PIPER CHEYENNE SERVICE MANUAL

LISTOF ILLUSTRATIONS

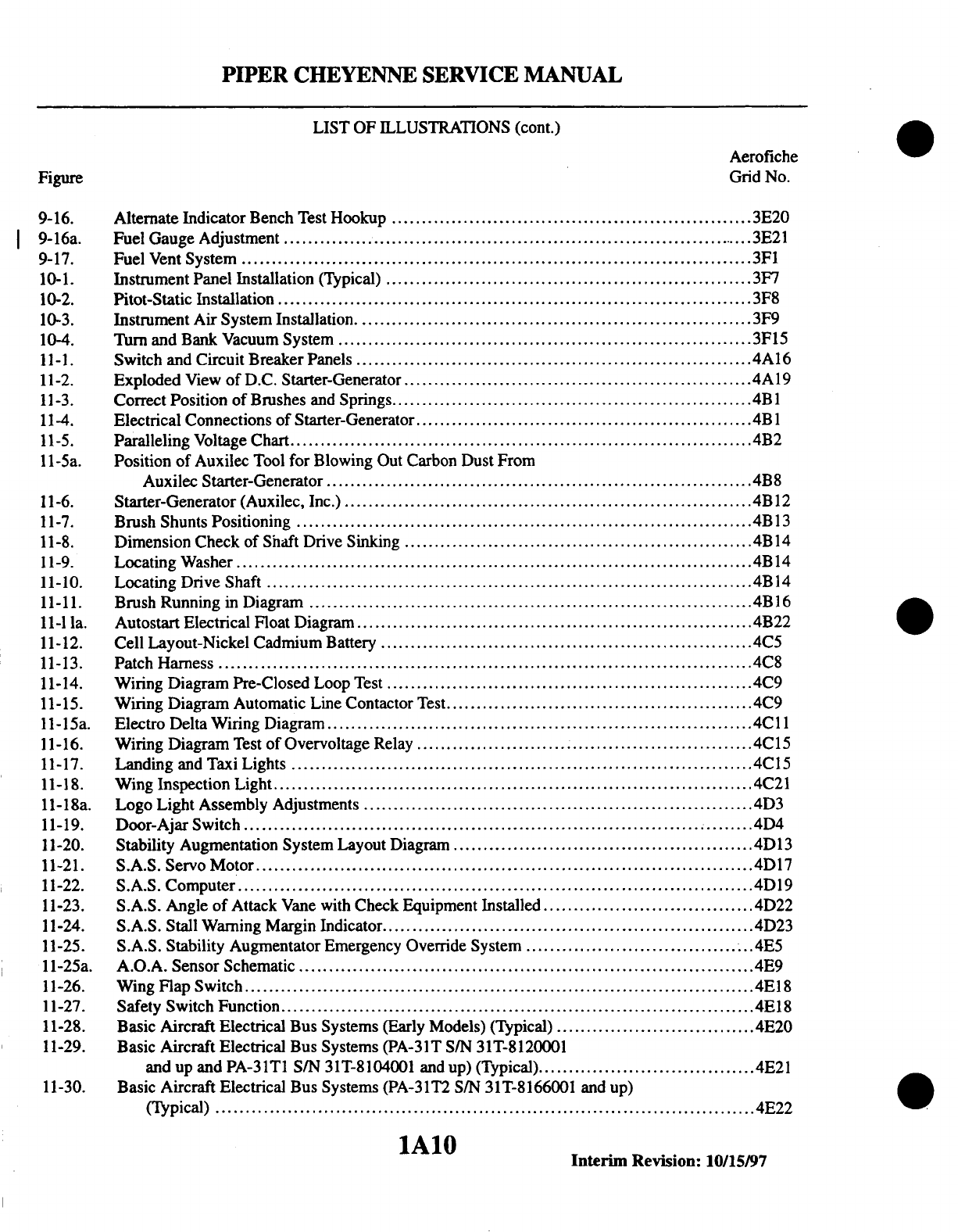

Aerofiche

Figure Grid No.

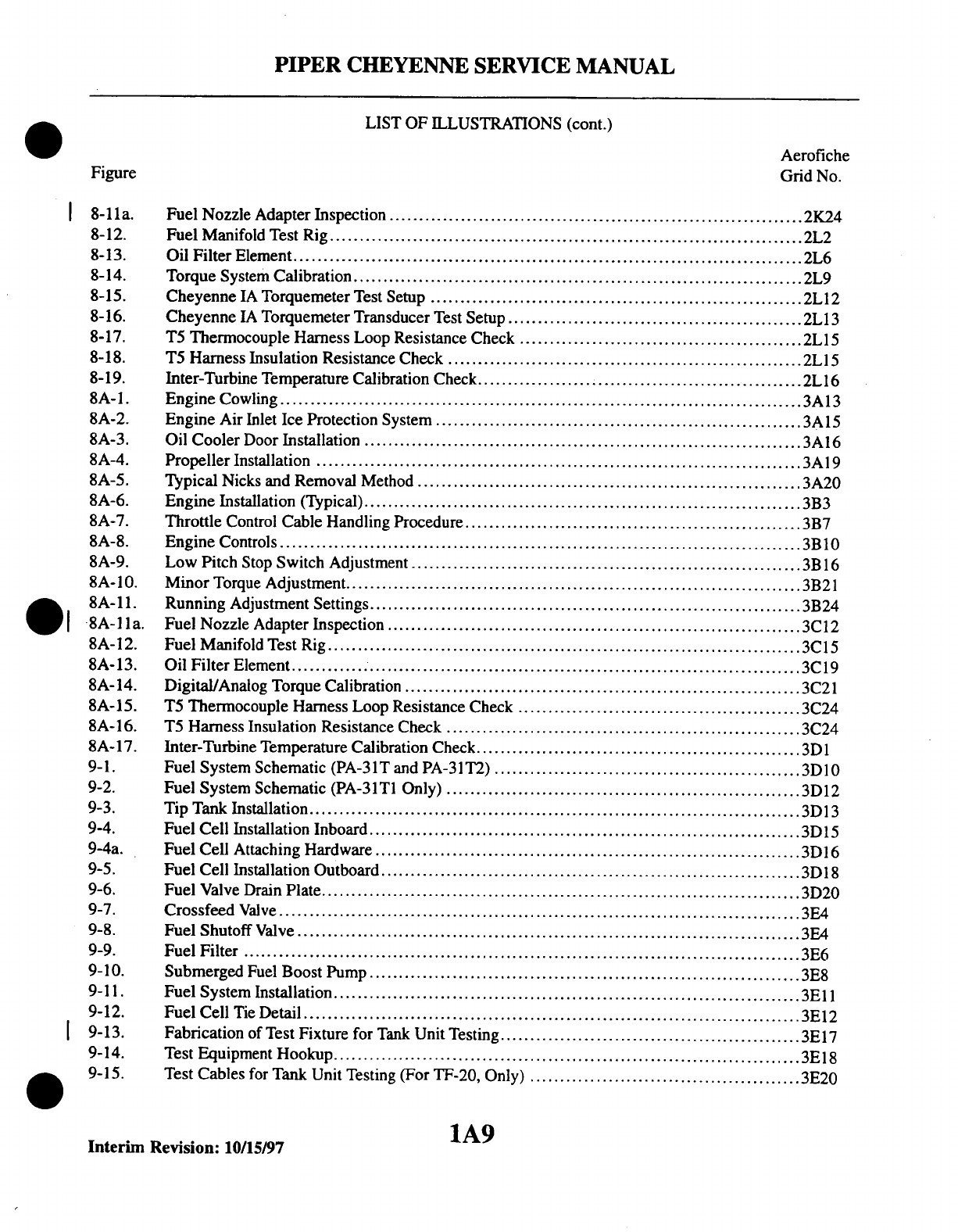

2-1. Three View ofthe Piper Cheyenne (PA-31Tand PA-31T1) ...................................... 1B1

2-2. Three View ofthe Piper Cheyenne (PA-31T2)

..................................................... 1B2

2-3. Station Reference Lines .............................................................................. B3

2-4. AccessPlates and Panels, Fuselage, Interior, Fuselageand Empennage

(PA-31Tand PA-31T1).......................................................................... B6

2-5. Access Plates and Panels, Fuselage Interior,Fuselage and Empennage

(PA-31T2)

................... ............................................. B8

2-6. Access Plates and Panels, Wings ......... ................... ......... ................

1B10

2-7. Jacking Configuration (Typical)....................................... .. ................... 1B14

2-8. Weighing Configuration (Typical)

................................................................... B19

2-9. Leveling Longitudinally and Laterally

.............................................................. B20

2-10. TowTurn Limits and Radius

............................ B..............................B22

2-11. Service Points ......................................................................................... B24

2-12. Servicing Landing Gear Shock Struts............................................................... C4

2-12a. Tire Balancer......... ..................................................................... C7

2-12b. Aircraft Lubrication Charts ..................................... ................................ C14

2-13. Fabricated Jack Stand forPiper Jack, Part No. 18338-0

.......................................... 1D9

2-14. Fabricated TailStand .................................................................... ID10

2-15. Protective Closures Installation...................................................................... 1D11

2-16. Special Tools................................................................... ............. D16

3-1. Wing Flap Transmission Inspection................................................................ 1E2

3-2. Wing Flap Actuator Cable .......................................................................... 1E3

3-3. Friction Reduction in Wing Flap System ........................................................... 1E6

3-4. Wing Flap Motor

......... .. ......... .................................................... E8

3-5. Inspection of Aileron Sprocketand Chain....................................... 1E9

3-6. V-Band Coupling Lock Wire ................................................ ...................

4-1. Aileron and Flap Installation......................................................................... E18

4-2. Methods of Blocking TrimCables .................................................................. 1E21

4-3. Fuselage Cradle (Typical)............................................................................ E24

4-4. Wing Installation................... ........................................... F2

4-5. Empennage Installation ......... .......................................................... 1F5

4-6. Windshield Installation (Earlier Models) .......... ...... .................. .......... .... F16

4-6a. Heated Windshield (Earlier Models)................ ...................................... 1F17

4-7. Windshield Installation (Later Models)............................. ................................ F18

4-7a. Heated Windshield (Later Models).................................................................. 1F20

4-8. Windshield Wiper(PA-31T,PA-31T1)

......... .. ......... ...................... 1F21

4-8a. Windshield Wiper(PA-31T2)

........................................................................ F23

4-9. Emergency Exit and Eyebrow Window

............................................................. F24

4-9a. Storm Window Installation ......... ................................................. G3

4-10. Cabin EntranceDoor ............. ........................................................ 1G7

4-11. Cargo Door Installation ............ ............................................ G12

4-12. Checking Aileron Balance ................................................. .............. 1G19

4-13. Checking ElevatorBalance ..................... .....................

.......

.. 1G19

4-14. Elevator BalanceWeight Modification ...................................... G.........

.......... .20

4-15. Checking RudderBalance ......... ............................................................. 20

4-16. Elevator Friction Measurement...................................................................... 1H1

4-17. Skin Thickness ................................................................. 1 H3

InterimRevision:

10/15/97 1A5

Interim Revision: 10/15/97