ntroduction

Thank you for purchasing this quality product. To minimize the risk of injury we urge that our cli-

ents take some basic safety precautions when using this device. Please read the operation in-

structions carefully and make sure you have understood its content.

Keep these operation instructions safe.

Safety instructions

Check the delivery for completeness and intactness. Should pieces be missing or defective,

the tool must not be used.

lways wear suitable protective equipment (protective gloves, work shoes, safety goggles,

etc.). Normal spectacles are not protective goggles.

Wear appropriate clothes. Do not wear loose clothing or jewellery, tie long hair together. Oth -

erwise they could get caught up in the rotating parts, which leads to injuries.

Wear non-slip shoes. Make sure to have a secure stance and always keep your balance.

Keep your work area clean and provide sufficient lighting. Untidy or badly lit work areas in -

crease the risk of accidents.

Keep children and by-standers away from your work area.

Provide padlocks to make your workshop childproof.

Maintain tool with care. Make sure that tools stay sharp and tidy to obtain the best and the

safest performance. Obey the instructions for lubricating the tools and replacing the accessor-

ies.

Make sure that the handles are and stay dry, tidy, oil-free and lubricant-free.

ppropriately secure workpieces while working on them and make sure that you are able to

control them during the entire process. Use clamps or a vice to secure a workpiece.

Keep all parts of your body away from rotating parts. Risk of injuries!

Do not apply force on tools. It will do a better and safer work if used within the performance

range that it is intended for.

Use the right tool for your work. Do not use any tool or accessory for a work that it has not

been designed for.

Only use accessories recommended. Using inappropriate accessories increases the risk of in-

juries.

Before each use, check the tool for damages. The protection devices and the accessories

should be checked, too, to know if they work correctly and can be used as intended. Check

the alignment of movable parts, find broken parts, check the assembly and all conditions that

could impair the use. Protection devices or parts damaged should be repaired correctly or re-

placed.

Do not use the tool if under the influence of alcohol, drugs or medicine, that alter your con-

sciousness.

Never stand on tool. Should the tool tilt over, serious injuries or damages might follow.

Technical specifications

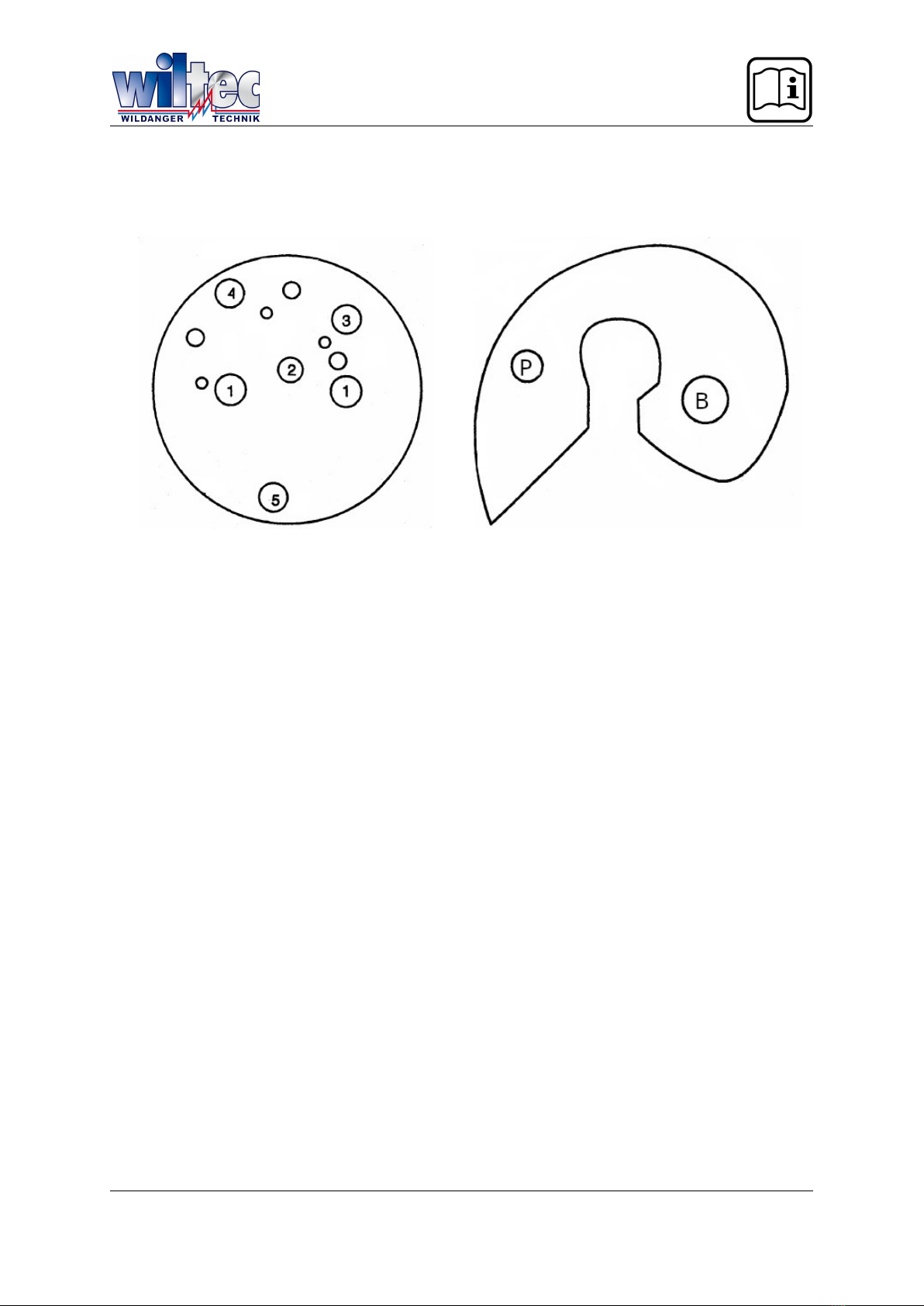

Material Cast iron

Use for flat steel up to (㎜) 30×8

for round steel up to (㎜) 15

for square steel up to (㎜) 13

Folding angle (°) 0–360

Weight (kg) 23

© by WilTec Wildanger Technik GmbH Item 61856 Page 3

http://www.WilTec.de

http://www.aoyue.eu 04 2021-1

http://www.teichtip.de