Camshafttiming

pulley

(4) Camshaftcover

(5) Circularplug

(6) Camshaftbearing

cap

(7) Exhaustcamshaft,

(8) Intakecamshaft,

(9) Oilseal

(10)Springretainer

(11)Wavewasher

(12)Intake camshaft

sub-gear

(13)Snapring

(14)Locknut

(15)Flange

Non-reusablepart

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

13

Exhaust

Intake

4Removalofcamshaftcovercapandcamshaft

bearingcover

(1)Align themarksonthecamshaftgearsasshownin

therightfigure.

Setbolt

(2)Usebolttopositionthemasterandslavegearson

theairinletcamshaft,asshownintherightfigure.

Attention Inorderto eliminate theradialforce, keepthe

camshaftintheleveledpositionbeforedismounting it

(toavoidpossibledamagescausedbyexcessiveradial

forces)

(3)Removetheboltsinthesequence showninthe

rightfigure;

Removethecamshaftbearing cover

SST

(4)Removethesparkplug

(5)Removethecamshaftslavegear.Usethespecial

toolasshownintherightfigure.

Clipthecamshafttightly,andturnthegear,tokeep

thebitestateofmasterandslavegear;removethefixing

boltsofslavegear.

Attention Donotdamagethesurface ofthecamshaft.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

14

(6)Usetensioningapparatustoremovethebearing use

elasticsnapring, removewavewasherandteethedring.

3-3Camshaft

1Usethecalipertomeasuretheheightofthecamshaft.

If itisbelowthespecifiedlimits,makeproper

replacement.

Camshaft Unit:mm

EF

Model

Item ZL

RL GL GS

ZS

IN φ23.0-0.02-0.033

StandardEX φ23.0-0.02-0.033

IN

22.9

LimitEX 22.9

2Checksoncamshaftaxialclearance

(1)、 Whentheaxialspacing ismeasuredwitha clipper

tobelargerthanthebenchmarkvalue,thecamshaftisto

bereplaced.

Theairinlet camshaft axialclearance is0.1~0.170mm。

Theairexhaustcamshaftaxialspacing is0.1 ~

0.173mm。

Limitsforoperation:0.18mm

3-4Cleaning

1、Clearoffthesparkplugcarbonaccumulationwitha

metalbrush.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

15

3-5Installation

Fixthetwo φ6holesofthecamshaftgearS/A.

②Turnthe slave geartotheright,matchthemarkhole

ontheslavegearwiththemarkonthemastergear,or

alignthemarksontheslavegearwiththemarkonthe

mastergear;thenfixtheslavegearwithbolt.

(thread:M5;pitch:0.8)

SST

2、Installationofthecamshaft

Attention Sizeoftheaxialclearanceofthecamshaft

(1)、Smearlubricatingoilatthecamshaftgearsection

andthecylindercoveraxialdiametersection.

(2)、Fixthecamshaftslavegearbyroughlyadjusting on

the cylinder cover.

(3)Itisnecessarytomeasurethesize ofaxialclearing

ofcamshaft.

Exhaust

Intake

(4)Installcamshaft,thetimingmarkmustbealigned

shownastherightfigure.

(5)Smearlubricatingoil onthecamshaftassembly, the

gearsandthe cylinder headaxialdiametersection.

3Tightenthecamshaftbearingcapshownasright

figure.

4Removetheboltforfixingtheslavegearofthe

camshaftassembly.

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

16

SST

5installationofcamshaftheadcap

Smearthefluidsealantonthecamshaftheadcapsection

(withoil groove)shownastherightfigure.

Tightentheboltsaccordingtothesequencesshownas

therightfigurewiththespecifiedtorques.

6Aftersmearing oilintheplugcapholeandassembling

surface oftheplug, useSSTtopress thepluglid

Attention·Installthepluglidshownastheright

illustration.

Keepunbiasedwithcylinderheadendsurfaceafter

pressing.

outside

7Smearengineoil ontheoil sealinstallationportof

cylinderhead,camshaftoilsealedgeofbladeand

outsidering,useM10 bolt(length50-60 mm)andSST

pressthecylinder,lower1mm than theendsurface of

thecylinder4head.

Attention ·Undertheconditionofusetheoil seal

repeatedly,pressherewithengineoiladhesiveagent

-Theoil sealshouldnotbepressedinclining tooneside.

8Installationofthetiminggearofcamshaft

Aftersmearing thefluidsealant,useSSTtoprevent

rotating,tightenthetiming gearboltofcamshaft

according toregulatedtorqueof100±5N.m.

Sealingline

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

17

9Installationofvalvechambercovercap

Theusedbasefacing thecylindercoverofthetiming⑴

beltcovermustbecleanedthoroughly.

Installthenewbasecorrectlyintothegrooveofthe⑵

valvecagecovercap

Installvalvecagecovercaptocylinderhead⑶fromtwo

sidestothecentresymmetricallyaccording tothe

regulatedtorqueof6±1N.m

1 Usefeelergaugetocheckthethrottleclearance.

Attention·Makesuretomeasuretheclearance between

basiccircleofcamandvalveadjusting gasket.

Standardofvalveclearance:

IN 0.18±0.05

valve

spacing EX

0.25±0.05

2Whenitisbeyondthebenchmarkvalue,the

adjustmentwasherhastobereplacedandtheclearance

shouldbeadjusted.

Attention Thevalvenumberthatgoesbeyondthe

benchmarkvaluehastoberecorded,andtheresultof

measurementsshouldberecordedas well

(1)Useacalipertomeasureandadjustthethickness of

theseparationcushion.

2.18 2.40 2.62

2.20 2.42 2.64

2.22 2.44 2.66

2.24 2.46 2.68

2.26 2.48 2.70

2.28 2.50 2.72

2.30 2.52 2.74

2.36 2.58 2.80

2.34 2.56 2.78

2.32 2.54 2.76

2.38 2.60

(2)Selectproperseparationcushiononthebasisofthe

throttlethrustingrodbenchmarkvalues.

IN

Selectedcushionthickness=removedcushion

thickness +(measuredthrottlespacing –0.18mm)

EX②

Selectedcushionthickness=removedcushion

thickness +(measuredthrottlespacing –

0.25mm)

[Reference]thereare32kindsofshimisthickness ,

shownastheillustration

PDF 文件使用 "pdfFactory Pro" 试用版本创建 www.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

18

Forword

lower

(7)Usetheselectedadjustinggaskettoadjustthe

throttleclearance.

Attention Install thefeeler withtheidentification mark

facing downwards.

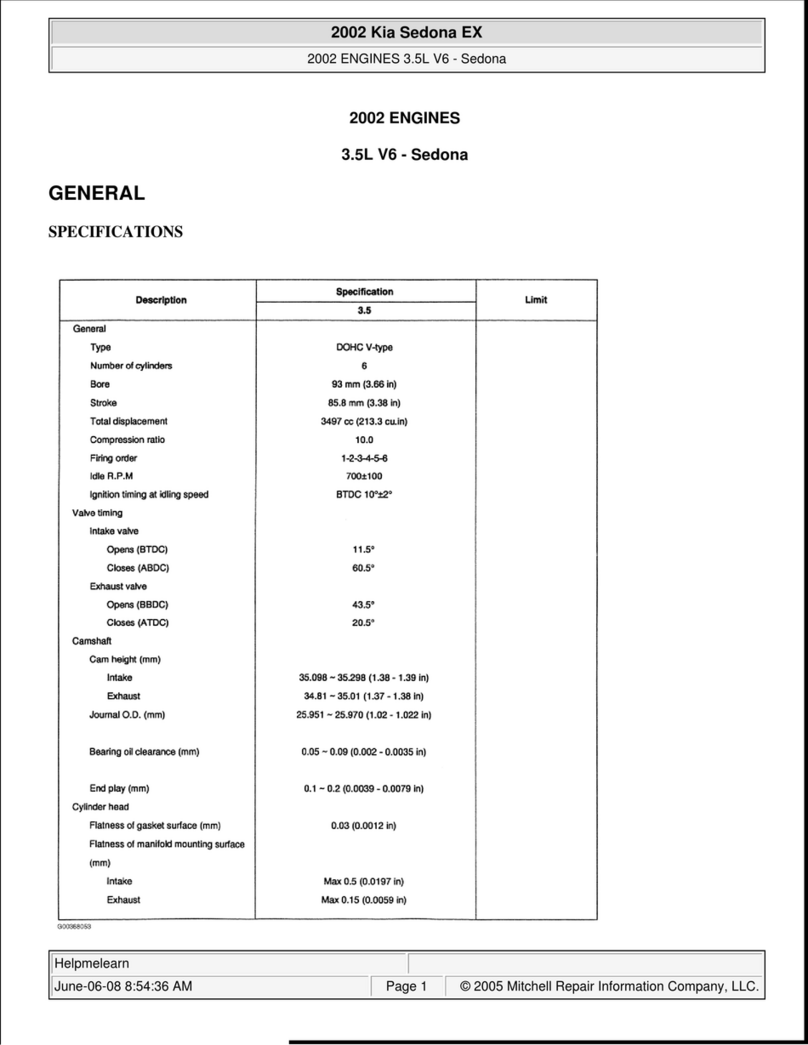

4.Cylinderhead

4-1Configurationdiagram(Dothefollowingoperationsintheproceduresforthedismountingand

installationofthecamshaft)

(1)Sparkplug20±1Nm

(2)Cylinderhead

(3)WeathersealI

(4)Cylinderheadgasket

(5)Adjustshim

(6)Valvelifter

(7)Keeper

(8)Valvespringseat

(9)Valvespring

(10)Intake valve

(11)Exhaustvalve

(12)Valveoil seal

(13)Valveseat

(14)Valveguide

※:Non-reusable part

Unit:N·m(kg·cm)

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

19

4-2Dismounting

1、Removalofsparkplug

2Thereare8cylindercoverbolts.Intheprocess ofremoving the

cylinder,pleasefollowthesequencesshownastheright

illustration, loosenthe boltsonebyone evenlyand gently.

3Removalofthecylinderdustproofsealingandcylinder

coverbase.

Attention Thecylindercushioncannotbeused

repeatedly.

4Removalofthrottleadjustingseparationcushionand

valvethrustingrod

5Usespecialtoolstoremovethevalvespringlocking

block,throttlespring stand,valvespring,INvalveand

EXvalve

6Removalofvalveoilsealandvalvespring washer

4-3Clearing

1Theaccumulatedcarbonresiduecoveredonthevalve

mustbecleared.

2Usescrapertoclearthecylindercover,theairinlet

andexhaustbranching pipesurfacesandbottoms

Attention

Donotdamagethecylindercoversurfacebyscraping

duringtheprocess ofclearing.

Donotdropfilthintotheairinletandthewaterchannel.

SSTforvalveoilseal

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

SQR7080Service Manual372EngineMechanicalSystem

CheryAutomobile Co., Ltd

20

4-4Routinechecks

4-4-1Cylindercover

1Usethestraightknifesharpedgerulertomeasurethe

levelness atvariouspointsasshowninthefigure.

Cylindercover0.10mm

Airinletbranchingpipesurface0.10mm

2Useasquarerulertomeasuretherightangleofthe

valvespring.Replacethespring ifit failstomeetthe

specifications.

[Limit] 1.2mm

3Measurethefree stateofspring

[Benchmarkvalue]37mm

4-4-3Throttle

Routinechecksonthrottles

1.Checktosee iftherearesomedeformations,obvious

tearsandwears

RoutinechecklistonvalveUnit:mm

Item Standard Limit

IN

0.85~1.41 ___

Wide E

X

1.07~1.36 ___

IN

1.0±0.2 0.75

Widthofvalvetop

E

X

1.0±0.2 0.75

Width

Measure outside

diameter

PDF 文件使用 "pdfFactory Pro" 试用版本创建 ÿwww.fineprint.com.cn

Other manuals for SQR372

1

Table of contents

Other Chery Engine manuals

Popular Engine manuals by other brands

Siemens

Siemens 1LA8 operating instructions

BRP

BRP ROTAX 125 MAX DD2 evo Installation instructions and operators manual

Briggs & Stratton

Briggs & Stratton 110400 Operating & maintenance instructions

Siemens

Siemens SINAMICS S120 Function manual

GGP

GGP RS Operator's manual

Grizzly

Grizzly H5377 Wiring diagram