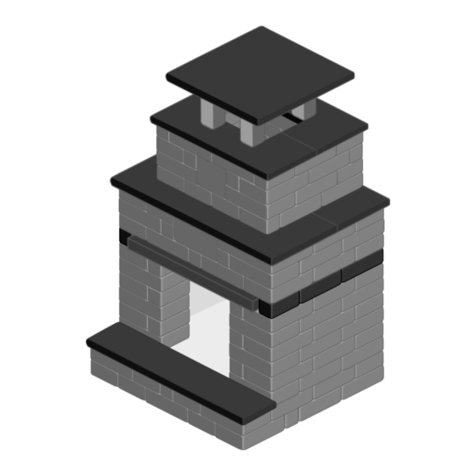

Chesney's The Bronze Urn Instruction Manual

Table of contents

Other Chesney's Indoor Fireplace manuals

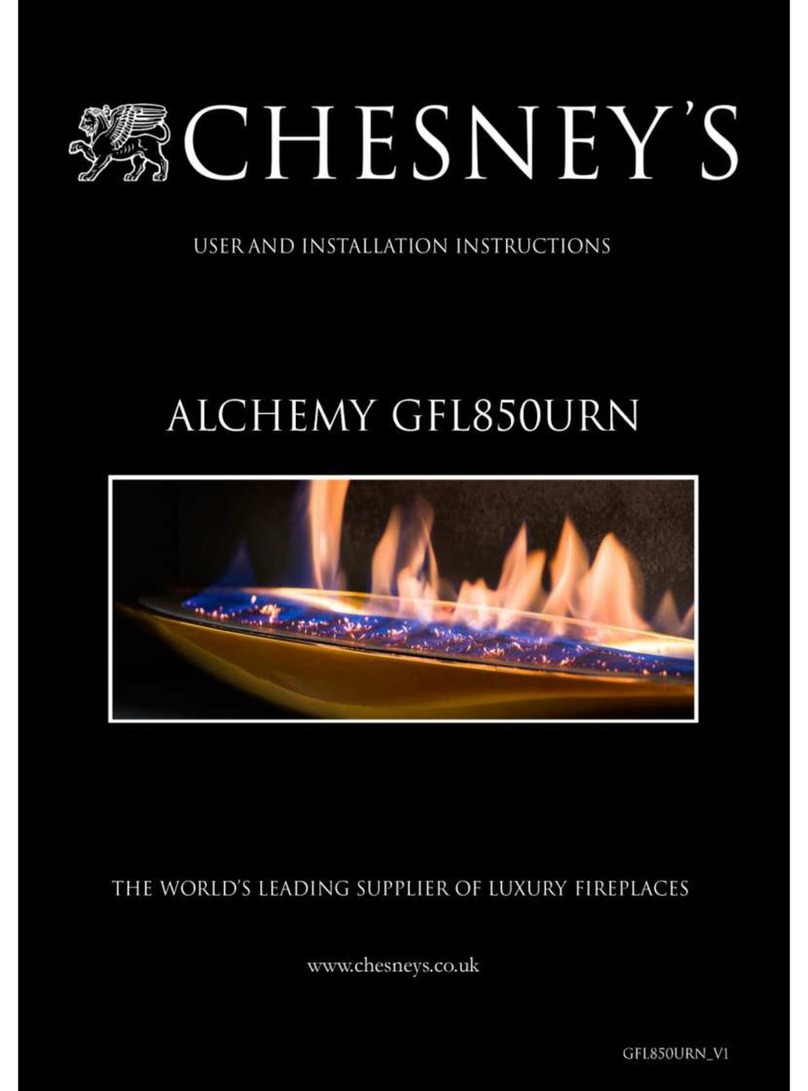

Chesney's

Chesney's Alchemy GFL850URN Operating instructions

Chesney's

Chesney's EFB22 Instruction Manual

Chesney's

Chesney's EFB1200 Instruction Manual

Chesney's

Chesney's Marble User manual

Chesney's

Chesney's CUBB18 Alchemy Operating instructions

Chesney's

Chesney's CUBB18 Alchemy Operating instructions

Chesney's

Chesney's EFB1200 User manual

Chesney's

Chesney's CUBB18 Alchemy Operating instructions

Chesney's

Chesney's Alchemy FB18 Instruction Manual

Popular Indoor Fireplace manuals by other brands

Monessen Hearth

Monessen Hearth ILDV30 Specifications

Montigo

Montigo M38DVM Installing and operating instructions

Dimplex

Dimplex CAS400 manual

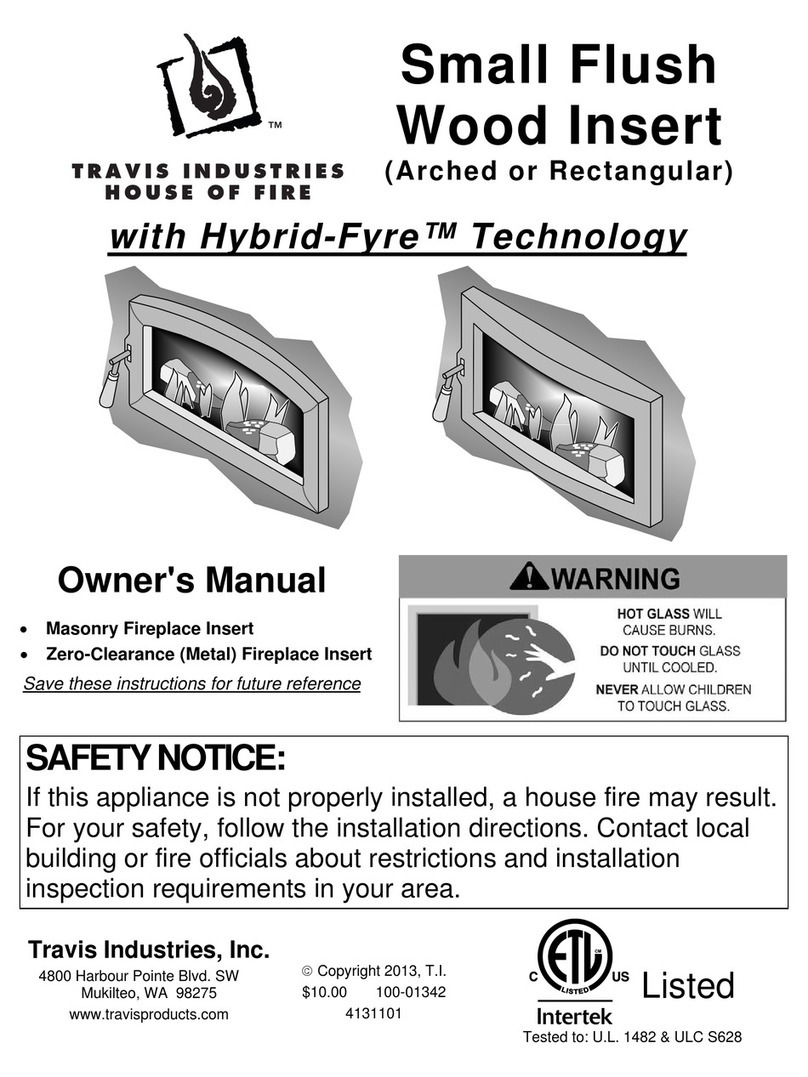

Travis Industries

Travis Industries Small Flush owner's manual

La Hacienda

La Hacienda Colorado Mesh Chimenea XL User instructions

Italkero

Italkero Camino Series User, installation and technical assistance

livn

livn Essence EF313A instruction manual

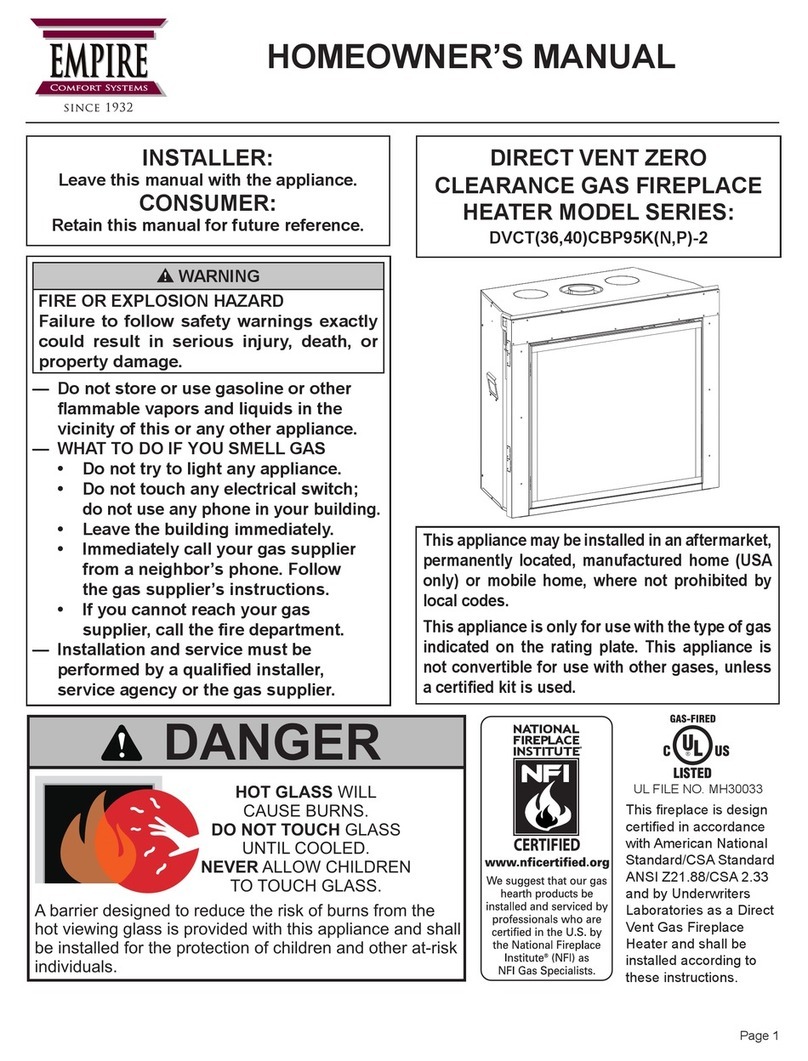

Empire Comfort Systems

Empire Comfort Systems DVCT36CBP95KN-2 Homeowner's manual

Napoleon

Napoleon GD19 Installation and operating instructions

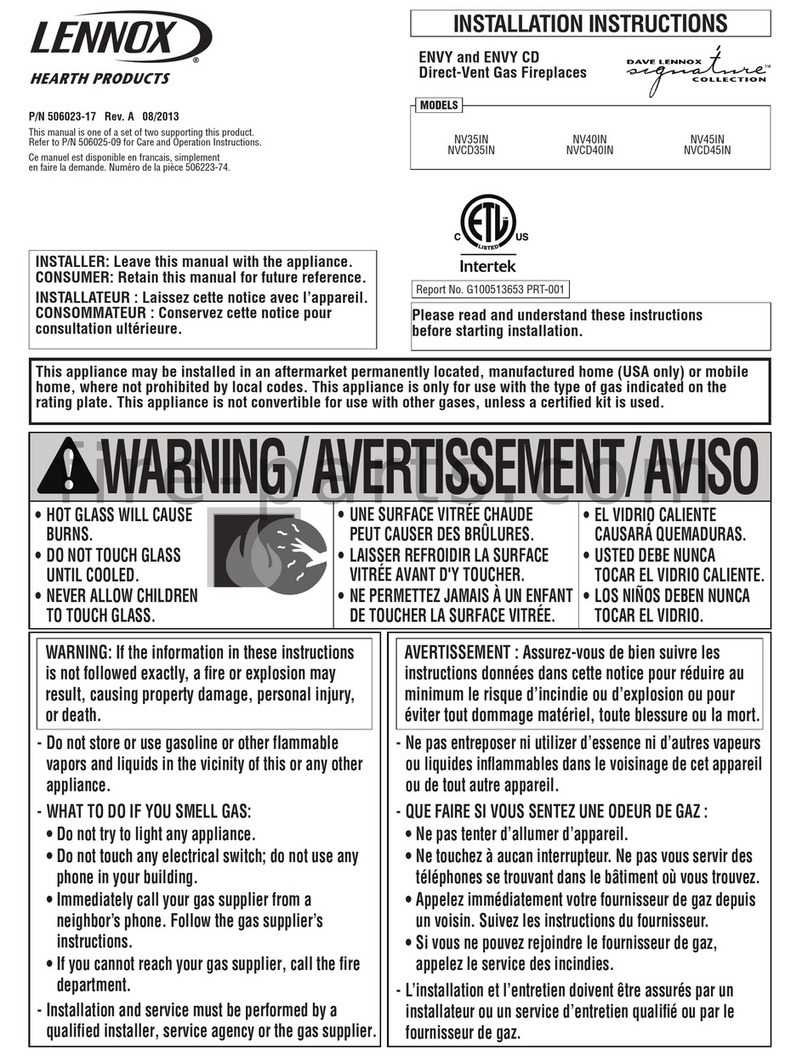

Lennox

Lennox ENVY installation instructions

Twin-Star International

Twin-Star International 18II310GRA manual

Valor

Valor 534AN Installation and owner's manual