Chicago Dryer AIR CHICAGO EXPRESS User manual

AIR CHICAGO®

EXPRESS

Towel Folder

INSTRUCTION MANUAL

©Chicago Dryer Company

Instruction Manual #3019-120

CHICAGO DRYER COMPANY

2200 N. Pulaski Road, Chicago, Illinois USA 60639-3737

Telephone: (773) 235-4430 Fax: (773) 235-4439 www.chidry.com

Air Chicago Express Table of Contents

i

TABLE OF CONTENTS

MANUAL

Chapter 1 - Introduction

Chapter 2 - Installation

Chapter 3 - Operating Guidelines

Chapter 4 - Preventive Maintenance

Chapter 5 - Operating Principles

Chapter 6 - Troubleshooting

Chapter 7 - Repair

CHI•TOUCH BULLETIN

PARTS LIST

SCHEMATICS

APPENDIX

Floor Plans

Technical Specifications

Torque Specifications

INDEX

TOC

INDEX

Table of Contents Air Chicago Express

ii

CHAPTER 1 INTRODUCTION

1.1 Warranty .................................................................................................. 1-2

1.2 Scope of Manual ..................................................................................... 1-2

1.3 Safety ...................................................................................................... 1-3

Safe Work Habits .................................................................................... 1-3

Safety Features ....................................................................................... 1-4

1.4 Optional Equipment ................................................................................. 1-6

TOC

INDEX

Air Chicago Express Table of Contents

iii

CHAPTER 2 INSTALLATION

2.1 Site and Utility Requirements .................................................................. 2-2

2.2 Installation Procedures ............................................................................ 2-3

Inspection ................................................................................................ 2-3

Uncrating and Positioning ....................................................................... 2-4

Compressed Air Supply Connection ....................................................... 2-5

Electrical Connection .............................................................................. 2-6

Final Protective Wrapper Removal .......................................................... 2-8

2.3 Pre-Operational Checkout ....................................................................... 2-8

Security of Hardware ............................................................................... 2-9

Compressed Air Supply Checkout .......................................................... 2-9

Ribbon Rotation Checkout .....................................................................2-11

Safety Device Checkout ........................................................................ 2-12

Primary Fold Operation Checkout ......................................................... 2-14

Crossfold Operation Checkout .............................................................. 2-15

Checkout Completion ............................................................................ 2-15

Cleaning the Unit ................................................................................... 2-15

TOC

INDEX

Table of Contents Air Chicago Express

iv

CHAPTER 3 OPERATING GUIDELINES

3.1 Safety Features ....................................................................................... 3-2

Main Disconnect Switch .......................................................................... 3-2

Safety STOP Buttons .............................................................................. 3-2

Air Permeable Barriers (Safety Guards) ................................................. 3-2

Safety Interlock Switches ........................................................................ 3-3

Safety Labels .......................................................................................... 3-3

3.2 Operating Controls .................................................................................. 3-4

3.3 Daily Operating Procedures .................................................................... 3-7

Start-Up ................................................................................................... 3-7

Handling Jams and Misfeeds Safely ....................................................... 3-9

Fold Operation ........................................................................................ 3-9

Interconnected Stop Circuit (Option) Operation Notes .......................... 3-12

Shut-Down ............................................................................................ 3-12

3.4 Operating Techniques ........................................................................... 3-13

Processing Standards ........................................................................... 3-13

Work Habits ........................................................................................... 3-14

TOC

INDEX

Air Chicago Express Table of Contents

v

CHAPTER 4 PREVENTIVE MAINTENANCE

PM Task Table .................................................................................................... 4-1

4.1 Daily PM (8 Hours) .................................................................................. 4-2

Watch and Listen for Anything Abnormal ................................................ 4-2

General Cleanliness ................................................................................ 4-2

Check and Clean Photosensors .............................................................. 4-3

Check Safety Equipment ......................................................................... 4-3

4.2 Weekly PM (50 Hours) ............................................................................ 4-4

Check and Clean Inverter ....................................................................... 4-4

Polish Metal Surfaces ............................................................................. 4-5

Check Stacker Drive Belt Condition and Tension .................................... 4-5

Check and Grease Stacker Door Bearings ............................................. 4-6

Inspect Air Filter/Auto Drain .................................................................... 4-7

Check Air Pressure Settings ................................................................... 4-7

Check Ribbon Condition and Tension ..................................................... 4-9

4.3 Monthly PM (200 Hours) ......................................................................... 4-9

Check Setscrews................................................................................... 4-10

Check and Clean Main Drive Motor ...................................................... 4-10

Clean and Lubricate Drive Chains .........................................................4-11

Lubricate Primary Fold Ski Bearings and Linkages .............................. 4-12

Check and Grease Bearings ................................................................. 4-13

4.4 Semi-Annual PM (1000 Hours) ............................................................. 4-14

Clean Air Filter/Auto Drain ..................................................................... 4-14

4.5 Annual PM (2000 Hours) ....................................................................... 4-15

Check All Electrical Connections ........................................................... 4-16

Check Insulation Resistance to Earth Ground ...................................... 4-16

TOC

INDEX

Table of Contents Air Chicago Express

vi

CHAPTER 5 OPERATING PRINCIPLES

Safety ................................................................................................................ 5-2

5.1 Electrical System ..................................................................................... 5-2

Power System ......................................................................................... 5-2

Control System ........................................................................................ 5-6

5.2 Compressed Air System ........................................................................ 5-10

Air Filter/Regulators............................................................................... 5-10

Air Pressure Switch ............................................................................... 5-10

Air Reservoirs ........................................................................................ 5-10

Air Valves/Air Valve Solenoids ...............................................................5-11

Air Cylinders ...........................................................................................5-11

Air Bars ...................................................................................................5-11

5.3 Mechanical System ............................................................................... 5-12

Main Drive System ................................................................................ 5-12

Second Crossfold Drive System ........................................................... 5-13

Stacker Drive System ............................................................................ 5-13

Exit Drive System .................................................................................. 5-13

Ribbon Sets ........................................................................................... 5-14

5.4 Sequence of Operation ......................................................................... 5-15

Stand-by Phase ..................................................................................... 5-15

Start-up Phase ...................................................................................... 5-16

Primary Fold Phase ............................................................................... 5-16

Crossfold Phrase ................................................................................... 5-17

Stacking Phase ..................................................................................... 5-17

Exit Phase ............................................................................................. 5-17

TOC

INDEX

Air Chicago Express Table of Contents

vii

CHAPTER 6 TROUBLESHOOTING

Troubleshooting Symptoms ............................................................................... 6-2

6.1 LED Diagnostics ...................................................................................... 6-4

6.2 Electrical .................................................................................................. 6-6

6.3 Mechanical ............................................................................................ 6-10

6.4 Primary Folding ..................................................................................... 6-12

6.5 First Crossfold ....................................................................................... 6-14

6.6 Second Crossfold .................................................................................. 6-15

6.7 Stacker .................................................................................................. 6-16

6.8 Exit Conveyor ........................................................................................ 6-17

6.9 Sensor Function .................................................................................... 6-18

6.10 Compressed Air System ........................................................................ 6-19

TOC

INDEX

Table of Contents Air Chicago Express

viii

CHAPTER 7 REPAIR

7.1 Safety Considerations ............................................................................. 7-2

7.2 Parts Availability ...................................................................................... 7-3

7.3 Ribbons and Rolls ................................................................................... 7-4

Primary Fold Ribbon Tension Adjustment ............................................... 7-5

First Crossfold Ribbon Tension Adjustment ............................................. 7-6

Transfer Ribbon Tension Adjustment ...................................................... 7-7

Second Crossfold Ribbon Tension Adjustment ....................................... 7-8

Stacker Ribbon Tension Adjustment ........................................................ 7-9

Exit Conveyor Ribbon Tension Adjustment ............................................. 7-9

Ribbon Replacement ............................................................................. 7-10

Tracking Tape Overview ........................................................................ 7-12

Exit Conveyor Ribbon Idler Roll Tracking Tape Replacement ............... 7-13

Riveted Tracking Tape Replacement ..................................................... 7-14

7.4 Chains and Belts ................................................................................... 7-16

Main Drive Chain Tension Adjustment ................................................... 7-17

Second Crossfold Ribbon Drive Chain Tension Adjustment .................. 7-18

Stacker Ribbon Drive Belt Tension Adjustment ..................................... 7-19

7.5 Sensors ................................................................................................. 7-20

Photosensor Replacement .................................................................... 7-20

Primary Fold Ski Position Detect Proximity Sensor Adjustment ............ 7-21

Primary Fold Ski Position Detect Proximity Sensor Replacement ........ 7-22

7.6 Compressed Air System ........................................................................ 7-23

Primary Fold Air Bar Alignment ............................................................. 7-24

Crossfold Air Bar Alignment .................................................................. 7-25

Primary Fold Ski Air Cylinder Air Flow Adjustment ................................ 7-26

Stacker Door Air Cylinder Air Flow Adjustment ..................................... 7-27

Air Valve Repair ..................................................................................... 7-28

TOC

INDEX

Air Chicago Express Repair

7-1

Chapter 7

REPAIR

Although designed for long service life, some individual consumable components of the Air Chicago®

Express eventually wear during normal use and must be adjusted or replaced. Adjustment and replacement

subjects covered are:

7.1 Safety Considerations 7.4 Chains and Belts

7.2 Parts Availability 7.5 Sensors

7.3 Ribbons and Rolls 7.6 Compressed Air System

As a general rule:

Replace ribbons when they are worn or break, when the tension can no longer be adjusted, or

when flatwork does not properly enter or exit the unit.

Replace tracking tape when it is worn smooth or when ribbons slip in place.

Follow the Preventive Maintenance Schedule at the beginning of the PREVENTIVE

MAINTENANCE chapter.

WARNING

Do not try to repair or correct any condition without reading and

understanding this Repair Chapter.

Only qualified personnel should troubleshoot and repair the machine.

WARNING

Always make sure the power is shut OFF at the main disconnect

switch before servicing the unit.

•

•

•

TOC

INDEX

Repair Air Chicago Express

7-2

7.1 Safety Considerations

Before attempting any repair work, review

these safety steps and precautions to protect

yourself and the machine.

Safety must always be the primary

concern of anyone making repairs or

adjustments.

Except where specifically directed, make

sure that power is turned OFF at the

main disconnect switch.

WARNING

Always use extreme caution

when performing any repair

procedure that requires the

unit to be operating.

Take every precaution

to keep hands and loose

clothing from coming into

contact with any moving

parts. Serious injury could

result.

Whenever the unit is running,

one person should be ready

at a red safety STOP button

at all times to stop the unit

if necessary.

All maintenance procedures should

be handled by at least two qualified

persons. Using the “buddy system”

facilitates a quicker procedure and

decreases the risk of an accident.

Always keep hands and clothing away

from the moving parts of the folder

when it must be running to make repairs

or adjustments.

•

•

•

•

Never bypass any of the unit’s safety

features. Only operate the unit with

endframe doors and all guards in

place and all safety features operating

correctly.

Never stand, sit or kneel on any part of

the unit.

Your site should lockout/tagout

procedures in place that comply with

government standards for performing

maintenance and repair. Ask your

supervisor for specific information.

WARNING

Know the proper lockout/

tagout procedures for

equipment during repair.

Follow the rules of your work

site. Failure to do so could

result in serious injury.

Do not repair or correct any

condition without reading

and understanding the repair

procedure.

Only qualified personnel

should troubleshoot and

repair this unit.

Always make sure that power

is disconnected before

servicing the unit.

•

•

•

TOC

INDEX

Air Chicago Express Repair

7-3

7.2 Parts Availability

Replacement and repair parts can be ordered

through your local authorized CHICAGO®

distributor. Questions about the operation,

maintenance, troubleshooting, or repair of the

folder can also be directed to your distributor.

Orders may also be placed directly with the

Chicago Dryer Company Parts Department.

Questions may be directed to your local authorized

CHICAGO® dealer or the service department at

(773) 235-4430.

NOTE: Use only factory warranty

tested and approved replacement

parts when repairing a CHICAGO®

unit. They are designed for each

specific model and serial number

folder. Overnight shipment of parts

is available.

TOC

INDEX

Repair Air Chicago Express

7-4

Primary Fold Ribbons

Stacker Ribbons Second Crossfold Ribbons

Transfer Ribbons

First Crossfold Ribbons

Exit Conveyor Ribbons

Figure 7-1: Air Chicago Express ribbons sets.

7.3 Ribbons and Rolls

Flatwork is directed through the folder by

several sets of ribbons (Figure 7-1). In order for

the machine to do its work properly, these ribbon

sets must be kept adjusted and aligned. Failure

to do so can increase the likelihood of jams or

other malfunctions.

With extended use, ribbons may begin to sag

or track to one side of the unit. Both conditions

cause excessive wear and shorten ribbon life, so

tension should occasionally be adjusted for better

finish and longer ribbon life.

In addition, the unit should never be operated

with broken or missing ribbons.

The following procedures are included:

Primary Fold Ribbon Tension

Adjustment

First Crossfold Ribbon Tension

Adjustment

Transfer Ribbon Tension Adjustment

Second Crossfold Ribbon Tension

Adjustment

Stacker Ribbon Tension Adjustment

Exit Conveyor Ribbon Tension

Adjustment

Ribbon Replacement

•

•

•

•

•

•

•

Turning rolls power the ribbons. Materials

attached to various rolls grip the ribbons to

ensure their proper movement. Over time, these

materials can become worn or damaged and must

be replaced. This includes:

Tracking Tape Replacement

Overview

Gray (Exit Conveyor Rolls) Tracking

Tape

Black (All Folder Rolls w/Tape) Track-

ing Tape

•

a)

b)

c)

TOC

INDEX

Air Chicago Express Repair

7-5

Primary Fold Ribbon Tension

Adjustment

Required Tools

Wrenches:

3/8”

9/16”

Perform only when the unit is OFF

with power disconnected.

Turn power OFF at the main disconnect

switch.

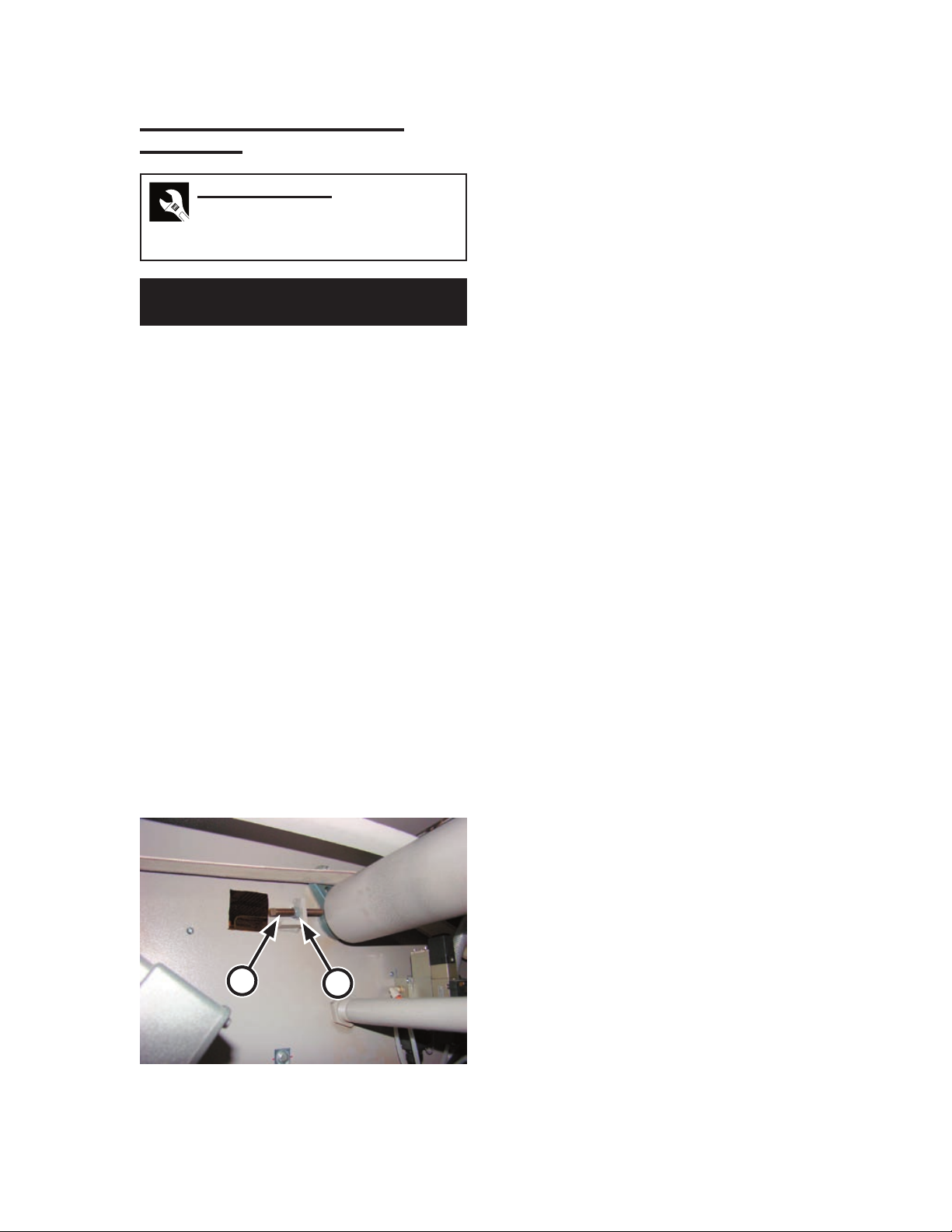

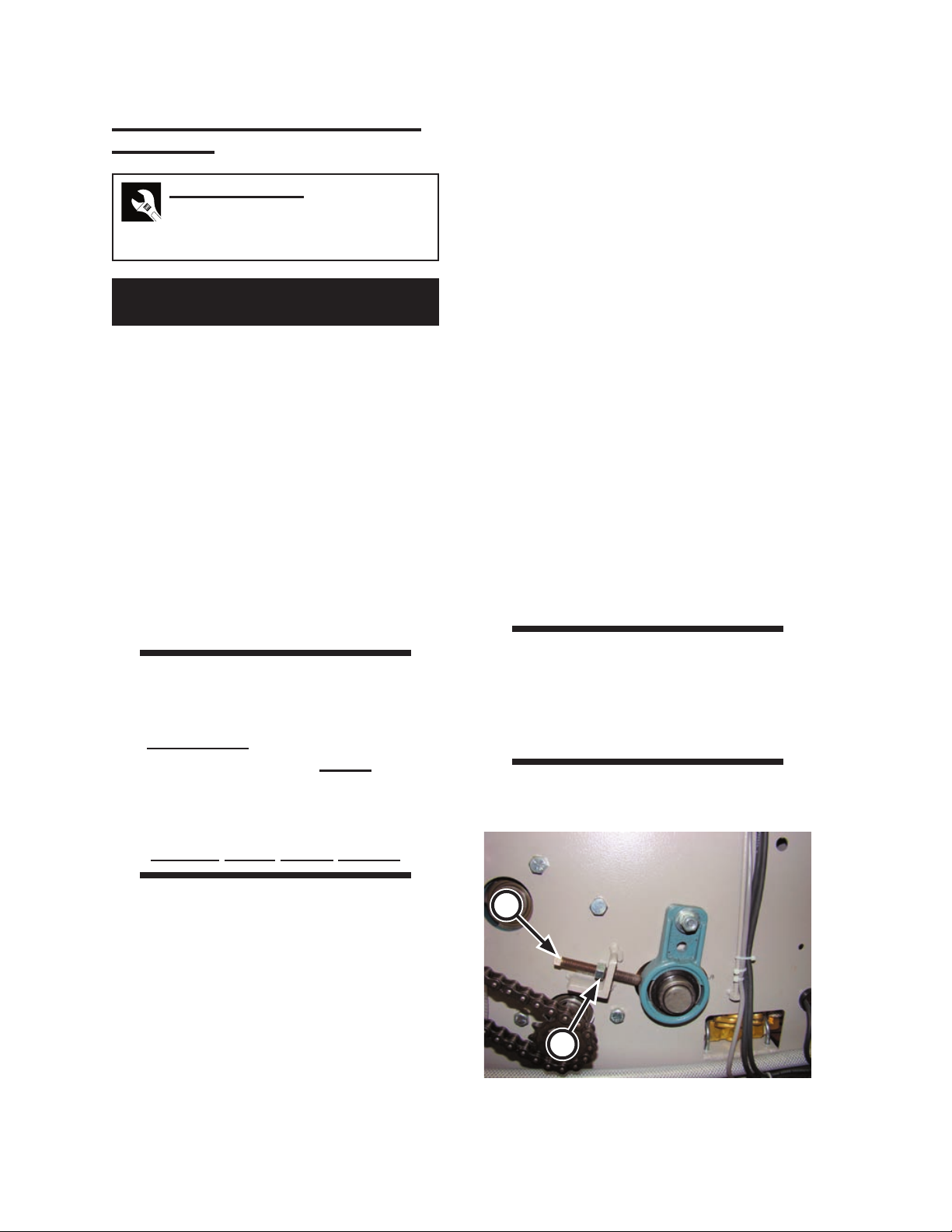

Under the unit at the front, locate the

primary fold ribbons idler roll tension

adjustment bolts (Figure 7-2, A). There is

one on each side of the machine.

While holding each adjustment bolt in

place, loosen its locknut (Figure 7-2, B).

Adjust each bolt the same number of turns

clockwise until the ribbons have the proper

tension.

1.

2.

3.

4.

Turn power ON at the main disconnect

switch.

Run the unit briefly and make sure the

ribbons track straight.

If tension on the ribbons is uneven, the

ribbons will track toward the end of the

drive roll where tension is highest.

Stop the unit and turn power OFF at the

main disconnect switch.

Either turn the adjusting bolt counter-

clockwise at the high tension end, or turn

the adjusting bolt clockwise at the low

tension end.

Repeat Steps 5 to 9 until the ribbons have

the correct tension and track evenly.

Stop the unit and turn power OFF at the

main disconnect switch.

While holding each adjustment bolt in

place, secure its locknut.

5.

6.

7.

8.

9.

10.

11.

12.

Figure 7-2: Primary fold ribbon tension

adjustment.

AA

TOC

INDEX

Repair Air Chicago Express

7-6

First Crossfold Ribbon Tension

Adjustment

Required Tools

Wrenches:

3/8”

9/16”

Perform only when the unit is OFF

with power disconnected.

Turn power OFF at the main disconnect

switch.

Remove both rear endframe panels.

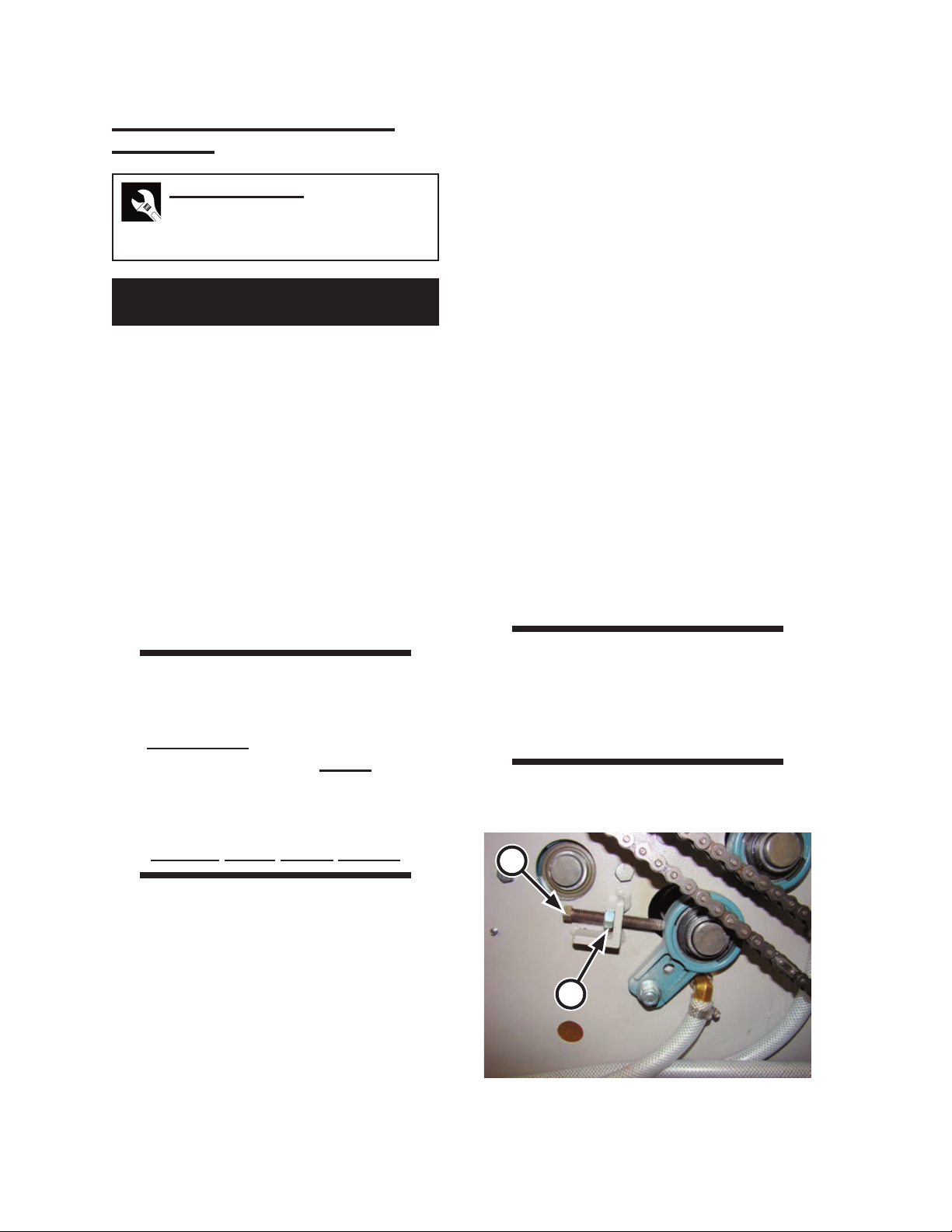

Locate the first crossfold ribbons drive

roll tension adjustment bolts (Figure 7-

3, A). There is one on each side of the

machine.

While holding each adjustment bolt in

place, loosen its locknut (Figure 7-3, B).

Adjust each bolt the same number of turns

until the ribbons have the proper tension.

WARNING

This safety interlock switch

is only to be defeated

temporarily while performing

this procedure. Never

operate the unit unless

all safety systems

are working correctly.

Serious Injury Could Result.

The machine will not operate while a

safety microswitch is open. As a tempo-

rary measure during this work, defeat each

endframe interlock switch by inserting

one of the switch keys that shipped with

the unit.

Turn power ON at the main disconnect

switch.

1.

2.

3.

4.

5.

6.

7.

Run the unit briefly and make sure the

ribbons track straight.

If tension on the ribbons is uneven, the

ribbons will track toward the end of the

drive roll where tension is highest.

Stop the unit and turn power OFF at the

main disconnect switch.

Either turn the adjusting bolt counter-

clockwise at the high tension end, or turn

the adjusting bolt clockwise at the low

tension end.

Repeat Steps 7 to 11 until the ribbons have

the correct tension and track evenly.

Stop the unit and turn power OFF at the

main disconnect switch.

While holding each adjustment bolt in

place, secure its locknut.

Remove the interlock switch keys; then,

replace and secure the endframe panels.

WARNING

Never operate the unit unless

all safety covers are in place

and all safety equipment is

working correctly.

8.

9.

10.

11.

12.

13.

14.

15.

Figure 7-3: First crossfold ribbon tension

adjustment.

B

A

TOC

INDEX

Air Chicago Express Repair

7-7

Transfer Ribbon Tension Adjustment

Required Tools

Wrenches:

3/8”

9/16”

Perform only when the unit is OFF

with power disconnected.

Turn power OFF at the main disconnect

switch.

Remove both rear endframe panels.

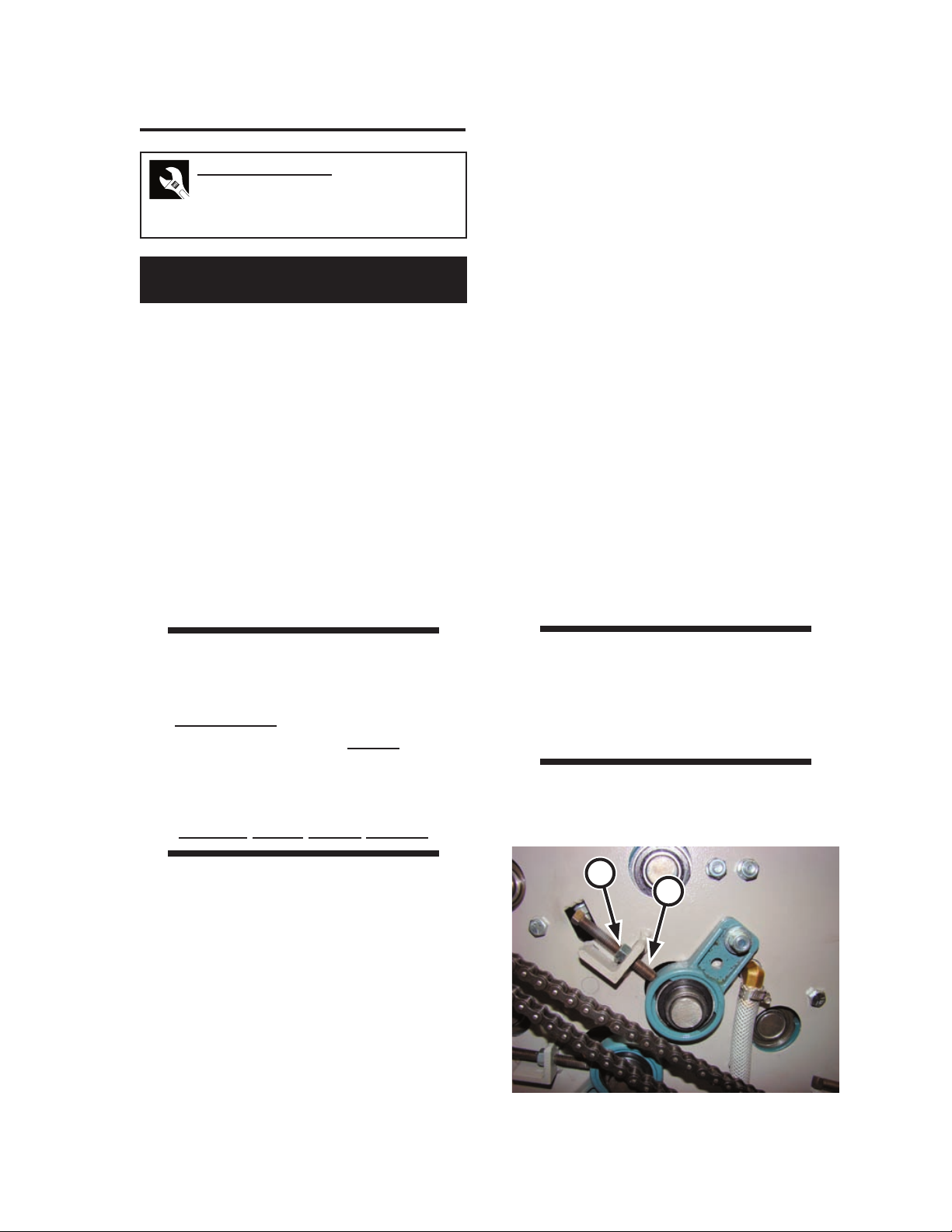

Locate the transfer ribbons idler roll

tension adjustment bolts (Figure 7-4,

A). There is one on each side of the ma-

chine.

While holding each adjustment bolt in

place, loosen its locknut (Figure 7-4, B).

Adjust each bolt the same number of turns

until the ribbons have the proper tension.

WARNING

This safety interlock switch

is only to be defeated

temporarily while performing

this procedure. Never

operate the unit unless

all safety systems

are working correctly.

Serious Injury Could Result.

The machine will not operate while a

safety microswitch is open. As a tempo-

rary measure during this work, defeat each

endframe interlock switch by inserting

one of the switch keys that shipped with

the unit.

Turn power ON at the main disconnect

switch.

1.

2.

3.

4.

5.

6.

7.

Run the unit briefly and make sure the

ribbons track straight.

If tension on the ribbons is uneven, the

ribbons will track toward the end of the

drive roll where tension is highest.

Stop the unit and turn power OFF at the

main disconnect switch.

Either turn the adjusting bolt counter-

clockwise at the high tension end, or turn

the adjusting bolt clockwise at the low

tension end.

Repeat Steps 7 to 11 until the ribbons have

the correct tension and track evenly.

Stop the unit and turn power OFF at the

main disconnect switch.

While holding each adjustment bolt in

place, secure its locknut.

Remove the interlock switch keys; then,

replace and secure the endframe panels.

WARNING

Never operate the unit unless

all safety covers are in place

and all safety equipment is

working correctly.

8.

9.

10.

11.

12.

13.

14.

15.

Figure 7-4: Transfer ribbon tension adjustment.

A

B

TOC

INDEX

Repair Air Chicago Express

7-8

Second Crossfold Ribbon Tension

Adjustment

Required Tools

Wrenches:

3/8”

9/16”

Perform only when the unit is OFF

with power disconnected.

Turn power OFF at the main disconnect

switch.

Remove both rear endframe panels.

Locate the first crossfold ribbons drive

roll tension adjustment bolts (Figure 7-

5, A). There is one on each side of the

machine.

While holding each adjustment bolt in

place, loosen its locknut (Figure 7-5, B).

Adjust each bolt the same number of turns

until the ribbons have the proper tension.

WARNING

This safety interlock switch

is only to be defeated

temporarily while performing

this procedure. Never

operate the unit unless

all safety systems

are working correctly.

Serious Injury Could Result.

The machine will not operate while a

safety microswitch is open. As a tempo-

rary measure during this work, defeat each

endframe interlock switch by inserting

one of the switch keys that shipped with

the unit.

Turn power ON at the main disconnect

switch.

1.

2.

3.

4.

5.

6.

7.

Figure 7-5: Second crossfold ribbon tension

adjustment.

B

A

Run the unit briefly and make sure the

ribbons track straight.

If tension on the ribbons is uneven, the

ribbons will track toward the end of the

drive roll where tension is highest.

Stop the unit and turn power OFF at the

main disconnect switch.

Either turn the adjusting bolt counter-

clockwise at the high tension end, or turn

the adjusting bolt clockwise at the low

tension end.

Repeat Steps 7 to 11 until the ribbons have

the correct tension and track evenly.

Stop the unit and turn power OFF at the

main disconnect switch.

While holding each adjustment bolt in

place, secure its locknut.

Remove the interlock switch keys; then,

replace and secure the endframe panels.

WARNING

Never operate the unit unless

all safety covers are in place

and all safety equipment is

working correctly.

8.

9.

10.

11.

12.

13.

14.

15.

TOC

INDEX

Air Chicago Express Repair

7-9

Stacker Ribbon Tension Adjustment

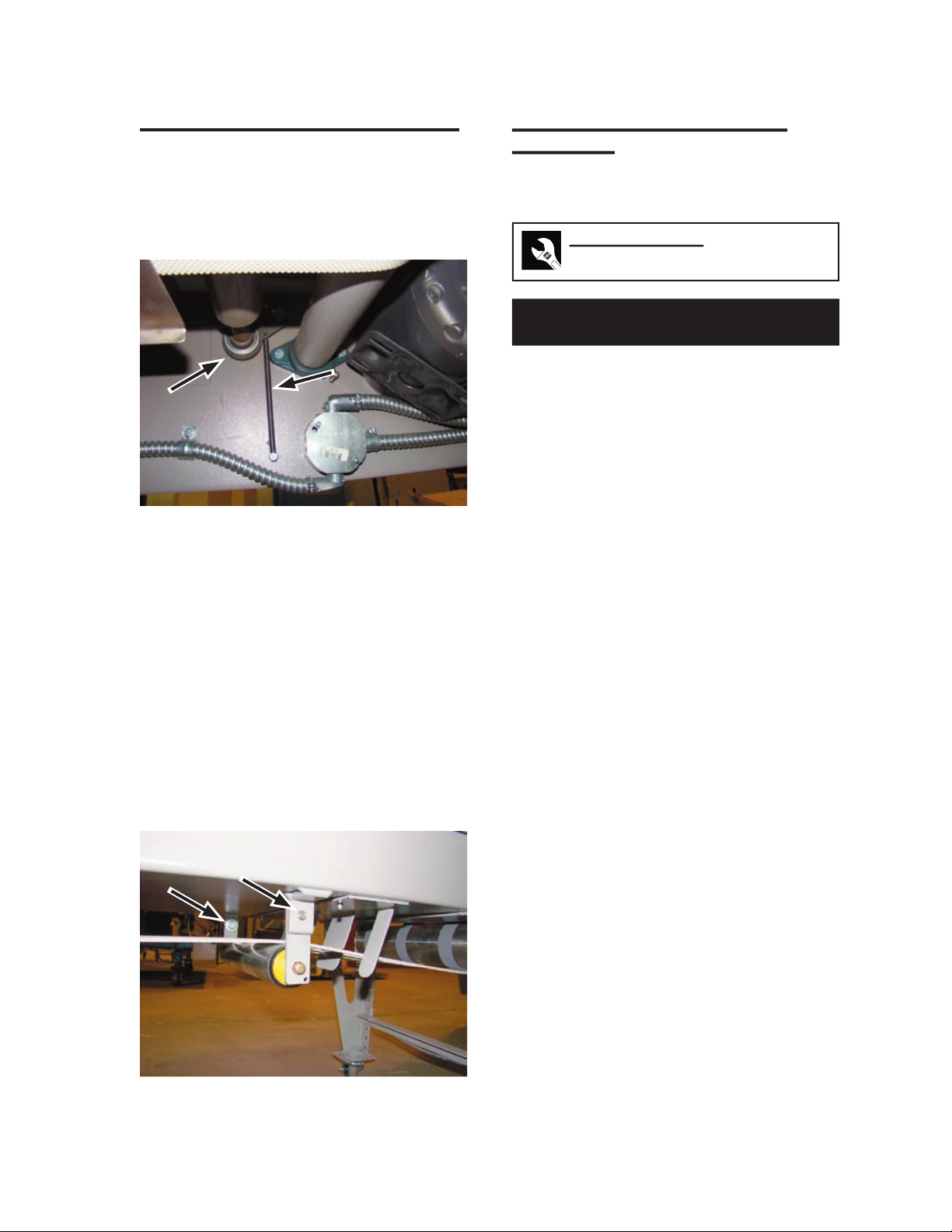

Tension on the stacker ribbons is maintained

by a spring-tensioned idler roll (Figure 7-6).

If proper tension on the ribbons is not being

maintained, the spring has stretched and must

be replaced.

Figure 7-6: Stacker ribbon tension is maintained

by a spring-tensioned idler roll.

Exit Conveyor Ribbon Tension

Adjustment

Front Conveyor Section

Required Tools

Wrenches: 9/16”

Perform only when the unit is OFF

with power disconnected.

Turn power OFF at the main disconnect

switch.

Locate the exit conveyor tensioning idler

(Figure 7-7).

Loosen the bolts which secure the idler

in position.

Pivot the idler until the ribbons have the

proper tension.

Secure the bolts.

Turn power ON at the main disconnect

switch.

Run the unit briefly and make sure the

ribbons track straight.

If tension on the ribbons is uneven, the

ribbons will track toward the end of the

drive roll where tension is highest.

Stop the unit and turn power OFF at the

main disconnect switch.

Make sure the roll is parallel with the

conveyor.

Repeat Steps 5 to 9 until the ribbons have

the correct tension and track evenly.

Stop the unit and turn power OFF at the

main disconnect switch.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Figure 7-7: Exit conveyor ribbon tension

adjustment.

TOC

INDEX

Repair Air Chicago Express

7-10

Rear Conveyor Section

Required Tools

Phillips screwdriver: #3

Wrench: 7/16”

Perform only when the unit is OFF

with power disconnected.

Turn power OFF at the main disconnect

switch.

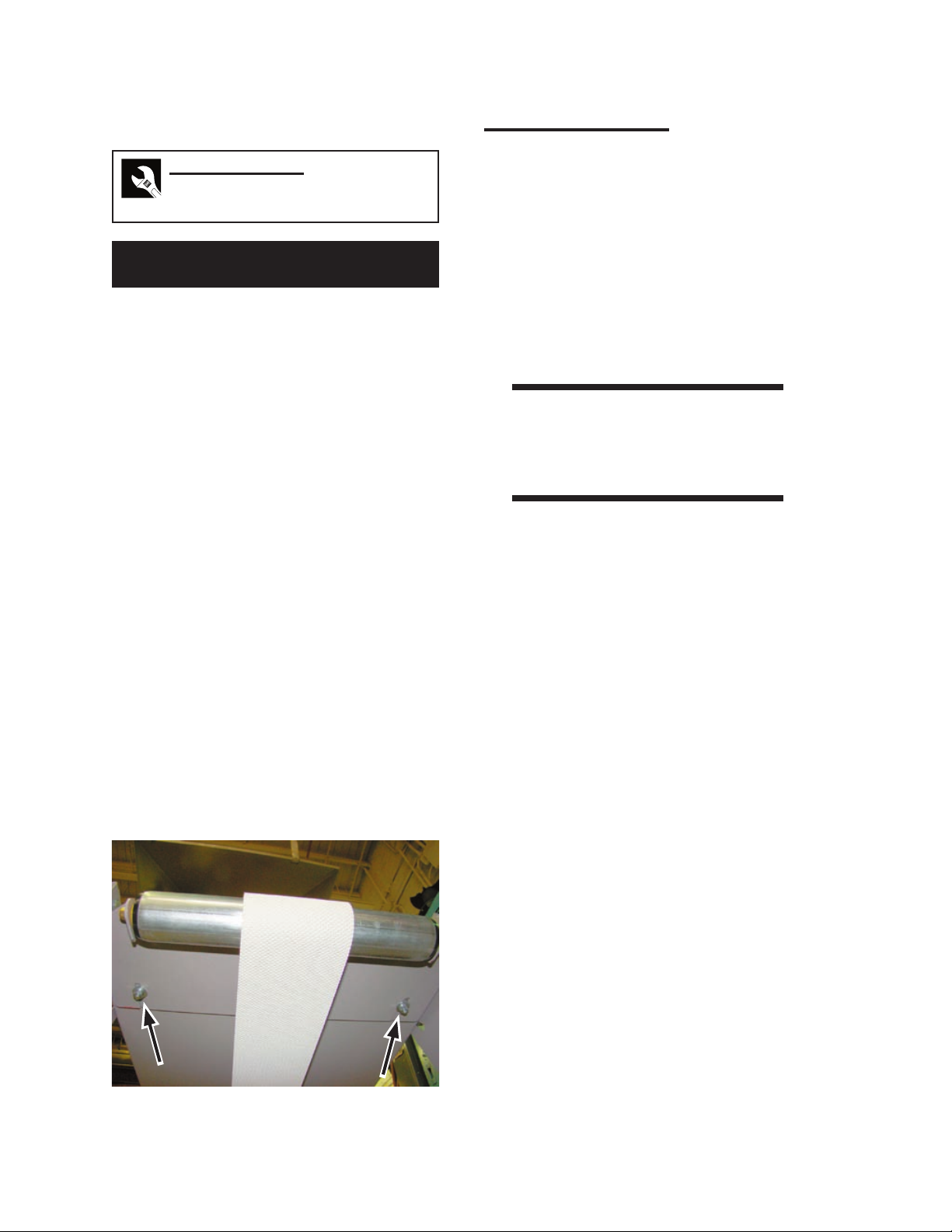

Loosen the nuts (Figure 7-8) holding the

adjustable plate in place.

Move the plate until the ribbon is snug.

Secure the nuts while holding the screws

in place.

Turn power ON at the main disconnect

switch.

Run the unit briefly and make sure the

ribbon tracks straight.

If the tension on the ribbon is uneven,

it will track toward the end where the

tension is highest. Stop the unit and turn

power OFF at the main disconnect switch.

Either reduce tension at the highest end or

increase at the low end.

Repeat Steps 1 to 7 until the ribbon has the

correct tension and track evenly.

1.

2.

3.

4.

5.

6.

7.

8.

Ribbon Replacement

Over a period of time, ribbons stretch. When

the tension on a set of ribbons can no longer

be adjusted, the entire set of ribbons must be

replaced.

Ribbons that break should be replaced

immediately. It is recommended that the entire set

of ribbons be replaced in order to avoid excessive

stress on only one new (slightly shorter) ribbon.

At a minimum, it is recommended that ribbons

be replaced in pairs.

WARNING

Make sure power is shut

OFF at the main disconnect

switch.

To replace a broken ribbon, remove one ribbon

from BOTH ends of the machine and use one to

replace the broken ribbon following the procedure

below. Then follow this procedure to replace the

ribbons at BOTH ends of the machine with new

ribbons.

Figure 7-8: Ribbon tension adjustment screws.

TOC

INDEX

Other manuals for AIR CHICAGO EXPRESS

2

Table of contents

Other Chicago Dryer Folding Machine manuals